Introduction

In the bustling world of manufacturing and production, maintaining high standards of quality is paramount. One essential tool in this quest for excellence is the quality inspection table, a dedicated workspace designed to facilitate thorough inspections and ensure that products meet rigorous standards. Understanding what a quality inspection table entails, along with its various applications and benefits, sets the stage for exploring critical concepts like the four types of quality inspections, levels of QC inspection, and the standard of AQL.

Understanding Quality Inspection Tables

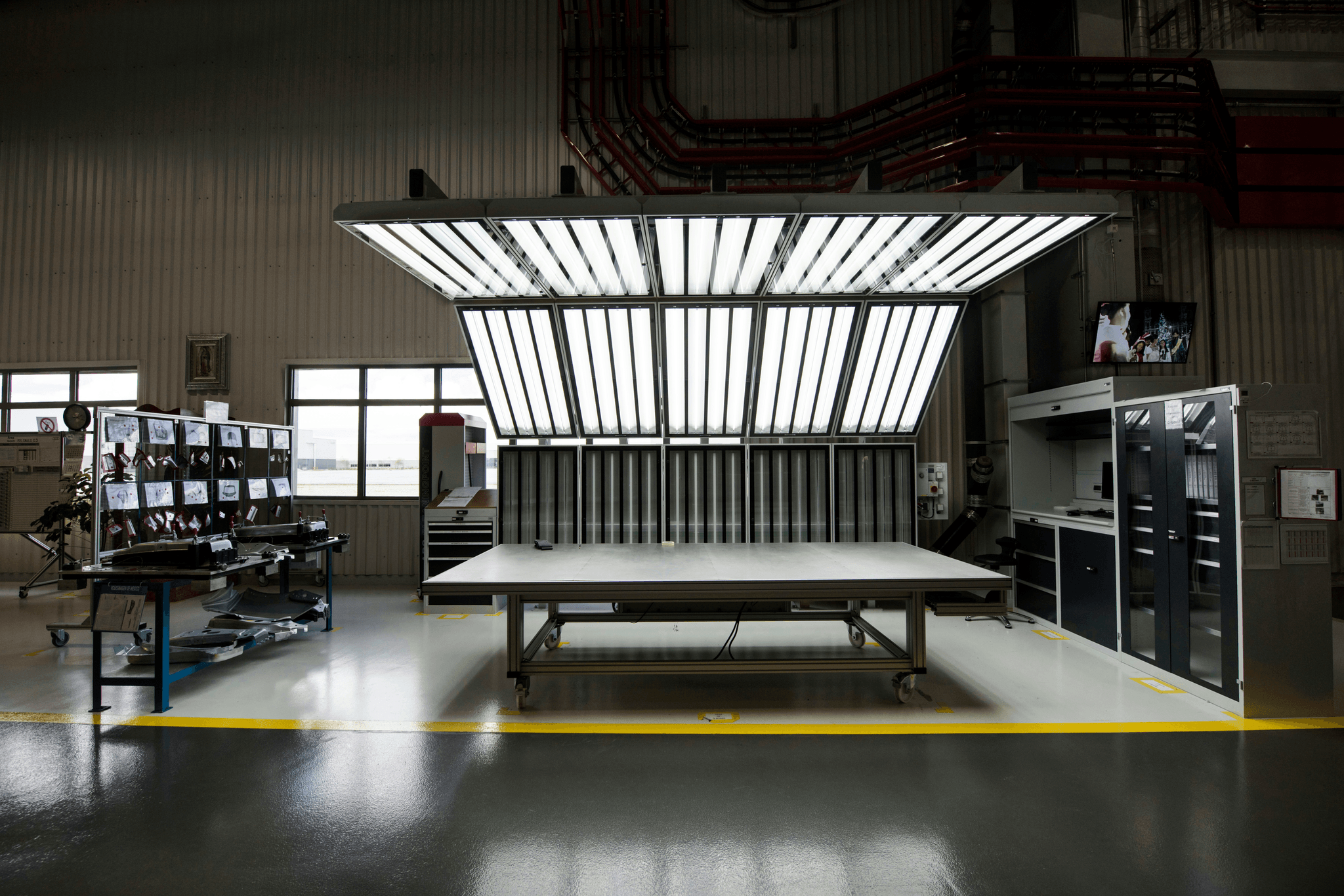

A quality inspection table serves as a focal point for assessing product integrity throughout various stages of production. These tables are not just functional; they are equipped with features that enhance accuracy and efficiency during inspections. By grasping what constitutes a quality inspection table, we can better appreciate its role in ensuring that every product meets both industry standards and customer expectations.

Importance of Industrial Workstations

Industrial workstations play an indispensable role in optimizing productivity while maintaining strict adherence to quality control protocols. They provide a structured environment where inspectors can conduct their evaluations without distractions or interruptions, making it easier to identify defects or inconsistencies early on. The importance of these workstations cannot be overstated; they serve as the backbone for effective QC processes across various industries.

Key Features for Effective QC

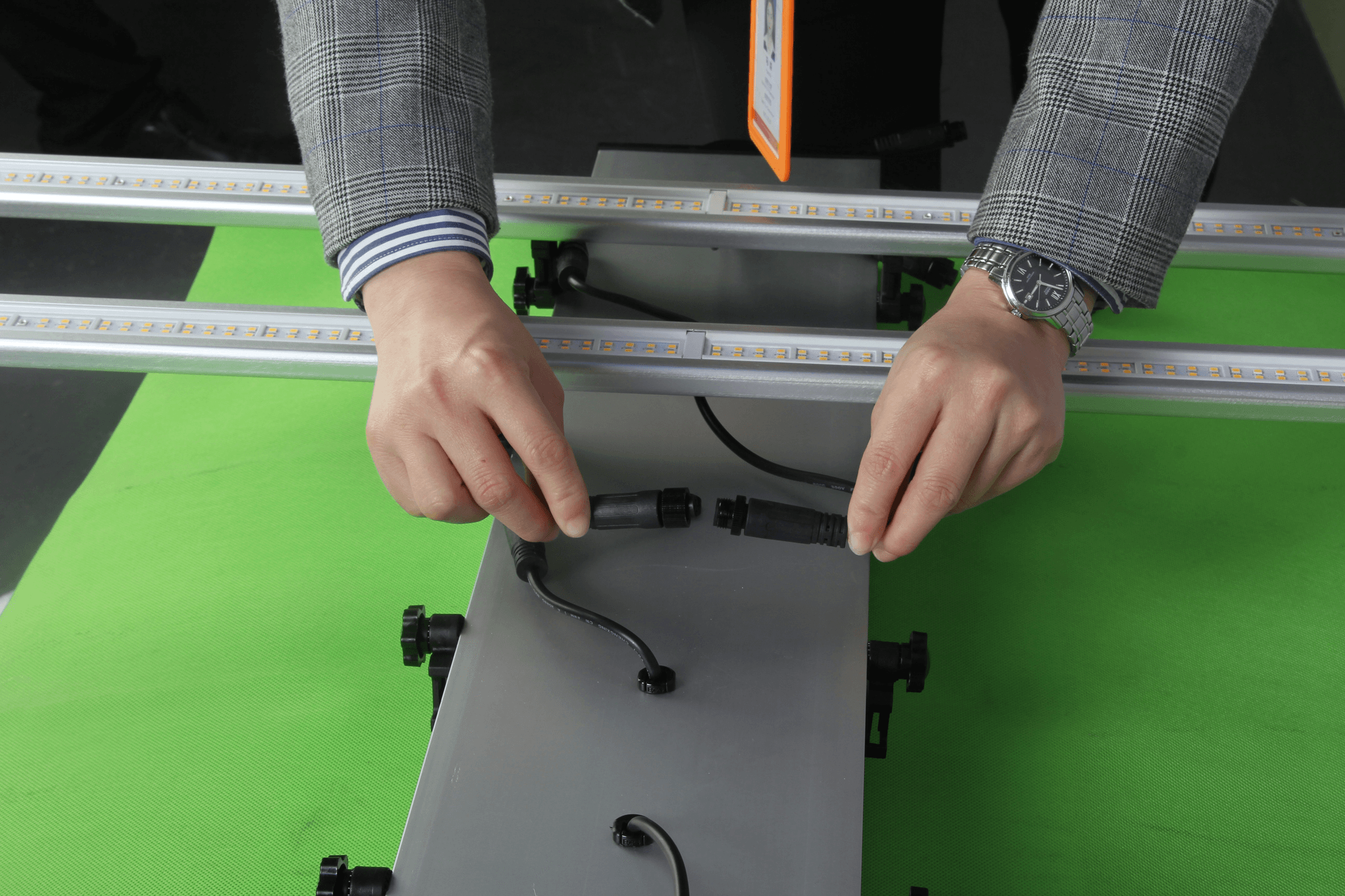

Effective quality control hinges on several key features found in well-designed quality inspection tables. These may include adjustable heights for ergonomic comfort, integrated lighting systems for enhanced visibility, and storage solutions for tools and materials needed during inspections. Recognizing these features helps organizations select the right equipment tailored to their specific needs while facilitating smooth operations throughout all levels of QC inspection.

What is a Quality Inspection Table?

A quality inspection table is an essential tool in various industrial settings, designed specifically for inspecting and assessing products or components to ensure they meet predefined quality standards. Its purpose goes beyond mere functionality; it acts as a dedicated workspace where inspectors can evaluate items systematically, making it easier to identify defects or deviations from specifications. In essence, the quality inspection table facilitates the process of maintaining high-quality output in manufacturing and assembly environments.

Definition and Purpose

At its core, a quality inspection table is a flat surface equipped with features that aid in the examination of products during different stages of production. The primary purpose of this table is to provide inspectors with an organized space to conduct thorough evaluations, which can include visual inspections, measurements, and tests. By having a designated area for these activities, companies can streamline their processes and enhance the effectiveness of their quality control measures.

Types of Quality Inspection Tables

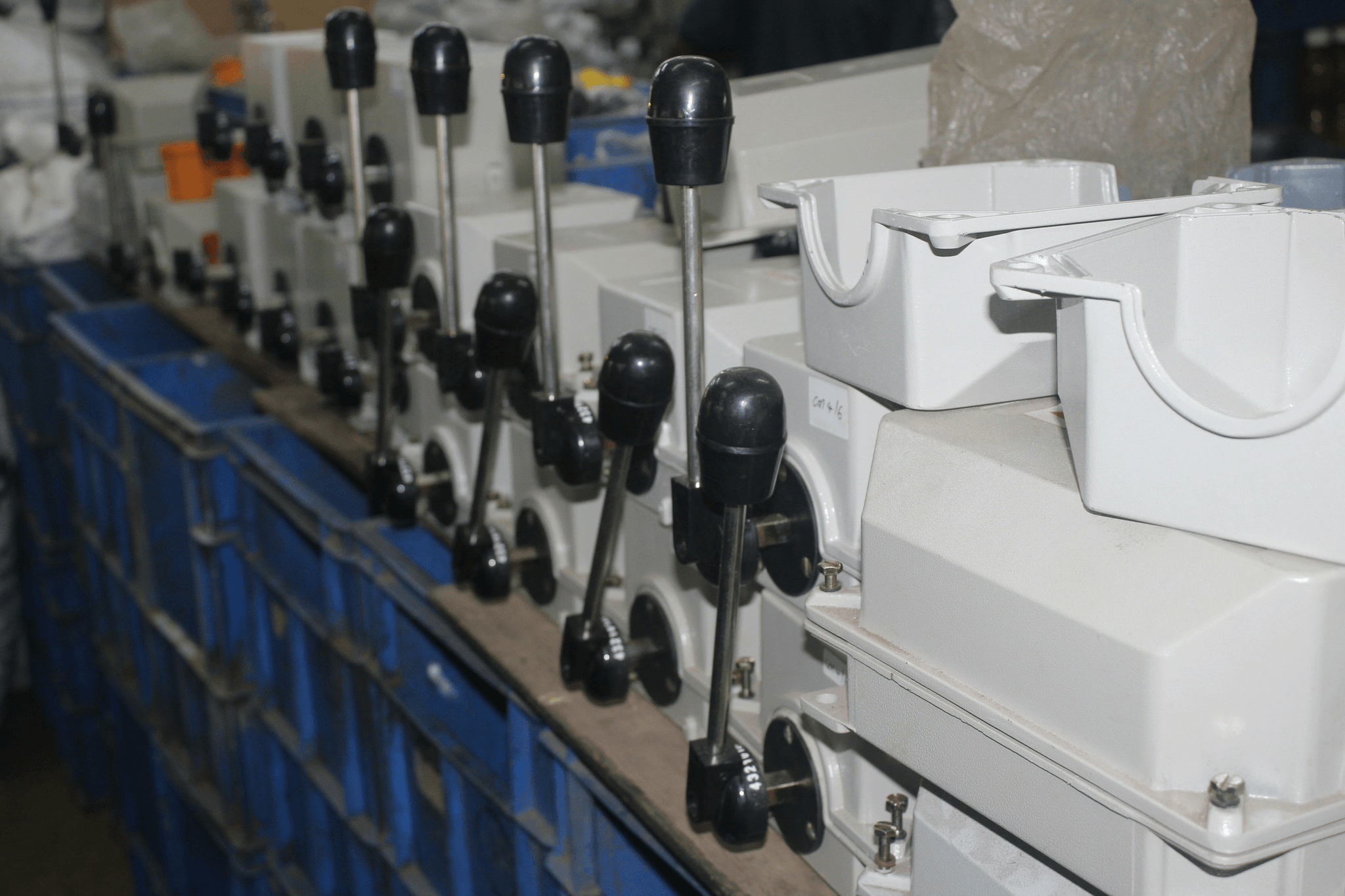

There are several types of quality inspection tables tailored to meet specific needs within different industries. For instance, some tables are designed for incoming inspections where raw materials are checked before they enter production; others cater to in-process inspections that monitor products during various manufacturing stages. Additionally, final inspection tables focus on evaluating finished goods before they reach customers while specialized sample inspection tables allow for random checks based on predetermined criteria—answering the question: what are the 4 types of quality inspections?

Benefits for Industrial Settings

Implementing a quality inspection table brings multiple benefits to industrial settings that prioritize efficiency and accuracy in their operations. First and foremost, these tables help standardize the inspection process by providing clear guidelines on how evaluations should be conducted—addressing concerns related to what is the standard of AQL (Acceptable Quality Level). Furthermore, by utilizing these dedicated workspaces, companies can reduce error rates and increase productivity through well-defined workflows that align with established QC protocols—ultimately enhancing overall product reliability.

What are the 4 Types of Quality Inspections?

Understanding the various types of quality inspections is crucial for maintaining high standards in industrial settings. Different inspection methods serve specific purposes and can significantly affect product quality and compliance with regulations. In this section, we will delve into the four primary types of quality inspections, shedding light on their unique techniques and applications.

Incoming Inspection Techniques

Incoming inspection techniques are the first line of defense in quality control. This type of inspection involves assessing raw materials or components before they enter the production process to ensure that they meet specified standards. By utilizing a quality inspection table during incoming inspections, companies can systematically evaluate each batch for defects or discrepancies, preventing potential issues down the line.

These techniques often include visual checks, measurements against specifications, and functional tests to verify that materials meet established criteria. Implementing robust incoming inspection protocols helps mitigate risks associated with subpar materials entering production lines. Ultimately, this proactive approach reinforces overall product integrity and aligns with what is considered best practice in industrial operations.

In-Process Inspection Methods

In-process inspection methods focus on monitoring production as it unfolds, ensuring adherence to quality standards throughout manufacturing stages. Utilizing a quality inspection table during this phase allows inspectors to catch potential defects early on rather than waiting until final checks are performed. This method not only enhances efficiency but also reduces waste by addressing issues before they escalate.

Common in-process techniques include regular sampling, statistical process control (SPC), and operator self-inspections guided by clear criteria laid out on the workstation's QC table. These practices help maintain consistent output quality while fostering a culture of accountability among operators. By integrating these inspections into daily routines, businesses can better manage variations in processes and sustain high-quality outputs.

Final Inspection Procedures

Final inspection procedures represent a critical checkpoint before products reach customers or clients. This stage typically occurs after production is completed but before items are packaged or shipped out—ensuring that everything meets required specifications using established criteria outlined on a quality inspection table. Final inspections can encompass various assessments such as visual examinations, performance testing, and packaging evaluations.

During final inspections, teams look for any remaining flaws that may have slipped through earlier checks while confirming compliance with customer expectations and regulatory requirements like AQL standards (acceptable quality levels). The importance of thorough final inspections cannot be overstated; they serve as a last bastion against delivering defective products to consumers who expect nothing less than excellence from your brand.

Sample Inspection Standards

Sample inspection standards involve evaluating a subset of items from larger batches to draw conclusions about overall product quality without inspecting every single unit—a strategy often employed when resources are limited or time is constrained. Using statistical sampling methods ensures that even within these smaller groups assessed via a quality inspection table, results remain representative of the entire production lot's integrity.

This approach balances efficiency with thoroughness by allowing organizations to maintain acceptable levels of scrutiny without overwhelming their resources—especially crucial in industries where speed-to-market is paramount! However, it’s essential to establish appropriate sample sizes based on AQL metrics to ensure reliable results while still adhering to industry best practices regarding what constitutes effective sample inspection standards.

What are the Levels of QC Inspection?

Quality control (QC) inspection is a critical process in ensuring that products meet specified standards and requirements. Understanding the various levels of QC inspection helps organizations maintain product quality while minimizing defects. Each level serves a distinct purpose, from initial checks to final acceptance, ensuring that every aspect of quality is thoroughly evaluated.

Overview of Inspection Levels

Inspection levels are categorized into distinct phases that address different stages of the production and quality assurance processes. These levels include preliminary checks, process control, and final acceptance inspections, each designed to catch issues at different points in time. By understanding what are the levels of QC inspection, companies can implement more effective strategies for maintaining high standards throughout their operations.

Level 1: Preliminary Checks

Preliminary checks are the first line of defense against potential quality issues before production begins in earnest. This stage involves verifying incoming materials and components against specifications to ensure they meet required standards—essentially answering the question: what is the quality inspection? Conducting thorough preliminary checks on a quality inspection table can save time and resources by identifying problems early on.

Level 2: Process Control

Once production is underway, process control inspections come into play to monitor ongoing operations closely. These inspections assess whether manufacturing processes conform to established parameters and help identify any deviations that could affect product quality. Knowing what are the 4 types of quality inspections allows teams to implement effective process controls, ensuring consistency and reliability throughout production.

Level 3: Final Acceptance

Final acceptance inspections serve as a comprehensive review before products reach customers or end-users. This level evaluates finished goods against predefined criteria to determine if they meet acceptable quality levels (AQL). Understanding what is the standard of AQL becomes crucial here; it influences decisions regarding product release or rework based on findings from these critical final assessments.

What is the Standard of AQL?

When it comes to quality control, understanding the standard of Acceptable Quality Level (AQL) is crucial. AQL helps define what constitutes acceptable quality in products, ensuring that they meet specific criteria before reaching consumers. This standard plays a significant role in maintaining efficiency and reliability at quality inspection tables.

Defining Acceptable Quality Levels

Acceptable Quality Levels (AQL) refer to the maximum number of defective items considered acceptable during random sampling inspections. Essentially, AQL sets the bar for product quality by specifying how many defects can be tolerated before a batch is rejected. This concept is vital when discussing what is the quality inspection process, as it guides inspectors on how to evaluate products effectively.

In practice, different industries may adopt varying AQL standards depending on their unique requirements and risk tolerances. For instance, electronics might have stricter AQL limits compared to textiles due to safety considerations. Understanding these levels helps businesses align their quality inspection processes with industry standards while optimizing their operational efficiencies.

AQL's Role in Quality Control

AQL plays a pivotal role in quality control by establishing thresholds that help organizations maintain product consistency and reliability. By using this standard, companies can minimize waste and reduce costs associated with excessive rework or returns due to poor-quality products. The integration of AQL into what are the 4 types of quality inspections ensures that each stage—incoming, in-process, final, and sample inspections—is aligned with an overarching goal of maintaining high-quality outputs.

Moreover, implementing an effective AQL strategy fosters trust between manufacturers and consumers by ensuring that only products meeting specified standards reach the market. This trust contributes significantly to brand reputation and customer satisfaction—a win-win situation! Ultimately, understanding what is the standard of AQL empowers businesses to make informed decisions regarding their production processes.

Calculating AQL in Inspections

Calculating AQL involves determining the sample size based on batch size and identifying acceptable defect levels within that sample during inspections at your quality inspection table. The formula typically used includes factors such as lot size and desired confidence level—essentially creating a statistical framework for evaluating product quality systematically. This calculation helps answer critical questions about what are the levels of QC inspection needed for different batches.

For example, if you're inspecting a lot of 10,000 units with an established AQL of 1%, you would determine how many units need testing based on statistical sampling methods like ANSI/ASQC Z1.4 or ISO 2859-1 standards—both widely recognized frameworks for conducting such assessments effectively. By calculating these metrics accurately at your quality inspection table, you ensure that your inspections are both efficient and reliable while adhering to established industry practices.

Choosing the Right Quality Inspection Table

Selecting the right quality inspection table is crucial for enhancing efficiency in your quality control processes. With various options available, it can be overwhelming to determine which table best meets your industrial needs. By understanding key factors and exploring popular brands, you can make an informed decision that aligns with your specific requirements.

Factors to Consider

When choosing a quality inspection table, several factors come into play that can significantly impact its effectiveness. First and foremost, consider the size and layout of your workspace; a well-fitted table will maximize productivity without crowding the area. Additionally, think about the materials used in construction; durable surfaces can withstand rigorous inspections while ensuring longevity.

Another essential factor is adjustability—tables that offer height adjustments or modular designs allow for greater flexibility during inspections. This adaptability is particularly important when considering What are the levels of QC inspection? since different stages may require varying setups. Lastly, don't forget about integrated features such as lighting and storage solutions that enhance usability and streamline workflows during quality inspections.

Popular Brands and Models

Several brands have established themselves as leaders in providing high-quality inspection tables tailored for industrial use. For instance, brands like BenchPro and ULINE offer robust options known for their durability and functionality, catering to various industrial environments effectively. Each model comes equipped with unique features designed to facilitate What are the 4 types of quality inspections? by providing ample workspace alongside tools necessary for thorough checks.

Moreover, consider ergonomic designs from companies like Global Industrial or ESD Systems that prioritize user comfort while maintaining productivity standards. These models often include anti-static surfaces ideal for electronic component inspections—an essential feature when adhering to What is the standard of AQL? standards in electronics manufacturing settings. Ultimately, investing in a reputable brand ensures you're equipped with a reliable quality inspection table that meets your operational needs.

China Inspection Pro: A Quality Leader

Among industry leaders, China Inspection Pro stands out as a premier choice for those seeking top-notch quality inspection tables tailored specifically for diverse manufacturing environments. Their commitment to innovation ensures that each product not only meets but exceeds industry standards related to What is the quality inspection? process requirements. With an array of customizable options available, businesses can select features tailored to their specific operational workflows.

China Inspection Pro also emphasizes value through competitive pricing without compromising on quality—a critical consideration when evaluating potential investments in equipment designed for What are the levels of QC inspection?. Their reputation as a trusted supplier stems from years of experience dedicated solely to enhancing product integrity through effective solutions like specialized tables designed explicitly for thorough inspections aligned with AQL standards.

In conclusion, selecting the right quality inspection table involves careful consideration of factors such as size, adjustability, brand reputation, and integrated features that support efficient workflow management during various types of inspections. With numerous popular brands available alongside industry leaders like China Inspection Pro offering tailored solutions at competitive prices—investing wisely will undoubtedly enhance productivity while ensuring adherence to rigorous quality control protocols.

Conclusion

In the world of manufacturing and production, the importance of a quality inspection table cannot be overstated. These tables are not just surfaces to work on; they are vital components that streamline various processes, ensuring that quality control (QC) is both efficient and effective. By incorporating well-designed QC workstations, industries can significantly enhance their operational efficiency while minimizing errors and waste.

Maximizing Efficiency with QC Workstations

To truly maximize efficiency with a quality inspection table, one must understand what are the 4 types of quality inspections available in the industry today. Each type plays a crucial role in maintaining product integrity—from incoming inspections to final checks before delivery. By strategically placing these inspection types within an industrial setting, companies can ensure that every stage of production adheres to high standards.

Moreover, knowing what are the levels of QC inspection helps organizations implement a structured approach to quality assurance. From preliminary checks to final acceptance evaluations, each level serves as a checkpoint that guarantees products meet established criteria before reaching consumers. This systematic approach not only boosts productivity but also fosters a culture of continuous improvement.

The Future of Quality Inspections

Looking ahead, the future of quality inspections seems promising with advancements in technology and automation transforming how we approach QC processes. Innovations such as AI-driven analytics and real-time monitoring systems will redefine what is possible in terms of accuracy and speed during inspections. As industries adapt to these changes, understanding what is the standard of AQL will become increasingly important for maintaining product consistency and customer satisfaction.

Additionally, integrating smart technology into quality inspection tables can provide valuable insights into performance metrics over time. This data will empower organizations to make informed decisions about their production processes while ensuring compliance with industry standards. As we move forward, embracing these technological advancements will be key for businesses aiming for excellence in their quality control efforts.

Investing in Quality for Success

Investing in high-quality QC workstations is not just about purchasing equipment; it's about committing to excellence throughout your organization’s operations. By prioritizing what is the quality inspection process at every level—from incoming materials through final delivery—companies position themselves for long-term success and customer loyalty.

Furthermore, understanding how to calculate AQL effectively can set businesses apart from their competitors by ensuring that they consistently deliver products that meet or exceed customer expectations. This focus on quality ultimately translates into enhanced brand reputation and increased market share over time—an investment well worth making for any serious manufacturer.