Introduction

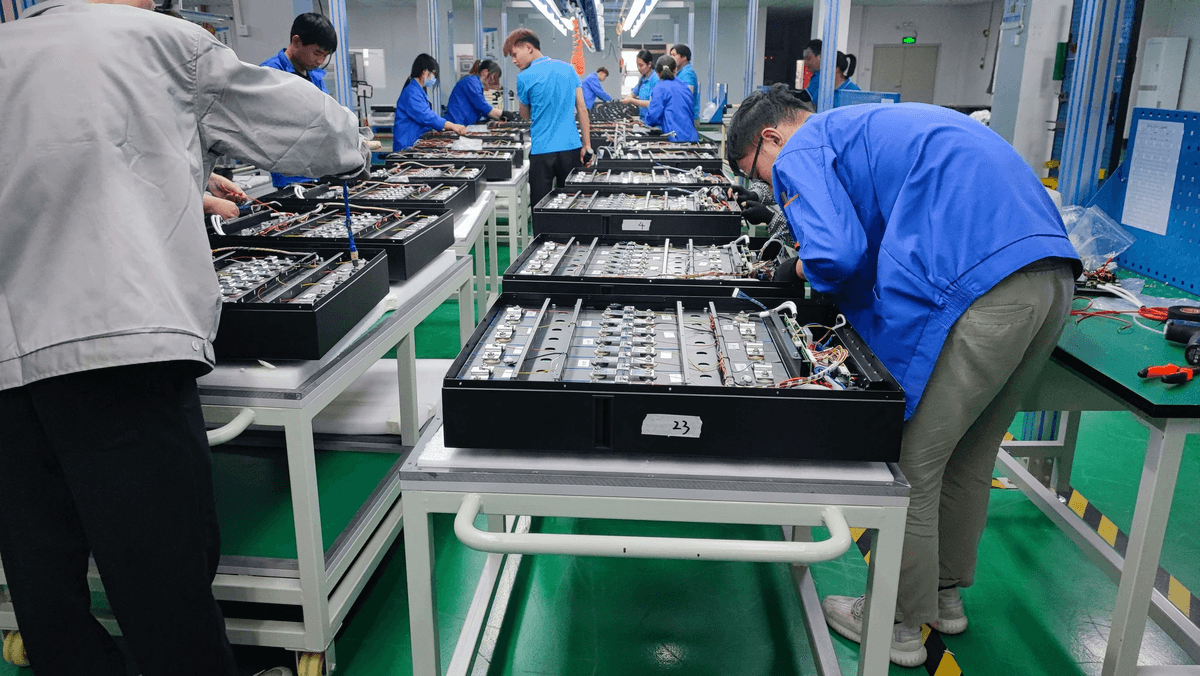

In the world of machinery and tools, inspections are not just a bureaucratic checkbox; they are essential for ensuring safety, efficiency, and longevity. Understanding how to conduct inspection of defective equipment is crucial for preventing accidents and costly downtime. A thorough inspection can reveal hidden issues that may compromise performance, making it a vital practice for any organization.

Understanding the Importance of Inspections

Regular inspections serve as the backbone of effective equipment management. They help identify potential failures before they escalate into serious problems, safeguarding both personnel and assets. By mastering the Equipment Inspection Checklist, you can streamline your processes and ensure that every critical aspect is evaluated systematically.

Common Defective Equipment Issues

From worn-out components to misaligned parts, defective equipment can manifest in various ways that affect performance and safety. Common issues include leaks, corrosion, electrical malfunctions, and mechanical wear—each requiring careful attention during inspections. Knowing these pitfalls can help you focus on key areas while conducting the inspection of tools and equipment.

Benefits of a Thorough Inspection

The benefits of conducting thorough inspections extend beyond mere compliance; they encompass cost savings, improved operational efficiency, and enhanced safety culture within an organization. A well-executed inspection process ensures that equipment operates at peak performance levels while minimizing risks associated with defects. Ultimately, investing time in inspections pays off by prolonging equipment life and fostering a safer work environment.

Equipment Inspection Checklist

An Equipment Inspection Checklist not only helps you stay organized but also ensures that no critical aspect of the inspection is overlooked. This systematic approach is crucial for identifying defects and maintaining equipment safety.

Essential Items to Include

Your Equipment Inspection Checklist should be comprehensive yet focused on essential items that directly impact functionality and safety. Start by including a section for visual inspections, where you can note any signs of wear, corrosion, or other visible defects. Next, incorporate functional tests to assess whether each piece of equipment operates as intended; this could include checking gauges, switches, and other operational components.

Don't forget about maintenance records! Keeping track of past repairs and scheduled maintenance can give valuable insights into potential recurring issues during your inspections. Additionally, ensure that you include items specific to your industry or equipment type; this tailored approach will enhance the effectiveness of how to conduct inspection of defective and equipment.

Safety Standards to Consider

Safety standards play a pivotal role in the inspection process and should never be an afterthought. Familiarize yourself with industry-specific regulations such as OSHA guidelines or ISO standards relevant to your equipment type; these will serve as benchmarks for your inspections. Ensuring compliance with these standards not only protects employees but also minimizes liability risks associated with defective tools and equipment.

Moreover, consider including personal protective equipment (PPE) requirements in your checklist—this ensures that inspectors are adequately prepared before they even start their evaluation process. Regularly reviewing safety protocols can also help you adapt your checklist over time, keeping it aligned with evolving regulations and best practices in the field.

Creating a Customized Checklist

Creating a customized checklist tailored specifically for the types of tools and equipment you inspect is essential for effective management. Begin by analyzing past inspection reports to identify areas where issues frequently arise; this data-driven approach will inform what items need more focus on future inspections.

Once you've gathered this information, group similar items together on your checklist—this will streamline the inspection process and make it easier for inspectors to follow along without missing critical elements during their evaluations. Finally, remember that flexibility is key: regularly update your customized checklist based on new findings or changes in safety regulations so it remains relevant over time.

The Steps to Inspect Equipment

Knowing how to conduct inspection of defective and equipment can save time, money, and potentially lives. Here, we break down the essential steps into manageable segments that will enhance your overall inspection process.

Initial Visual Inspection Techniques

The first step in any effective equipment inspection is the initial visual examination. This phase is all about spotting obvious defects such as cracks, corrosion, or loose parts—issues that might not require advanced testing tools but can indicate deeper problems. Utilize your Equipment Inspection Checklist during this stage; it serves as a guide to ensure you don’t miss any critical areas.

While examining tools and equipment visually, pay close attention to safety labels and warnings that may have faded or been removed over time. This visual check should also include assessing the environment where the equipment operates; things like excessive dust or moisture can lead to unforeseen defects down the line. Remember, a keen eye at this stage can prevent more significant issues later on.

Functional Testing Methods

Once you've completed your initial visual assessment, it’s time to dive into functional testing methods that reveal how well your equipment performs under operational conditions. This step involves running tests that simulate normal use—think of it as giving your gear a workout! Whether it's checking the power output of machinery or ensuring safety features engage correctly, these tests provide valuable insights into performance quality.

Be sure to refer back to your Equipment Inspection Checklist for specific tests related to each piece of equipment you’re reviewing. Incorporating both qualitative observations and quantitative data will give you a comprehensive understanding of whether an item is truly defective or simply in need of maintenance. The goal here is not just identifying flaws but also understanding how they impact overall functionality.

Documenting Findings Effectively

After conducting thorough inspections through visual checks and functional tests, documenting findings effectively becomes paramount. A well-structured report serves as both a record and a roadmap for future inspections or repairs; it’s essential for communicating with stakeholders who rely on accurate information about their tools and equipment's condition.

Ensure your documentation includes details from both the visual inspection techniques and functional testing methods performed earlier—this creates a complete picture of what was found during the inspection process of tools and equipment. Use clear language and straightforward formatting so anyone reading the report can easily grasp what was inspected, what defects were found, and recommended next steps for corrective action.

Tools for Effective Inspections

A well-equipped inspector is like a chef with the best knives; they can slice through problems with ease. The following sections will delve into recommended inspection tools, how technology enhances accuracy, and how China Inspection Pro plays a vital role in ensuring thorough inspections.

Recommended Inspection Tools

To conduct an effective inspection of defective equipment, you need a solid arsenal of tools at your disposal. Basic items like screwdrivers, wrenches, and pliers are essential for hands-on checks, but don’t overlook specialized instruments such as multimeters for electrical tests or ultrasonic thickness gauges for material integrity assessments. An Equipment Inspection Checklist should include these essential tools to ensure no stone is left unturned in your inspections.

Additionally, consider investing in personal protective equipment (PPE) to keep yourself safe while inspecting potentially hazardous machinery. This includes gloves, goggles, and helmets that provide protection against unexpected mishaps. Remember, safety first; after all, you can't inspect anything if you're not around!

Using Technology for Accurate Results

In today's digital age, knowing how to conduct inspection of defective equipment means leveraging technology to enhance accuracy and efficiency. Drones equipped with high-resolution cameras can perform aerial inspections of hard-to-reach areas while thermal imaging cameras can detect heat anomalies that signify malfunctioning parts. Incorporating these technologies into your Equipment Inspection Checklist not only speeds up the process but also increases reliability.

Mobile apps designed specifically for inspections allow inspectors to document findings on-the-go easily and even share reports instantly with stakeholders. This real-time data collection ensures that everyone involved stays informed about any issues discovered during the inspection process. By embracing technology in your inspections, you ensure that you're not just checking boxes but genuinely assessing equipment quality.

Role of China Inspection Pro in Inspections

When it comes to conducting thorough inspections of defective equipment, organizations like China Inspection Pro offer invaluable support and expertise. They provide trained professionals equipped with advanced tools who specialize in various types of machinery and can identify issues that might go unnoticed by less experienced eyes. Their services often include creating customized Equipment Inspection Checklists tailored specifically to client needs.

Moreover, China Inspection Pro employs cutting-edge technology that enhances traditional inspection methods—think drones or remote sensors—allowing them to deliver precise results quickly and efficiently. By partnering with such professionals, companies can significantly reduce risks associated with faulty equipment while ensuring compliance with safety standards across multiple industries.

In conclusion, whether you're assembling your toolkit or integrating advanced technology into your workflow, having the right resources is key when conducting an effective inspection of defective equipment.

Best Practices for Inspecting Defective Equipment

When it comes to the inspection of tools and equipment, best practices can make all the difference. A systematic approach not only enhances safety but also extends the lifespan of your equipment. By focusing on hidden defects, timing your inspections right, and involving the right personnel, you can ensure that your inspections are thorough and effective.

Tips for Identifying Hidden Defects

Identifying hidden defects is crucial when learning how to conduct inspection of defective equipment. Start by examining areas that are often overlooked, such as joints, welds, and internal components that may not be visible during a standard inspection. Utilizing non-destructive testing methods like ultrasonic or magnetic particle inspection can also help uncover issues that would otherwise remain undetected.

Don’t forget to refer back to your Equipment Inspection Checklist throughout this process; it’s your trusty guide! Focus on documenting any anomalies or irregularities you encounter during the inspection—it could save you from future headaches. Remember, a thorough examination today means fewer surprises tomorrow!

Timing and Frequency of Inspections

The timing and frequency of inspections play a pivotal role in maintaining equipment integrity. Establishing a regular schedule based on usage patterns helps ensure that potential issues are caught early before they escalate into costly repairs or accidents. For high-use equipment, consider more frequent checks; for less frequently used tools, semi-annual or annual inspections might suffice.

Incorporating seasonal checks into your plan can also help catch wear and tear caused by environmental factors like humidity or temperature fluctuations. The key is to find a balance between thoroughness and practicality—over-inspecting can lead to unnecessary downtime while under-inspecting risks safety hazards. Stay proactive with your Equipment Inspection Checklist to keep everything on track!

Involving the Right Personnel

Involving the right personnel in the inspection process is essential for effective results when inspecting defective equipment. Ensure that those conducting inspections are well-trained in both safety standards and specific equipment requirements; their expertise will lead to more accurate findings. Additionally, fostering an environment where team members feel comfortable discussing potential issues encourages open communication about any concerns they may have.

Collaboration between maintenance teams and operators can provide valuable insights into how tools are being used daily—this knowledge is invaluable when planning inspections! Don’t hesitate to bring in external experts if needed; sometimes an outside perspective can reveal issues that internal teams might miss during routine checks of tools and equipment. Ultimately, having a dedicated team focused on quality assurance will elevate your overall inspection game!

Reporting Inspection Results

When it comes to reporting inspection results, clarity and detail are paramount. A well-structured report not only captures the findings but also serves as a reference for future inspections and maintenance. This section will guide you through compiling effective inspection reports, communicating findings to stakeholders, and implementing strategies for continuous improvement.

How to Compile Inspection Reports

Compiling an inspection report requires attention to detail and a systematic approach. Start by organizing your notes from the Equipment Inspection Checklist, ensuring all observations regarding defective tools and equipment are included. Use clear headings for different sections—such as visual inspections, functional tests, and any anomalies found—to make it easy for readers to navigate through the document.

Next, summarize your findings concisely but thoroughly; include both positive aspects and areas needing improvement. If you discovered defects during the inspection of tools and equipment, be sure to categorize them by severity or type of issue, which will help prioritize repairs or replacements later on. Finally, don't forget to include photographs or diagrams where applicable—visual evidence can often speak louder than words.

Communicating Findings to Stakeholders

Once your report is compiled, it's time to communicate those findings effectively to stakeholders who rely on this information for decision-making. Tailor your communication style based on your audience; technical jargon may be appropriate for engineers but could confuse management or clients unfamiliar with equipment specifics.

Consider holding a meeting or presentation where you can discuss key points from the report in person—this allows for immediate questions and clarifications about how to conduct inspection of defective equipment efficiently. Follow up with a written summary of the discussion along with the full report so that everyone has access to all relevant details.

Moreover, keep lines of communication open after sharing findings; stakeholders may have insights or concerns that could lead to further improvements in how inspections are conducted in the future.

Strategies for Continuous Improvement

One strategy is regularly reviewing past inspection reports alongside current data; this will help identify recurring issues with specific tools or types of equipment that may require more focused attention during future inspections.

Another approach is involving personnel at various levels in discussions about how inspections are conducted; their firsthand experiences can uncover hidden defects that might otherwise go unnoticed during standard procedures outlined in your Equipment Inspection Checklist. Additionally, consider investing in training programs focused on advanced inspection techniques—this not only enhances skills but also fosters a culture of safety and quality within your organization.

Finally, leverage technology by utilizing software solutions designed for tracking inspection results over time; these systems can provide valuable analytics that inform better practices moving forward.

Conclusion

In wrapping up our discussion on how to conduct inspection of defective equipment, it's crucial to remember that a systematic approach can make all the difference. Successful inspections hinge on a well-structured Equipment Inspection Checklist that encompasses all necessary components, ensuring nothing slips through the cracks. Additionally, embracing best practices and involving the right personnel can elevate your inspection process from mediocre to exceptional.

Key Takeaways for Successful Inspections

Always utilize an Equipment Inspection Checklist tailored to your specific needs, which will help you maintain thoroughness in every inspection. Remember, regular inspections not only identify defects but also foster a culture of safety and accountability within your organization.

Leveraging Professional Services Effectively

While self-conducted inspections are valuable, knowing when to call in professional services is equally important. Professionals bring expertise in how to conduct inspection of defective equipment that might otherwise go unnoticed by untrained eyes. By leveraging these services effectively, you can ensure that your inspections yield accurate results while freeing up internal resources for other critical tasks.

Ensuring Equipment Quality and Safety

Ultimately, ensuring equipment quality and safety should be at the forefront of every inspection effort. A proactive approach—one that includes frequent assessments using an Equipment Inspection Checklist—can significantly reduce risks associated with defective equipment. Remember, investing time in thorough inspections today pays dividends in safety and efficiency tomorrow.