Introduction

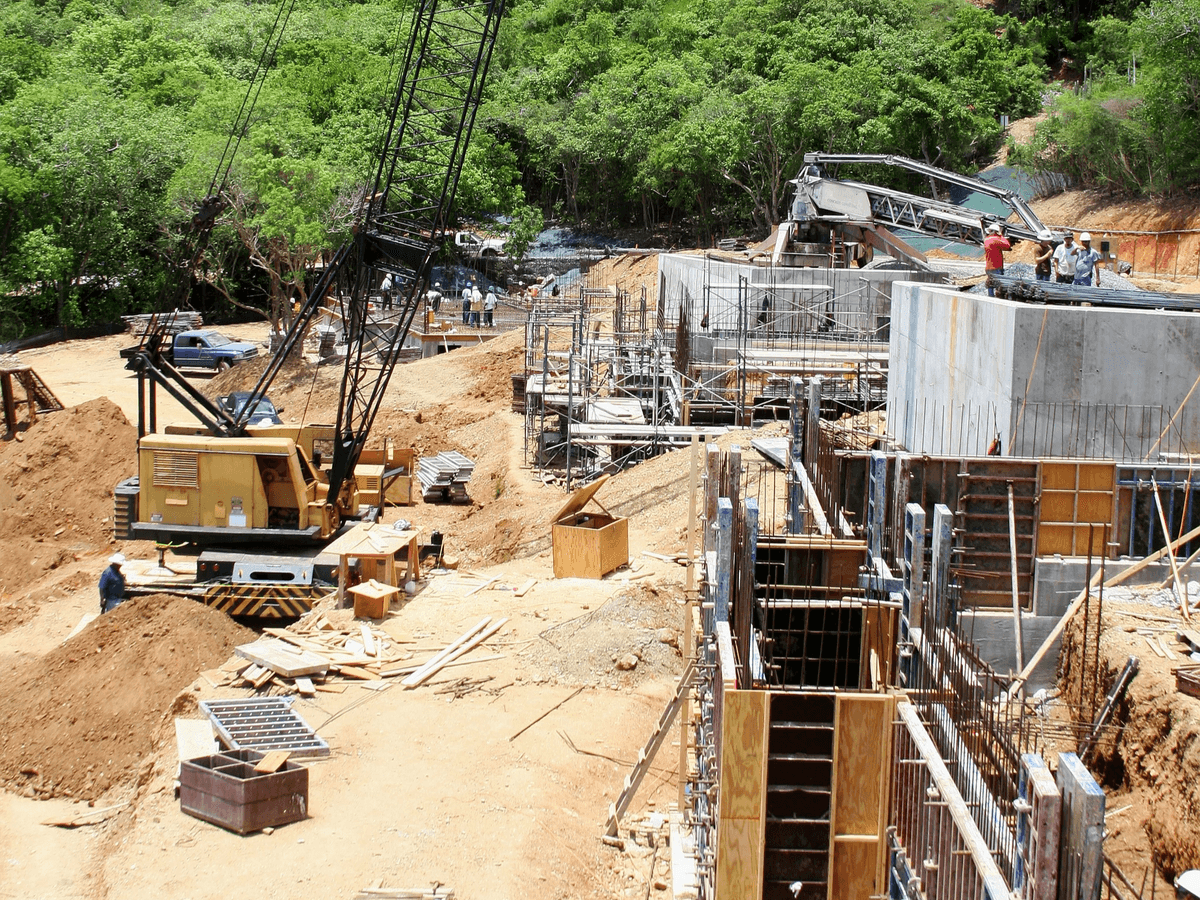

Quality control in civil engineering is the backbone of successful construction projects, ensuring that every aspect meets rigorous industry standards. In an era where construction and project management are under constant scrutiny, the importance of effective quality control cannot be overstated. This introduction sets the stage for understanding how quality assurance (QA) and quality control (QC) processes shape the landscape of civil construction.

Understanding Quality Control in Civil Engineering

Quality control in civil engineering encompasses a set of procedures and standards designed to ensure that construction projects are completed to specification. By establishing a robust QA QC plan for construction projects, engineers can systematically assess materials, workmanship, and overall project integrity. This proactive approach not only mitigates risks but also enhances the reliability and durability of structures.

Importance of Effective Construction Management

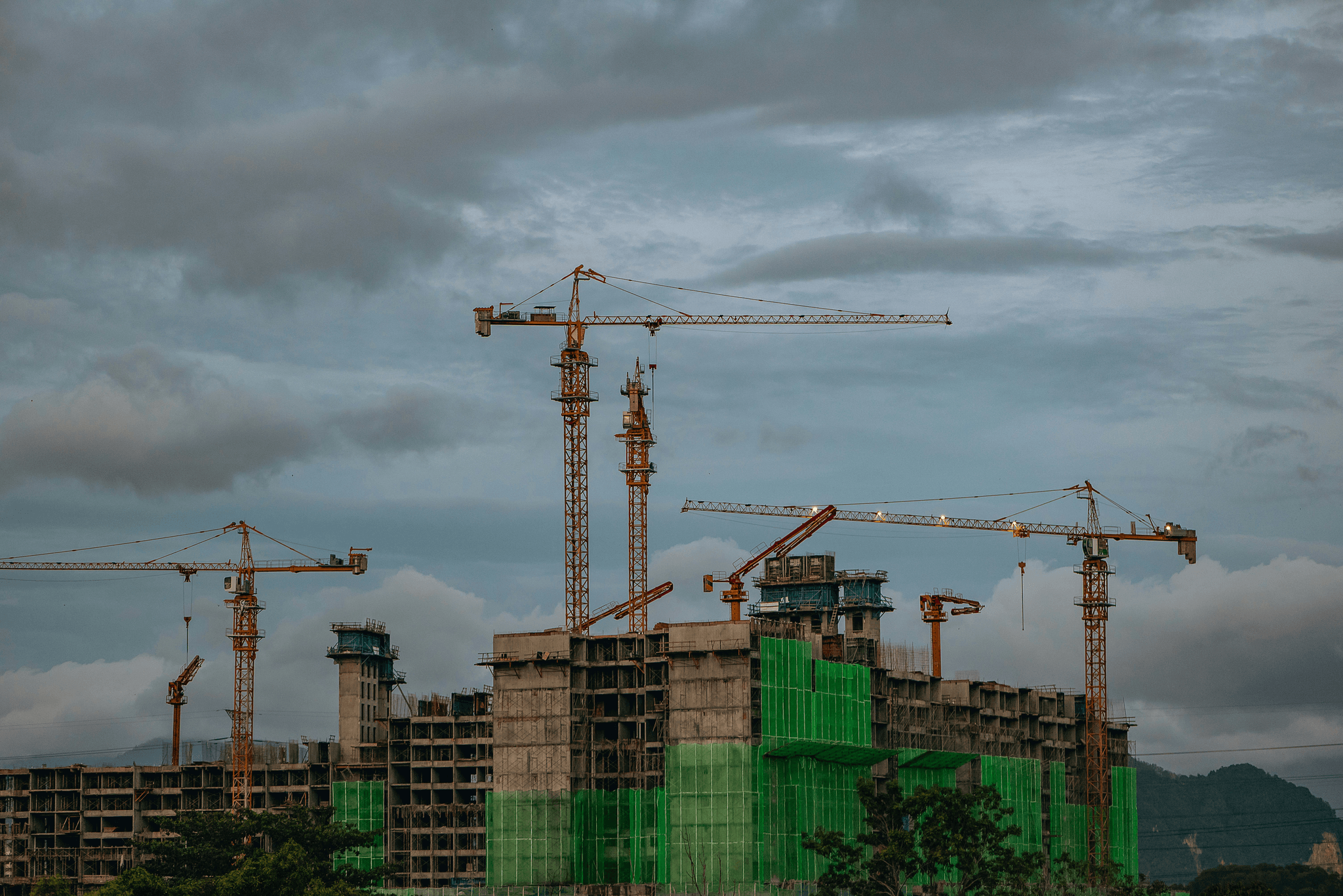

Effective construction management is critical for delivering high-quality results within budget and on schedule. When integrated with quality control measures, it ensures that all phases of a construction project align with predetermined objectives and client expectations. The best construction project management practices involve continuous monitoring and adaptation to maintain high standards throughout the project lifecycle.

Role of Third-Party Inspectors

Third-party inspectors play a pivotal role in reinforcing quality control in civil engineering by providing unbiased assessments during various stages of construction. Their independent evaluations help identify potential issues early on, allowing teams to address them before they escalate into costly problems. Partnering with reputable inspection agencies not only enhances trust but also elevates the overall quality assurance process within any civil construction endeavor.

Fundamentals of Quality Control in Civil Engineering

In the realm of civil construction, quality control is not merely a box to tick; it’s the backbone of successful construction and project management. Without well-defined quality control standards, projects can quickly veer off course, leading to costly delays and safety hazards. By establishing robust quality benchmarks, stakeholders ensure that every aspect of a construction project meets the required specifications and expectations.

Defining Quality Control Standards

Quality control standards in civil engineering serve as a guiding light for all phases of construction projects. These standards encompass material specifications, workmanship criteria, and compliance with regulatory requirements, ensuring that every element aligns with industry best practices. By adhering to these established norms, teams can mitigate risks associated with subpar work or materials, ultimately enhancing the overall integrity of civil construction.

Moreover, defining these standards involves collaboration among engineers, architects, and contractors to create a comprehensive framework that addresses potential challenges upfront. This proactive approach not only minimizes rework but also fosters an environment where quality is prioritized from day one. As such, understanding and implementing quality control standards is essential for effective construction project management.

Key Components of a QA QC Plan

A well-structured QA QC plan for construction projects is crucial in maintaining high-quality outcomes throughout the project's lifecycle. At its core, this plan should include detailed protocols for inspections, testing procedures for materials used on-site, and guidelines for documentation that tracks compliance with established standards. Additionally, it should outline roles and responsibilities within the team to ensure accountability at every stage.

Another vital component is risk management strategies that identify potential issues before they escalate into significant problems. By integrating preventive measures into the QA QC plan, teams can navigate challenges more effectively while maintaining adherence to quality control in civil engineering practices. Ultimately, a robust QA QC plan acts as both a roadmap and safety net for successful project execution.

Real-World Applications and Expectations

In practice, the application of quality control in civil engineering manifests through various real-world scenarios where adherence to QA QC plans directly impacts project success rates. For instance, consider large-scale infrastructure projects like bridges or highways; rigorous testing protocols are essential to ensure structural integrity under diverse conditions over time. Clients expect nothing less than excellence when investing in such significant undertakings.

Furthermore, successful case studies illustrate how effective implementation of quality control measures has led to timely project completions while staying within budget constraints—an ultimate goal in best construction project management practices. Teams must embrace these expectations by continuously refining their processes based on lessons learned from past experiences while also remaining adaptable to new technologies emerging within the industry landscape.

Integrating Technology in Quality Control

In the fast-paced world of civil construction, integrating technology into quality control processes is not just a luxury; it’s a necessity. As projects become more complex, the need for effective construction and project management tools becomes paramount. The right software solutions can streamline operations, enhance communication, and ultimately lead to better outcomes in quality control in civil engineering.

Utilizing Software Solutions for Quality Management

Software solutions have revolutionized how quality control is approached in civil engineering. From project management platforms to specialized QA QC plan tools, these technologies provide a structured way to monitor compliance with quality standards throughout the construction project lifecycle. By utilizing software designed specifically for construction and project management, teams can easily track progress, manage documentation, and ensure that all stakeholders are aligned on quality expectations.

Moreover, these systems often come equipped with features that allow for real-time updates and notifications, which are crucial for timely decision-making. For instance, if an issue arises on-site that could impact the overall quality of work being performed, immediate alerts can be sent out to relevant team members. This proactive approach not only minimizes delays but also ensures adherence to the best construction project management practices.

Importance of Real-Time Data in Construction Projects

Real-time data has emerged as a game-changer in maintaining high standards of quality control in civil engineering projects. With access to up-to-the-minute information regarding materials used, labor hours logged, and equipment status, project managers can make informed decisions swiftly. This immediacy helps identify potential issues before they escalate into costly problems that could compromise the integrity of the construction project.

Furthermore, real-time data analytics enables teams to assess performance against established benchmarks within their QA QC plan for construction projects effectively. By continuously monitoring key performance indicators (KPIs), stakeholders can adjust strategies as needed to optimize workflow and maintain high-quality standards throughout every phase of development. In an industry where time is money, leveraging real-time data translates directly into increased efficiency and reduced waste.

Case Studies of Technological Integration

Several successful case studies illustrate how technological integration enhances quality control processes within civil construction projects. One notable example involves a large-scale infrastructure project where cloud-based software was implemented to manage documentation and compliance checks effectively. This approach allowed team members across various locations to access critical information instantly while ensuring adherence to stringent QA QC plans tailored for their specific needs.

Another compelling case study highlights a mid-sized contractor who adopted mobile inspection applications during their projects' execution phases. These apps enabled field inspectors to document findings immediately through photographs and notes directly from their devices—eliminating delays associated with paperwork or verbal communication back at the office. The result? A marked improvement in both response times and overall quality assurance measures across multiple job sites.

By embracing these technological advancements within their operations—whether through sophisticated software solutions or innovative mobile applications—construction firms are setting themselves up for success while navigating the complexities inherent in modern civil engineering projects.

Training and Development for Quality Assurance

In the realm of quality control in civil engineering, training and development are pivotal in fostering a culture that prioritizes excellence. A quality-focused culture permeates every aspect of construction and project management, ensuring that all team members understand their roles in maintaining high standards. By instilling this mindset from the ground up, organizations can significantly enhance their performance on construction projects.

Creating a Quality-Focused Culture

Creating a quality-focused culture within civil construction projects starts with leadership commitment to quality control standards. This involves not just setting expectations but also modeling behaviors that prioritize safety, efficiency, and excellence in every task. Engaging employees through workshops or seminars can reinforce the importance of adhering to the QA QC plan for construction projects, transforming it from a mere checklist into a shared value among all team members.

Moreover, recognizing and rewarding individuals who exemplify quality-focused behaviors can motivate others to follow suit. This approach creates an environment where everyone feels responsible for maintaining high standards throughout the project lifecycle. Ultimately, cultivating such a culture ensures that quality control becomes second nature rather than an afterthought.

Best Practices for Training Civil Engineers

When it comes to training civil engineers effectively, incorporating practical experiences alongside theoretical knowledge is crucial. Hands-on workshops that simulate real-world scenarios help bridge the gap between classroom learning and actual construction environments. By focusing on best practices for training civil engineers, organizations can ensure their teams are well-equipped to address challenges related to quality control in civil engineering.

Additionally, leveraging technology such as virtual reality or simulation software can provide immersive training experiences without the risks associated with live projects. Regularly updating training materials to reflect current industry standards and innovations also keeps teams informed about best practices in construction project management. This proactive approach fosters continuous learning and adaptation within the workforce.

Continuous Improvement in Skill Development

Continuous improvement is essential for skill development in any field, especially within civil construction where technologies and methodologies evolve rapidly. Establishing ongoing education programs allows engineers to stay abreast of new trends related to quality control in civil engineering while enhancing their existing skill sets. These programs should be tailored not only to meet current demands but also anticipate future challenges faced by professionals in construction project management.

Feedback mechanisms play a vital role here; soliciting input from team members about areas needing improvement can guide future training initiatives effectively. Furthermore, mentorship opportunities where experienced professionals guide newcomers foster an atmosphere of knowledge sharing and growth within teams working on various projects. In doing so, organizations contribute not only to individual career advancement but also elevate overall project outcomes through enhanced skills.

Collaborating with Third-Party Inspection Agencies

In the realm of civil construction, collaborating with third-party inspection agencies is often a game-changer for ensuring quality control in civil engineering projects. These partnerships not only bolster the integrity of construction but also enhance overall project management efficiency. By leveraging the expertise of specialized agencies, construction teams can focus on their core competencies while still adhering to rigorous quality standards.

Benefits of Partnering with China Inspection Pro

Partnering with China Inspection Pro brings a wealth of benefits to any construction project. Their extensive experience in quality control in civil engineering ensures that all aspects of a project meet or exceed established standards, which is essential for maintaining a robust qa qc plan for construction projects. Moreover, their local knowledge and understanding of regional regulations can help mitigate risks and streamline processes, ultimately leading to better outcomes and smoother project execution.

Additionally, working with such an agency fosters transparency and accountability throughout the construction process. This partnership creates an environment where potential issues are identified early on, allowing teams to make necessary adjustments without significant delays or cost overruns. In essence, engaging with China Inspection Pro equips construction managers with the tools they need to achieve best practices in construction project management.

How Third-Party Inspections Enhance Quality Control

Third-party inspections play a vital role in enhancing quality control within civil engineering projects by providing unbiased evaluations and assessments. These inspections serve as an independent verification mechanism that helps ensure compliance with the qa qc plan for construction projects, thereby reducing the likelihood of defects or failures down the line. By having an external party scrutinize work processes and materials used, stakeholders gain confidence that industry standards are being met consistently.

Moreover, third-party inspectors bring specialized expertise that may not be available within internal teams. Their insights can lead to improved methodologies and innovative solutions for common challenges faced during construction phases. This collaborative approach not only elevates overall quality but also cultivates a culture of continuous improvement throughout the project's lifecycle.

Selecting the Right Inspection Partner

Choosing the right inspection partner is crucial for maximizing benefits from third-party collaborations in civil construction projects. When evaluating potential partners like China Inspection Pro, it’s essential to assess their track record in delivering effective quality control in civil engineering services tailored to specific project needs. Factors such as industry experience, certifications, and client testimonials should weigh heavily in decision-making processes.

Additionally, communication plays a pivotal role; selecting an inspection agency that prioritizes clear dialogue ensures alignment between all parties involved throughout each stage of the project management process. A strong partnership built on trust will facilitate open discussions about challenges encountered during inspections and encourage proactive problem-solving strategies moving forward into future endeavors.

Lastly, consider how well potential partners integrate technology into their inspection processes; this capability can significantly enhance real-time data collection and reporting mechanisms critical for effective decision-making within any qa qc plan for construction projects.

Monitoring and Evaluating Quality Control Processes

Monitoring and evaluating quality control processes is a critical aspect of successful construction project management. Effective oversight ensures that all aspects of the construction project adhere to the established standards, ultimately leading to superior outcomes in civil construction. By implementing a structured approach to quality control, stakeholders can identify potential issues early, allowing for timely interventions.

Setting Metrics for Success in Construction Projects

Establishing clear metrics is essential for gauging success in any construction project. These metrics serve as benchmarks against which quality control in civil engineering can be measured, ensuring that every phase of the project aligns with the overall goals outlined in the QA QC plan for construction projects. Common metrics include adherence to timelines, budget constraints, safety incidents, and compliance with quality standards—each providing invaluable insights into the project's health.

Moreover, these metrics should be tailored to fit the specific context of each civil construction endeavor. For instance, a high-rise building may prioritize structural integrity and safety measures differently than a road development project would. By customizing metrics based on project type and scope, teams can better monitor progress and make informed decisions throughout the lifecycle of the construction project.

Regular Audits and Their Importance

Conducting regular audits is a cornerstone of effective quality control in civil engineering. These audits not only verify compliance with established standards but also reveal areas where improvements can be made within the QA QC plan for construction projects. Consistent evaluations allow teams to assess both processes and outcomes, ensuring that any deviations from expected performance are promptly addressed.

Audits can take various forms—internal assessments conducted by team members or external evaluations performed by third-party inspectors—and both play crucial roles in maintaining high-quality standards. The insights gained from these audits create an opportunity for continuous improvement within construction and project management practices. Ultimately, regular audits foster accountability among team members while reinforcing a culture of excellence across all levels of operation.

Adjusting Strategies Based on Evaluation Results

The ability to adapt strategies based on evaluation results is what separates best construction project management from mediocre practices. When monitoring reveals gaps or shortcomings in quality control processes, it's vital for teams to pivot quickly—revising their approaches as needed to ensure ongoing compliance with established standards in civil engineering projects. This flexibility not only enhances overall performance but also reinforces stakeholder confidence in the project's direction.

Incorporating feedback loops into your evaluation process allows teams to learn from past experiences actively and apply those lessons moving forward. By regularly revisiting goals set out at the beginning of a construction project, stakeholders can realign their efforts towards achieving desired outcomes more effectively than before. This iterative process cultivates an environment where continuous improvement thrives—a hallmark characteristic of successful civil construction initiatives.

Conclusion

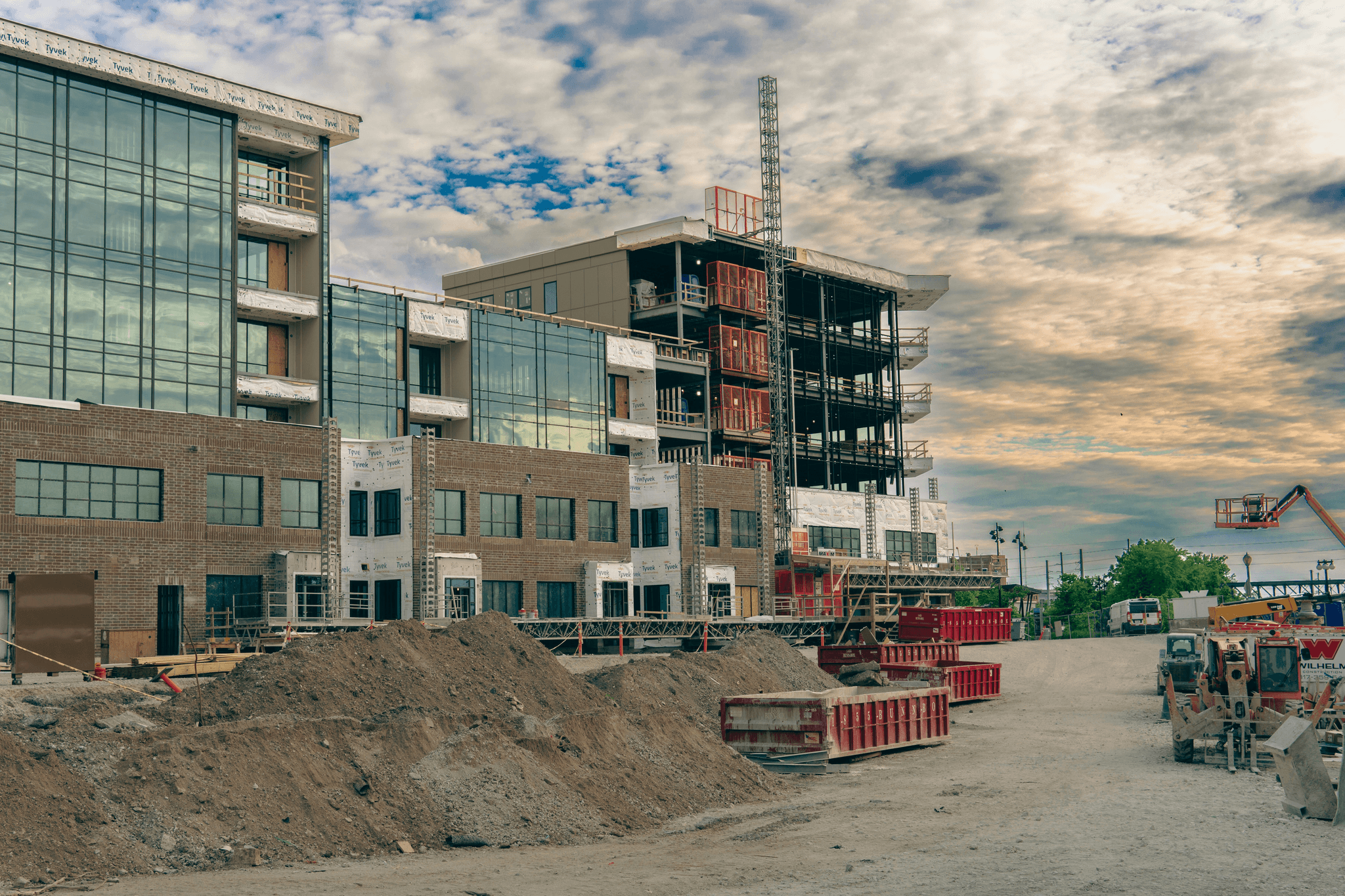

In the realm of civil construction, effective quality control is not just a checkbox to tick but a vital component that influences the overall success of any construction project. By integrating robust QA QC plans into construction and project management processes, stakeholders can ensure that each phase of development meets predetermined standards and expectations. Ultimately, prioritizing quality control in civil engineering leads to enhanced safety, reduced costs, and improved project timelines.

Key Takeaways for Effective Quality Control

To achieve effective quality control in civil engineering, it is essential to establish clear standards and protocols from the outset. A well-structured QA QC plan for construction projects serves as a roadmap, guiding teams through various phases while ensuring compliance with industry regulations and best practices. Remember that investing in training and development for all personnel involved not only fosters a culture focused on quality but also empowers team members to identify issues before they escalate.

Future Trends in Civil Construction Quality Assurance

As we look ahead, several trends are shaping the future of quality assurance in civil construction. The integration of advanced technology—such as artificial intelligence and machine learning—into construction project management is set to revolutionize how quality control processes are monitored and executed. Moreover, sustainability practices will increasingly influence QA QC plans, emphasizing environmentally friendly materials and methods without compromising structural integrity.

Building Trust Through Consistent Quality Control

Building trust among clients and stakeholders hinges on consistent quality control throughout the lifespan of construction projects. When civil engineers adhere strictly to their QA QC plans for construction projects, they foster confidence that can lead to repeat business and referrals. In an industry where reputation is paramount, maintaining high standards reinforces credibility while demonstrating a commitment to excellence.