Introduction

In the ever-evolving landscape of manufacturing, the role of a Supplier Quality Engineer has become increasingly crucial. These professionals are at the forefront of ensuring that products meet stringent quality standards, making them key players in the production of quality goods and services. Understanding supplier quality roles and responsibilities is essential for any organization aiming to maintain high standards and enhance customer satisfaction.

Understanding Supplier Quality Engineer's Role

A Supplier Quality Engineer (SQE) acts as a bridge between manufacturers and suppliers, ensuring that all components meet specific quality criteria before they are integrated into final products. This role often overlaps with that of a quality assurance compliance specialist, who ensures adherence to industry regulations and standards throughout the supply chain. By focusing on testing electronic components and conducting thorough evaluations, SQEs help mitigate risks associated with poor-quality materials.

Importance of Quality Assurance in Manufacturing

Quality assurance is not just a buzzword; it’s a critical component of successful manufacturing operations. The importance of maintaining high-quality standards cannot be overstated—defective products can lead to recalls, financial losses, and damage to brand reputation. With effective quality assurance practices in place, organizations can minimize defects and ensure efficient production processes while meeting customer expectations.

Overview of Supplier Quality Responsibilities

Supplier quality responsibilities encompass various tasks aimed at maintaining product integrity from sourcing through delivery. This includes conducting supplier audits to evaluate compliance with established standards, collaborating with suppliers for continuous improvement initiatives, and implementing robust quality control measures. Additionally, social compliance auditing has gained traction as organizations strive to promote ethical sourcing practices while holding suppliers accountable for their labor conditions and environmental impact.

Supplier Selection and Evaluation

Selecting the right suppliers is a cornerstone of effective supplier quality roles and responsibilities. A well-structured evaluation process ensures that suppliers meet the necessary standards for quality, reliability, and compliance. This not only enhances the overall production of quality goods and services but also mitigates risks associated with subpar materials or components.

Criteria for Supplier Assessment

When it comes to assessing potential suppliers, several key criteria should be considered. These include financial stability, production capabilities, past performance records, and adherence to quality assurance standards. Additionally, evaluating their commitment to social compliance auditing can provide insights into their ethical practices and sustainability efforts.

A comprehensive assessment process involves gathering data through questionnaires, interviews, and site visits to gauge a supplier's operational effectiveness. The criteria should also encompass their ability to consistently deliver on time while maintaining high-quality standards in the testing of electronic components. Ultimately, these assessments help build a robust supply chain that aligns with the organization's goals.

Role of Quality Assurance Compliance Specialists

Quality assurance compliance specialists play a pivotal role in ensuring that suppliers adhere to established guidelines and regulations throughout the selection process. Their expertise allows them to identify potential risks associated with non-compliance early on, ensuring that suppliers meet necessary quality benchmarks before they are onboarded. These specialists not only focus on product quality but also advocate for ethical sourcing practices through social compliance auditing.

By collaborating closely with procurement teams, these specialists ensure that supplier evaluations align with both business objectives and industry standards. They are instrumental in training internal teams about supplier quality roles and responsibilities so everyone understands what is at stake when selecting partners. Their proactive involvement fosters an environment where continuous improvement is prioritized across the supply chain.

Conducting Supplier Audits

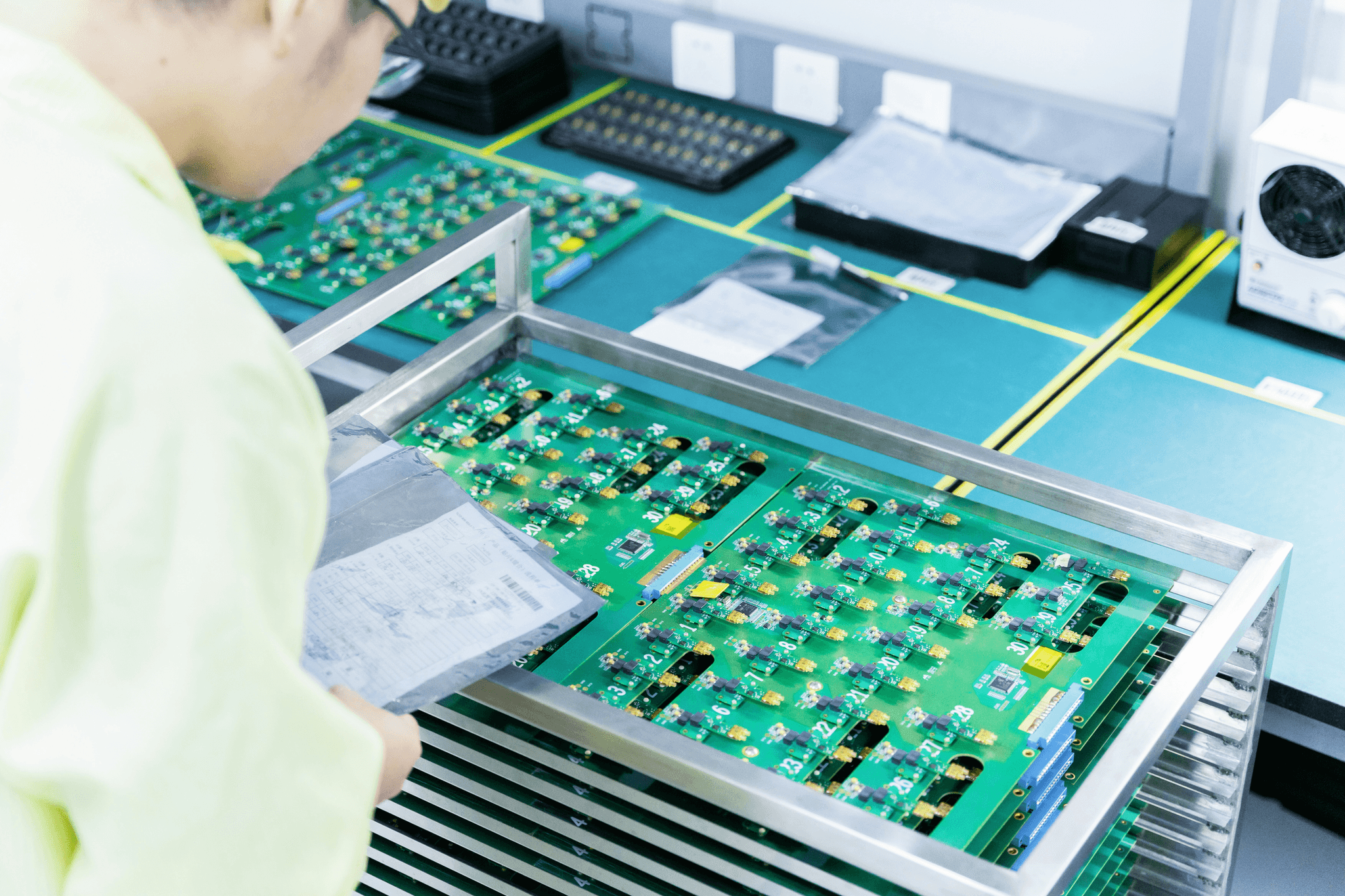

Conducting thorough supplier audits is essential for maintaining high standards of quality assurance within any organization’s supply chain management strategy. Audits provide an opportunity to evaluate suppliers against set criteria while offering insights into their operational processes related to the production of quality goods and services. During these audits, various aspects such as manufacturing practices, documentation accuracy, and adherence to safety regulations are scrutinized.

These evaluations often involve checking compliance with both internal policies as well as external regulatory requirements concerning product safety or environmental impact—factors crucial in today’s market landscape where corporate responsibility matters more than ever. Furthermore, audits can reveal areas where improvements can be made in testing electronic components or enhancing overall efficiency within production lines.

Ultimately, regular audits reinforce accountability among suppliers while fostering long-term partnerships built on trust and transparency—key elements needed for successful collaboration in any industry focused on delivering high-quality products consistently.

Quality Control Measures

Quality control measures are essential in ensuring that the products manufactured meet the required standards and specifications. Supplier quality roles and responsibilities play a pivotal part in this process, as they help in establishing effective quality assurance protocols. A robust quality control system not only enhances product reliability but also fosters customer satisfaction and trust.

Implementing Quality Standards

Implementing quality standards is the cornerstone of any successful manufacturing operation. These standards dictate how products should be designed, produced, and tested to ensure they meet both regulatory requirements and customer expectations. Quality assurance compliance specialists are crucial in this phase, as they help define these standards and ensure that all suppliers adhere to them throughout the production of quality goods and services.

Moreover, by setting clear quality benchmarks, organizations can better evaluate their suppliers' performance over time. This continuous evaluation helps identify potential areas for improvement while fostering a culture of accountability among suppliers. In doing so, companies can mitigate risks associated with non-compliance or subpar product offerings.

The Role of a QC Inspector

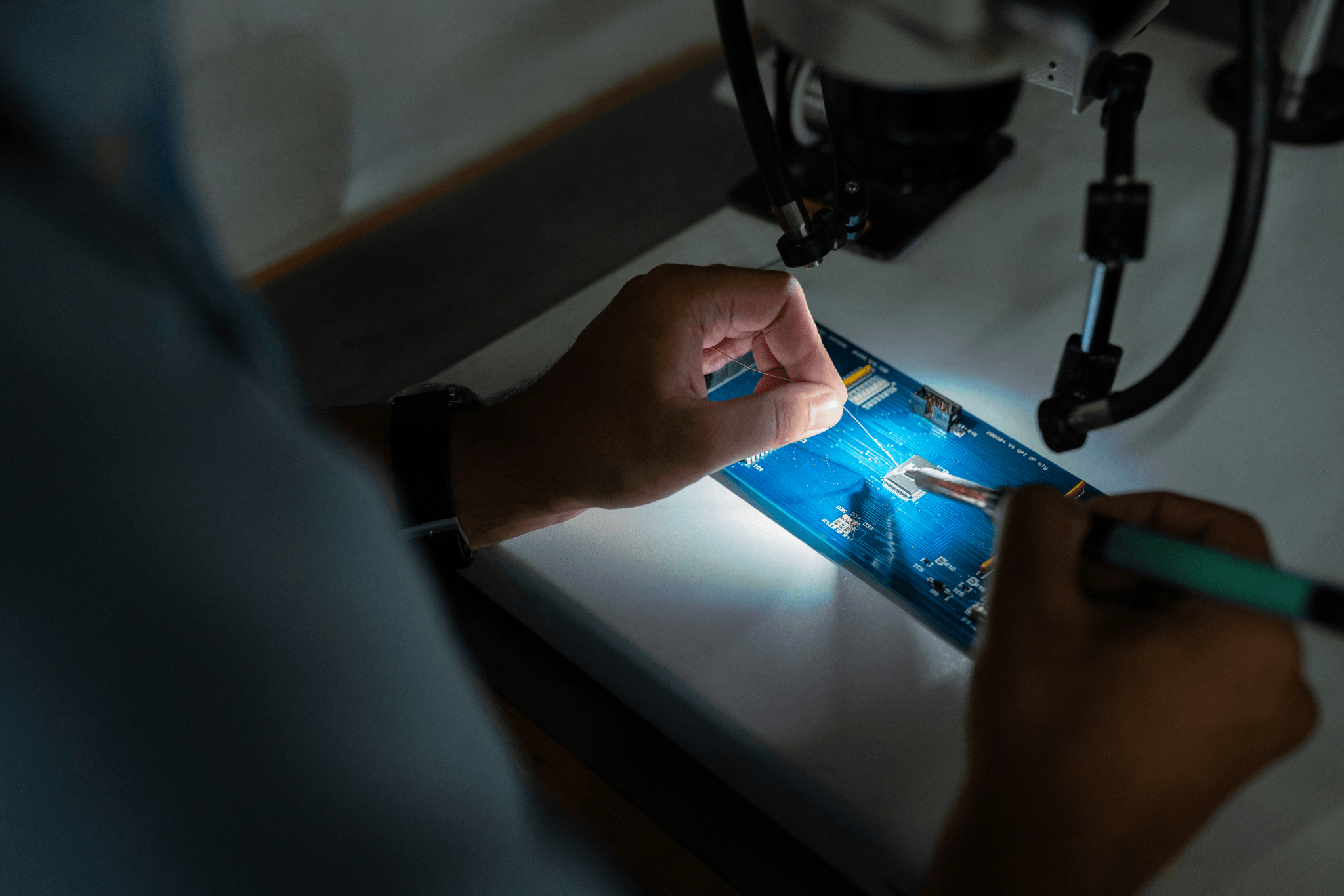

What is a QC inspector? A QC inspector is a dedicated professional responsible for monitoring production processes and ensuring that finished products meet established quality standards. Their role involves conducting inspections at various stages of production to catch defects early on—an essential aspect of supplier quality roles and responsibilities.

QC inspectors utilize various tools and techniques to assess product integrity, including visual inspections, measurements, and functional testing. They also collaborate closely with quality assurance compliance specialists to address any issues that arise during inspections effectively. This teamwork ensures that corrective actions are taken promptly, thus maintaining high-quality outputs.

Additionally, QC inspectors play an educational role by training staff on best practices for maintaining product quality throughout the manufacturing process. By fostering an environment where everyone understands their part in achieving high-quality outcomes, companies can significantly enhance overall efficiency.

Ongoing Monitoring and Testing of Electronic Components

Ongoing monitoring and testing of electronic components are vital for maintaining product reliability in today’s fast-paced market environment. With technology constantly evolving, it’s crucial to ensure that new components meet rigorous performance standards before they reach consumers’ hands. Supplier quality roles and responsibilities encompass regular testing protocols designed to assess the functionality and safety of these components thoroughly.

Testing methods may include stress tests, environmental simulations, or lifecycle assessments tailored specifically for electronic parts—a task often overseen by skilled professionals like QC inspectors who specialize in electronics manufacturing processes. The results from these tests provide invaluable data that inform future design improvements or supplier evaluations based on past performance metrics.

In addition to ensuring compliance with existing regulations through social compliance auditing practices—where ethical sourcing is scrutinized—ongoing monitoring reinforces commitment not just to product excellence but also corporate responsibility across supply chains worldwide.

Process Improvement Initiatives

In the ever-evolving world of manufacturing, process improvement initiatives are essential for maintaining high standards of quality assurance. Supplier quality roles and responsibilities play a pivotal part in identifying inefficiencies and implementing solutions that elevate product quality. By focusing on continuous improvement, organizations can enhance their operational effectiveness and ensure the production of quality goods and services.

Identifying Areas for Improvement

To kick off any process improvement initiative, it’s crucial to identify specific areas needing enhancement. This often involves a thorough analysis of existing workflows, where quality assurance compliance specialists come into play by assessing current practices against established benchmarks. Whether it’s streamlining processes or addressing bottlenecks, pinpointing these areas is the first step toward fostering a culture of excellence in supplier quality roles and responsibilities.

Once problem areas have been identified, teams can employ various techniques such as root cause analysis to understand underlying issues better. This proactive approach not only helps in addressing immediate concerns but also lays the groundwork for long-term improvements in the testing of electronic components and overall production processes. Ultimately, clear identification leads to targeted strategies that ensure ongoing compliance with industry standards.

Collaborating with Suppliers for Quality Enhancements

Collaboration is key when it comes to enhancing quality across supply chains. Engaging suppliers in discussions about their own processes allows organizations to share insights on best practices while fostering a partnership rooted in mutual goals—namely, producing top-notch products that meet customer expectations. In this context, supplier quality roles and responsibilities extend beyond mere oversight; they evolve into collaborative efforts aimed at driving continuous improvements.

Quality assurance compliance specialists often facilitate these collaborations by providing training sessions or workshops focused on best practices within the industry. By working closely with suppliers, companies can ensure they’re aligned on expectations regarding social compliance auditing as well as product specifications. This kind of teamwork not only strengthens relationships but also enhances overall product integrity through shared knowledge.

Furthermore, regular communication channels should be established between manufacturers and suppliers to keep everyone informed about new developments or changes in requirements—whether it's regarding testing protocols for electronic components or updates on regulatory standards affecting production methods. Such collaboration ultimately leads to enhanced trust and accountability throughout the supply chain.

Techniques for Production of Quality Goods and Services

When it comes to actualizing high-quality outputs, several techniques can be employed throughout the production process. Lean manufacturing principles are often utilized to minimize waste while maximizing efficiency—a crucial aspect when considering supplier quality roles and responsibilities within an organization’s framework. These methodologies help streamline operations while ensuring that every component produced adheres to rigorous quality standards.

Another effective technique is implementing robust inspection protocols led by QC inspectors who meticulously evaluate products at various stages—be it incoming materials or finished goods—to verify conformity with specifications before they reach consumers' hands. Understanding what is a QC inspector's role is vital here: they serve as gatekeepers who ensure that only top-quality items proceed through the production line.

Additionally, integrating technology such as automated testing systems can significantly enhance the accuracy of electronic component evaluations during manufacturing processes. These advancements not only bolster confidence in product reliability but also align with social compliance auditing efforts by demonstrating commitment towards ethical sourcing practices throughout all stages—from raw material procurement to final delivery.

Documentation and Reporting

In the realm of supplier quality roles and responsibilities, effective documentation and reporting are crucial components that ensure transparency and accountability in quality assurance processes. Accurate record-keeping not only helps in tracking compliance with standards but also serves as a foundation for continuous improvement initiatives. With the right documentation, organizations can enhance their ability to respond swiftly to any issues that may arise during production or sourcing.

Importance of Accurate Record Keeping

Accurate record-keeping is vital for maintaining a clear audit trail throughout the supply chain. It allows quality assurance compliance specialists to verify that suppliers adhere to required standards and practices consistently. Furthermore, well-maintained records facilitate the identification of trends over time, which can be instrumental in enhancing the production of quality goods and services.

Reporting Non-Conformances

Reporting non-conformances is an essential aspect of ensuring supplier accountability in meeting quality standards. When discrepancies occur, it’s critical for QC inspectors to document these issues promptly so that corrective actions can be implemented swiftly. This proactive approach not only addresses immediate problems but also contributes to long-term improvements in supplier performance by fostering a culture of transparency within social compliance auditing practices.

Utilizing Data for Quality Analysis

Utilizing data for quality analysis is at the heart of effective decision-making in supplier management. By analyzing data collected from various stages—such as testing of electronic components—organizations can identify patterns that lead to non-conformance or inefficiencies within their supply chain processes. This analytical approach empowers teams to collaborate with suppliers on targeted improvements, ultimately enhancing overall product quality while fulfilling their supplier quality roles and responsibilities.

Social Compliance Auditing

Social compliance auditing is a crucial component of the supplier quality roles and responsibilities that ensures suppliers adhere to ethical standards in labor practices, environmental impact, and overall corporate responsibility. By implementing social compliance standards, organizations can mitigate risks associated with unethical practices while fostering a culture of accountability among their suppliers. This not only enhances brand reputation but also aligns with the growing consumer demand for responsible sourcing.

Understanding Social Compliance Standards

Social compliance standards encompass a range of guidelines that govern labor rights, health and safety, environmental stewardship, and fair business practices. These standards are often set by international organizations such as the International Labour Organization (ILO) or specific industry groups aiming to promote ethical behavior within supply chains. Quality assurance compliance specialists play a pivotal role in interpreting these standards and ensuring that suppliers meet or exceed them during audits.

Evaluating Supplier Practices

Evaluating supplier practices involves thorough assessments to determine if they comply with established social compliance standards. This process may include on-site inspections, interviews with employees, and reviewing documentation related to labor conditions and environmental policies. By conducting these evaluations regularly, companies can identify potential issues early on and work collaboratively with suppliers to address them—ultimately enhancing the production of quality goods and services while safeguarding workers' rights.

Promoting Ethical and Responsible Sourcing

Promoting ethical and responsible sourcing is not just about ticking boxes; it's about fostering long-term partnerships based on trust and shared values between companies and their suppliers. Engaging in social compliance auditing encourages suppliers to take ownership of their practices while empowering them to implement necessary changes for improvement. When organizations prioritize these values within their supply chain management strategy, they contribute significantly to sustainable development goals while reinforcing their commitment to supplier quality roles and responsibilities.

Conclusion

In wrapping up our exploration of supplier quality roles and responsibilities, it’s clear that these positions play a pivotal role in ensuring the integrity of manufacturing processes. From the meticulous selection and evaluation of suppliers to the rigorous testing of electronic components, each step is integral to maintaining high standards. Quality assurance compliance specialists are at the forefront, ensuring that every product meets established benchmarks before it reaches consumers.

Key Takeaways on Supplier Quality Roles

One cannot overstate the importance of understanding supplier quality roles and responsibilities in today’s competitive landscape. These roles encompass everything from conducting thorough supplier audits to implementing quality control measures that safeguard production lines. Ultimately, these efforts culminate in the production of quality goods and services that not only meet but exceed customer expectations.

The Impact of Quality Engineering on Business

Quality engineering has a profound impact on business operations, influencing everything from customer satisfaction to overall profitability. By effectively managing supplier relationships and enforcing compliance through social compliance auditing, companies can mitigate risks associated with subpar materials or processes. This proactive approach not only enhances product reliability but also fosters brand loyalty among consumers who value quality.

Future Trends in Quality Assurance Practices

Looking ahead, we can anticipate several exciting trends shaping the future of quality assurance practices. The integration of advanced technologies such as AI and machine learning will revolutionize how we approach testing of electronic components, making processes more efficient than ever before. Furthermore, with increasing emphasis on ethical sourcing, social compliance auditing will become even more critical as businesses strive for transparency and accountability within their supply chains.