Introduction

In today's fast-paced market, ensuring the quality of products is paramount for businesses aiming to maintain a competitive edge. Quality assurance inspections serve as a crucial checkpoint in the production process, providing an opportunity to evaluate and verify that products meet predefined standards. However, understanding the intricacies of quality assurance and the potential pitfalls associated with relying solely on suppliers is essential for safeguarding your brand's reputation.

Understanding Quality Assurance Inspections

Quality assurance inspections are systematic evaluations aimed at ensuring products conform to specific requirements and standards. These inspections can help identify defects early in the production process, ultimately leading to improved outcomes and reduced costs associated with poor quality. By implementing effective QA quality measures, businesses can not only enhance their product offerings but also build trust with their customers.

The Risks of Relying on Suppliers

While suppliers play a vital role in the supply chain, relying exclusively on them for quality assurance poses significant risks. Suppliers may prioritize production speed over rigorous quality checks, leading to inconsistencies that can affect end-user satisfaction. Furthermore, conflicts of interest may arise when suppliers conduct their own quality assurance assessments, resulting in a lack of objectivity that could compromise product integrity.

The Value of Third-Party Inspections

Engaging third-party inspectors provides an unbiased perspective on product quality that is often lacking when relying solely on suppliers' assurances. These independent evaluations contribute significantly to maintaining high standards of QA quality assurance by ensuring compliance with industry benchmarks and regulations. Ultimately, leveraging third-party inspections enhances accountability within the supply chain while fostering transparency—key components for building long-lasting customer relationships.

The Supplier's Perspective

When it comes to quality assurance, suppliers often find themselves in a precarious position. Their dual role as both manufacturers and quality controllers can lead to significant conflicts of interest in quality assurance inspections. This dynamic creates an environment where the integrity of the QA process may be compromised, ultimately affecting the overall quality assurance and product reliability.

Conflicts of Interest in Quality Assurance

Suppliers are primarily driven by production targets, which can overshadow their commitment to maintaining high-quality standards during quality assurance inspections. When a supplier’s profits hinge on volume rather than quality, there’s an inherent conflict that can compromise the objectivity required for effective QA quality assessments. This susceptibility to bias raises questions about whether the results from internal inspections truly reflect the product's integrity or merely serve as a façade for meeting contractual obligations.

The Supplier's Focus on Production

The relentless focus on production efficiency often sidelines the critical aspects of quality assurance and compliance with industry standards. Suppliers may prioritize speed over precision, leading them to overlook essential QA processes that ensure product excellence. Consequently, this lack of attention can result in inconsistencies in product output and diminish overall confidence in their ability to deliver reliable goods.

Lack of Objectivity in Quality Inspections

When suppliers conduct their own quality inspections, there is an undeniable risk of subjectivity creeping into the evaluation process. Without independent oversight, these internal assessments are prone to bias and may not accurately reflect true product performance or adherence to established standards for qa quality assurance. As a result, reliance on these self-assessments can lead businesses down a path fraught with potential pitfalls—where expectations clash with reality due to unchecked flaws slipping through unnoticed.

Inadequate Training and Standards

Supplier Variability in Quality Processes

Supplier variability is a common hurdle in achieving effective quality assurance inspection. Each supplier may have different interpretations of what constitutes acceptable quality standards, resulting in a patchwork of practices that lack coherence. This inconsistency makes it difficult for companies to ensure that every product meets the same level of qa quality assurance, ultimately jeopardizing customer satisfaction and brand integrity.

The Risk of Inconsistent QA Quality

Inconsistent QA quality poses a serious threat to any organization relying on suppliers for their products. When one batch passes inspection while another fails due to inadequate training or differing standards, it creates confusion and distrust among stakeholders. Companies must recognize that inconsistent qa assurance not only impacts their bottom line but also damages relationships with customers who expect reliability.

Challenges in Maintaining Industry Standards

Maintaining industry standards is no small feat when faced with inadequate training among suppliers. Many organizations struggle to enforce consistent practices across diverse teams and locations, leading to gaps in quality assurance and overall performance. The challenge lies not just in setting high-quality benchmarks but also ensuring that all parties involved understand and adhere to these crucial guidelines—because after all, when it comes to quality and assurance, consistency is key.

Elevated Costs of Poor Quality

When it comes to quality assurance, overlooking the potential costs associated with poor quality can be a costly mistake. Many businesses fail to recognize that the ramifications of inadequate Quality Assurance Inspections extend far beyond immediate financial losses. These hidden costs can accumulate and wreak havoc on a company's bottom line, making it essential to understand the broader implications of QA quality failures.

Hidden Costs of Quality Assurance Failures

The hidden costs tied to quality assurance failures are often insidious and difficult to quantify. For instance, when a product fails to meet quality standards, it can lead to increased warranty claims and returns, which drain resources and time that could be better spent elsewhere. Additionally, companies may face additional expenses related to rework or recalls, not to mention the potential legal fees if defective products lead to customer harm.

Moreover, these hidden costs can also manifest in less obvious ways; for example, employee morale may decline if workers are consistently dealing with issues stemming from poor QA quality assurance practices. This decline in morale can lead to reduced productivity and higher turnover rates—further complicating an already challenging situation. Ultimately, investing in robust Quality Assurance Inspection processes is crucial for mitigating these hidden costs before they spiral out of control.

Impact on Brand Reputation and Sales

Brand reputation is one of the most valuable assets a company possesses; however, it can be severely damaged by poor-quality products resulting from inadequate QA practices. When customers have negative experiences due to defective items or subpar service, they are likely to share their dissatisfaction through reviews or word-of-mouth—a phenomenon that spreads like wildfire in today’s digital age. The impact on sales can be devastating as potential customers shy away from brands known for inconsistent quality assurance.

Additionally, restoring a tarnished brand reputation requires significant investment in marketing campaigns and public relations efforts—resources that could have been allocated more effectively elsewhere had proper QA measures been implemented initially. Companies must recognize that maintaining high-quality standards not only fosters customer loyalty but also enhances brand image over time. In essence, investing in effective QA quality processes pays dividends long after the initial inspection has taken place.

The Long-Term Cost of Product Returns

Product returns are perhaps one of the most direct indicators of poor-quality assurance practices within a supply chain management framework. Each return represents not just lost sales revenue but also logistical headaches—think shipping fees back and forth—and administrative burdens associated with processing those returns efficiently. Over time, these cumulative costs can significantly erode profit margins while simultaneously damaging customer trust.

Furthermore, frequent returns due to substandard products create an unsettling cycle: customers become wary of making future purchases based on prior experiences with faulty goods or services linked back directly to inadequate QA quality assurance protocols. This wariness leads directly into diminished sales figures as consumers choose competitors who prioritize rigorous Quality Assurance Inspections over convenience or lower prices alone. Ultimately, understanding the long-term implications of product returns emphasizes why investing in comprehensive QA processes is not just wise but essential for sustainable business growth.

The Importance of Transparency

In today’s competitive marketplace, transparency in quality assurance is more than just a buzzword; it’s a necessity. When companies prioritize open communication and independent quality assurance inspections, they foster an environment of trust that benefits everyone involved. This trust is crucial for maintaining strong relationships with suppliers and customers alike, ultimately enhancing the overall quality of products.

Building Trust Through Independent Inspections

Independent inspections serve as a reliable bridge between manufacturers and consumers, ensuring that the products meet established standards of quality assurance. By engaging third-party services for quality assurance inspections, businesses can demonstrate their commitment to transparency and accountability in their processes. This not only builds confidence among stakeholders but also reassures customers that the products they receive have undergone rigorous quality checks.

How Transparency Affects Customer Relationships

Transparency in qa quality assurance can significantly impact customer relationships by fostering loyalty and satisfaction. Customers today are increasingly informed and demand openness regarding product sourcing and manufacturing processes; they want to know how their purchases align with their values. When companies provide clear information about their quality assurance practices, including third-party inspections, they empower customers to make informed choices.

By showcasing a commitment to transparency through regular updates on inspection results or certifications received from independent agencies, businesses can enhance customer trust further. This proactive approach not only strengthens customer relationships but also encourages repeat business as consumers feel confident in the brand's integrity and commitment to delivering high-quality products consistently. In essence, transparency becomes a key differentiator in building lasting connections with clients.

Enhancing Accountability with Third-Party QA

Utilizing third-party qa assurance services adds an essential layer of accountability that internal teams may overlook due to bias or conflicts of interest. Third-party inspectors bring objectivity into the evaluation process, ensuring that every aspect of production meets the required standards without any favoritism toward suppliers or internal pressures influencing outcomes. This impartiality reinforces the idea that all parties must uphold stringent quality measures.

Additionally, having an external entity conduct regular quality assurance inspections means there’s always someone watching over the process—keeping everyone accountable for delivering exceptional products consistently. This heightened level of scrutiny helps mitigate risks associated with poor-quality outputs while simultaneously elevating overall industry standards through shared best practices identified during these assessments. In turn, this fosters an environment where excellence is expected rather than merely hoped for.

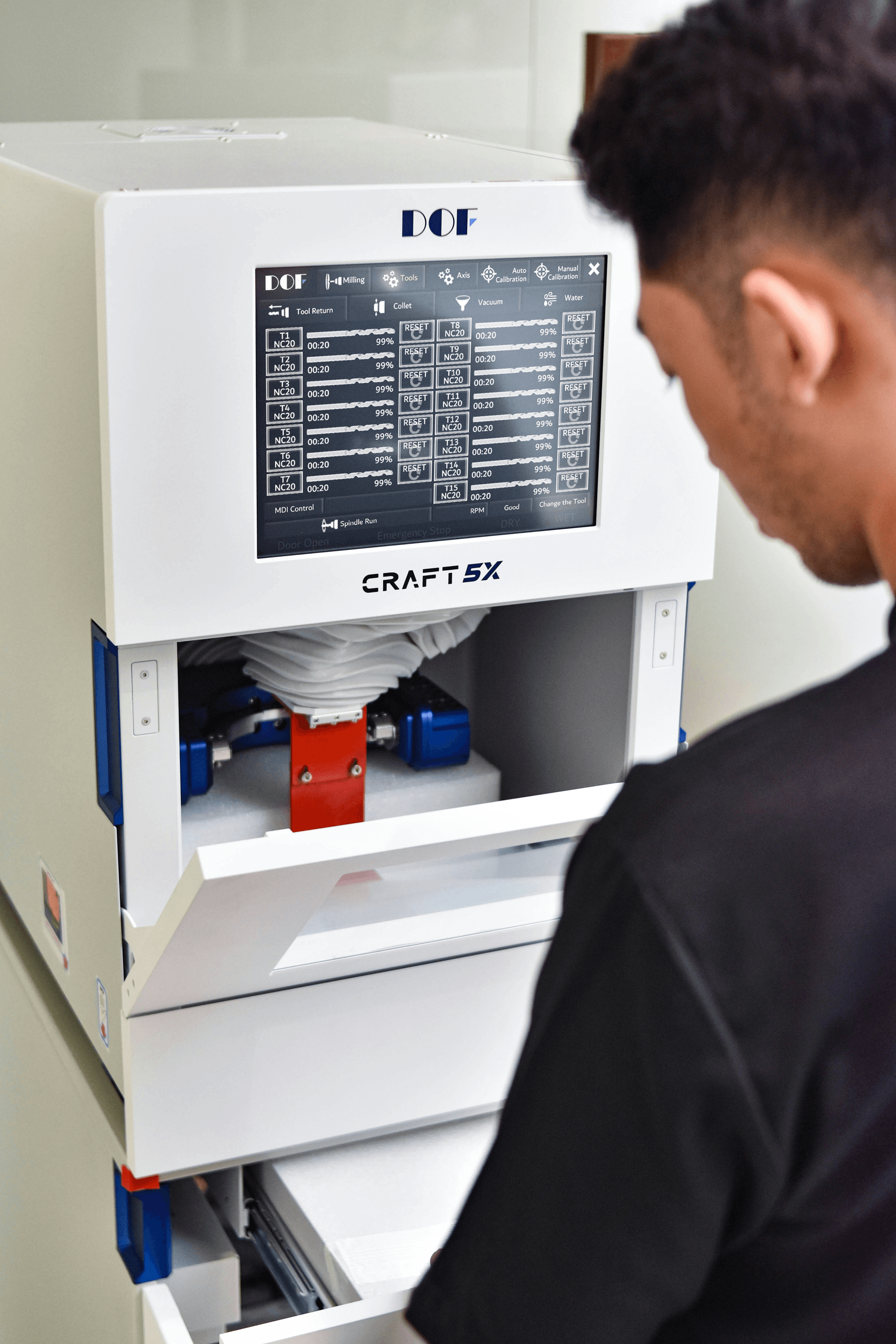

Leveraging Professional Expertise

In the complex world of manufacturing and supply chains, having a trusted partner for Quality Assurance Inspection can make all the difference. This is where China Inspection Pro shines, providing specialized services that enhance quality assurance processes across various industries. By leveraging professional expertise, businesses can ensure that their products meet the highest standards of quality and assurance.

Why Choose China Inspection Pro

China Inspection Pro stands out as a leader in the realm of quality assurance and inspections due to its unwavering commitment to excellence. With an experienced team dedicated to quality assurance inspection, they bring a wealth of knowledge about industry standards and best practices. Choosing them means opting for a partner who prioritizes your brand's integrity and ensures that every product meets stringent qa quality benchmarks.

Moreover, their extensive network allows for swift response times and thorough inspections at any stage of production. Businesses can rest easy knowing that their products are being assessed by professionals who understand the nuances of global supply chains. This level of expertise is crucial in mitigating risks associated with supplier reliance while enhancing overall confidence in product delivery.

Advantages of External Quality Assurance

This impartiality leads to more accurate assessments and ultimately better decision-making regarding product releases.

Additionally, external QA experts come equipped with advanced tools and methodologies designed specifically for rigorous testing and evaluation processes. Their insights not only help identify potential issues before they escalate but also streamline operations by ensuring compliance with international standards for quality assurance and safety regulations. In turn, this proactive approach fosters trust among stakeholders by demonstrating a commitment to maintaining high-quality standards.

Improving Quality Assurance and Confidence

Improving qa assurance practices through professional expertise translates directly into enhanced brand reputation and customer loyalty. When customers know they can rely on your products' consistent quality, it fosters long-term relationships built on trust—an invaluable asset in today's competitive marketplace. Moreover, investing in robust quality assurance processes minimizes costly recalls or returns resulting from subpar products.

Furthermore, regular collaboration with experts like those at China Inspection Pro allows companies to stay ahead of industry trends regarding best practices in QA processes—ensuring they remain competitive while adhering to evolving market demands for transparency and accountability in production methods. As businesses embrace these external partnerships for their QA needs, they not only elevate their own operational standards but also contribute positively to the overall ecosystem within which they operate.

Conclusion

In the realm of supply chain management, the significance of quality assurance cannot be overstated. Quality Assurance Inspections serve as a critical checkpoint that ensures products meet industry standards and customer expectations. As we’ve explored, the importance of objectivity in these inspections is paramount for maintaining integrity and trust in supplier relationships.

Emphasizing the Importance of Objectivity

Objectivity in quality assurance is essential for fair evaluation and accurate reporting on product quality. When inspections are conducted without bias, it fosters a culture of transparency that benefits both suppliers and customers alike. Ultimately, this objectivity leads to higher standards in QA quality assurance processes and builds confidence across the supply chain.

Mitigating Risks in Supply Chain Management

The risks associated with relying solely on suppliers for quality assurance can be significant; therefore, mitigating these risks should be a priority for any business. By incorporating third-party QA inspections into your processes, you can identify potential failures before they escalate into costly issues. This proactive approach not only protects your brand's reputation but also enhances overall quality assurance efforts within your organization.

Choosing the Right Quality Assurance Partner

Selecting an appropriate partner for your quality assurance needs is crucial for long-term success in today's competitive market. Look for organizations that prioritize independent assessments and offer expertise tailored to your specific industry requirements. By choosing a reliable partner like China Inspection Pro, you can ensure that your QA quality meets high standards while fostering trust and accountability throughout your supply chain.