Introduction

Quality assurance inspection is a critical component in the lifecycle of product development, ensuring that every item meets established standards and specifications. The process of QA quality assurance not only focuses on identifying defects but also emphasizes continuous improvement, which is essential for maintaining competitive advantage in today's market. By prioritizing quality at every stage, businesses can enhance their reputation and foster customer loyalty.

Understanding Quality Assurance Inspection

At its core, quality assurance inspection refers to the systematic monitoring and evaluation of various aspects of a project or product to ensure compliance with predetermined standards. This process involves a combination of planned activities designed to prevent defects and ensure that products are safe for consumer use. Emphasizing QA assurance means recognizing the importance of thorough inspections, which can significantly reduce risks associated with poor-quality products.

Importance of Quality in Product Development

In an era where consumers are increasingly discerning about the products they purchase, quality has emerged as a non-negotiable factor in product development. Ensuring high-quality standards not only enhances user satisfaction but also minimizes costly recalls and potential legal issues stemming from faulty products. Therefore, integrating robust QA quality practices into development processes is essential for building trust with customers and establishing a strong market presence.

Overview of QA Quality Assurance Processes

The QA quality assurance processes encompass a series of structured steps that organizations follow to uphold their commitment to excellence throughout production cycles. These processes typically include planning, execution, monitoring, and continuous improvement efforts aimed at refining product quality over time. By implementing effective QA assurance strategies, companies can better navigate challenges while consistently delivering top-notch products that meet or exceed consumer expectations.

What is Quality Assurance Inspection?

Quality assurance inspection is a systematic process designed to evaluate and ensure that products meet specified standards of quality. This involves assessing both the processes and outputs in manufacturing to identify any defects or areas for improvement. The ultimate goal of QA quality assurance is not just to find faults, but to foster a culture of continuous improvement within organizations.

Definition and Goals of QA Quality Assurance

At its core, QA quality assurance encompasses all activities aimed at ensuring that products are developed with the highest standards in mind. The primary goals include preventing defects, enhancing product reliability, and ensuring compliance with industry regulations. By implementing effective quality assurance inspection practices, businesses can significantly reduce risks associated with product failures while boosting overall customer satisfaction.

Roles and Responsibilities in Quality Assurance

In the realm of quality assurance, various roles contribute to the effectiveness of QA assurance processes. Quality inspectors are tasked with conducting inspections, documenting findings, and communicating results to relevant stakeholders. Additionally, management plays a crucial role in fostering an environment that prioritizes quality through training programs and resource allocation for ongoing QA quality initiatives.

Common Inspection Procedures Explained

Quality assurance inspections typically involve several well-defined procedures aimed at evaluating product integrity throughout the production cycle. Common inspection methods include visual checks for defects, measurements against specifications, and functional testing under real-world conditions. Each step is critical; thorough documentation ensures that findings are recorded accurately for future reference and continuous improvement efforts within the organization.

The Importance of Quality Assurance in Manufacturing

In the competitive landscape of manufacturing, quality assurance inspection plays a pivotal role in ensuring that products meet the highest standards. A robust QA quality assurance framework not only enhances product quality but also safeguards consumer safety. By prioritizing quality assurance, manufacturers can establish a reputation for reliability and excellence.

Enhancing Product Quality and Safety

At the heart of any successful manufacturing operation is the commitment to enhancing product quality and safety through rigorous QA assurance processes. Quality assurance inspection identifies defects early in the production cycle, preventing faulty products from reaching consumers. This proactive approach not only mitigates risks associated with product recalls but also reinforces a culture of safety within organizations.

Moreover, implementing effective QA quality measures ensures compliance with industry regulations and standards, thereby protecting both consumers and manufacturers from potential legal repercussions. When companies invest in comprehensive quality assurance protocols, they are not just checking boxes; they are actively working towards creating safer products that inspire confidence among users. In this way, enhanced product quality becomes synonymous with brand integrity.

Reducing Costs Through Effective QA Assurance

One might think that investing in QA quality checks is an added expense, but the reality is quite the opposite—effective QA assurance can lead to significant cost reductions over time. By catching defects early through meticulous quality assurance inspection processes, manufacturers can avoid costly recalls and repairs down the line. This translates into lower operational costs while maximizing profitability.

Furthermore, when businesses streamline their production processes with robust quality controls in place, waste is minimized and efficiency is maximized. The financial benefits extend beyond immediate savings; companies that prioritize QA often find themselves enjoying long-term gains as customer loyalty builds around their reputation for delivering high-quality products consistently. Ultimately, reducing costs through effective QA isn't just smart business; it's essential for sustainable growth.

Building Customer Trust and Satisfaction

Quality assurance inspection directly impacts customer trust and satisfaction—two invaluable assets for any manufacturer looking to thrive in a crowded market space. When consumers know that a brand adheres to stringent QA standards, they are more likely to choose its products over competitors'. Trust fosters loyalty; satisfied customers become repeat buyers who advocate for your brand.

Moreover, positive experiences driven by high-quality products lead to word-of-mouth referrals that can significantly boost sales without additional marketing costs. In today’s digital age where reviews can make or break a business overnight, investing in qa quality measures becomes imperative for maintaining an excellent public image. Thus, building customer trust through unwavering commitment to quality assurance isn't merely an option—it's a necessity.

Quality Assurance Inspection Procedures: Step by Step

Quality assurance inspection is a systematic approach that ensures products meet specified standards and requirements. This section outlines the essential procedures involved in quality assurance inspections, from initial planning to final reporting. By following these steps, organizations can enhance their QA quality assurance processes and ultimately deliver superior products.

Initial Assessment and Planning

The first step in any effective quality assurance inspection is conducting an initial assessment and planning phase. This involves identifying the specific quality standards that need to be met, as well as determining the scope of the inspection process. A thorough understanding of product specifications, regulatory requirements, and customer expectations is crucial for establishing a solid foundation for QA quality assurance efforts.

During this phase, teams should also allocate resources effectively to ensure that all necessary tools and personnel are available for the inspection process. Setting clear objectives will help focus efforts on key areas that require attention during the inspection. Additionally, developing a timeline for each stage of the QA assurance process can streamline operations and improve overall efficiency.

Inspection Execution Techniques

Once planning is complete, it’s time to dive into the heart of quality assurance inspections: execution techniques. Various methods can be employed depending on the nature of the product and its complexity; visual inspections, functional tests, or even automated testing systems might be utilized to assess compliance with established standards. Each technique plays a vital role in ensuring thorough evaluations are conducted during QA quality assessments.

Incorporating advanced technologies such as drones or robotics can significantly enhance inspection accuracy while reducing human error. These modern tools allow inspectors to gather data more efficiently than traditional methods alone could provide. However, it's essential to remember that no matter how sophisticated your techniques may be, they must always align with your established quality criteria for effective results.

Documentation and Reporting of Findings

The final step in any successful quality assurance inspection is documentation and reporting of findings—an often underestimated but critical component of QA processes. Proper documentation not only provides evidence of compliance but also serves as a valuable reference for future inspections or audits in your QA quality framework. Clear records help identify trends over time and facilitate continuous improvement initiatives within organizations.

When compiling reports, it’s crucial to present findings in an organized manner that highlights key observations while offering actionable recommendations based on those insights. Utilizing visuals such as charts or graphs can make complex data more digestible for stakeholders who may not have technical expertise in QA assurance matters. Ultimately, effective communication through robust documentation fosters transparency within teams and builds trust with clients regarding product integrity.

Tools and Techniques for Quality Assurance

In the ever-evolving landscape of product development, effective tools and techniques are essential for maintaining high standards in quality assurance inspection. These tools not only streamline processes but also enhance the overall quality assurance experience, ensuring that products meet or exceed customer expectations. Let's delve into some of the most impactful advancements in quality assurance.

Advanced Inspection Technologies

Advanced inspection technologies have revolutionized the field of quality assurance, making it easier to detect defects and ensure compliance with industry standards. Innovations such as automated visual inspection systems use artificial intelligence to analyze products at lightning speed, identifying flaws that human inspectors might overlook. By integrating these technologies into QA quality assurance processes, companies can achieve higher accuracy rates while reducing inspection time and costs.

Moreover, non-destructive testing methods like ultrasonic and X-ray inspections allow for thorough assessments without compromising product integrity. These advanced techniques not only enhance the reliability of inspections but also provide a comprehensive view of product quality throughout its lifecycle. As organizations adopt these cutting-edge solutions, they can significantly improve their QA assurance capabilities and maintain a competitive edge in the market.

Statistical Process Control in QA Quality Assurance

Statistical Process Control (SPC) is a cornerstone technique within QA quality assurance that leverages data analysis to monitor and control manufacturing processes. By employing statistical methods to track process variations, businesses can identify trends that may indicate potential issues before they escalate into costly defects or failures. This proactive approach not only enhances product quality but also fosters a culture of continuous improvement within organizations.

Implementing SPC involves collecting data from various stages of production and analyzing it using control charts and other statistical tools. This allows teams to visualize performance metrics over time, making it easier to pinpoint areas needing attention or adjustment. Ultimately, effective use of SPC in qa assurance leads to reduced variability in production processes, resulting in more consistent product outcomes that satisfy customer demands.

Leveraging Software for Quality Management

In today's digital age, leveraging software solutions for quality management has become indispensable for effective QA quality assurance practices. Robust software platforms streamline documentation processes, automate reporting tasks, and provide real-time insights into product performance metrics—all crucial elements of an efficient quality assurance inspection strategy. These tools facilitate collaboration among teams while ensuring compliance with regulatory requirements.

Additionally, many modern software solutions incorporate features like risk assessment modules and corrective action tracking systems that help organizations stay ahead of potential issues before they arise. With integrated dashboards offering a comprehensive overview of key performance indicators (KPIs), businesses can make informed decisions based on accurate data rather than guesswork alone. Embracing technology through software applications ultimately empowers companies to elevate their qa assurance efforts while driving continuous improvement across all facets of operations.

Case Studies: Successful Quality Assurance Implementation

In the world of manufacturing, quality assurance inspection plays a pivotal role in ensuring that products meet stringent standards. This section delves into real-world case studies that highlight successful implementations of QA quality assurance processes, showcasing both triumphs and lessons learned from failures.

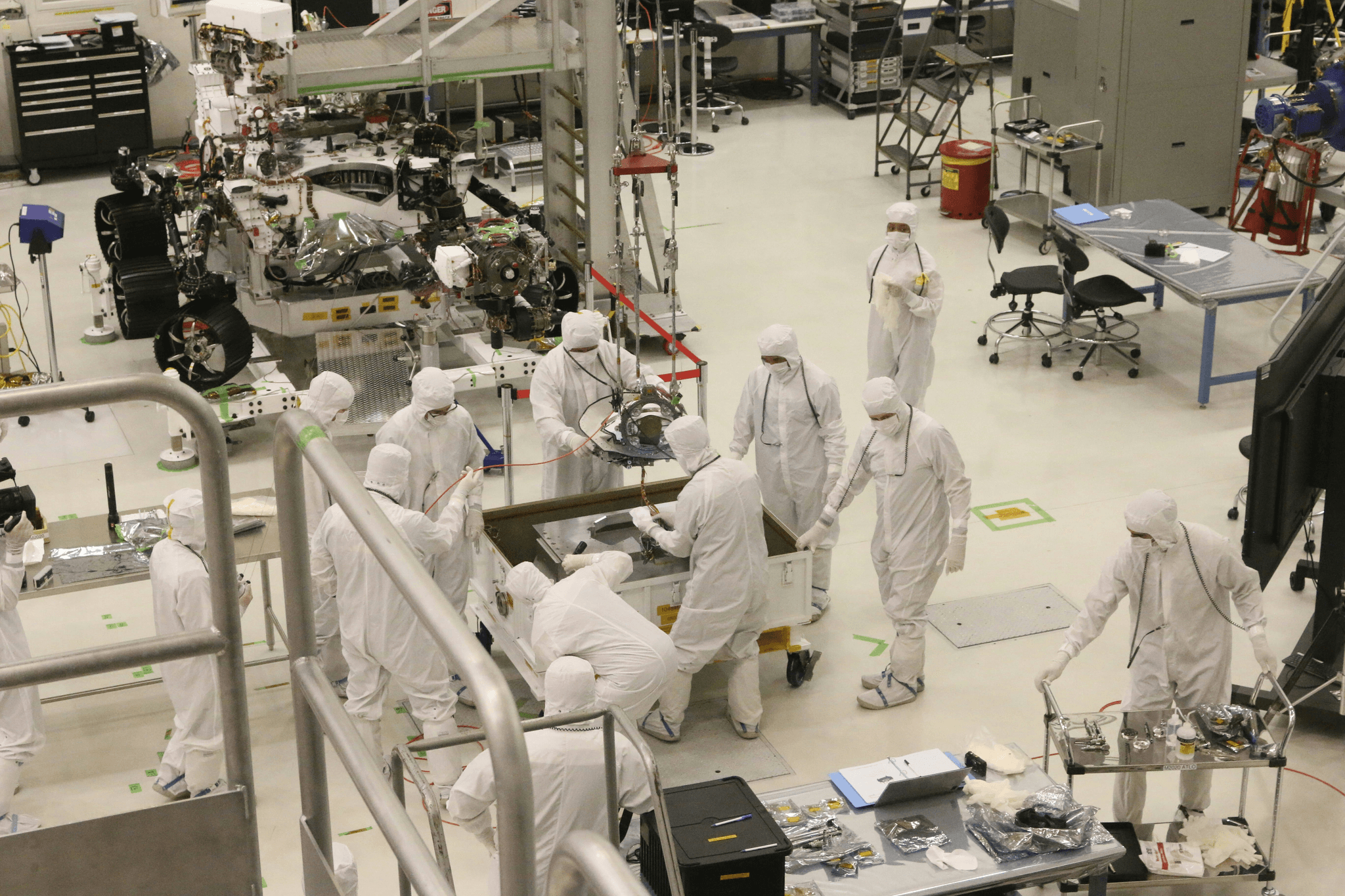

How China Inspection Pro Drives Product Excellence

China Inspection Pro has emerged as a leader in the realm of quality assurance inspection, providing comprehensive services that elevate product standards. Their approach combines rigorous inspection protocols with advanced technologies to ensure every product is thoroughly vetted before reaching consumers. By focusing on QA quality assurance, they not only enhance product excellence but also cultivate trust among manufacturers and clients alike.

One standout feature of China Inspection Pro's methodology is their emphasis on pre-production inspections, which help identify potential issues early in the manufacturing process. This proactive stance minimizes risks associated with defects and reinforces the importance of QA assurance in maintaining high-quality outputs. The result? A notable reduction in costly recalls and an impressive track record for satisfied clients.

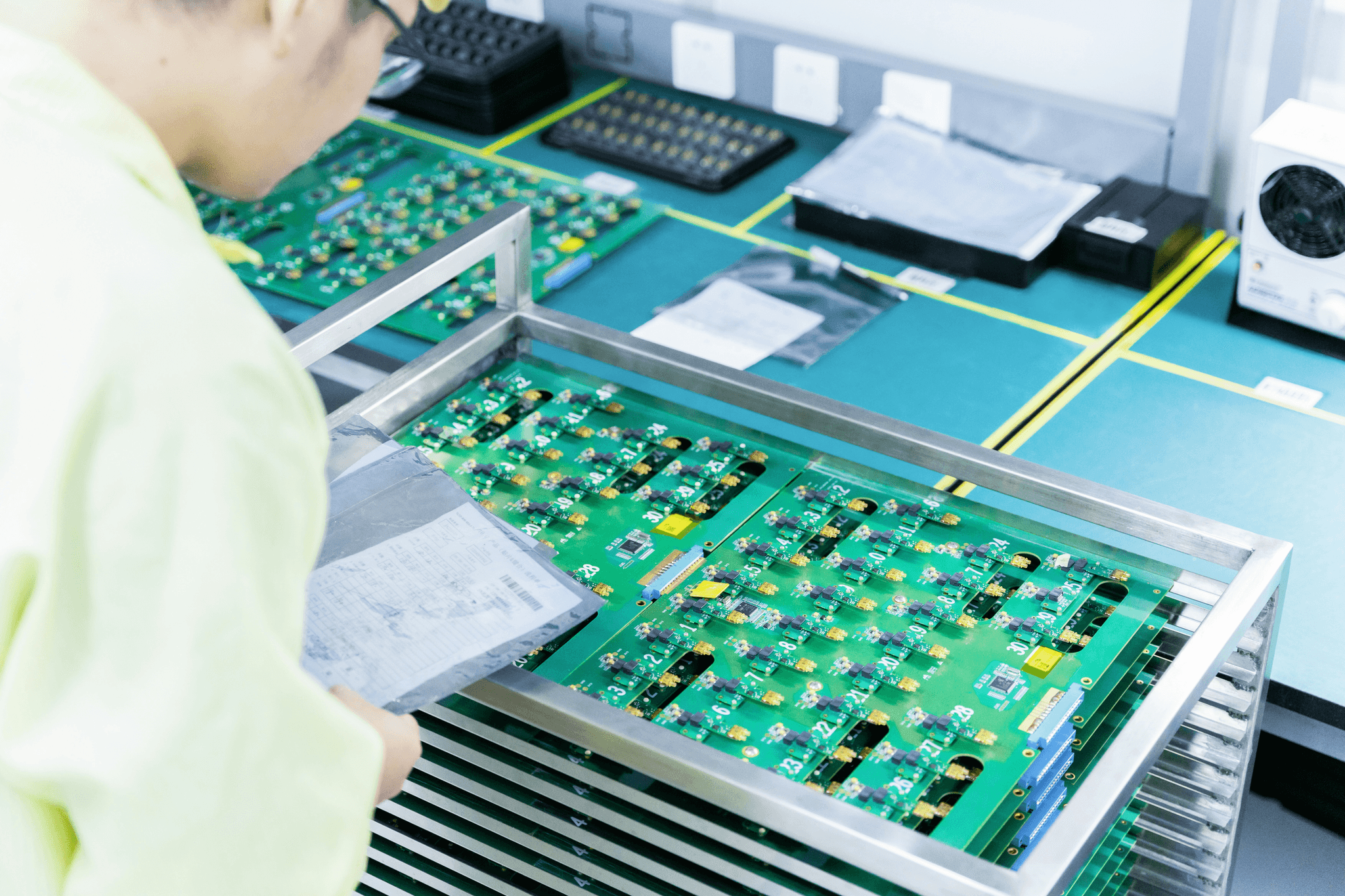

Real-World Applications and Outcomes

The application of effective QA quality assurance practices can be seen across various industries, from electronics to textiles. For instance, a major electronics manufacturer implemented a robust quality assurance inspection system that included regular audits and real-time monitoring during production cycles. This initiative led to a remarkable 30% decrease in defect rates within just six months, demonstrating how strategic QA measures can significantly enhance product reliability.

Moreover, companies that prioritize quality through consistent inspection procedures often experience increased customer loyalty and market share. By aligning their operations with stringent QA standards, businesses not only improve their bottom line but also foster long-term relationships with consumers who value high-quality products over lower-priced alternatives.

Lessons Learned from Quality Assurance Failures

While success stories abound, there are also valuable lessons to be gleaned from instances where quality assurance efforts fell short. One notorious case involved a leading automotive manufacturer whose negligence in implementing comprehensive QA processes led to widespread safety recalls due to faulty components. This failure underscored the critical need for thorough quality assurance inspection at every stage of production—an oversight that cost the company millions and tarnished its reputation.

Another lesson can be drawn from a food processing company that faced severe backlash after failing to conduct adequate inspections on its supply chain partners' products. The resulting contamination incident highlighted how lapses in QA quality could have dire consequences not just for businesses but also for public health and safety.

By examining these failures alongside successful implementations like those at China Inspection Pro, companies can better appreciate the necessity of robust QA practices as an integral part of their operational strategy.

Conclusion

In wrapping up our exploration of quality assurance inspection, it’s clear that a robust QA quality assurance framework is vital for any organization aiming for excellence. Quality assurance isn’t just about checking boxes; it’s about fostering a culture of continuous improvement and reliability in product development. The insights gleaned from this discussion highlight the multifaceted nature of QA and its essential role in enhancing product quality and customer satisfaction.

Key Takeaways on Quality Assurance Inspection

One of the most significant takeaways from our examination is that quality assurance inspection serves as a proactive measure to identify potential issues before they escalate. By implementing effective QA quality assurance practices, companies can not only enhance product safety but also streamline their operations, ultimately saving costs in the long run. Additionally, understanding the roles and responsibilities within QA teams ensures that everyone is aligned toward a common goal: delivering high-quality products that meet or exceed customer expectations.

Strategies for Continuous Improvement in QA

Continuous improvement should be at the heart of any successful qa assurance program. Regular training sessions for QA personnel can keep them updated on the latest inspection techniques and technologies, fostering an environment where learning is valued. Furthermore, incorporating feedback loops into the quality assurance process allows organizations to adapt their strategies based on real-world outcomes, ensuring that their qa quality initiatives remain relevant and effective over time.

Future Trends in Quality Assurance Inspection Procedures

Looking ahead, we can anticipate several exciting trends in quality assurance inspection procedures that will shape the industry landscape. The integration of artificial intelligence and machine learning into qa quality processes promises to revolutionize how inspections are conducted by providing predictive analytics and real-time data insights. Moreover, as sustainability becomes increasingly important, we may see more emphasis on eco-friendly materials and processes within quality assurance frameworks to meet both regulatory standards and consumer demand.