Introduction

In the fast-paced world of manufacturing, understanding how to achieve and maintain high standards of manufacturing quality is crucial. Companies must unlock the secrets that lie within effective quality control processes to ensure their products meet consumer expectations and industry regulations. The journey towards excellence begins with a keen focus on inspection in quality control, which serves as the backbone of any successful quality assurance strategy.

Unlocking the Secrets of Manufacturing Quality

Manufacturing quality encompasses various elements, including the processes, materials, and methods employed to produce goods that meet specific standards. One key aspect is understanding what is quality control inspection, which involves systematic examination and assessment of products throughout the production cycle. By implementing robust inspection methods, manufacturers can identify defects early in the process and significantly reduce waste while enhancing overall product reliability.

Why Quality Control Matters Today

Quality control has never been more critical than it is today due to increasing consumer demands and global competition. With the rise of e-commerce and retail giants, maintaining high-quality standards through effective quality assurance in retail has become essential for survival in a crowded marketplace. Businesses that prioritize their inspection quality not only build trust with consumers but also protect their brand reputation against potential pitfalls associated with subpar products.

Enhancing Your Competitive Edge

To gain a competitive edge in today's manufacturing landscape, companies must invest time and resources into refining their quality inspection process. This includes exploring various types of inspection methods tailored to specific production needs while leveraging technology for efficiency gains. Ultimately, organizations that embrace a culture centered around manufacturing quality are better positioned to adapt to changes in market demands while achieving sustainable growth.

Implement Rigorous Quality Control Processes

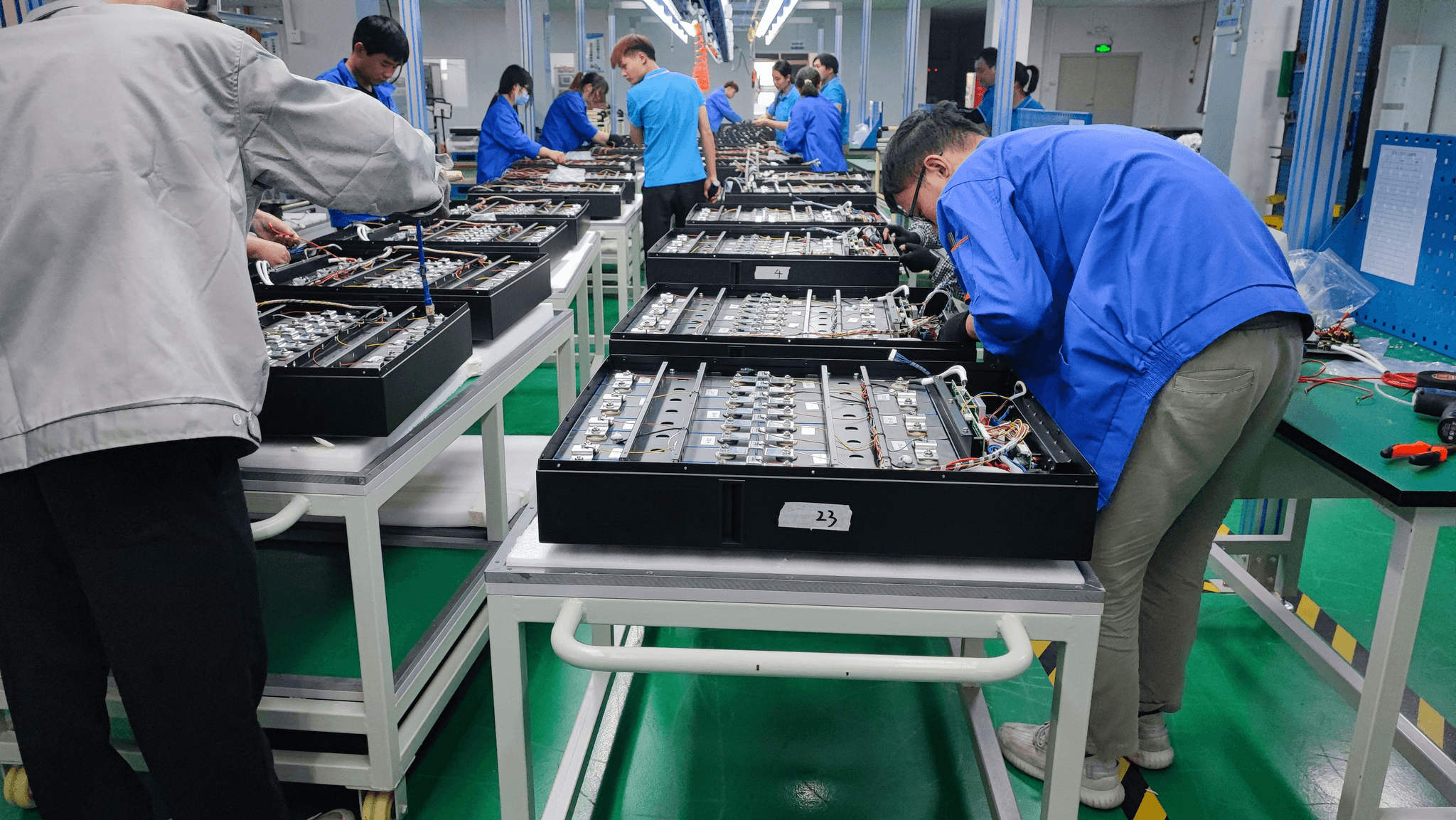

In the world of manufacturing quality, implementing rigorous quality control processes is not just a good idea; it's essential. Quality control inspection serves as the backbone of ensuring that products meet the required standards before they reach consumers. By establishing a robust framework for inspection in quality control, manufacturers can significantly reduce defects and enhance customer satisfaction.

Understanding What is Quality Control Inspection

So, what is quality control inspection? It’s the systematic examination of products or services to ensure they meet specific standards and specifications. This process involves various types of inspection methods, such as visual inspections, measurements, and functional tests, all aimed at assessing inspection quality to guarantee that only top-notch products make it to market.

Quality control inspection is crucial in identifying defects early in the production process, which can save time and resources down the road. By understanding its significance, businesses can position themselves better in terms of manufacturing quality while also fostering a culture that prioritizes excellence. Embracing this concept allows companies to create more reliable products and maintain their reputation.

The Role of Quality Assurance in Retail

Quality assurance in retail plays a pivotal role in maintaining high standards throughout the supply chain. It ensures that every product delivered meets consumer expectations for performance and safety while also adhering to regulatory requirements. With effective quality assurance practices in place, retailers can build trust with their customers by guaranteeing consistent product reliability.

Moreover, having a solid foundation in quality assurance helps retailers minimize returns due to defects or dissatisfaction—an often costly outcome for businesses. This proactive approach not only enhances customer loyalty but also contributes to overall manufacturing quality by encouraging suppliers to adhere strictly to established guidelines and best practices. Ultimately, investing time and resources into quality assurance leads to better relationships with both consumers and suppliers alike.

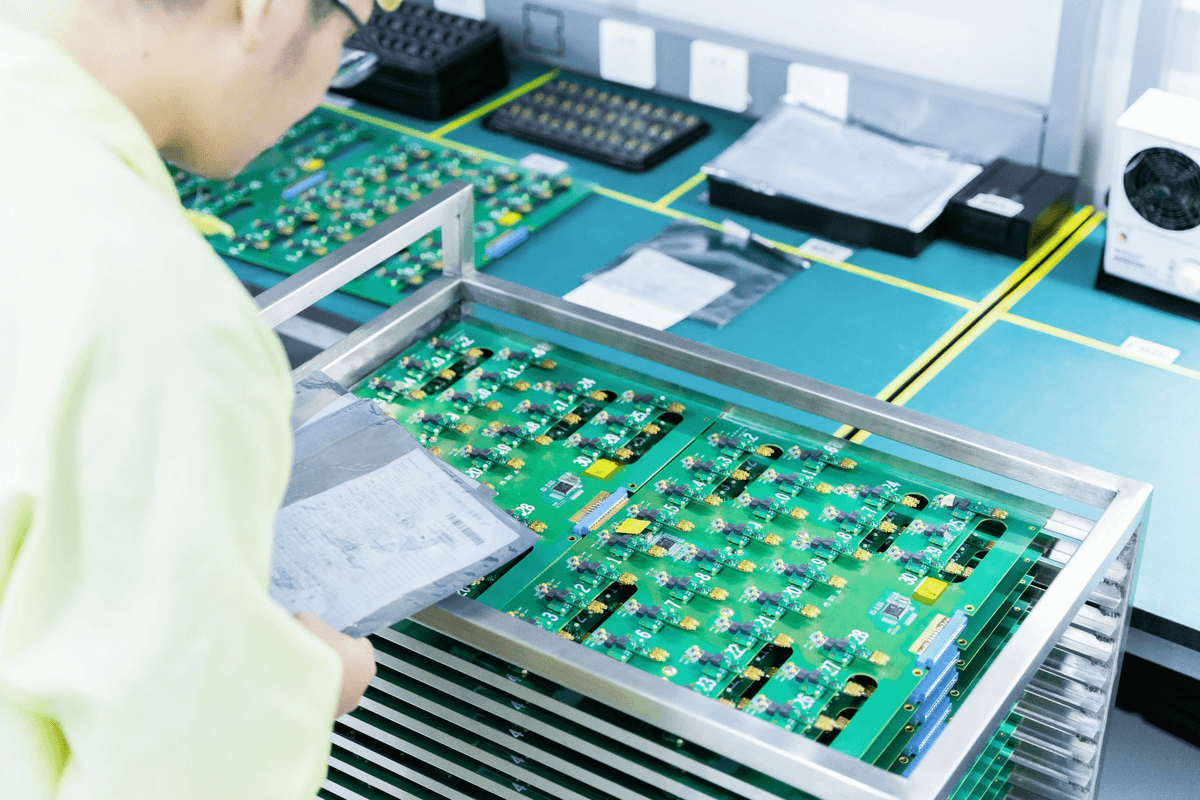

Integrating Quality Inspection Processes

Integrating quality inspection processes into your operations doesn’t just streamline workflows; it enhances overall efficiency across departments involved in manufacturing quality management. By employing various types of inspection methods at different stages—from raw materials through final assembly—businesses can catch issues before they escalate into larger problems later on.

A successful integration strategy involves training employees on how these processes fit within their daily tasks while fostering collaboration among teams responsible for different aspects of production. When everyone understands their role within the broader context of the quality inspection process, it creates an environment where continuous improvement thrives—leading to higher levels of customer satisfaction over time.

Furthermore, leveraging technology can aid this integration by automating portions of the inspection process or providing real-time data analytics on performance metrics related to inspection quality. As manufacturers embrace this holistic approach toward integrating these processes effectively, they position themselves as leaders committed not only towards delivering great products but also towards elevating industry standards as a whole.

Invest in Training and Development

In the realm of manufacturing quality, investing in training and development is not just an option; it's a necessity. Quality inspection processes are only as effective as the individuals who execute them, making it crucial to build a workforce equipped with the right skills. By prioritizing employee education, companies can ensure that their teams are proficient in various types of inspection methods, ultimately enhancing overall quality assurance in retail and manufacturing.

Building Skills for Quality Inspection

Building skills for quality inspection involves providing employees with comprehensive training programs tailored to their specific roles within the quality control framework. Understanding what is quality control inspection is fundamental for all team members, as it lays the groundwork for effective practices that uphold manufacturing quality standards. Workshops, hands-on training sessions, and certifications can significantly enhance employees' abilities to identify defects and ensure compliance with established guidelines.

Empowering Employees in Quality Control

Empowering employees in quality control means fostering an environment where they feel confident to take ownership of their roles. This empowerment can be achieved through clear communication about expectations and giving team members autonomy over their inspection duties. When employees understand the importance of their contributions to the overall inspection quality, they become more engaged and motivated to uphold high standards within the manufacturing process.

Continuous Learning for Manufacturing Quality

Continuous learning is vital for maintaining excellence in manufacturing quality amidst ever-evolving industry standards and technologies. Regularly updating training materials ensures that employees stay informed about new types of inspection methods and advancements in technology affecting the quality inspection process. By cultivating a culture that encourages ongoing education, organizations can adapt swiftly to changes while consistently enhancing their approach to quality assurance in retail.

Leverage Technology and Automation

In today's fast-paced manufacturing landscape, leveraging technology and automation is key to enhancing manufacturing quality. The integration of advanced tools not only streamlines the inspection in quality control but also ensures that products meet stringent quality assurance in retail standards. By adopting innovative technologies, businesses can elevate their quality inspection process to new heights.

Tools for Effective Inspection Quality

To achieve effective inspection quality, manufacturers must invest in state-of-the-art tools designed specifically for quality control. These tools range from digital calipers to sophisticated vision systems that accurately assess product specifications and detect defects. Understanding what is quality control inspection goes beyond just having the right equipment; it involves utilizing these tools to enhance the types of inspection methods employed throughout the production cycle.

Modernizing the Quality Inspection Process

Modernizing the quality inspection process is essential for any manufacturer aiming to stay competitive. This involves integrating software solutions that facilitate real-time data analysis and reporting, allowing teams to identify trends and areas for improvement quickly. By embracing modern techniques, companies can refine their approach to inspection in quality control, ensuring consistent adherence to quality standards throughout their operations.

The Impact of AI on Manufacturing Quality

Artificial Intelligence (AI) represents a transformative force in manufacturing quality by automating routine inspections and providing deep insights into production processes. AI-driven technologies can analyze vast amounts of data from various types of inspection methods, enabling quicker decision-making and reducing human error significantly. As we explore the impact of AI on manufacturing quality, it becomes clear that its role in enhancing overall efficiency cannot be understated—leading to better products and greater customer satisfaction.

Adopt a Lean Manufacturing Approach

In the ever-evolving world of manufacturing quality, adopting a lean manufacturing approach can be a game changer. Lean principles focus on maximizing value while minimizing waste, which not only enhances efficiency but also improves inspection in quality control. By streamlining processes, companies can achieve better quality outcomes and ensure that every step in the production line adds value to the final product.

Streamlining for Better Quality Outcomes

Streamlining involves simplifying processes to improve efficiency and effectiveness, directly impacting manufacturing quality. When organizations clarify their workflows and eliminate unnecessary steps, they create an environment conducive to better inspection in quality control. This leads to fewer defects and higher satisfaction among customers who expect nothing less than top-notch products.

By focusing on what is essential during the quality inspection process, manufacturers can allocate resources more effectively and respond swiftly to issues as they arise. This proactive approach ensures that teams are not just reacting to problems but are actively working towards preventing them from occurring in the first place. Ultimately, streamlining operations fosters a culture of continuous improvement where everyone is invested in maintaining high standards of quality assurance in retail.

Reducing Waste in Quality Control

Waste reduction is at the heart of lean manufacturing practices and plays a crucial role in enhancing overall manufacturing quality. By identifying areas where resources are being wasted—be it time, materials, or labor—companies can make informed decisions that lead to significant cost savings without sacrificing quality. In fact, effective waste management often results in improved inspection quality by allowing teams to focus on critical areas rather than getting bogged down by inefficiencies.

One common method for reducing waste is through implementing standardized types of inspection methods that ensure consistency across all levels of production. These methods help identify flaws early on, reducing rework costs and ensuring that only high-quality products reach consumers’ hands. Companies can also leverage data analytics to pinpoint inefficiencies within their existing processes, leading to smarter strategies for waste reduction.

Lean Practices in Quality Inspection

Integrating lean practices into the quality inspection process transforms how organizations approach manufacturing quality altogether. Techniques such as 5S (Sort, Set in order, Shine, Standardize, Sustain) help create organized workspaces that enhance productivity while making it easier for employees to adhere to rigorous standards during inspections. By fostering an environment where cleanliness and organization are prioritized, companies significantly reduce errors associated with cluttered or chaotic workspaces.

Moreover, collaboration among teams becomes more seamless when lean practices are employed; this encourages open communication about potential issues related to product defects or inconsistencies during inspections. Regular training sessions focused on these methodologies empower employees with knowledge about what is required for effective inspection procedures while instilling a sense of accountability throughout the organization’s culture of quality assurance in retail settings.

In conclusion, adopting a lean manufacturing approach isn't just about cutting costs; it's about elevating your entire operation's commitment to excellence through smarter practices aimed at enhancing overall manufacturing quality.

Collaborate with Reliable Inspection Partners

In the world of manufacturing quality, collaboration with reliable inspection partners is crucial for maintaining high standards. Quality control processes hinge on effective partnerships that enhance the overall inspection quality, ensuring products meet or exceed expectations. By choosing the right providers, businesses can bolster their quality assurance in retail and manufacturing alike.

Choosing the Right Quality Inspection Provider

Selecting the right quality inspection provider is like finding a needle in a haystack—challenging but essential. Look for companies that specialize in various types of inspection methods, from visual checks to advanced technological assessments, to ensure comprehensive coverage of your needs. Remember, what is quality control inspection without expertise? A provider with a solid reputation and industry experience will help streamline your quality inspection process and elevate your manufacturing quality.

When evaluating potential partners, consider their track record in delivering consistent results and their ability to adapt to your specific requirements. Ask about their approach to integrating modern technology into their inspections; this can significantly enhance efficiency and accuracy in identifying defects or non-compliance issues. Ultimately, choosing wisely means investing not just in a service but also in peace of mind regarding your product's integrity.

How China Inspection Pro Enhances Quality Assurance

China Inspection Pro stands out as a formidable ally in enhancing quality assurance across various sectors. With extensive experience in the field, they provide an array of tailored services designed specifically for manufacturers aiming for excellence in product delivery. Their commitment to rigorous inspection standards ensures that businesses can trust their products will meet both local and international regulations.

Their expertise encompasses numerous types of inspection methods that are adaptable based on client needs—from pre-production checks to final random inspections before shipment. This flexibility allows manufacturers to maintain high levels of manufacturing quality while simultaneously reducing risks associated with defective goods entering the market. Moreover, China Inspection Pro employs cutting-edge technology within its processes, making them a leader in modernizing the quality inspection process.

By partnering with China Inspection Pro, companies gain access not only to thorough inspections but also valuable insights into improving production practices and addressing potential issues proactively. This collaborative approach fosters an environment where continuous improvement becomes part of everyday operations—a win-win scenario for all involved!

Building Strong Relationships for Quality Success

Building strong relationships with your chosen inspection partner isn't just about contracts; it's about fostering trust and open communication channels that lead to long-lasting success. The foundation of any fruitful partnership lies in mutual understanding—both parties must be aligned on goals related to manufacturing quality and expectations from the outset. Regular check-ins and feedback sessions can go a long way toward refining processes related to the quality assurance in retail.

Moreover, sharing insights from both sides helps identify trends concerning common defects or areas needing improvement within your production line—after all, knowledge is power! When you work closely together on refining types of inspection methods used during audits or assessments, it creates an atmosphere conducive to innovation and growth throughout the supply chain.

Ultimately, nurturing these relationships leads not only to enhanced inspection quality but also establishes a culture centered around excellence—one where everyone involved strives toward achieving superior outcomes consistently over time.

Regularly Review and Improve Inspection Methods

In the fast-paced world of manufacturing quality, staying ahead means consistently evaluating and refining your inspection methods. The quality inspection process is not a one-time event; rather, it requires regular scrutiny to ensure it meets evolving standards and effectively identifies defects. By committing to this practice, businesses can enhance their overall quality assurance in retail and manufacturing sectors.

Types of Inspection Methods Explained

Understanding the various types of inspection methods is crucial for effective quality control. Common approaches include visual inspections, where trained eyes assess product appearance; dimensional inspections, which measure physical attributes against specifications; and functional tests that evaluate performance under operational conditions. Each method plays a significant role in the broader context of what is quality control inspection, allowing manufacturers to tailor their strategies according to specific needs.

Analyzing Inspection Quality for Continuous Improvement

Analyzing inspection quality is essential for continuous improvement within the manufacturing landscape. By collecting data on defect rates and inspection outcomes, companies can identify trends that highlight areas needing enhancement in their quality control processes. This iterative approach not only bolsters confidence in the products but also fosters a culture where feedback drives innovation in the quality inspection process.

Adapting to Industry Changes in Quality Standards

The manufacturing sector is ever-evolving, with new technologies and regulations frequently reshaping industry standards. Adapting to these changes ensures that your approach to inspection in quality control remains relevant and effective. By staying informed about updates in regulations and emerging best practices, businesses can refine their methodologies and maintain high levels of manufacturing quality while satisfying consumer expectations.

Foster a Culture of Quality

Creating a culture of quality within an organization is not just about implementing processes; it’s about instilling a mindset where every team member feels responsible for manufacturing quality. When employees understand that they play a crucial role in the inspection in quality control, they become more engaged and proactive in their duties. This collective accountability can lead to significant improvements in the overall quality assurance in retail and manufacturing environments.

Encouraging Team Accountability in Quality Control

To foster accountability, management should encourage open communication about quality issues and successes. When employees are empowered to speak up about potential problems or suggest improvements related to the quality inspection process, it creates an environment of trust and collaboration. By regularly discussing what is quality control inspection and its importance, teams can better appreciate their roles in maintaining high standards.

Moreover, establishing clear metrics for success helps teams understand how their individual contributions impact the broader goals of manufacturing quality. Regular feedback sessions can keep everyone aligned on expectations while celebrating small wins reinforces positive behaviors related to inspection quality. Ultimately, when everyone understands that they are part of the solution, it enhances commitment to maintaining high-quality standards.

Recognizing Achievements in Manufacturing Quality

Acknowledging team members' efforts toward achieving excellence is vital for sustaining motivation within a culture of quality. Recognition can take many forms—from verbal praise during meetings to formal awards for outstanding contributions toward improving types of inspection methods or reducing defects through effective processes. Celebrating these achievements not only boosts morale but also emphasizes the importance of each person's role in achieving high manufacturing quality standards.

Implementing programs that spotlight individuals or teams who excel at maintaining product integrity through diligent inspection practices encourages others to aspire towards similar goals. Highlighting success stories during company-wide communications reinforces best practices while demonstrating how teamwork contributes to improved outcomes across all areas of production and retail operations. This recognition fosters an environment where striving for excellence becomes contagious.

Long-term Benefits of a Quality-Centric Culture

Investing time and effort into cultivating a culture focused on manufacturing quality yields long-term benefits that far outweigh initial challenges or resistance encountered along the way. Organizations that prioritize this culture often see reduced costs associated with rework or product returns due to enhanced efficiency stemming from robust inspection processes implemented by empowered employees who take pride in their work output—leading ultimately towards increased customer satisfaction levels as well.

Moreover, companies with strong cultures centered around continuous improvement tend to attract top talent eager for meaningful work experiences linked directly back into producing high-quality goods/services—further driving innovation within industries reliant upon precision-driven practices such as those found within various types of inspection methods utilized today! In summary, fostering such an environment creates not only superior products but also lasting relationships with customers who appreciate commitment demonstrated by brands committed fully toward delivering consistent results over time.

Conclusion

In the competitive landscape of manufacturing, ensuring high standards of quality is not just a box to check—it's a vital component that can define success. The journey toward exceptional manufacturing quality involves implementing rigorous inspection processes, investing in employee training, and embracing innovative technologies. As we've explored, each aspect contributes significantly to the overall quality assurance in retail and manufacturing sectors.

Key Takeaways for Manufacturing Quality

First and foremost, understanding what is quality control inspection lays the groundwork for effective practices that enhance inspection quality. By integrating various types of inspection methods into your workflow, you can identify issues early and mitigate risks before they escalate. Furthermore, fostering a culture that prioritizes quality empowers teams to take ownership of their roles in maintaining high standards.

Next Steps to Enhance Your Quality Strategy

To elevate your quality strategy, begin by conducting an audit of your current processes related to the quality inspection process. Identify gaps where improvements can be made—whether through technology upgrades or enhanced training programs focused on specific types of inspection methods. Collaborating with reliable partners and continuously reviewing your practices will ensure that your approach remains agile and responsive to industry changes.

Embracing Quality as a Core Business Value

Ultimately, embracing manufacturing quality as a core business value transforms how organizations operate from top to bottom. It instills accountability within teams while recognizing achievements fosters motivation and commitment toward excellence in every aspect of production. By embedding this mindset into your corporate culture, you not only enhance product reliability but also build lasting relationships with customers who trust your brand.