Introduction

In a world where consumers are increasingly discerning, understanding quality control fundamentals becomes essential for businesses striving to thrive. Quality control is not just a buzzword; it is a systematic approach to ensuring products meet specific standards and satisfy customer expectations. As we delve into the intricacies of the quality control process, we will explore how effective procedures can elevate business performance and foster customer loyalty.

Understanding Quality Control Fundamentals

At its core, quality control refers to the processes that organizations implement to maintain the desired level of excellence in their products or services. This involves various quality control process steps designed to identify defects, ensure compliance with standards, and enhance overall efficiency. When companies grasp these fundamentals, they can better navigate challenges and streamline their operations for optimum results.

The Importance of Quality in Business

Quality is not merely an operational concern; it has far-reaching implications for brand reputation and profitability. Businesses that prioritize quality control procedures often enjoy enhanced customer satisfaction, reduced returns, and improved market share. In today's competitive landscape, understanding which of the following is not a step in the quality control process can be just as critical as mastering those that are—it's all about making informed decisions that lead to success.

Overview of Quality Control Types

Quality control encompasses various approaches tailored to different industries and operational needs. From statistical methods that analyze data trends to inspection-based techniques focusing on product evaluation, each type serves a unique purpose in maintaining high standards. Moreover, familiarizing oneself with the 4 types of quality control can empower organizations to adopt best practices suited for their specific contexts while continuously improving their processes.

What is Quality Control?

Quality control is a systematic approach to ensuring that products and services meet specified requirements and standards. It involves various processes designed to monitor, maintain, and improve quality throughout the production cycle. The ultimate purpose of quality control is to enhance customer satisfaction by delivering products that consistently meet or exceed expectations.

Definition and Purpose of Quality Control

At its core, quality control refers to the methods employed to maintain a desired level of excellence in products or services. This includes establishing benchmarks, conducting inspections, and implementing corrective actions when necessary. The purpose of quality control is not just about meeting regulatory requirements; it’s about fostering an organizational culture that prioritizes excellence and continuous improvement.

In the context of which of the following is not a step in the quality control process?, it’s crucial for businesses to clearly define their quality control process steps so everyone understands their roles. This clarity helps prevent confusion and ensures that all team members are aligned towards achieving high-quality outcomes. When everyone knows what steps are involved in maintaining quality, it reduces errors and enhances efficiency.

Historical Context of Quality Control

Quality control has evolved significantly over time, tracing its origins back to the early 20th century when manufacturing processes began adopting more systematic approaches. Pioneers like W. Edwards Deming introduced statistical methods for quality management during World War II, which laid the groundwork for modern practices we see today. Over decades, industries have embraced various philosophies surrounding quality – from inspection-based approaches to more holistic systems focusing on continuous improvement.

As organizations grew more complex, so did the need for robust quality control procedures that could adapt to changing market demands and technological advancements. Today, companies leverage data analytics alongside traditional inspection methods as part of their comprehensive strategies for maintaining product integrity. Understanding this historical context helps businesses appreciate how far we’ve come in refining our approach to ensuring product excellence.

Key Components of the Quality Control Process

The key components of any effective quality control process include defining standards, monitoring compliance through inspections or testing, analyzing data for trends or anomalies, and implementing corrective actions when necessary. Each step plays an integral role in maintaining high-quality outputs while minimizing waste and inefficiencies within manufacturing operations.

For instance, identifying specific quality control process steps allows teams to focus on critical areas where improvements can be made while ensuring adherence to established specifications throughout production cycles. Additionally, documenting these efforts provides valuable insights into what works well versus areas needing adjustment — a hallmark of successful continuous improvement techniques often discussed among the 4 types of quality control methodologies available today.

In summary, understanding these key components equips organizations with tools necessary not only for compliance but also for fostering a culture dedicated towards ongoing enhancement — ultimately leading them closer toward achieving business success through superior product offerings.

Quality Control Process Steps

In the realm of quality control, understanding the process steps is crucial for any business aiming to maintain high standards. The quality control process steps serve as a roadmap, guiding organizations through the intricate landscape of ensuring product excellence. By following these steps, businesses can effectively implement quality control procedures that enhance their manufacturing processes and overall operational efficiency.

Identifying Quality Standards and Specifications

The first step in the quality control process involves identifying clear quality standards and specifications that products must meet. These benchmarks are essential for ensuring consistency in production and alignment with customer expectations. Organizations need to ask themselves: which of the following is not a step in the quality control process? This reflection helps clarify what truly constitutes effective standards, ranging from material properties to performance metrics.

Once established, these specifications act as a reference point throughout the manufacturing journey, influencing everything from design to final inspection. By clearly defining expectations upfront, businesses can minimize errors and defects later on—a key aspect of successful quality control procedures. Ultimately, setting precise standards lays a solid foundation for all subsequent quality control activities.

Inspecting and Testing Products

After identifying quality standards, the next logical step in the quality control process is inspecting and testing products at various stages of production. This phase ensures that every item produced adheres to established benchmarks before reaching consumers or clients. Various methods can be employed during this stage—from visual inspections to more sophisticated testing techniques—each tailored to different types of products.

Regular inspections help catch defects early on, reducing waste and rework costs while enhancing overall production efficiency—a major benefit highlighted in discussions about the quality control process in manufacturing. Moreover, rigorous testing provides valuable data that informs future iterations of products or processes, reinforcing continuous improvement techniques found within 4 types of quality control frameworks. In essence, thorough inspection acts as both a safeguard against poor-quality outputs and an opportunity for ongoing enhancement.

Analyzing Data and Making Decisions

The final step in this critical journey is analyzing data collected from inspections and tests to make informed decisions about product quality and improvements needed within processes. This analysis allows organizations to identify patterns or recurring issues that may indicate deeper systemic problems requiring corrective actions—an integral part of effective quality control procedures. It’s here where questions like which of the following is not a step in the quality control process? become relevant; understanding what should be included helps refine focus on meaningful metrics.

By leveraging statistical tools or software designed for data analysis, companies can gain insights into their operations that facilitate smarter decision-making regarding resource allocation or adjustments needed within production lines—key components when discussing best practices in manufacturing contexts involving 4 types of quality control methods. Ultimately, thorough data analysis empowers businesses not just to react but also proactively shape their approach toward achieving excellence.

Quality Control Procedures

Quality control procedures are critical in ensuring that products meet the established standards and specifications. These procedures not only help maintain product quality but also enhance operational efficiency within a business. By implementing robust quality control measures, organizations can prevent defects and reduce waste, ultimately leading to increased customer satisfaction.

Establishing Effective Quality Checkpoints

Establishing effective quality checkpoints is a cornerstone of any successful quality control process. These checkpoints serve as critical junctures where products are evaluated against predetermined criteria, ensuring that any deviations from quality standards are caught early. By clearly defining these checkpoints within the quality control process steps, businesses can streamline their operations and minimize the risk of defects slipping through unnoticed.

To determine which of the following is not a step in the quality control process, organizations should regularly review their established checkpoints to ensure they align with industry best practices and adapt them as necessary. This ongoing evaluation contributes to a culture of continuous improvement, which is essential for maintaining high-quality standards. Ultimately, effective checkpoints not only safeguard product integrity but also foster trust among consumers.

Implementing Corrective Actions

When issues arise during the quality control process, implementing corrective actions becomes imperative to rectify any identified problems efficiently. These actions may include adjusting production processes, retraining staff, or even redesigning products to meet specific standards better. The key is to respond promptly and effectively; delayed corrective measures can lead to more significant issues down the line.

Incorporating corrective actions into your quality control procedures allows businesses to learn from mistakes and continually refine their processes. It’s essential for teams to document these actions meticulously so that they can analyze trends over time—helpful insights that inform future decisions about manufacturing practices or product design changes. Through proactive corrections based on thorough analysis, companies can significantly enhance their overall effectiveness in maintaining product quality.

Documenting Quality Control Efforts

Documenting quality control efforts is crucial in establishing accountability and transparency within an organization’s operations. Detailed records allow teams to track compliance with established standards and provide evidence during audits or inspections—essential for maintaining credibility with stakeholders and customers alike. Moreover, comprehensive documentation serves as a valuable resource for training new employees on the organization's commitment to quality.

As part of your overall strategy regarding 4 types of quality control methods employed in your business, ensure that documentation encompasses all facets—from initial inspections through final assessments—creating an invaluable historical record of performance over time. This not only aids in identifying persistent issues but also highlights successful strategies worth repeating across different departments or projects. Ultimately, thorough documentation enhances communication within teams while reinforcing a culture focused on continuous improvement and excellence.

Quality Control Process in Manufacturing

The quality control process in manufacturing is a crucial factor that directly impacts production efficiency and overall product quality. By implementing effective quality control procedures, manufacturers can ensure that their products meet established standards and specifications, thus minimizing waste and maximizing productivity. Understanding the intricacies of the quality control process steps involved is essential for any organization aiming to thrive in a competitive market.

Impact on Production Efficiency

Production efficiency is significantly enhanced through systematic quality control processes. When manufacturers establish clear quality control procedures, they can identify defects early, reducing rework and scrap rates, which ultimately saves time and resources. Moreover, streamlined quality control process steps lead to smoother operations; when everyone knows what to check for and when, it creates a harmonious workflow that boosts overall productivity.

Additionally, a robust quality control process in manufacturing fosters a culture of continuous improvement among employees. Workers become more engaged when they understand how their roles contribute to maintaining high-quality standards. This engagement not only enhances morale but also encourages innovative solutions to potential issues—ensuring that production runs efficiently without compromising on quality.

Case Studies from Toyota and Boeing

Examining case studies from industry giants like Toyota and Boeing reveals the profound impact of effective quality control processes on manufacturing success. Toyota's renowned Toyota Production System (TPS) emphasizes jidoka, or automation with a human touch, which allows workers to stop production if they detect an issue—this is one of the many innovative steps within their comprehensive quality control procedures. By integrating such practices into their daily operations, Toyota has consistently maintained high levels of efficiency while delivering top-notch vehicles.

On the other hand, Boeing's approach highlights how critical adherence to strict quality standards can be in complex manufacturing environments like aerospace. The company employs various statistical methods as part of its 4 types of quality control strategies to monitor every aspect of production—from materials used to final assembly checks—ensuring safety and reliability are never compromised. These case studies illustrate that successful implementation of the quality control process not only improves product integrity but also strengthens brand reputation.

Best Practices for Quality Assurance

To enhance the effectiveness of their manufacturing processes, companies should adopt best practices for establishing robust quality assurance systems within their operations. First and foremost, organizations must clearly define their specific quality standards and ensure all employees are trained on these expectations—this forms the foundation upon which all other steps in the quality control process rest. Regular audits should be conducted as part of ongoing monitoring efforts; this ensures compliance with established protocols while identifying areas for improvement.

Another best practice involves fostering open communication among teams regarding any observed discrepancies or potential issues during production runs—a proactive approach is vital in preventing minor problems from escalating into major setbacks later on. Additionally, leveraging technology such as automated inspection tools can streamline many aspects of the quality control procedures by providing real-time data analysis—which helps manufacturers make informed decisions quickly.

In conclusion, understanding the importance of an efficient quality control process in manufacturing cannot be overstated; it serves as both a shield against defects and a catalyst for operational excellence across industries.

4 Types of Quality Control

Quality control is a multifaceted discipline that employs various methodologies to ensure products and services meet established standards. Understanding the 4 types of quality control allows businesses to implement effective strategies tailored to their specific needs. Each type serves a unique purpose, contributing to the overall quality control process steps necessary for success.

Statistical Quality Control Methods

Statistical Quality Control (SQC) methods leverage statistical techniques to monitor and control production processes. By analyzing data collected from different stages of manufacturing, businesses can identify variations and trends that may indicate potential quality issues. This proactive approach helps answer the question: which of the following is not a step in the quality control process? It’s essential for organizations to understand how statistical methods can enhance their quality control procedures.

SQC includes tools like control charts, process capability analysis, and sampling plans, enabling companies to make informed decisions based on empirical data rather than guesswork. Implementing these methods can lead to significant improvements in product consistency and customer satisfaction. Companies that adopt SQC often find themselves ahead in maintaining high-quality standards throughout their operations.

Inspection-Based Quality Control

Inspection-based quality control focuses on examining products at various stages of production to ensure they meet specified requirements before reaching consumers. This method involves visual inspections, measurements, and testing samples against predefined criteria, making it one of the most straightforward approaches in the quality control process in manufacturing. However, relying solely on inspection raises questions about efficiency; after all, which of the following is not a step in the quality control process?

While inspection is vital for catching defects early on, it should complement other techniques rather than serve as a standalone solution. A robust inspection-based approach includes establishing clear checkpoints where products are evaluated systematically throughout production cycles. By integrating this method with other forms of quality assurance, businesses can significantly reduce waste and enhance overall product reliability.

Continuous Improvement Techniques

Continuous improvement techniques are essential for fostering an organizational culture dedicated to ongoing enhancement in processes and products. Approaches such as Lean Manufacturing and Six Sigma encourage teams to regularly assess performance metrics against established benchmarks while identifying areas for improvement within their existing frameworks—essentially refining their quality control procedures over time. In doing so, companies not only address current challenges but also anticipate future demands.

These techniques emphasize employee involvement at all levels by encouraging them to suggest improvements based on firsthand experiences with processes or products—creating a sense of ownership over quality outcomes among staff members. As organizations embrace continuous improvement methodologies, they often find themselves better equipped to adapt quickly when faced with changes or challenges within their industry landscape.

Quality Audits and Their Importance

Quality audits play a crucial role in evaluating whether an organization’s operations align with its stated policies regarding product or service delivery standards—a vital component within any comprehensive approach toward maintaining high-quality outputs across sectors! These audits involve systematic examinations conducted by internal or external parties who assess compliance with regulatory requirements while identifying gaps requiring corrective action; thus addressing which of the following is not a step in the quality control process? becomes clearer through this lens.

The insights gained from conducting regular audits inform decision-makers about areas needing attention while reinforcing accountability across departments involved directly with product development or service delivery efforts—ultimately enhancing overall effectiveness within established workflows! Organizations committed to rigorous auditing practices often cultivate trust among stakeholders by demonstrating transparency concerning adherence levels toward industry regulations governing safety protocols alongside operational excellence objectives.

Real-World Examples of Quality Control

Quality control is not just a theoretical concept; it’s a practical necessity that can make or break a business. Companies across various industries have embraced quality control processes to ensure their products meet both customer expectations and regulatory standards. By examining real-world examples, we can see how effective quality control procedures lead to success.

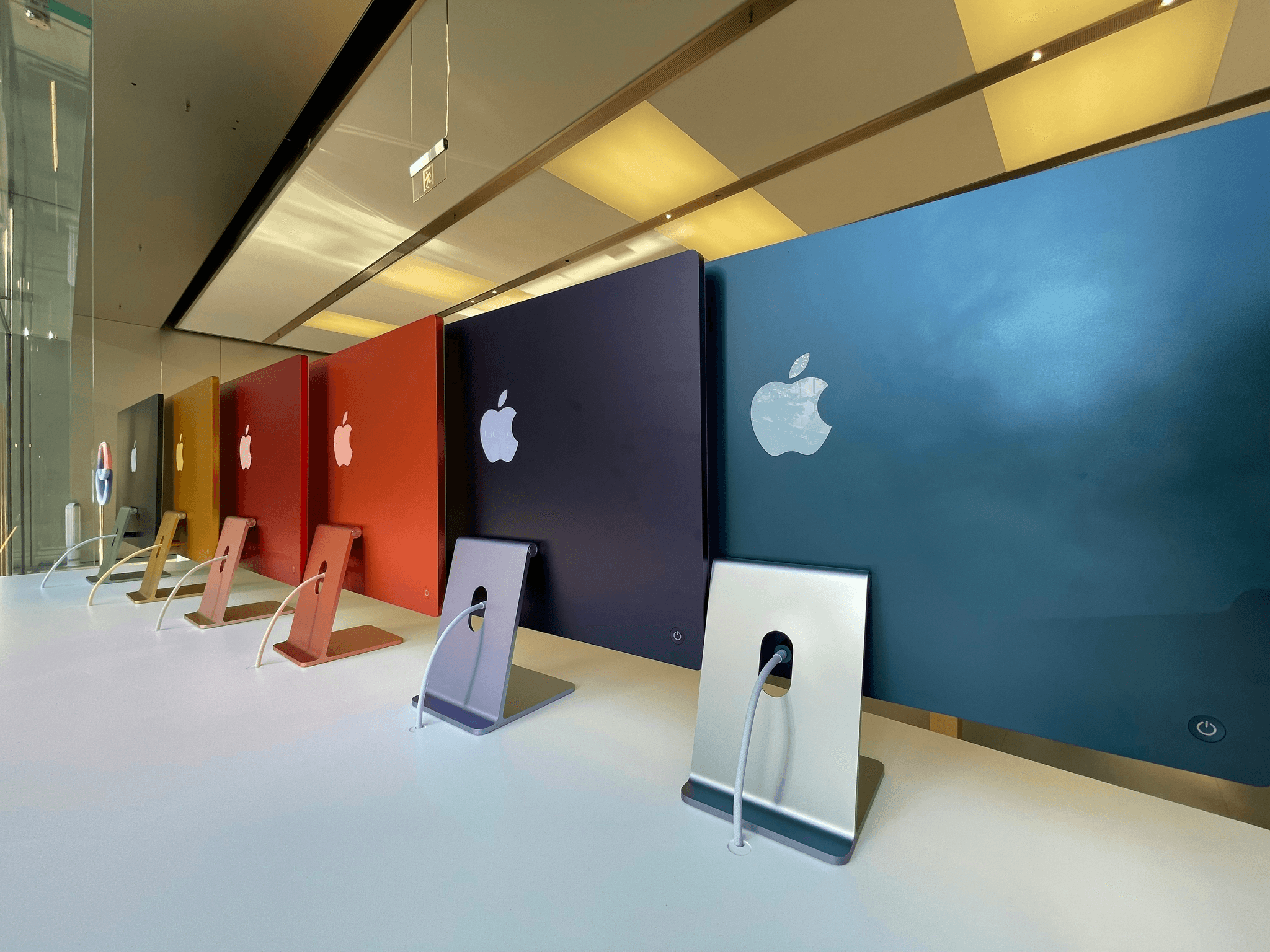

How Apple Ensures Product Quality

Apple is renowned for its commitment to quality, and this dedication is evident in its rigorous quality control process in manufacturing. The company employs a multi-faceted approach that includes stringent inspections at various stages of production, ensuring each product meets high standards before it reaches consumers. One could ask, which of the following is not a step in the quality control process? when discussing Apple's meticulous methods—because every step they take is designed to uphold their reputation for excellence.

From raw materials to final assembly, Apple utilizes advanced technology and skilled professionals to maintain its high-quality benchmarks. Their emphasis on continuous improvement techniques allows them to adapt quickly to market demands while ensuring product reliability. As part of the 4 types of quality control, Apple's statistical methods help identify potential defects early in the production cycle, saving time and resources.

The Role of China Inspection Pro in Quality Assurance

China Inspection Pro plays an essential role in global supply chains by providing comprehensive quality assurance solutions for businesses sourcing products from China. They specialize in implementing effective quality control procedures that include pre-production inspections and factory audits—key components of any robust quality control process steps. This ensures that companies receive products that meet their specifications without unpleasant surprises upon delivery.

With an eye on continuous improvement techniques, China Inspection Pro helps businesses refine their processes by identifying common issues faced during production runs. Their insights allow clients to make data-driven decisions about suppliers and production methods—ultimately enhancing overall product quality and reducing costs associated with poor-quality goods. In this context, one might ponder which of the following is not a step in the quality control process? The answer would reveal just how crucial each step truly is.

Success Stories from Leading Brands

Numerous leading brands have successfully integrated quality control into their operational strategies, resulting in impressive outcomes both financially and reputationally. For instance, companies like Toyota have built entire philosophies around continuous improvement techniques known as Kaizen—a hallmark of effective manufacturing practices within their industry sector. By focusing on statistical quality control methods alongside inspection-based approaches, these brands ensure they consistently deliver top-notch products.

Moreover, some firms have turned challenges into triumphs by adopting comprehensive quality audits as part of their regular operations—highlighting another one of the 4 types of quality control that can significantly impact business success. These audits help identify gaps within existing procedures while fostering an environment where corrective actions are swiftly implemented when necessary—a testament to proactive management practices across industries! Ultimately, these success stories underscore how vital it is for organizations to embrace structured approaches like those seen at Apple or China Inspection Pro when considering their own paths toward superior product offerings.

Conclusion

In wrapping up our exploration of quality control, it’s clear that understanding the various aspects of this discipline is crucial for any business aiming for success. Quality control isn’t just a set of procedures; it’s a comprehensive approach that encompasses everything from identifying quality standards to implementing corrective actions. As we’ve seen, the quality control process steps are vital in ensuring products meet customer expectations and regulatory requirements.

Key Takeaways on Quality Control

One of the most critical takeaways is that effective quality control procedures can significantly enhance product reliability and customer satisfaction. Remember, when asking yourself which of the following is not a step in the quality control process? you’re actually engaging with fundamental concepts that can make or break your business's reputation. Additionally, embracing the 4 types of quality control—statistical methods, inspection-based techniques, continuous improvement practices, and thorough audits—can create a robust framework for maintaining high standards.

Future Trends in Quality Management

Looking ahead, future trends in quality management will likely focus on integrating advanced technologies such as AI and machine learning into traditional manufacturing processes. These innovations promise to refine the quality control process in manufacturing by enabling real-time data analysis and predictive maintenance strategies that minimize defects before they occur. Moreover, as businesses increasingly adopt agile methodologies, there's an emerging need to adapt existing quality control procedures to be more flexible and responsive to rapid market changes.

Enhancing Quality Control for Business Success

To enhance your approach to quality control for long-term business success, consider fostering a culture of continuous improvement where every employee feels empowered to contribute ideas on how to streamline processes or elevate product standards. Regular training sessions on the 4 types of quality control can also keep teams updated on best practices while reinforcing their commitment to excellence. Ultimately, by prioritizing effective quality management strategies today, businesses can build a resilient foundation for tomorrow’s challenges.