Introduction

In the world of manufacturing and production, understanding fat testing meaning is crucial for ensuring product quality and compliance. Fat testing, a key aspect of quality control, involves assessing the fat content in various products to meet industry standards. This process not only guarantees that products are safe for consumption but also enhances overall quality assurance.

Understanding Fat Testing Meaning

Fat testing meaning refers to the analytical methods used to determine the fat content in food and other products. This testing is vital for manufacturers as it directly impacts nutritional labeling, product formulation, and compliance with health regulations. By grasping fat testing meaning, businesses can better navigate the complexities of maintaining high-quality standards while satisfying consumer demands.

The Importance of Quality Control

Quality control is more than just a checkbox on a production list; it's a comprehensive approach that ensures products meet specific standards before they reach consumers. Implementing effective quality control methods helps prevent defects and ensures that each item produced adheres to safety regulations and customer expectations. A robust quality control framework not only protects consumers but also enhances brand reputation and trust.

Overview of Inspection Methods

Inspection methods play a pivotal role in maintaining product integrity throughout the production process. Various techniques are employed, from equipment inspection to quality assurance inspections that occur at different stages of production—before, during, and after manufacturing. Understanding which type of inspection occurs before production versus after can significantly influence the effectiveness of quality control and pre-shipment inspection processes.

What is Fat Testing?

Fat testing is a crucial aspect of quality control in various industries, particularly in food production and manufacturing. It involves measuring the fat content in products to ensure they meet specified standards and regulations. Understanding the fat testing meaning helps stakeholders maintain product integrity and consumer safety.

Defining Fat Testing Meaning

At its core, fat testing refers to the analytical process used to determine the amount of fat present in a given sample. This measurement can be pivotal for products like dairy, meat, and processed foods where fat content directly affects quality and health implications. The fat testing meaning extends beyond mere numbers; it encapsulates the assurance that products adhere to nutritional guidelines and consumer expectations.

Relevance in Quality Control

In the realm of quality control, fat testing serves as a fundamental quality control method that ensures compliance with industry standards. By accurately assessing fat levels, companies can prevent potential issues related to flavor, texture, and shelf life of their products. Moreover, consistent fat testing strengthens brand reputation by demonstrating a commitment to high-quality production practices.

Common Practices in Fat Testing

Common practices in fat testing often involve various techniques such as solvent extraction or nuclear magnetic resonance (NMR). These methods are typically implemented during equipment inspection processes to guarantee accurate results before products reach consumers or retailers. Additionally, incorporating regular quality inspection and testing throughout production phases allows for timely adjustments based on findings, ultimately leading to enhanced product quality.

Various Quality Control Methods

In the realm of manufacturing, quality control methods are indispensable for ensuring that products meet established standards. Among these methods, equipment inspection plays a critical role in identifying potential issues before they escalate into costly problems. By implementing effective quality inspection and testing protocols, companies can maintain product integrity and uphold their reputation.

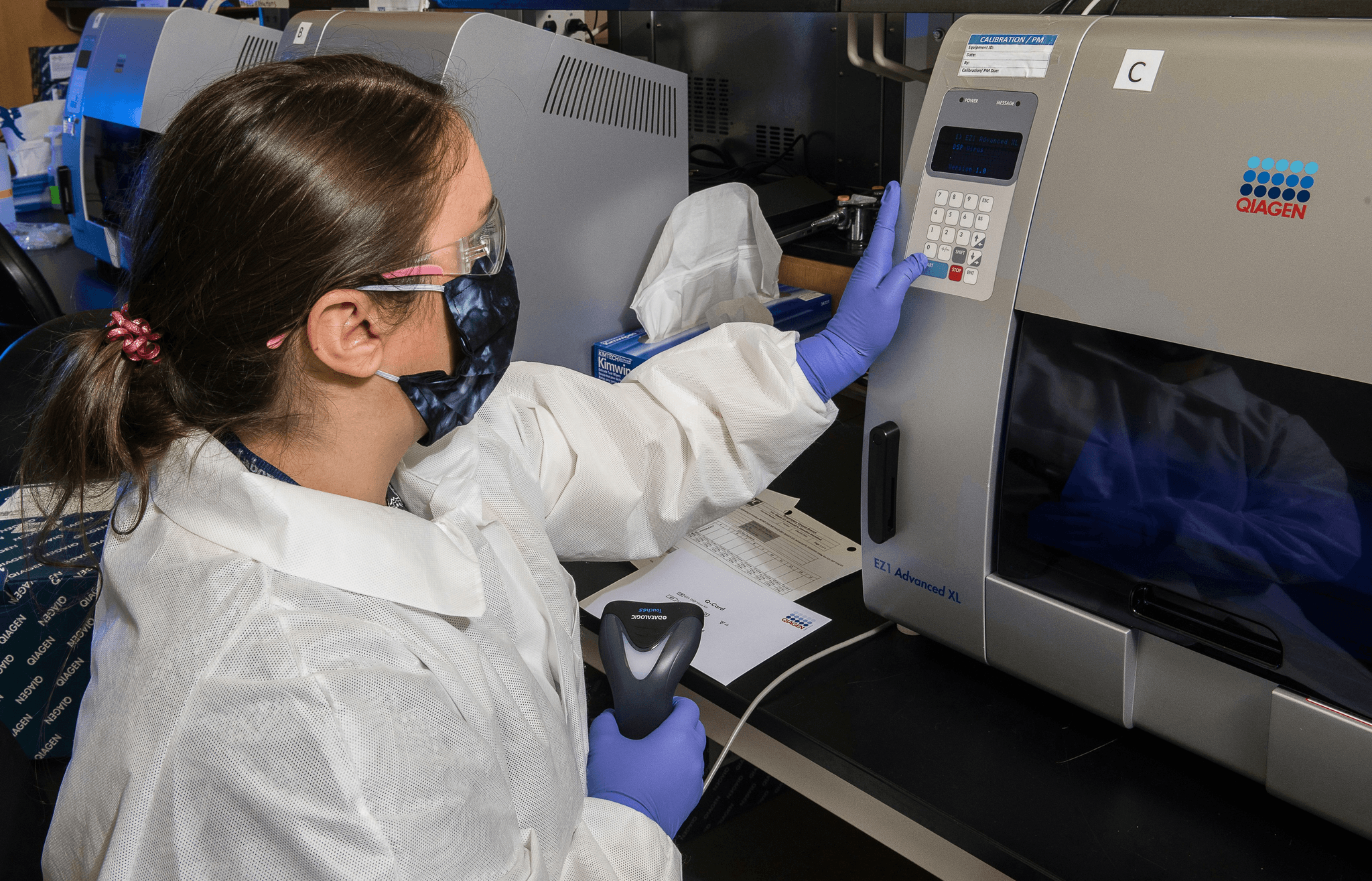

Overview of Equipment Inspection

Equipment inspection is a systematic process that evaluates machinery and tools used in production to ensure they function correctly and safely. This form of quality control method is essential not only for compliance with industry standards but also for enhancing operational efficiency. Regular equipment inspections can prevent breakdowns, thereby minimizing downtime and maintaining consistent production flow.

Importance of Quality Control and Pre Shipment Inspection

Quality control and pre shipment inspection are vital components in the supply chain that safeguard against defects reaching customers. By conducting thorough inspections before shipping products, manufacturers can address any discrepancies related to fat testing meaning or other specifications early on. This proactive approach not only enhances customer satisfaction but also reduces the risk of returns or complaints.

The Role of Quality Assurance Inspection

Quality assurance inspection serves as a backbone for maintaining high standards throughout the production process. It involves a comprehensive review of both processes and outputs to ensure adherence to established guidelines, including those related to fat testing meaning. By integrating quality assurance into every phase—before, during, and after production—companies can better manage risks associated with product quality.

Fat Testing in Production Phases

In the realm of quality control, understanding the phases of fat testing is crucial for ensuring product integrity and compliance. Each stage of production involves specific inspections that help maintain high standards and meet regulatory requirements. From pre-production checks to post-production evaluations, knowing what type of inspection occurs before and after production can make all the difference.

Which Type of Inspection Occurs Before Production?

Before production kicks off, several quality control methods come into play to ensure everything is set for success. One key step is the initial equipment inspection, where machinery and tools are evaluated for functionality and safety. This proactive approach helps identify potential issues early on, allowing manufacturers to address them before they affect the production line.

Moreover, quality assurance inspections during this phase focus on verifying that raw materials meet specified standards and regulations. By assessing material quality upfront, businesses can prevent costly errors down the road while also emphasizing the importance of fat testing meaning in establishing a solid foundation for product development. Ultimately, these pre-production inspections set a standard that guides subsequent processes.

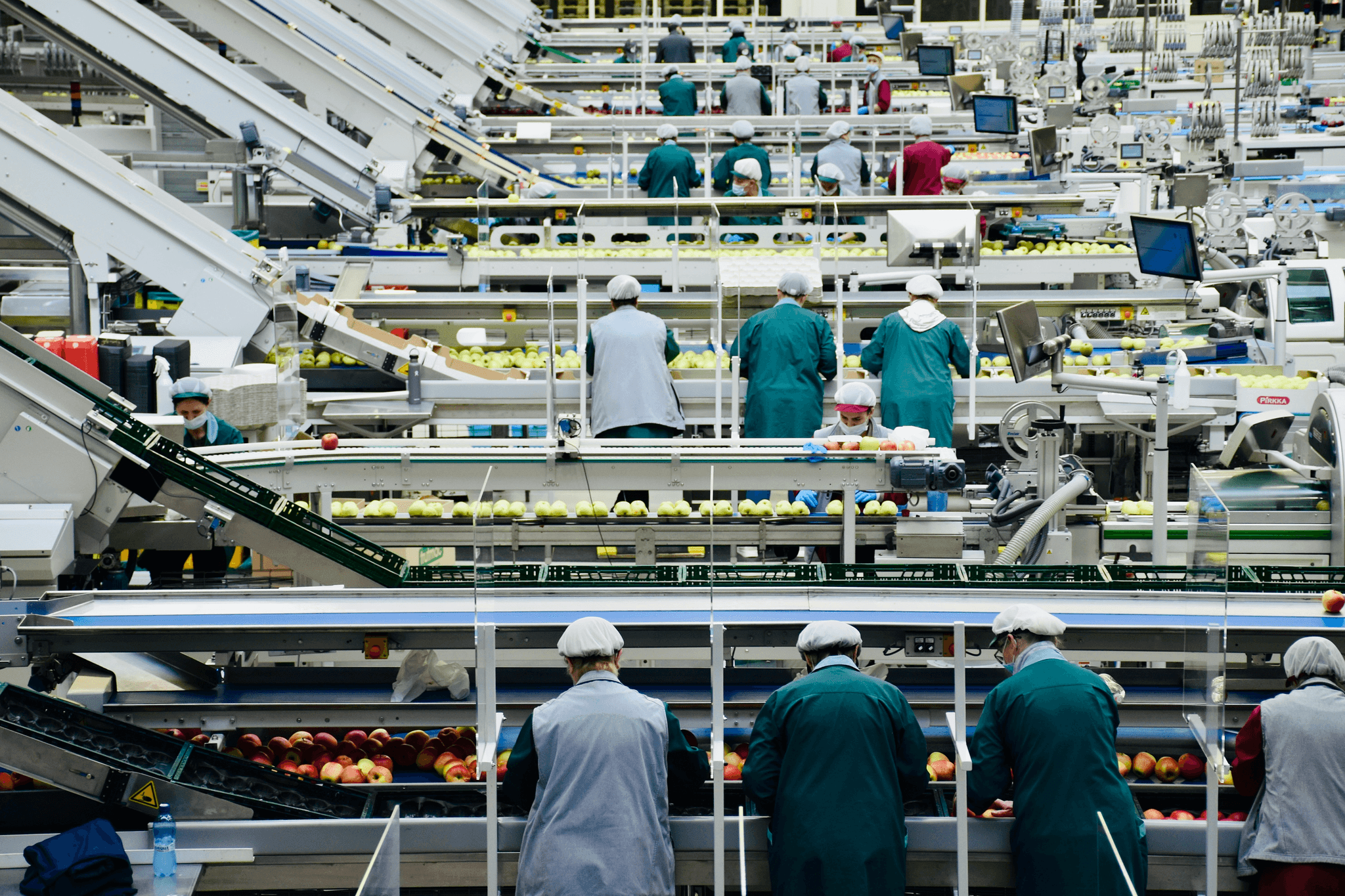

Inspection Processes During Production

As production unfolds, continuous monitoring through various inspection processes becomes essential to uphold quality standards. Quality control and pre-shipment inspection are vital during this phase to ensure that products conform to specifications as they are being manufactured. Regular checks help catch any deviations from established parameters early on, minimizing waste and safeguarding against subpar output.

Additionally, implementing systematic fat testing during production allows manufacturers to assess fat content accurately at different intervals throughout the process. This not only ensures compliance with health regulations but also enhances product consistency—a critical factor in consumer satisfaction. By maintaining rigorous quality inspection and testing protocols during production, companies can effectively manage risks associated with non-compliance or inferior products.

What Happens After Production?

Once production wraps up, it’s time for thorough evaluation through post-production inspections—this is where quality assurance truly shines! These inspections typically involve final checks on finished goods before they leave the facility or head towards distribution channels. Conducting comprehensive assessments at this stage helps confirm that products align with both safety standards and customer expectations.

Moreover, it's essential to conduct social compliance audits at this point; what is a social compliance audit? It’s an assessment focused on ensuring ethical practices within manufacturing processes—covering labor rights and environmental responsibility among other factors. By integrating these audits into post-production evaluations alongside fat testing meaning assessments, companies can bolster their reputation while ensuring adherence to both industry norms and consumer demands.

In conclusion, understanding each phase of fat testing throughout production—from pre-inspection preparations through ongoing monitoring during manufacturing to final evaluations—is crucial for maintaining high-quality standards in today's competitive market landscape.

Social Compliance Audits Explained

In the realm of quality control, social compliance audits play a pivotal role in ensuring that manufacturing practices align with ethical standards and legal requirements. These audits assess various aspects of a company's operations, including labor practices, workplace safety, and environmental impact. By integrating social compliance into the framework of quality inspection and testing, businesses can bolster their reputation while ensuring adherence to quality control methods.

What is a Social Compliance Audit?

A social compliance audit is an evaluation process aimed at determining whether a company meets established standards regarding its labor practices and overall ethical conduct. This type of audit addresses issues such as fair wages, working hours, child labor policies, and health and safety regulations. By conducting these audits regularly, organizations can ensure that they not only comply with local laws but also uphold international standards in their supply chains.

The Connection Between Audits and Quality Assurance

The relationship between social compliance audits and quality assurance is integral to maintaining high standards in production processes. Quality assurance inspection encompasses various aspects of manufacturing that directly affect product integrity, including equipment inspection and pre-shipment inspections. By incorporating social compliance audits into the quality assurance framework, companies can enhance their overall quality control method while fostering trust among consumers who are increasingly concerned about ethical sourcing.

Impact of Social Compliance on Quality Control

Social compliance has a significant impact on overall quality control by ensuring that products are manufactured under safe and fair conditions. When companies prioritize ethical practices through regular audits, they often see improvements not only in employee morale but also in product consistency and reliability—key components of effective fat testing meaning in production environments. Additionally, maintaining high standards for social responsibility can lead to better market positioning as consumers gravitate toward brands committed to both quality assurance inspection and ethical practices.

The Role of China Inspection Pro

In the ever-evolving landscape of quality control, China Inspection Pro stands out as a pivotal player in enhancing quality inspection and testing. By leveraging advanced methodologies and skilled professionals, they ensure that each product meets stringent standards before reaching the market. This commitment to excellence not only safeguards manufacturers but also protects consumers by ensuring that products are safe and effective.

How China Inspection Pro Enhances Quality Inspection and Testing

China Inspection Pro enhances quality inspection and testing through a comprehensive approach that includes fat testing meaning as a cornerstone of their services. By utilizing state-of-the-art equipment inspection techniques, they can accurately assess the quality of materials used in production. Moreover, their focus on quality control and pre-shipment inspection ensures that potential issues are identified early, thus preventing costly recalls or customer dissatisfaction later on.

Their team conducts thorough evaluations at every stage of production, ensuring that all aspects comply with industry standards. This proactive stance minimizes risks associated with subpar materials or processes, reinforcing the importance of quality assurance inspection in maintaining product integrity. Ultimately, this meticulous attention to detail fosters trust between manufacturers and consumers alike.

Benefits of Professional Equipment Inspection

The benefits of professional equipment inspection cannot be overstated when discussing effective quality control methods. With experts like China Inspection Pro at the helm, businesses can rest assured that their equipment operates efficiently and safely during production phases. This level of scrutiny is crucial; after all, what type of inspection occurs before production can significantly influence overall product outcomes.

Investing in professional inspections leads to enhanced operational efficiency by identifying potential faults before they escalate into significant issues. Furthermore, it ensures compliance with relevant regulations—an essential component for any manufacturer aiming for longevity in today’s competitive market. The result is not just improved safety but also increased profitability through reduced downtime and fewer errors.

Transforming Findings into Actionable Insights

Transforming findings from inspections into actionable insights is where the real magic happens in quality control practices. After conducting thorough evaluations—including fat testing meaning assessments—China Inspection Pro provides detailed reports outlining areas for improvement along with strategic recommendations tailored to each client’s needs. These insights empower businesses to make informed decisions about their production processes while addressing any deficiencies uncovered during inspections.

Moreover, understanding what is a social compliance audit becomes vital here; these audits often highlight ethical considerations alongside technical ones in manufacturing processes. By integrating these findings into their operational strategies, companies can enhance both product quality and corporate responsibility simultaneously. In essence, this transformative process not only elevates product standards but also strengthens brand reputation in an increasingly conscientious marketplace.

Conclusion

In summary, understanding fat testing meaning is crucial for maintaining high standards in production and quality assurance. It serves as a critical quality control method that ensures products meet specified requirements before reaching consumers. Through effective equipment inspection and quality inspection and testing, businesses can minimize risks associated with subpar products.

Key Takeaways on Fat Testing Meaning

Fat testing meaning revolves around the measurement of fat content in various products, which is essential for both consumer safety and satisfaction. This process not only aids in compliance with industry standards but also enhances the overall quality control method employed by manufacturers. By prioritizing fat testing, companies can ensure their offerings are both safe and appealing to consumers.

The Importance of Quality Assurance in Production

Quality assurance inspection plays a pivotal role in production by ensuring that every stage meets predetermined standards. It helps identify potential issues early on, thus preventing costly mistakes later in the process. Furthermore, effective quality control and pre-shipment inspection safeguard against delivering defective products to market, thereby protecting brand reputation.

Next Steps for Effective Quality Control

To enhance effective quality control, businesses should adopt a systematic approach that includes regular equipment inspection and rigorous fat testing protocols. Understanding which type of inspection occurs before and after production is vital; pre-production inspections can catch issues early while post-production checks confirm product integrity before shipment. Additionally, integrating social compliance audits into the quality assurance framework can provide insights into ethical practices that further elevate product credibility.