Introduction

In the world of electronics, testing is the unsung hero that ensures reliability and functionality. Whether you’re designing a new gadget or troubleshooting an existing one, understanding how to test electronic components is crucial for success. Without proper testing methods in place, even the most innovative designs could fall flat due to faulty components.

Understanding the Importance of Testing

Testing serves as a safety net in the intricate realm of electronics, helping engineers identify issues before they escalate into costly problems. From ensuring compliance with industry standards to enhancing product longevity, effective testing methods like Inductance Testing and Frequency Testing are vital for maintaining quality control. By rigorously assessing each component’s performance, manufacturers can significantly reduce the risk of failure in their final products.

Key Testing Methods for Components

When it comes to ensuring that electronic components perform as intended, several key testing methods come into play. Inductance Testing helps verify that inductors operate within specified parameters, while Frequency Testing assesses the response of circuits at various frequencies. Meanwhile, Functional Testing evaluates whether all components work together harmoniously—an essential step before any product hits the market.

The Role of Quality Inspections

Quality inspections act as a final checkpoint in the testing process, providing an additional layer of assurance that everything meets required specifications. Partnering with experienced inspection services can enhance your ability to test electronic components effectively by identifying potential issues early on. This proactive approach not only boosts confidence in your products but also elevates overall industry standards by promoting best practices in quality assurance.

Types of Electronic Components

Understanding the various types of electronic components is fundamental for anyone involved in testing electronic components. Each component serves a unique function and has specific characteristics that can affect performance and reliability. In this section, we will explore the basics of resistors and capacitors, delve into inductors, and take a brief look at specialty components.

Resistors and Capacitors Basics

Resistors are the unsung heroes of electronic circuits, controlling current flow and voltage levels to ensure that components operate within their safe limits. They come in various types, including fixed, variable, and specialty resistors designed for specific applications. Similarly, capacitors store electrical energy temporarily and release it when needed; they play a crucial role in filtering signals and stabilizing power supplies.

When you test electronic components like resistors and capacitors, it's essential to understand their specifications—like resistance value or capacitance—so you can ascertain whether they meet design requirements. Both resistors and capacitors are often tested using multimeters or LCR meters to verify their values against expected standards. This foundational knowledge is pivotal when conducting more advanced testing methods such as inductance testing or frequency testing.

Understanding Inductors

Inductors are passive components that store energy in a magnetic field when electrical current flows through them; they play an essential role in many applications like filters, transformers, and oscillators. The primary characteristic of an inductor is its inductance value measured in henries (H), which indicates how effectively it can store magnetic energy. Understanding inductors is key when you want to test electronic components that require precise control over current flow.

Inductance testing is crucial for ensuring that inductors perform as expected under various conditions; this involves measuring their inductance with specialized tools like LCR meters or impedance analyzers. Properly functioning inductors contribute significantly to circuit stability and efficiency; hence any discrepancies found during testing should be addressed immediately. Knowledge about these components enhances your ability to conduct thorough functional testing as well.

Specialty Components Overview

Specialty components encompass a wide range of devices designed for specific functions within electronic systems—think thermistors for temperature sensing or varistors for voltage clamping. These unique parts often have specialized properties tailored to particular applications such as signal processing or power management. Testing these specialty components requires an understanding of their unique characteristics alongside standard practices like frequency testing.

When you test electronic components that fall into the specialty category, you're not just checking basic functionality but also evaluating performance under specific environmental conditions or stress scenarios. This ensures reliability across diverse operating environments—a must-have trait for any high-quality product on the market today! Additionally, mastering functional testing techniques will help validate whether these specialized parts meet stringent design specifications.

Inductance Testing Explained

Inductance testing is a crucial aspect of ensuring that electronic components function correctly within a circuit. By measuring the inductance of coils, transformers, and other inductive components, engineers can confirm their performance and reliability. This section will guide you through the necessary tools, a step-by-step process for inductance testing, and how to analyze results effectively to ensure quality in your electronic components.

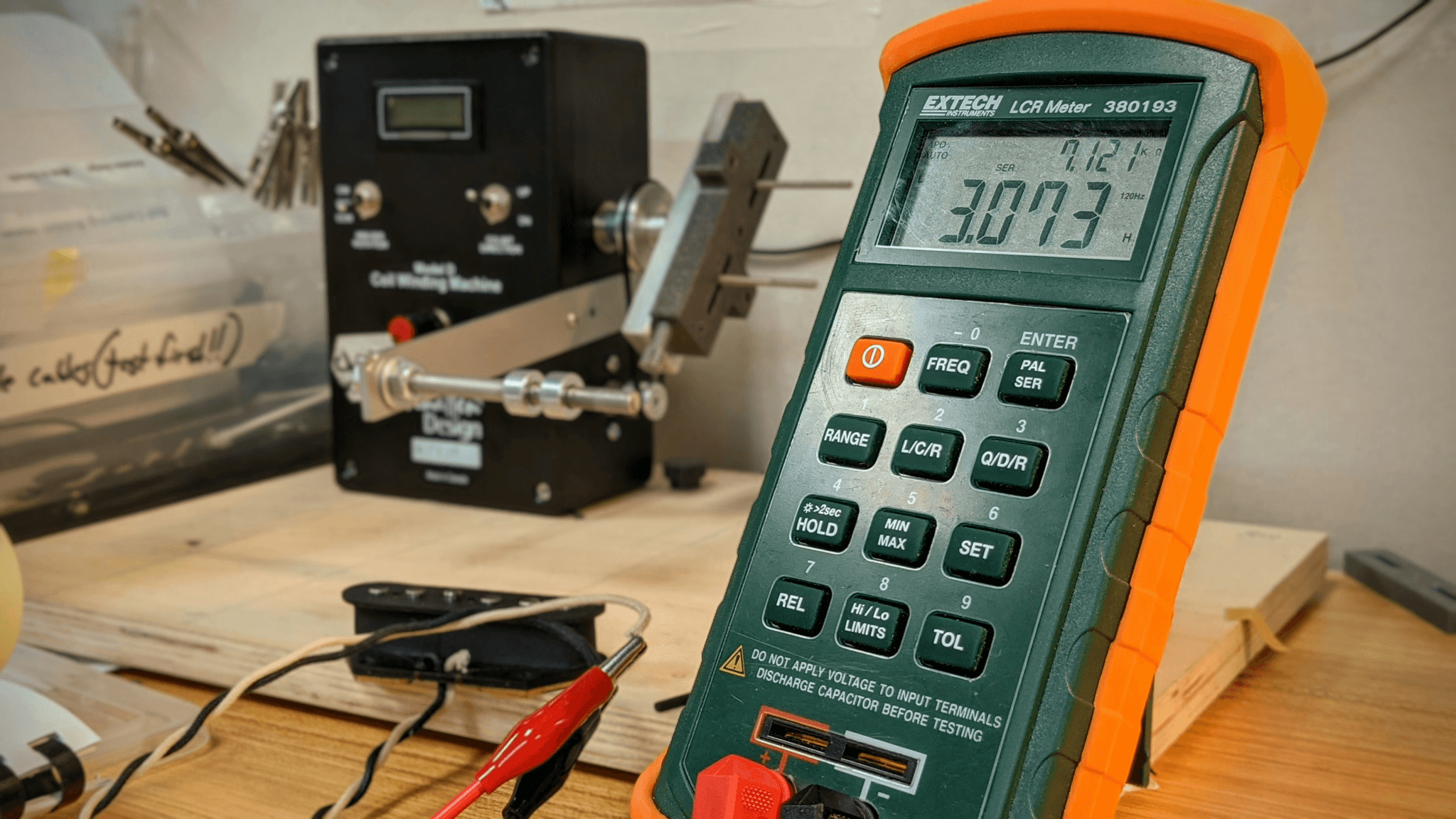

Tools Required for Inductance Testing

To embark on your inductance testing journey, you'll need some essential tools in your toolkit. The primary instrument is an LCR meter (which stands for Inductance (L), Capacitance (C), and Resistance (R)) that can measure inductance accurately across various frequencies. Additionally, having test leads with alligator clips will make it easier to connect the meter to the component being tested; you might also consider using an oscilloscope for more advanced analysis.

Don’t forget about safety equipment! While testing electronic components like inductors usually involves low risk, it’s always wise to have safety goggles handy just in case something goes awry during your tests. With these tools at your disposal, you're well-equipped to tackle any inductance measurement challenge.

Step-by-Step Inductance Testing Guide

Now that you've gathered the necessary tools, let’s dive into a step-by-step guide for conducting effective inductance testing. First off, ensure that the component you're testing is disconnected from any circuit—safety first! Next, set up your LCR meter by selecting the appropriate mode for measuring inductance; this usually involves turning a dial or pressing buttons on digital meters.

Once everything's set up, connect your test leads securely to both ends of the inductor or coil you’re measuring. Press measure on your LCR meter and watch as it displays the value of inductance; take note of this reading as it forms the basis for further analysis later on. Lastly, repeat this process multiple times if needed or try different frequencies if your LCR meter allows—this can provide valuable insights into how frequency affects performance in real-world applications.

Analyzing Results Effectively

After completing your inductance tests, it's time to analyze those results effectively so you can draw meaningful conclusions about each component's performance. Start by comparing measured values against manufacturer specifications; if there's significant deviation from expected values, further investigation may be necessary.

Consider factors such as temperature and frequency during testing since they can influence readings significantly—this is where understanding Frequency Testing comes into play! If discrepancies arise consistently across multiple tests or under varying conditions, it could indicate potential issues with quality or design that need addressing before incorporating these components into larger systems.

In conclusion, mastering inductance testing not only helps you test electronic components efficiently but also ensures that they meet industry standards and function reliably within their intended applications.

Frequency Testing Fundamentals

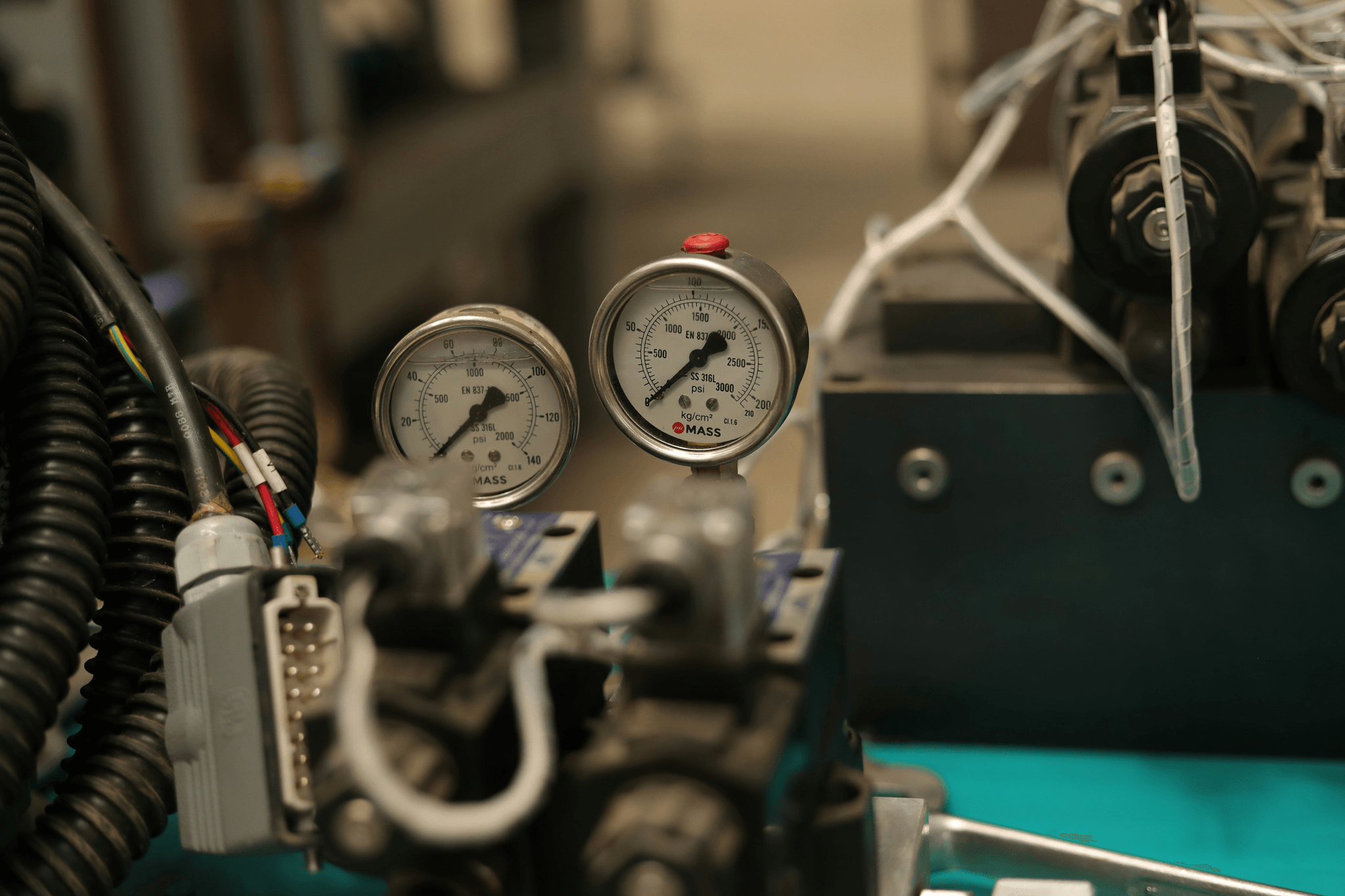

Frequency testing is a critical aspect of ensuring that electronic components function optimally within their specified parameters. By measuring the frequency response of various components, engineers can assess performance and identify potential issues before they escalate. Understanding the fundamentals of frequency testing is essential for anyone looking to test electronic components effectively.

Frequency Testers and Their Uses

Frequency testers come in various shapes and sizes, each designed for specific applications within the realm of electronics. From simple handheld devices to sophisticated benchtop analyzers, these tools allow technicians to measure frequency output and analyze signal integrity. Whether you're working with oscillators or amplifiers, having the right frequency tester can make all the difference in your ability to test electronic components accurately.

One common type of frequency tester is the function generator, which produces various waveforms at different frequencies for testing purposes. Another essential tool is the spectrum analyzer, which helps visualize frequency responses across a range of signals. By understanding these devices' capabilities and limitations, you can select the right equipment for your specific needs in frequency testing.

Conducting Accurate Frequency Testing

To conduct accurate frequency testing, it’s crucial first to ensure that your equipment is properly calibrated. Calibration ensures that your measurements will be reliable and consistent throughout your testing process. Once you've verified calibration, connect your device under test (DUT) to the tester using appropriate cables and connectors to minimize signal loss or interference during measurement.

Next, set up your tester according to manufacturer specifications while considering any environmental factors that could affect results—such as temperature fluctuations or electromagnetic interference from nearby devices. During testing, it's important to take multiple readings at different frequencies to get a comprehensive understanding of how well your component performs across its operational range. Recording these results meticulously will aid in analyzing performance later on.

Finally, after conducting tests on multiple frequencies, analyze the data collected carefully for any anomalies or unexpected behaviors in signal output or quality. This analysis will help you identify areas where improvements are necessary or if further functional testing might be required on specific components.

Common Pitfalls in Frequency Testing

While frequency testing may seem straightforward at first glance, several common pitfalls can lead to inaccurate results if not addressed properly. One frequent issue is improper grounding; inadequate grounding can introduce noise into measurements that skew results significantly when trying to test electronic components accurately. Ensure all connections are secure and grounded correctly before starting any tests.

Another common mistake involves overlooking environmental factors such as temperature variations or electromagnetic interference from other devices nearby during tests—these factors can distort readings considerably! Be mindful of where you're conducting tests; ideally, use a controlled environment free from external influences whenever possible.

Lastly, failing to document findings thoroughly can lead you down a rabbit hole when troubleshooting issues later on; without accurate records of what was measured and observed during each test session—especially with Inductance Testing—you may find yourself retracing steps unnecessarily! Keep detailed notes on settings used during tests so you have a clear reference point should problems arise down the line.

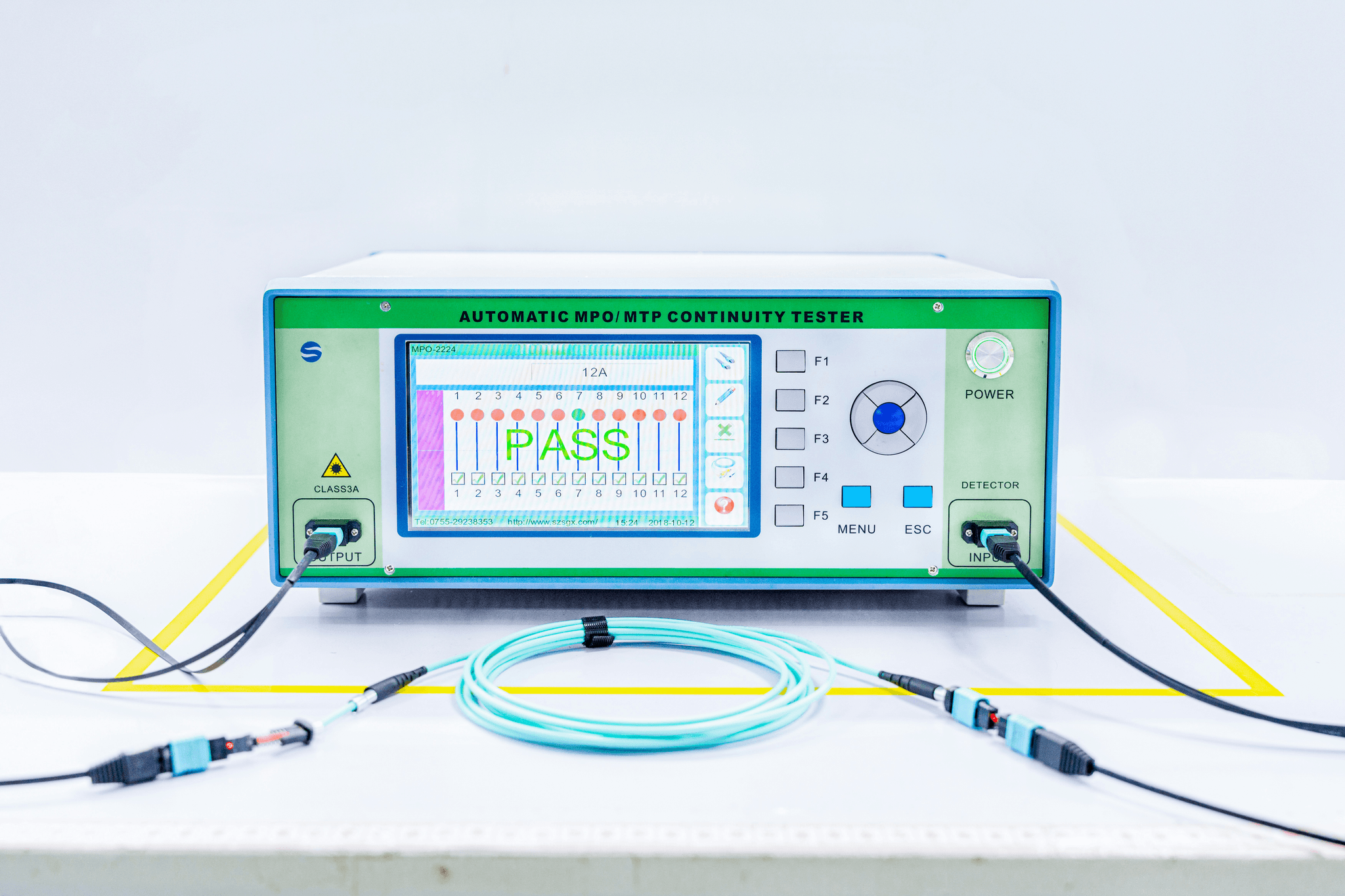

Functional Testing in Action

Functional testing is a crucial phase in the process of ensuring that electronic components perform as intended under real-world conditions. This type of testing verifies that each component functions correctly within its specified parameters, allowing engineers to identify any issues before products reach consumers. By focusing on the overall operation rather than individual parts, functional testing provides a comprehensive view of how well electronic components work together.

What is Functional Testing?

Functional testing is essentially about validating the functionality of electronic components against their design specifications. It goes beyond simple measurements to assess whether each component behaves properly when integrated into a larger system or circuit. By conducting functional tests, engineers can ensure that all parts are working harmoniously and that the final product meets quality and performance standards.

Best Practices for Functional Testing

To effectively test electronic components through functional testing, it’s essential to establish clear criteria and procedures beforehand. Start by defining expected outcomes for each component based on its specifications; this will serve as your benchmark during testing. Additionally, using automated tools can streamline the process, reduce human error, and enhance accuracy—especially when dealing with complex systems involving inductance testing or frequency testing.

Another best practice is to conduct tests in stages; this allows for easier troubleshooting if something goes awry. Implementing thorough documentation throughout the process not only helps track results but also facilitates communication among team members regarding any adjustments or issues encountered during functional tests.

Case Studies on Successful Functional Testing

Numerous companies have successfully implemented functional testing strategies to enhance their product quality and reliability. For instance, a leading electronics manufacturer faced challenges with their new line of sensors due to inconsistent performance across various units. By employing rigorous functional testing protocols, they were able to pinpoint design flaws early in production and make necessary adjustments before mass production commenced—ultimately saving time and resources while improving customer satisfaction.

In another case study, an automotive company utilized functional testing extensively to ensure their vehicle's electronic systems operated seamlessly under various conditions—ranging from extreme temperatures to high-frequency environments. The results were impressive: not only did they reduce warranty claims significantly but also boosted consumer trust in their brand by demonstrating reliability through effective functional tests.

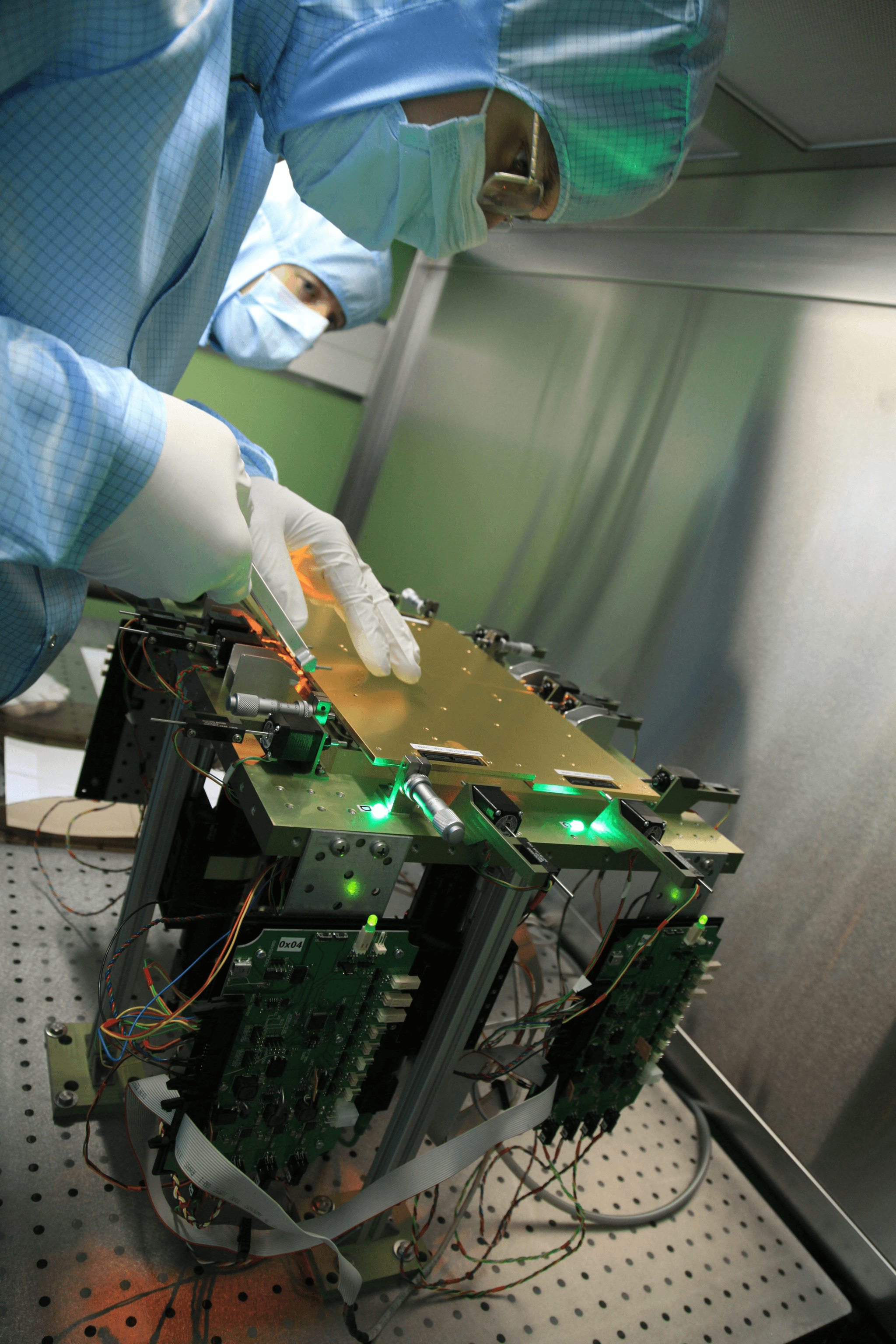

Quality Inspection Services

In the realm of electronic components, quality inspection services serve as the backbone of reliability and performance. By ensuring that components meet industry standards, these services help manufacturers and consumers alike feel confident in their products. Partnering with a reputable inspection service can greatly enhance the overall testing process for electronic components.

Benefits of Partnering with China Inspection Pro

When it comes to testing electronic components, partnering with China Inspection Pro brings numerous advantages to the table. Their expertise in various testing methods, including inductance testing, frequency testing, and functional testing, ensures that every component is thoroughly evaluated for quality and performance. Moreover, their extensive network in manufacturing allows them to provide timely inspections that can save you both time and money.

Additionally, working with China Inspection Pro means access to advanced technology and skilled professionals who are well-versed in the latest industry standards. This partnership not only streamlines your quality control processes but also enhances your overall product reliability. Ultimately, this collaboration empowers businesses to make informed decisions about their electronic component sourcing.

How Quality Inspections Enhance Testing

Quality inspections play a pivotal role in enhancing the effectiveness of various testing methods for electronic components. By integrating thorough inspections into inductance testing or frequency testing protocols, companies can identify potential issues before they escalate into costly problems. This proactive approach ensures that functional testing yields accurate results by verifying that all components meet specified criteria.

Moreover, quality inspections help establish a benchmark for performance by providing detailed reports on each component’s condition prior to assembly or deployment. This not only boosts confidence in the final product but also aids engineers during functional testing phases by highlighting areas needing attention or improvement. As a result, businesses can optimize their resources while maintaining high-quality standards across all operations.

Making Informed Decisions Through Inspection Findings

The findings from quality inspections offer critical insights that enable companies to make informed decisions regarding their electronic components. By analyzing detailed reports from inductance tests or frequency tests conducted by professionals like those at China Inspection Pro, businesses gain clarity on which components are reliable and which may require further scrutiny or replacement altogether. This data-driven approach is essential for minimizing risks associated with faulty parts.

Furthermore, understanding inspection results helps identify trends over time—such as recurring issues with specific suppliers or types of components—which can guide future purchasing decisions and strategies for improvement in functional testing practices. With clear visibility into component performance through rigorous quality checks, manufacturers are better equipped to elevate their standards and enhance customer satisfaction across the board.

In conclusion, investing in comprehensive quality inspection services not only fortifies your ability to test electronic components effectively but also fosters long-term success by ensuring consistent product excellence.

Conclusion

In the world of electronics, mastering the art of testing electronic components is not just a skill; it's an essential practice that can make or break a project. As we've explored, various testing methods such as Inductance Testing, Frequency Testing, and Functional Testing are crucial in ensuring that each component meets its specifications and performs reliably. By honing these skills and applying them diligently, engineers can significantly improve product quality and reliability.

Mastering Electronic Component Testing

To truly master the testing of electronic components, one must delve deep into the specifics of each method available. Inductance Testing allows engineers to assess how well inductors function within circuits, while Frequency Testing helps ensure that oscillators and related components operate at their intended frequencies. Meanwhile, Functional Testing serves as a comprehensive check-up for entire systems or assemblies, verifying that all parts work harmoniously together.

The journey to becoming proficient in these testing methods involves not only understanding theoretical concepts but also gaining hands-on experience with various tools and techniques. Practicing these tests regularly will build confidence and expertise in identifying potential issues before they escalate into costly problems. Ultimately, mastering electronic component testing equips professionals with the ability to deliver high-quality products that stand the test of time.

Ensuring Quality Through Expert Inspections

Quality inspections play a pivotal role in complementing rigorous testing methods like Inductance Testing and Frequency Testing by providing an additional layer of assurance. Partnering with reliable inspection services can help identify defects or inconsistencies that may have gone unnoticed during initial tests. This collaboration enhances overall quality control processes and ensures that products meet industry standards before reaching consumers.

Moreover, expert inspections offer valuable insights into manufacturing practices and component sourcing strategies. By identifying areas for improvement through thorough evaluations, companies can streamline their operations while boosting product reliability—making it easier to trust the results from functional tests performed on their components. In this way, integrating expert inspections into your workflow is not just beneficial; it’s essential for maintaining high standards.

Elevating Standards in Component Testing

As technology continues to evolve at breakneck speed, elevating standards in component testing becomes increasingly vital for staying competitive in the market. Embracing advanced techniques such as automated Inductance Testing systems or sophisticated Frequency Testing equipment allows companies to enhance accuracy while reducing human error during assessments. These innovations pave the way for more reliable outcomes across all types of electronic components.

Furthermore, fostering a culture of continuous improvement encourages teams to adopt best practices from successful case studies involving Functional Testing methodologies across various industries. By learning from others’ experiences—and perhaps even sharing your own—you contribute to a collective knowledge base that raises industry benchmarks over time. Ultimately, by prioritizing comprehensive testing strategies alongside quality inspections, organizations can ensure they are always at the forefront of excellence when it comes to electronic component performance.