Introduction

In the realm of quality control, visual inspection methods play a pivotal role in ensuring safety and reliability across various industries. From manufacturing to aerospace, understanding the types of visual inspection can significantly enhance the detection of defects and anomalies. This introduction sets the stage for exploring various techniques such as direct visual inspection, magnetic particle inspection, and remote visual inspection.

Understanding Visual Inspection Methods

Visual inspection methods are essential tools used to assess the integrity of materials and components without causing any damage. Among these methods, direct visual inspection is perhaps the most straightforward, relying on an inspector’s eyes to identify visible flaws. However, more advanced techniques like liquid penetrant inspection and microscopic inspection have emerged to provide deeper insights into material conditions that are not easily seen at first glance.

Importance of Various Inspection Techniques

The importance of various inspection techniques cannot be overstated; they serve as the first line of defense against potential failures in critical applications. Each type of visual inspection—be it acoustic emission testing or borescope usage—offers unique advantages tailored to specific scenarios. By employing a combination of these methods, organizations can ensure comprehensive evaluation and maintain high standards for quality control.

Overview of Inspection Processes

The visual inspection process typically involves several systematic steps designed to maximize effectiveness and accuracy. Initially, inspectors prepare by selecting appropriate tools and techniques based on the nature of the materials being examined; this could range from simple direct visual inspections to more complex liquid penetrant inspections or magnetic particle inspections for detecting subsurface flaws. Ultimately, understanding these processes enhances not only product quality but also operational efficiency across industries.

Types of Visual Inspection

When it comes to ensuring quality and safety in various industries, the types of visual inspection play a crucial role. Each method offers unique advantages and is tailored to specific applications, making it essential to understand their distinctions. From Direct Visual Inspection to advanced techniques like Liquid Penetrant Inspection and Remote Visual Inspection, these methods collectively enhance the integrity of products and structures.

Direct Visual Inspection Explained

Direct visual inspection is the simplest form of visual inspection, where an inspector examines a surface or object with the naked eye or basic tools. This approach is often used for routine checks in manufacturing and maintenance environments, allowing for quick assessments without sophisticated equipment. While it may seem straightforward, direct visual inspection can effectively identify visible defects such as cracks, corrosion, or misalignments—making it an invaluable part of quality control processes.

However, direct visual inspection does have its limitations; inspectors may miss subtle flaws that require more advanced techniques like Magnetic Particle Inspection or Microscopic Inspection. Therefore, this method is often complemented by other types of visual inspections for comprehensive evaluations. Ultimately, direct visual inspection serves as the first line of defense in identifying potential issues before they escalate into more significant problems.

Liquid Penetrant Inspection Basics

Liquid Penetrant Inspection (LPI) is a non-destructive testing method that reveals surface-breaking defects by utilizing liquid penetrants. The process involves applying a dye or fluorescent penetrant to the surface being inspected; after a specific dwell time, excess penetrant is removed before applying a developer that draws out any trapped penetrant from defects. This technique is particularly effective for detecting tiny cracks and porosities on non-porous materials such as metals and plastics.

One significant advantage of Liquid Penetrant Inspection lies in its versatility; it can be applied across various industries including aerospace, automotive, and manufacturing sectors where precision matters most. However, this method requires careful preparation and cleaning of surfaces prior to application to ensure accurate results—something that should not be overlooked! In essence, LPI complements other types of visual inspections by providing detailed insights into surface integrity.

Remote Visual Inspection Technologies

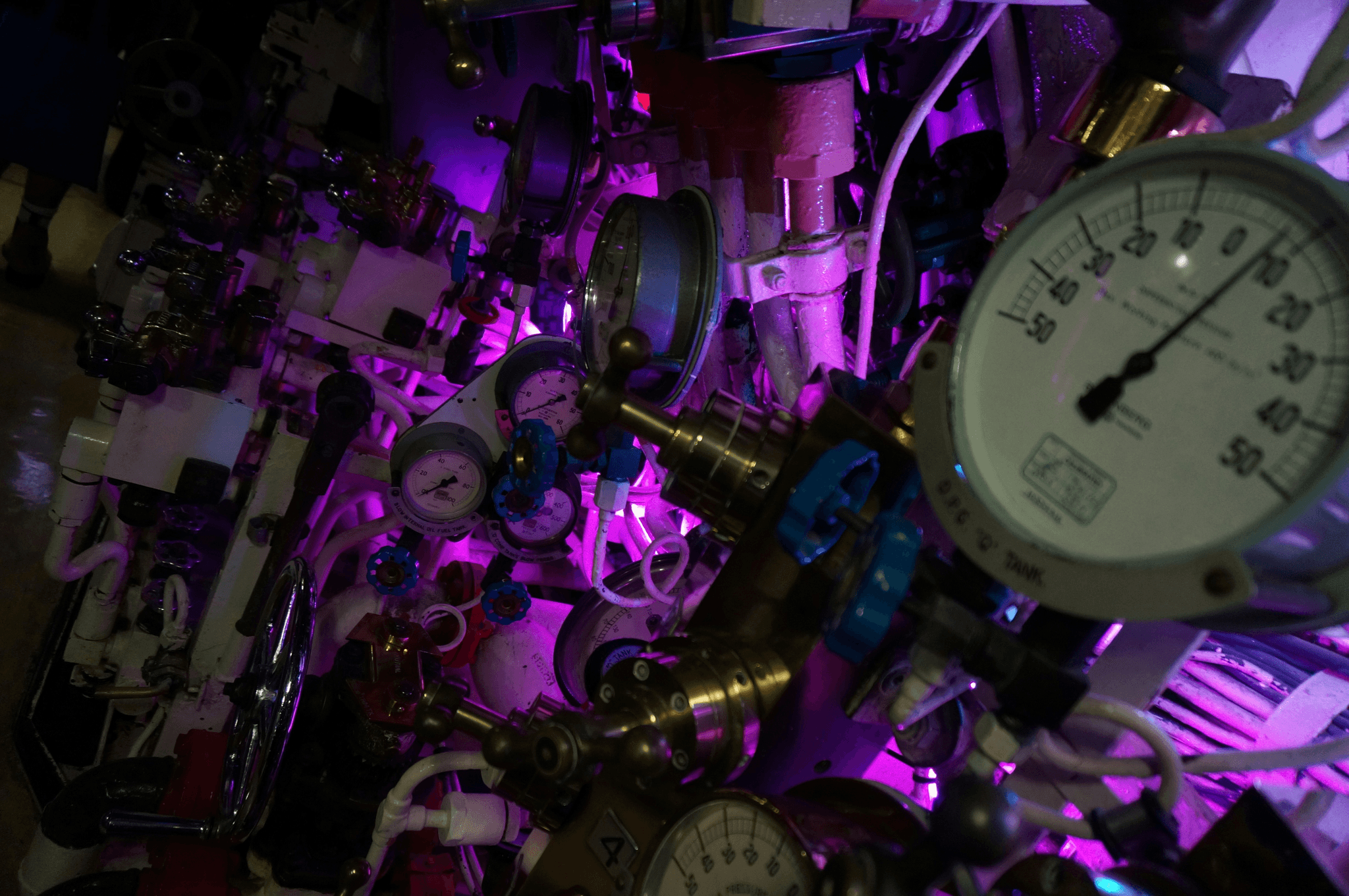

Remote Visual Inspection (RVI) technologies have revolutionized how inspections are conducted in hard-to-reach areas where traditional methods fall short. Utilizing specialized equipment like borescopes equipped with cameras allows inspectors to visualize conditions within confined spaces such as pipelines or machinery interiors without dismantling components—saving time and resources significantly! RVI combines convenience with high-quality imaging capabilities making it an essential tool across various sectors including oil & gas exploration and maintenance operations.

Moreover, remote technologies can integrate advanced features such as video recording capabilities which allow for thorough documentation during inspections—a game-changer when tracking changes over time or reporting findings to stakeholders! While RVI cannot replace all types of visual inspections due to certain limitations regarding depth perception or resolution at extreme distances, it undoubtedly enhances overall efficiency when combined with methods like Magnetic Particle Inspections or Acoustic Emission Testing for comprehensive assessments.

Advanced Techniques in Visual Inspection

In the realm of visual inspection, advanced techniques play a pivotal role in enhancing the accuracy and reliability of assessments. These methods go beyond traditional approaches, offering insights that are critical for ensuring quality and safety across various industries. Among these advanced techniques are Magnetic Particle Inspection, Microscopic Inspection, and Borescope Usage, each with unique applications that elevate the standards of visual inspection.

Magnetic Particle Inspection Overview

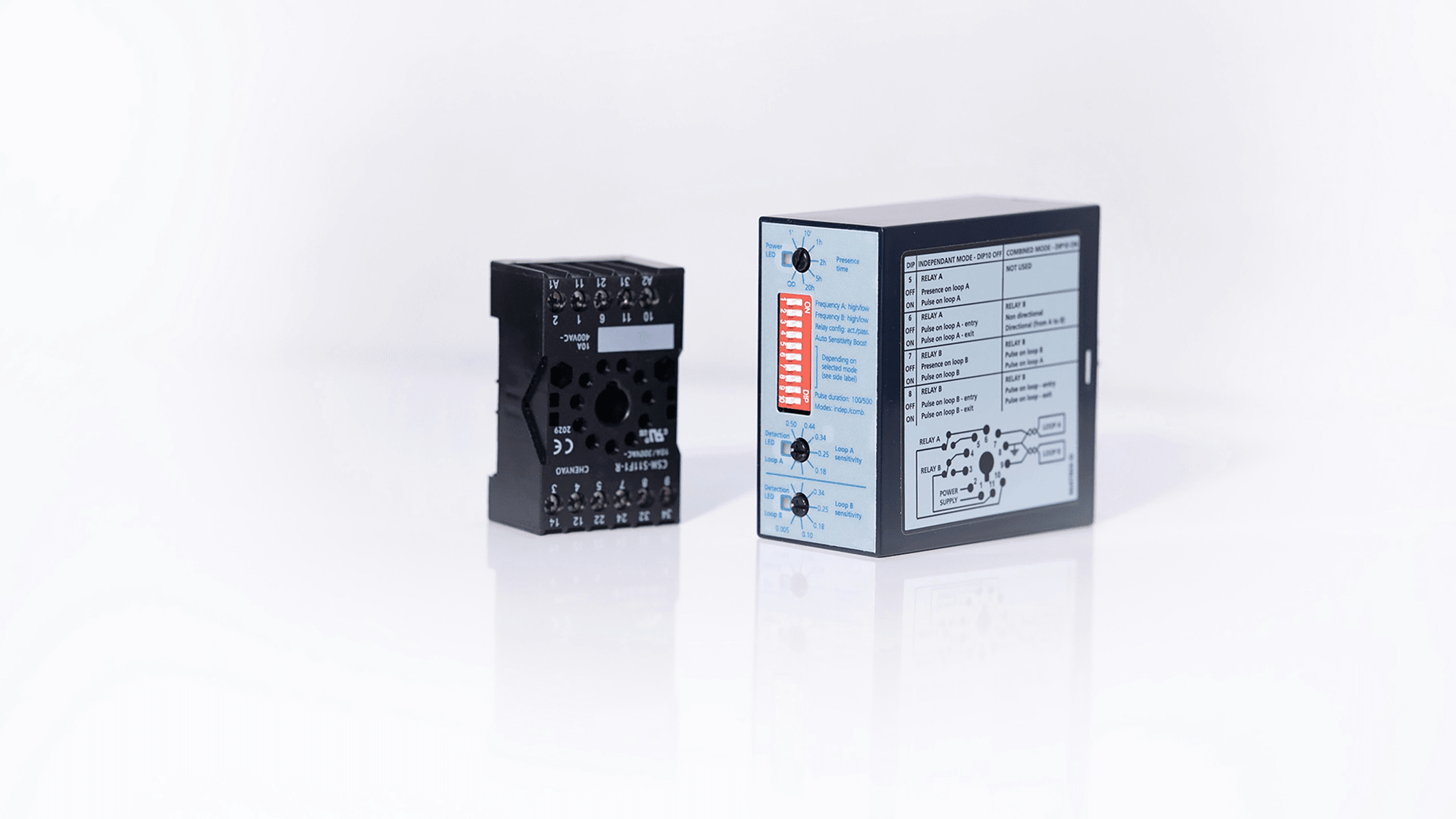

Magnetic Particle Inspection (MPI) is a non-destructive testing method primarily used to identify surface and near-surface discontinuities in ferromagnetic materials. This technique involves magnetizing the material and applying ferrous particles to its surface; any defects will disrupt the magnetic field, causing the particles to cluster at those points. MPI is particularly effective for detecting cracks or flaws invisible to direct visual inspection methods, making it an essential component of quality control processes.

The beauty of magnetic particle inspection lies in its ability to reveal defects that could lead to catastrophic failures if left unchecked. It’s widely utilized in industries such as aerospace, automotive, and manufacturing where safety is paramount. By integrating MPI into their quality assurance protocols, companies can ensure they are addressing potential issues before they escalate.

Microscopic Inspection Applications

Microscopic inspection takes visual examination to a whole new level by allowing inspectors to analyze materials at a microscopic scale. This technique is invaluable for examining surfaces or structures that require a closer look than what direct visual inspection can provide alone. With advancements in technology, microscopic inspection has become essential for fields like semiconductor manufacturing, medical device production, and materials science research.

Using high-powered microscopes enables inspectors to detect minute imperfections or anomalies that could compromise product integrity or performance. The precision offered by microscopic inspections means that even tiny flaws can be identified early on—long before they can cause significant problems down the line. As industries continue pushing towards tighter tolerances and higher standards of quality control, incorporating microscopic inspections becomes increasingly vital.

Borescope Usage in Inspections

Borescopes offer an innovative solution for remote visual inspection tasks where access is limited or impossible via traditional methods. These flexible instruments allow inspectors to view internal components without disassembly—a huge advantage when time and resources are at stake! Whether it's inspecting aircraft engines or pipeline interiors, borescopes provide real-time visuals that enhance understanding of potential issues.

The versatility of borescopes makes them applicable across several sectors including aviation maintenance, automotive diagnostics, and even building inspections where hidden structural elements need evaluation. With features such as high-definition imaging capabilities and adjustable lighting conditions, borescopes have revolutionized how professionals conduct inspections remotely—leading to improved efficiency and reduced downtime during maintenance activities. As we embrace more sophisticated technologies like acoustic emission testing alongside these tools, the landscape of types of visual inspection continues evolving rapidly.

Unique Approaches: Acoustic Emission Testing

Acoustic emission testing (AET) is a fascinating method in the realm of visual inspection that leverages sound waves to detect anomalies in materials. Unlike traditional methods such as direct visual inspection or liquid penetrant inspection, AET focuses on the sounds emitted by materials under stress. This technique allows for real-time monitoring, making it an invaluable tool in various industries where safety and integrity are paramount.

Fundamentals of Acoustic Emission Testing

At its core, acoustic emission testing involves capturing high-frequency sound waves generated by the rapid release of energy within a material. These emissions can occur during processes like deformation, crack propagation, or even corrosion—essentially any event that alters the structural integrity of an object. By using sophisticated sensors and data acquisition systems, technicians can interpret these sound waves to identify potential flaws that may not be visible through direct visual inspection or other types of visual inspection techniques.

AET is particularly effective because it provides insights into the condition of materials without requiring direct contact or invasive procedures. This non-destructive approach means that structures can remain operational while being monitored for issues—a significant advantage over more conventional methods like magnetic particle inspection or microscopic inspection, which often necessitate halting operations for thorough examination.

Benefits and Limitations of the Technique

One major benefit of acoustic emission testing is its ability to monitor large areas quickly and efficiently without extensive preparation or setup time. Unlike liquid penetrant inspection or borescope inspections, which may require significant surface preparation, AET can be deployed rapidly in various environments—making it perfect for ongoing maintenance checks in industries such as aerospace and manufacturing.

However, despite its advantages, there are limitations to consider with AET. The technique requires skilled personnel who can accurately interpret the data collected from acoustic emissions; otherwise, critical flaws might go unnoticed. Additionally, background noise can interfere with readings if not properly managed—an issue less prevalent in more straightforward methods like remote visual inspection.

Common Industries Using Acoustic Emission

Acoustic emission testing finds applications across a diverse range of industries due to its unique capabilities and efficiency in detecting faults early on. The aerospace sector frequently employs this technique during maintenance checks on aircraft components to ensure safety standards are met without disrupting operations—a crucial factor when considering the consequences of failure at high altitudes.

Similarly, industries involved in oil and gas extraction use AET extensively to monitor pipelines and storage tanks for leaks or structural weaknesses that could lead to catastrophic spills or failures. In this context, acoustic emission testing complements other types of visual inspection techniques like magnetic particle inspection and liquid penetrant inspection by providing a continuous assessment framework that enhances overall safety protocols.

In conclusion, while traditional methods such as direct visual inspections remain vital for many applications, acoustic emission testing offers a unique approach that enhances our ability to maintain quality control across various sectors efficiently.

The Visual Inspection Process

Visual inspection is a critical step in quality control, ensuring that products and structures meet safety and performance standards. This process encompasses various techniques, from direct visual inspection to advanced methods like acoustic emission testing. Understanding the steps involved, the tools required, and best practices can significantly enhance the effectiveness of any inspection.

Steps in Conducting a Visual Inspection

The first step in any visual inspection is planning, which involves identifying the type of visual inspection needed based on the specific requirements of the project. Depending on whether you choose direct visual inspection or more complex methods like liquid penetrant inspection or magnetic particle inspection, preparation will vary. Once the plan is set, inspectors should conduct a thorough examination of the area or item in question, documenting any findings meticulously.

Next comes execution, where inspectors utilize techniques such as remote visual inspection to access hard-to-reach areas without compromising safety or integrity. During this phase, it’s essential to remain vigilant for signs of defects or anomalies that could indicate underlying issues. After gathering data through various types of visual inspections—whether using a borescope for internal views or microscopic inspection for detailed analysis—inspectors compile their observations for review.

Finally, post-inspection analysis involves evaluating all findings against established criteria to determine if corrective actions are needed. This stage often includes discussions with stakeholders about potential risks identified during acoustic emission testing or other advanced methodologies employed during inspections. By following these structured steps diligently, organizations can ensure they maintain high-quality standards across their operations.

Key Tools and Equipment Used

Equipping inspectors with the right tools is paramount for conducting effective visual inspections across various industries. Essential equipment includes magnifying glasses and borescopes that allow for detailed examinations during direct visual inspections and microscopic inspections alike. Additionally, liquid penetrant kits are vital for identifying surface-breaking defects that might otherwise go unnoticed.

For more complex assessments involving magnetic particle inspection or remote visual inspections, specialized cameras and sensors become indispensable tools in an inspector's arsenal. These devices enable real-time data capture and analysis while minimizing disruption to ongoing operations. Acoustic emission testing equipment also plays a crucial role when assessing structural integrity over time by monitoring stress responses within materials.

Lastly, proper documentation tools cannot be overlooked; digital tablets equipped with software designed specifically for recording findings streamline reporting processes significantly after each type of visual inspection has been conducted thoroughly. With these key tools at hand—ranging from traditional magnifiers to cutting-edge sensors—inspectors can confidently tackle any challenge they encounter in their quest for quality assurance.

Best Practices for Effective Inspection

To maximize effectiveness during any type of visual inspection process, adherence to best practices is essential from start to finish. First off, thorough training ensures inspectors are well-versed not only in using specific tools like borescopes but also in understanding different types of visual inspections available today—including direct visual inspections and advanced methods such as liquid penetrant inspections or magnetic particle inspections.

Another best practice involves maintaining clear communication among team members throughout each phase of an inspection project; this fosters collaboration when discussing findings from acoustic emission testing results alongside traditional observations made via remote visuals or microscopic techniques used earlier on-site evaluations. Regular calibration checks on all equipment further guarantee accuracy while minimizing errors due to faulty instruments over time.

Lastly—and perhaps most importantly—documenting every detail meticulously allows organizations to track trends over time effectively; this insight ultimately leads them toward proactive maintenance strategies rather than reactive fixes later down the line! By embedding these best practices into routine procedures surrounding various types of visual inspections conducted regularly across industries worldwide today—a culture centered around quality assurance flourishes!

Role of Expert Services in Visual Inspections

The realm of visual inspections is vast, with various techniques such as direct visual inspection, magnetic particle inspection, and liquid penetrant inspection playing vital roles in quality assurance. However, the complexity of these methods often necessitates expert oversight to ensure accuracy and reliability. This is where specialized services like China Inspection Pro come into play, enhancing the overall quality of inspections across industries.

How China Inspection Pro Enhances Quality

China Inspection Pro is at the forefront of elevating visual inspection standards by employing a comprehensive approach that integrates multiple types of visual inspection methods. Their expertise spans direct visual inspection, remote visual inspection technologies, and even advanced techniques like microscopic inspection and acoustic emission testing. By leveraging state-of-the-art tools—including borescopes for intricate evaluations—they ensure that every aspect of an inspection meets stringent quality benchmarks.

Moreover, their team consists of seasoned professionals who are well-versed in various types of visual inspections such as liquid penetrant and magnetic particle inspections. This wealth of knowledge allows them to identify potential issues that might be overlooked by less experienced inspectors. Consequently, clients benefit from a higher level of precision and confidence in their findings.

Importance of Professional Oversight

Professional oversight is crucial when it comes to conducting effective inspections using diverse methods like acoustic emission testing or magnetic particle inspections. Trained experts not only understand the nuances associated with different types of visual inspections but also have the ability to interpret results accurately. This level of scrutiny ensures that any defects or anomalies are detected early on—preventing costly failures down the line.

With professional oversight from services like China Inspection Pro, companies can rest assured that their processes adhere to industry standards while maximizing safety and efficiency. The presence of skilled inspectors mitigates risks associated with faulty assessments which could lead to significant operational setbacks or even catastrophic failures in extreme cases. Thus, investing in professional services is not just beneficial; it's essential for maintaining high-quality outputs.

Transforming Findings into Actionable Insights

Once an inspection has been conducted—whether through liquid penetrant inspection or remote visual technologies—the real work begins: transforming findings into actionable insights for improvement. Expert services excel at analyzing data collected during various types of visual inspections to generate reports that are both informative and practical for decision-making processes. They can pinpoint specific areas needing attention based on detailed assessments derived from methods like microscopic or acoustic emission testing.

Furthermore, these insights enable organizations to implement targeted strategies aimed at enhancing performance while minimizing risks associated with equipment failure or non-compliance issues stemming from inadequate inspections. By providing tailored recommendations based on thorough evaluations—such as those obtained through borescope usage—China Inspection Pro empowers businesses to optimize their operations effectively.

In conclusion, expert services play an indispensable role in ensuring quality control through meticulous application and interpretation across all types of visual inspections—from direct methods to advanced techniques like magnetic particle testing and beyond.

Conclusion

In wrapping up our exploration of visual inspection methods, it's clear that the types of visual inspection available are diverse and tailored to meet specific needs across various industries. From Direct Visual Inspection, which employs the naked eye for immediate assessments, to more complex techniques like Magnetic Particle Inspection and Liquid Penetrant Inspection that reveal hidden flaws, each method plays a crucial role in quality assurance. Additionally, Remote Visual Inspection technologies and Borescope usage offer innovative solutions for inspecting hard-to-reach areas, enhancing safety and efficiency.

Recap of Visual Inspection Techniques

To recap the types of visual inspection discussed, we delved into several key methodologies. Direct Visual Inspection relies on straightforward observation but is often supplemented by advanced techniques like Microscopic Inspection for detailed analysis. Meanwhile, Acoustic Emission Testing stands out as a unique approach that captures real-time data from material stressors while also complementing traditional methods such as Liquid Penetrant Inspection.

The Significance of Quality Control

Quality control remains at the forefront of any successful operation, underscoring the importance of rigorous inspection processes. The various types of visual inspection not only help identify defects but also ensure compliance with industry standards and regulations. By integrating methods like Magnetic Particle Inspection and Remote Visual Inspection into their quality control frameworks, organizations can significantly reduce risks associated with product failures.

Future Trends in Visual Inspection

Looking ahead, the future trends in visual inspection are poised to embrace technological advancements that further enhance accuracy and efficiency. Innovations such as AI-driven analysis will likely revolutionize how we perform inspections—from Direct Visual Inspections to complex Acoustic Emission Testing—making them faster and more reliable than ever before. As industries continue to evolve, embracing these new technologies will be essential in maintaining high standards through effective quality control measures.