Introduction

In today’s highly competitive manufacturing landscape, understanding the product quality control process is not just beneficial—it's essential. Quality control (QC) acts as a safeguard, ensuring that products meet established standards and specifications before reaching consumers. With the right quality and control measures in place, businesses can enhance their reputation, reduce costs associated with defects, and ultimately drive customer satisfaction.

Understanding the Product Quality Control Process

The product quality control process involves a systematic approach to monitoring and managing quality throughout the manufacturing cycle. This includes defining quality standards, conducting inspections at various stages, and implementing corrective actions when necessary. By establishing a robust QC system management quality framework, organizations can ensure that every product aligns with both industry expectations and consumer demands.

Importance of Quality in Manufacturing

Quality is not merely an attribute; it is a fundamental aspect of any successful manufacturing operation. The implications of poor quality can be severe—ranging from financial losses to damage to brand integrity. By prioritizing QA quality practices within their operations, manufacturers can create reliable products that foster trust among customers while maintaining compliance with industry regulations.

Key Players in Quality Control

A successful product quality control process relies on collaboration among various key players within an organization. These include quality assurance teams, production staff, suppliers, and management personnel—all working together to define quality benchmarks and uphold them throughout production phases. Engaging these stakeholders ensures that everyone understands their role in maintaining high-quality standards while facilitating continuous improvement across processes.

Defining Quality and Standards

In the realm of manufacturing, defining quality and standards is paramount for a successful product quality control process. Quality isn't merely about meeting specifications; it's about ensuring that products consistently fulfill customer expectations while adhering to industry regulations. To achieve this, organizations must navigate a landscape filled with various definitions, standards, and compliance measures that govern quality control.

What Does Quality Mean?

Quality can be defined as the degree to which a product meets specified requirements and satisfies customer needs. It's not just about being defect-free; it encompasses performance, reliability, durability, and even aesthetics—elements that contribute to the overall user experience. In the context of the product quality control process, defining quality helps set clear benchmarks for both production teams and quality assurance (QA) professionals involved in maintaining these standards.

When we talk about quality in manufacturing, it’s essential to recognize that it can vary significantly across industries. For instance, while a high-end electronic gadget might prioritize advanced technology and sleek design as indicators of quality, a food product may focus more on safety and taste. This diversity underscores the importance of establishing specific criteria tailored to each sector's unique demands within the framework of quality control.

Industry Standards and Compliance

Industry standards serve as critical guidelines that help businesses maintain consistent levels of quality across their products. These standards are often established by regulatory bodies or industry associations aiming to ensure safety, reliability, and efficiency in manufacturing processes. Compliance with these standards is not just a legal obligation; it's also an integral part of any effective QC (quality control) strategy.

Different industries have varying compliance requirements that organizations must adhere to within their product quality control processes. For example, automotive manufacturers must comply with stringent regulations related to safety features and emissions controls—factors that are non-negotiable for consumer trust. By aligning their practices with established industry standards, companies can enhance their credibility while minimizing risks associated with non-compliance.

Moreover, adherence to industry standards facilitates smoother operations across supply chains by providing clear expectations for all stakeholders involved in production and distribution processes. When everyone understands what constitutes acceptable quality levels according to these benchmarks, it fosters better collaboration among suppliers, manufacturers, and retailers alike—a cornerstone principle in successful system management quality.

The Role of ISO Certifications

ISO certifications play a pivotal role in standardizing quality management practices across various sectors worldwide. These internationally recognized certifications provide frameworks for organizations seeking consistency in their operations while enhancing customer satisfaction through improved products or services. By obtaining ISO certifications relevant to their industries—such as ISO 9001 for general quality management—companies signal their commitment towards maintaining high-quality standards throughout their product lifecycle.

The process of acquiring an ISO certification involves rigorous evaluations against predefined criteria related to system management quality practices within an organization’s operations—from planning through execution up until post-delivery assessments like inspections or audits conducted during the product quality control process itself! Companies often find that pursuing such certifications not only strengthens internal processes but also boosts marketability among consumers who increasingly favor brands known for prioritizing QA (quality assurance).

Furthermore, ISO certifications can open doors for businesses looking to expand into new markets where compliance with international norms is crucial for entry or success—especially when competing against local firms already well-versed in those requirements! Thus investing time into understanding how best these certifications fit into one’s overall strategy offers tangible benefits beyond mere regulatory compliance; they enhance reputations while reinforcing confidence among customers regarding product integrity over time.

Steps in the Product Quality Control Process

The product quality control process is a systematic approach designed to ensure that products meet predefined quality standards throughout their lifecycle. It encompasses several critical steps, each aimed at identifying and mitigating potential quality issues before they escalate. By following a structured process, manufacturers can enhance their overall efficiency and customer satisfaction.

Initial Quality Planning

Initial quality planning is the cornerstone of an effective product quality control process. During this phase, teams define quality objectives and establish benchmarks that align with industry standards, ensuring that everyone understands what define quality means for their specific product. This stage often involves selecting appropriate metrics for measuring success and outlining procedures for maintaining consistent quality control throughout the manufacturing process.

Quality planning also includes risk assessments to identify potential pitfalls in production that could compromise the final product's integrity. By anticipating these challenges early on, companies can implement preventive measures to mitigate risks effectively. Ultimately, thorough initial planning sets the stage for successful QA (quality assurance) activities down the line.

In-Process Quality Inspections

In-process quality inspections are essential checkpoints within the product quality control process that occur during manufacturing rather than after production is complete. These inspections help ensure adherence to established standards by evaluating products at various stages of production, allowing teams to catch defects or deviations early on. Implementing QC (quality control) measures during this phase helps maintain high-quality outputs while minimizing waste and rework costs.

A variety of techniques can be employed during in-process inspections, including visual checks and more sophisticated statistical methods like Statistical Process Control (SPC). This proactive approach not only enhances product reliability but also fosters a culture of continuous improvement among employees who are trained to prioritize both quality and efficiency in their work habits. By integrating these inspections into daily operations, manufacturers can better achieve their overall system management quality goals.

Final Quality Assessments

Final quality assessments serve as the last line of defense in ensuring that products meet all specified requirements before reaching consumers or clients. This step involves comprehensive evaluations using various testing methods tailored to the specific nature of each product; whether it’s durability tests for electronics or taste tests for food items, nothing should be left unchecked in this crucial phase of QC (quality control).

These assessments not only verify compliance with industry standards but also provide valuable insights into areas where improvements might be needed for future production runs—essentially closing the loop on feedback from earlier phases like initial planning and in-process inspections. Ultimately, effective final assessments help build trust with customers by delivering high-quality products consistently while reinforcing a company's reputation within its market sector.

Quality Control Tools and Techniques

In the realm of the product quality control process, various tools and techniques play pivotal roles in ensuring that manufacturing meets the highest standards. These methods not only streamline operations but also enhance overall product quality. Understanding these techniques is essential for anyone involved in quality control, as they provide a structured approach to maintaining quality and control throughout the production lifecycle.

Statistical Process Control

Statistical Process Control (SPC) is a cornerstone of modern quality control systems, enabling manufacturers to monitor processes through statistical methods. By analyzing data collected during production, SPC helps identify variations that could affect product quality, allowing teams to intervene before issues escalate. Implementing SPC requires a solid understanding of data analysis and system management quality to ensure that processes remain within defined limits.

Through continuous monitoring, SPC can reveal trends and patterns that inform decision-making in real-time, making it an invaluable tool for maintaining high standards in the product quality control process. The proactive nature of SPC allows companies to achieve greater consistency in their products while minimizing waste and inefficiencies. Ultimately, this technique embodies the essence of qa quality by ensuring that every step of manufacturing adheres to established benchmarks.

Six Sigma Methodology

Six Sigma is another powerful methodology designed to improve product quality by identifying and eliminating defects within processes. This approach utilizes a data-driven framework aimed at reducing variability and enhancing overall performance across various stages of production. By employing Six Sigma principles, organizations can define quality more clearly and implement strategies that lead to measurable improvements.

At its core, Six Sigma emphasizes the importance of understanding customer needs and aligning processes accordingly—an essential aspect of effective qc quality control. The methodology involves rigorous training for team members who become certified practitioners capable of leading projects focused on efficiency gains. As companies embrace Six Sigma practices, they often witness significant enhancements in their product offerings as well as customer satisfaction levels.

Failure Mode and Effects Analysis

Failure Mode and Effects Analysis (FMEA) is a systematic approach used to identify potential failure points within a process or product design before actual production begins. By assessing risks associated with various failure modes, teams can prioritize actions needed to mitigate these risks effectively—essentially preempting issues before they impact the final output during the product quality control process. This proactive stance ensures that manufacturers maintain high-quality standards while minimizing costly rework or recalls.

FMEA encourages collaboration among cross-functional teams who bring diverse perspectives on potential failure points—an excellent practice for enhancing overall system management quality within organizations. Additionally, documenting findings from FMEA sessions creates valuable reference materials for future projects as well as ongoing training initiatives related to qc quality control practices. In short, FMEA serves as an indispensable tool for fostering a culture centered around continuous improvement in both products and processes.

Real-World Applications of Quality Control

Quality control isn't just a buzzword; it’s a lifeline for businesses across various industries. The product quality control process has become an integral part of how companies maintain high standards and ensure customer satisfaction. By examining real-world applications, we can better understand the significance of quality and control in manufacturing.

Case Studies in Automotive Quality Control

The automotive industry is a prime example where the product quality control process is paramount. Companies like Toyota have pioneered rigorous QC measures, employing techniques such as Just-In-Time (JIT) manufacturing to minimize waste while maintaining high-quality standards. Their commitment to quality and control not only enhances vehicle performance but also builds consumer trust, proving that effective QA quality can drive brand loyalty.

In recent years, Tesla has also entered the spotlight with its innovative approach to automotive QC. By integrating advanced technologies like artificial intelligence into their production lines, they’ve redefined how we define quality in the automotive sector. This shift not only improves efficiency but also ensures that every vehicle meets strict safety standards before it hits the road.

Moreover, case studies from Ford illustrate how systematic management quality processes can significantly reduce defects. By implementing Failure Mode and Effects Analysis (FMEA), they identify potential issues before they escalate into costly recalls or safety concerns. These examples highlight that investing in robust quality control systems pays off in dividends—both financially and reputationally.

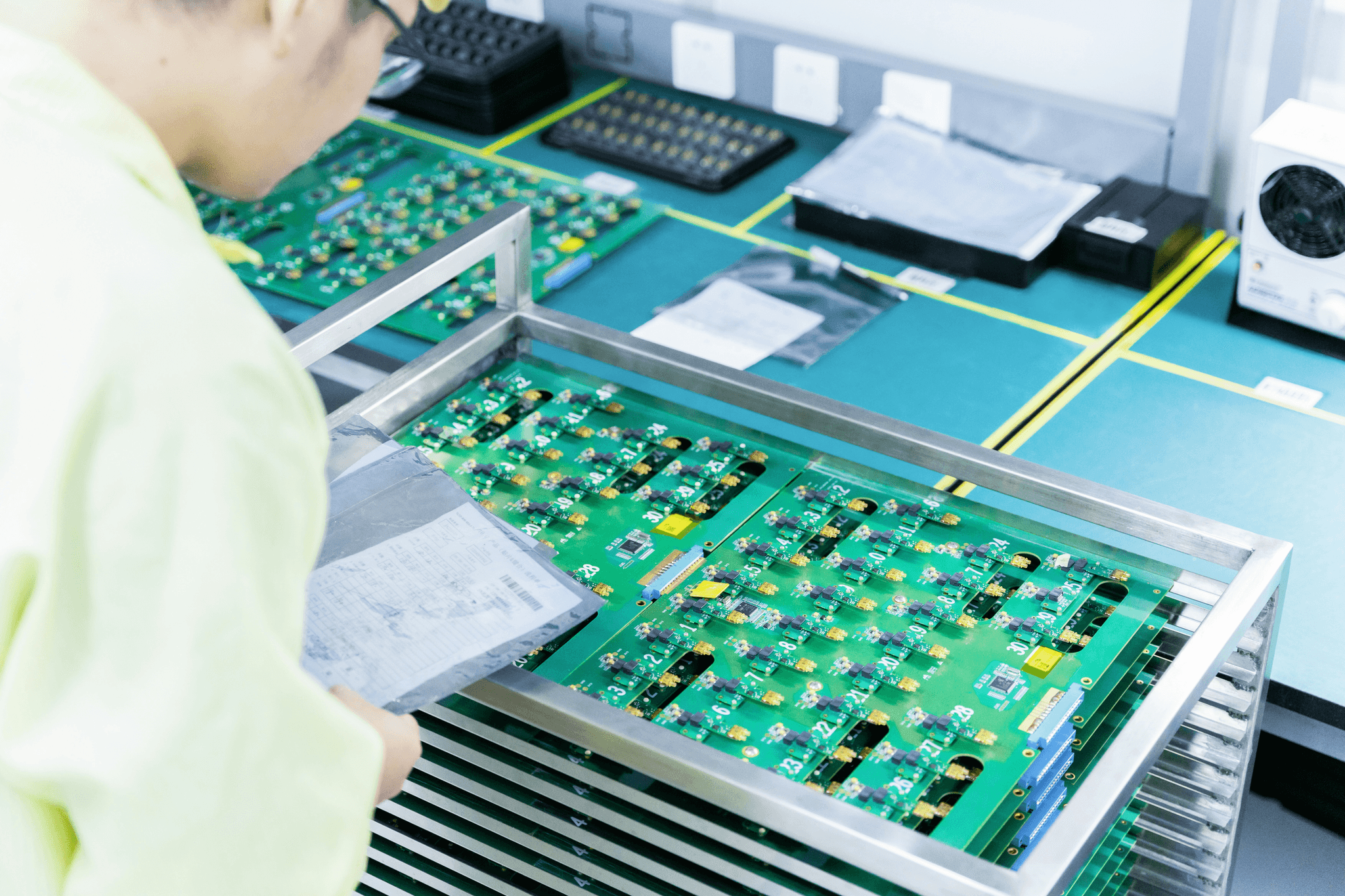

Product Quality Control in Electronics

When it comes to electronics, product quality control is non-negotiable due to the complexity and precision required in manufacturing processes. Companies like Apple invest heavily in their QC protocols, ensuring that every device meets specific performance criteria before reaching consumers' hands. This meticulous approach helps them maintain their reputation for excellence while minimizing returns due to defects.

Additionally, manufacturers of electronic components utilize Statistical Process Control (SPC) to monitor production processes continuously. By analyzing data trends during manufacturing runs, they can catch deviations from established standards early on—essentially nipping potential problems in the bud before they affect product integrity or lead to customer dissatisfaction.

Furthermore, partnerships with specialized QA services have become common practice among electronics manufacturers looking for an edge in maintaining high-quality outputs. These collaborations allow companies to leverage expert knowledge while focusing on core competencies without compromising on system management quality at any stage of production.

Lessons from the Food Industry

The food industry offers invaluable lessons on implementing effective quality control measures that ensure safety and compliance with health regulations. With stringent guidelines governing food safety, companies must rigorously apply their product quality control process throughout every stage—from sourcing ingredients to final packaging—to avoid contamination risks or recalls.

One notable example is Nestlé's commitment to maintaining high standards through comprehensive QC practices across its global supply chains. They employ both internal audits and third-party inspections as part of their strategy for ensuring compliance with international food safety regulations—demonstrating how vital QA quality is when it comes to consumer trust in food products.

Moreover, lessons learned from incidents involving foodborne illnesses highlight the critical need for robust systems management quality within this sector. Implementing proactive measures such as Hazard Analysis Critical Control Points (HACCP) allows businesses not only to define quality but also ensures ongoing monitoring throughout production processes—ultimately safeguarding public health while enhancing brand credibility.

Partnering with Quality Inspection Services

In today's competitive landscape, ensuring the integrity of your product quality control process is paramount. Many businesses turn to specialized quality inspection services to elevate their standards and streamline operations. By partnering with experts like China Inspection Pro, companies can enhance their quality and control measures while focusing on core business objectives.

Why Work with China Inspection Pro

When it comes to navigating the complexities of the product quality control process, China Inspection Pro stands out as a reliable ally. With extensive experience in various industries, they bring a wealth of knowledge in qc quality control practices that can significantly improve your outcomes. Their expertise ensures that every step of your manufacturing process adheres to defined quality standards, thus minimizing risks associated with non-compliance.

Moreover, working with China Inspection Pro means gaining access to a dedicated team focused on maintaining system management quality throughout production. They utilize advanced techniques and tools designed specifically for effective qa quality assurance, which can save you time and resources in the long run. Ultimately, this partnership allows businesses to concentrate on innovation while leaving the intricacies of quality control in capable hands.

Benefits of Professional Quality Assurance

Investing in professional quality assurance offers numerous benefits that go beyond mere compliance; it enhances overall business performance too! By implementing robust qc quality control measures through expert services like those provided by China Inspection Pro, businesses can achieve consistent product excellence that resonates with customers. This not only fosters brand loyalty but also establishes a reputation for reliability in an ever-evolving market.

Additionally, professional qa quality services help identify potential issues early in the production cycle through meticulous inspections and assessments. This proactive approach mitigates costly recalls or rework down the line—saving both time and money while ensuring adherence to industry standards. Ultimately, these benefits contribute to a more efficient operation where every detail aligns with your organization’s commitment to define quality.

Making Sense of Inspection Reports

Understanding inspection reports is crucial for leveraging insights from your product quality control process effectively. These documents provide valuable data regarding compliance levels and areas needing improvement within your manufacturing framework—essentially serving as a roadmap for future enhancements in your qc quality control efforts. Learning how to interpret these reports empowers decision-makers to implement strategies that bolster overall product integrity.

China Inspection Pro simplifies this process by offering clear explanations alongside their reports so you can easily grasp what each finding means for your operations. They break down technical jargon into actionable insights that align directly with your defined standards for success—making it easier than ever to stay ahead of potential pitfalls within system management quality practices. By mastering inspection report analysis, companies can make informed decisions that drive continuous improvement across all facets of production.

Conclusion

In the world of manufacturing, the product quality control process is not just a checkbox; it's an essential framework that ensures excellence. Quality control, or QC quality control as some might call it, is the backbone of any successful production line. As we wrap up this exploration of quality and control, it's vital to recognize that maintaining high standards is a continuous journey rather than a destination.

Best Practices for Effective Quality Control

To truly define quality in manufacturing, companies must implement best practices that resonate throughout their operations. This includes fostering a culture where every team member understands their role in the system management quality process. Regular training sessions on QA quality principles and hands-on experience with real-world scenarios can significantly enhance employee engagement and commitment to quality.

Another critical aspect of effective QC quality control is leveraging technology to streamline inspections and data collection. By utilizing advanced tools such as Statistical Process Control (SPC) and automated reporting systems, organizations can achieve higher accuracy in their assessments. These practices not only reduce errors but also improve overall efficiency, ensuring that product quality remains consistently high.

Finally, fostering open communication between departments enhances the entire product quality control process. When teams collaborate seamlessly—sharing insights from initial planning through final assessments—they create a robust feedback loop that drives continuous improvement. This holistic approach ensures that everyone is on the same page regarding standards and expectations.

Future Trends in Quality Management

As we look ahead, several future trends are set to reshape how we approach quality management in manufacturing environments. One significant trend is the increasing integration of artificial intelligence (AI) into the product quality control process. AI systems can analyze vast amounts of data quickly, identifying patterns and potential issues before they escalate into costly problems—redefining what it means to maintain high-quality standards.

Moreover, sustainability will play an increasingly pivotal role in defining quality moving forward. Manufacturers are now expected not only to produce high-quality products but also to do so responsibly by minimizing waste and reducing their carbon footprint. This shift towards eco-friendly practices aligns with consumer demand for transparency and ethical production processes while enhancing overall brand reputation.

Lastly, remote monitoring technologies will become standard practice within QC processes as businesses adapt to global challenges like pandemics or supply chain disruptions. These innovations allow for real-time oversight without being physically present on-site—ensuring that product integrity remains uncompromised regardless of external circumstances.

Enhancing Quality with Expert Partnerships

Partnering with specialized inspection services can significantly enhance your organization’s ability to manage the product quality control process effectively. Companies like China Inspection Pro offer invaluable expertise in navigating complex compliance landscapes while ensuring adherence to industry standards across various sectors—making them indispensable allies in your quest for excellence in QA quality assurance.

Engaging professional inspectors not only provides access to advanced tools but also brings fresh perspectives on potential pitfalls within your existing processes—a crucial advantage when striving for continuous improvement in both product output and operational efficiency. Their insights can help define specific areas needing attention while keeping you aligned with industry benchmarks.

In conclusion, building expert partnerships enables manufacturers to focus on core competencies while entrusting critical aspects of QC processes to those who specialize in them—ultimately leading to better products and happier customers alike!