Introduction

Quality control is the backbone of successful manufacturing and service industries, ensuring that products meet established standards and customer expectations. In an increasingly competitive market, understanding quality management fundamentals is crucial for businesses aiming to maintain a reputation for excellence. This introduction sets the stage for delving into the significance of quality inspection and its various methodologies.

Understanding Quality Control Fundamentals

At its core, quality control encompasses a range of processes aimed at ensuring that products or services are consistent, reliable, and meet specified requirements. The 4 types of quality control—visual inspection, measurement inspection, functional testing, and destructive testing—each play a pivotal role in maintaining high standards across different industries. By grasping these fundamentals, businesses can implement effective strategies that enhance overall quality assurance.

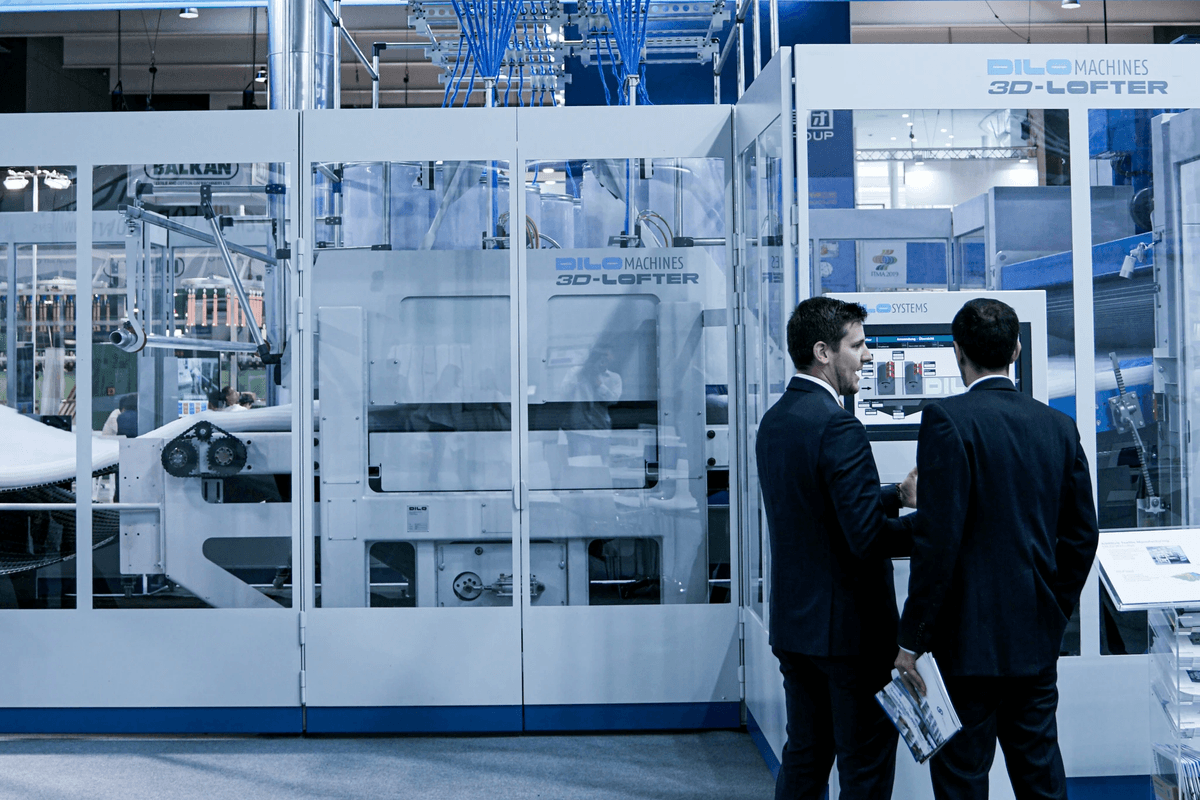

Importance of Quality Inspection in Industry

Quality inspection serves as a vital checkpoint in the production process, acting as a safeguard against defects and inconsistencies that could compromise product integrity. By prioritizing quality and assurance through rigorous inspections, companies not only protect their brand reputation but also foster customer trust and loyalty. In this landscape, the role of a quality assurance specialist becomes indispensable; they ensure that every aspect of production adheres to established standards.

Exploring the 4 Types of Quality Inspection

To navigate the complexities of quality management effectively, it’s essential to explore the 4 types of quality control methods employed across various sectors. Each type—visual inspection, measurement inspection, functional testing, and destructive testing—offers unique benefits tailored to specific challenges within production lines or service delivery frameworks. By understanding these diverse approaches to quality inspection, organizations can better leverage their resources to achieve optimal outcomes in product performance and reliability.

Visual Inspection

Visual inspection serves as the first line of defense in quality control, acting as a crucial checkpoint in the quality management process. This method relies on the human eye, often enhanced by tools and lighting, to identify defects or inconsistencies in products before they move further down the production line. By catching issues early, visual inspection helps maintain high standards of quality assurance and reduces waste in manufacturing.

The First Line of Quality Control

When it comes to quality control, visual inspection is often the unsung hero. It’s typically the first method employed to ensure that products meet required specifications before any advanced testing takes place. Quality assurance specialists frequently rely on this straightforward approach to spot glaring problems such as surface defects, color mismatches, or assembly errors—often without needing sophisticated equipment.

Techniques Used in Visual Inspection

Several techniques enhance the effectiveness of visual inspection within quality management frameworks. For instance, inspectors may use magnifying glasses or borescopes for detailed examinations of intricate components. Additionally, standardized checklists can guide inspectors through common defects associated with each product type, ensuring that no stone is left unturned during this critical phase of quality inspection.

Pros and Cons of Visual Inspection

Visual inspection has its share of advantages and disadvantages when considering the broader landscape of the 4 types of quality control. On one hand, it is cost-effective and quick; inspectors can make immediate decisions about product integrity based solely on their observations. However, human error remains a significant risk—fatigue or oversight can lead to missed defects—highlighting why balancing various methods within a comprehensive quality control strategy is essential for optimal results.

Measurement Inspection

Measurement inspection is a cornerstone of quality control that ensures products meet precise specifications and standards. In the realm of quality management, this type of inspection is vital for maintaining consistency and reliability in manufacturing processes. By focusing on exact measurements, companies can minimize defects and enhance overall product quality, reinforcing the importance of quality assurance.

Precision in Quality Management

Precision is the name of the game when it comes to measurement inspection. It allows quality assurance specialists to identify deviations from desired specifications that could lead to product failure or customer dissatisfaction. In a world where even minor discrepancies can have significant consequences, precision becomes a non-negotiable aspect of effective quality control.

Tools for Measurement Inspection

To achieve precision in measurement inspection, various tools are employed across industries. Calipers, micrometers, gauges, and laser measuring devices are just a few examples that help ensure accurate data collection during quality inspections. These tools not only facilitate thorough checks but also empower quality assurance specialists to make informed decisions about product integrity and compliance with standards.

Importance of Accurate Data

Accurate data is the lifeblood of effective quality management; without it, any assessment made during measurement inspection would be akin to navigating without a compass. It plays an essential role in driving continuous improvement initiatives within organizations by providing insights into areas needing enhancement or adjustment. Furthermore, reliable data fosters trust between manufacturers and consumers by ensuring that products consistently meet the established benchmarks for safety and performance.

Functional Testing

Functional testing is a vital component of the quality control process, ensuring that products perform their intended functions before reaching consumers. It’s not just about checking if something turns on; it’s about verifying that it meets all specifications and requirements laid out by the design team. This step in quality management helps identify defects early, reducing the risk of failure in real-world applications.

Ensuring Products Work as Intended

The primary goal of functional testing is to confirm that products operate correctly according to predefined criteria. This involves rigorous testing scenarios where each function is evaluated against expected outcomes, ensuring quality and assurance throughout the process. By doing so, manufacturers can confidently assert that their products not only exist but also work as intended in various conditions.

Common Functional Testing Methods

There are several common methods employed in functional testing, each suited for different types of products and industries. Techniques such as black-box testing focus solely on input-output relationships without delving into internal workings, while white-box testing examines internal structures or workings of an application. Other methods include regression testing to ensure new changes don’t disrupt existing functionality and user acceptance testing (UAT), where real users validate product performance against their expectations.

Role of Quality Assurance Specialists

Quality assurance specialists play a crucial role in functional testing by designing test cases and scenarios that reflect real-world usage patterns. They analyze results meticulously, providing insights into potential improvements or necessary adjustments before a product launch. Their expertise ensures that the 4 types of quality control—visual inspection, measurement inspection, functional testing, and destructive testing—are effectively integrated into a cohesive quality management strategy.

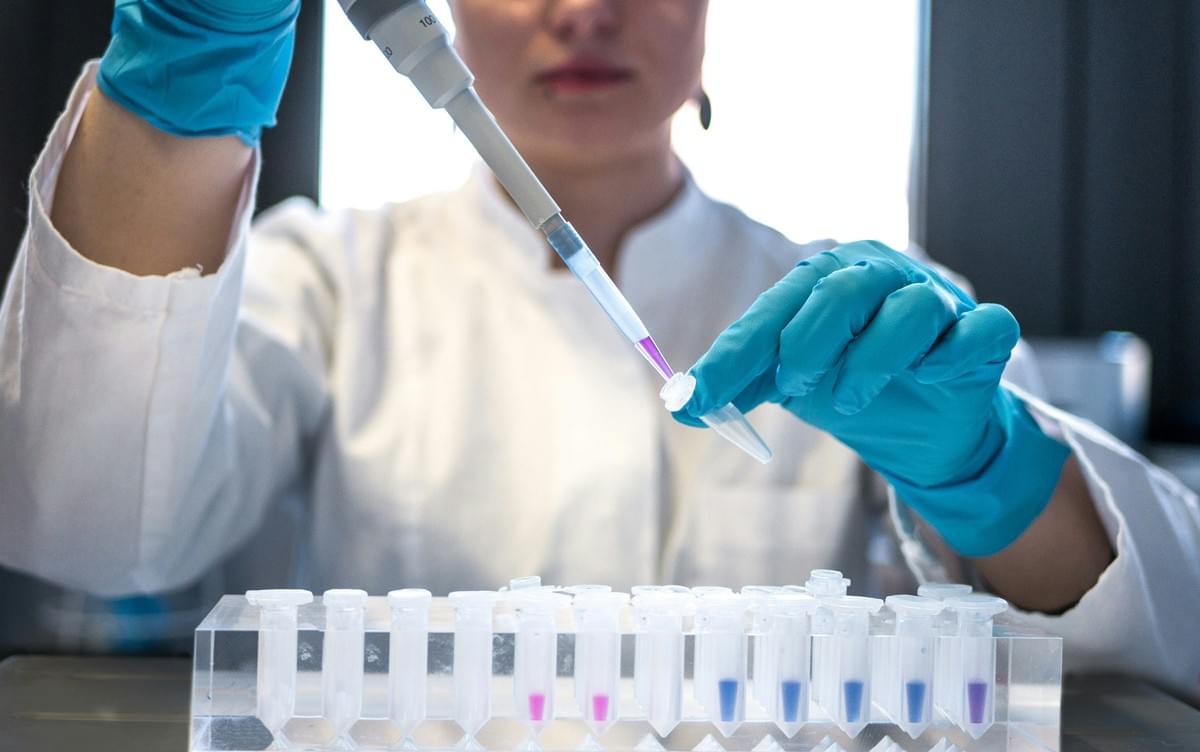

Destructive Testing

Destructive testing is an essential aspect of quality control that often involves sacrificing a product to ensure its reliability and safety. This method is particularly relevant in industries where the stakes are high, such as aerospace, automotive, and pharmaceuticals. By understanding the implications of destructive testing, organizations can better manage quality and assurance while still adhering to stringent safety standards.

When Quality Control Means Sacrifice

In the realm of quality management, sometimes you have to break a few eggs to make an omelet—or in this case, test a product's integrity. Destructive testing involves taking products out of circulation for thorough evaluation, which can be daunting for manufacturers concerned about costs and waste. However, this sacrifice ultimately leads to enhanced quality control by identifying potential failures before they reach consumers.

Types of Destructive Tests

There are several types of destructive tests that play pivotal roles in ensuring product reliability. Common methods include tensile testing, impact testing, and fatigue testing—each designed to assess different properties under stress or strain conditions. By employing these techniques as part of their quality inspection processes, companies can gather critical data that informs both product development and ongoing quality assurance initiatives.

Balancing Risk and Quality

Balancing risk with quality is no small feat in the world of manufacturing; it's like walking a tightrope without a safety net! Companies must weigh the benefits of conducting destructive tests against the potential losses incurred from damaged products or delayed timelines. Ultimately, effective quality management hinges on making informed decisions about when to utilize these tests—ensuring that the pursuit of excellence does not come at an unsustainable cost.

Conclusion

In wrapping up our exploration of the 4 types of quality control, it's essential to recognize how each method plays a pivotal role in maintaining high standards in various industries. Visual inspection, measurement inspection, functional testing, and destructive testing each offer unique advantages and challenges that contribute to effective quality management. By understanding these methods, organizations can enhance their overall quality assurance processes.

Recap of the 4 Types of Quality Control

The four types of quality control—visual inspection, measurement inspection, functional testing, and destructive testing—serve as foundational elements in any robust quality management system. Visual inspection provides an immediate assessment using human observation; measurement inspection relies on precise tools for data accuracy; functional testing ensures products perform as intended; while destructive testing sacrifices some items to gather critical data about durability and performance. Together, these methods form a comprehensive framework that reinforces the importance of quality and assurance throughout the production lifecycle.

How Quality Inspection Enhances Product Integrity

Quality inspection plays an integral role in enhancing product integrity by identifying defects before they can affect end users. Through rigorous processes such as visual inspections and functional tests, manufacturers can ensure that products meet established standards for safety and functionality. This proactive approach not only boosts customer satisfaction but also fosters trust in brands committed to maintaining high levels of quality control.

Leveraging China Inspection Pro for Quality Assurance

For businesses seeking reliable solutions in their quest for excellence, leveraging services like China Inspection Pro can be a game-changer in achieving effective quality assurance. Their expertise encompasses all four types of quality control methods tailored to meet specific industry needs while ensuring compliance with international standards. By partnering with experienced professionals like those at China Inspection Pro, companies can streamline their quality management efforts and ultimately enhance both product reliability and customer confidence.