Introduction

In the realm of industrial operations, equipment inspection serves as a cornerstone for ensuring safety and efficiency. Equipment inspections are systematic evaluations designed to assess the condition and functionality of machinery, tools, and systems. Understanding the nuances of these inspections is vital for maintaining a productive work environment and safeguarding personnel.

Understanding Equipment Inspections

Equipment inspections encompass various procedures aimed at identifying potential issues before they escalate into significant problems. These assessments can range from simple visual checks to comprehensive functional testing, each tailored to specific equipment types and operational contexts. By grasping what equipment inspections entail, organizations can better appreciate their role in preventing accidents and enhancing performance.

Why Equipment Inspections Matter

Why are equipment inspections important? They not only enhance safety by identifying hazards but also play a crucial role in preventing costly downtime that can disrupt operations. Additionally, regular equipment inspections ensure compliance with industry regulations, protecting businesses from legal repercussions while promoting a culture of accountability.

Overview of Inspection Types

There are several types of equipment inspections that organizations should be aware of to maintain operational integrity. Visual inspections allow for quick assessments of machinery condition, while functional testing verifies that equipment operates as intended under real-world conditions. Routine maintenance checks further support long-term reliability by addressing wear and tear proactively; understanding these types is essential for developing effective strategies around when you should conduct equipment inspections to mitigate risks effectively.

The Role of Equipment Inspections

Equipment inspections play a pivotal role in ensuring the smooth operation of machinery across various industries. By systematically evaluating equipment, businesses can identify potential issues before they escalate into serious problems. This proactive approach not only enhances safety but also contributes to long-term operational efficiency.

Enhancing Safety Standards

One of the primary reasons why equipment inspections are important is their significant contribution to enhancing safety standards. Regular checks help identify wear and tear, ensuring that all equipment operates within safe parameters. Additionally, adhering to inspection protocols mitigates risks associated with machinery failure, ultimately safeguarding employees and reducing liability for employers.

Preventing Costly Downtime

Preventing costly downtime is another critical role of equipment inspections. When machinery malfunctions unexpectedly, it can halt operations, leading to lost revenue and delayed projects. By implementing a robust schedule for types of equipment inspections—ranging from routine maintenance checks to more detailed assessments—companies can anticipate potential failures and address them before they disrupt productivity.

Compliance with Regulations

Compliance with regulations is non-negotiable in many industries, making equipment inspections essential for legal adherence. Various regulatory bodies mandate regular evaluations to ensure that machinery meets safety and operational standards; failing to comply can result in hefty fines or even shutdowns. Thus, conducting thorough inspections not only keeps businesses aligned with legal requirements but also fosters a culture of accountability and diligence within the organization.

Why Are Equipment Inspections Important?

Equipment inspections play a pivotal role in maintaining the smooth operation of machinery and tools across various industries. They are not just a box to check off on a compliance list; they are crucial for ensuring that everything runs as it should. So, why are equipment inspections important? Let's dive into the specifics.

Ensuring Operational Efficiency

Operational efficiency hinges on how well equipment performs under pressure, and regular inspections can significantly enhance this aspect. By identifying potential issues before they escalate, businesses can streamline their operations and avoid unexpected breakdowns that can disrupt productivity. When you prioritize equipment inspection, you're essentially investing in a smoother workflow and reducing the chances of costly delays.

Moreover, different types of equipment inspections cater to specific needs, ensuring that all angles are covered for optimal performance. From visual checks to functional testing, each method plays its part in keeping operations running efficiently. This proactive approach not only saves time but also resources in the long run.

Mitigating Risks and Hazards

One of the primary reasons for conducting thorough equipment inspections is to mitigate risks and hazards that could jeopardize safety. Faulty machinery can lead to accidents that might harm employees or damage property, making regular inspections essential for maintaining a safe working environment. By addressing potential hazards before they become serious issues, companies can foster a culture of safety among their workforce.

Additionally, navigating through equipment inspection challenges is integral to risk management strategies within organizations. Regular assessments help identify wear and tear or malfunctioning components that could pose dangers if left unchecked. Ultimately, prioritizing safety through diligent inspections protects both personnel and investments.

Boosting Equipment Longevity

It's no secret that well-maintained equipment lasts longer than neglected machines; thus, boosting longevity is another compelling reason for regular inspections. Routine checks ensure that minor issues are addressed promptly before they evolve into major repairs or replacements—saving both time and money in the long run. When you conduct your equipment inspection regularly using established best practices, you create an environment where machines thrive rather than just survive.

By implementing effective maintenance strategies alongside your inspection routine, you further enhance your equipment's lifespan while optimizing performance levels across the board. Remember: when should you conduct these crucial inspections? Establishing an inspection schedule aligned with operational demands allows businesses to maximize their assets effectively.

In conclusion, understanding why equipment inspections are important is key to achieving operational efficiency while mitigating risks and enhancing longevity—all essential factors for success in any industry.

Types of Equipment Inspections

When it comes to equipment inspection, understanding the different types is crucial for maintaining safety and efficiency. Each type serves a unique purpose and addresses specific aspects of equipment functionality and compliance. By familiarizing yourself with these categories, you can better appreciate why equipment inspections are important in your operational framework.

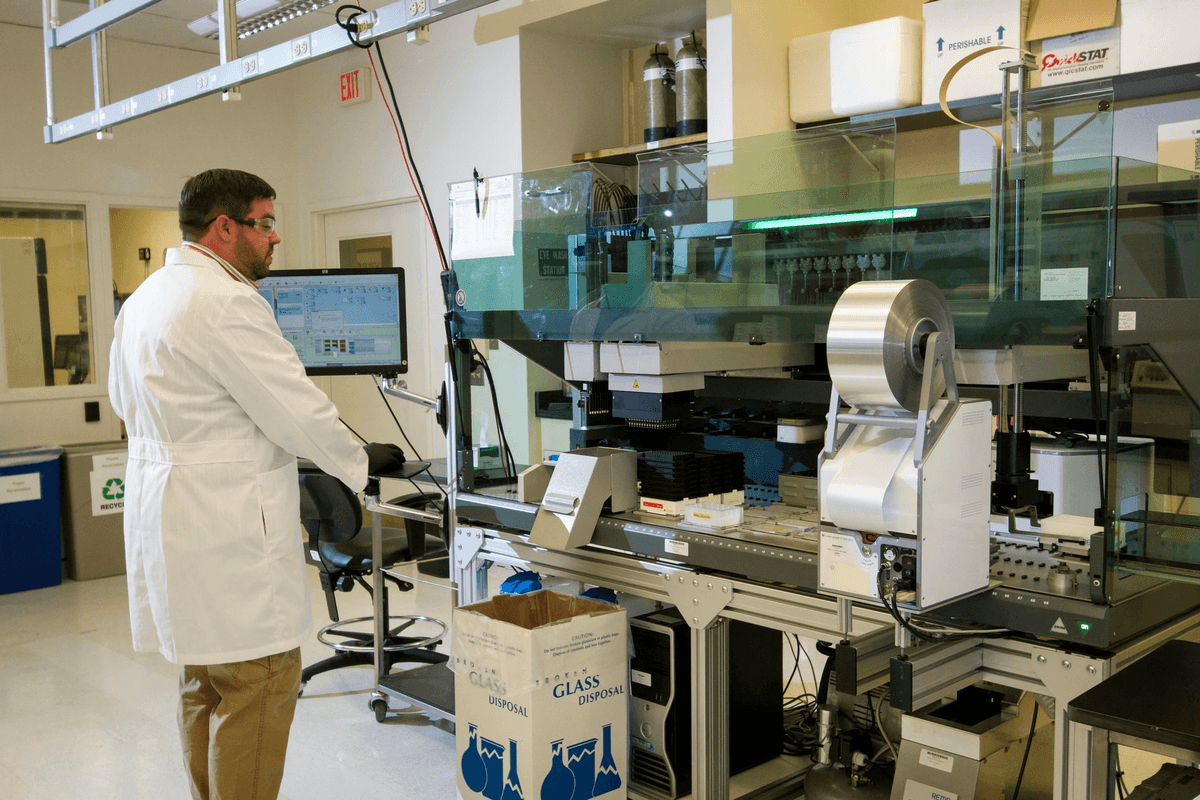

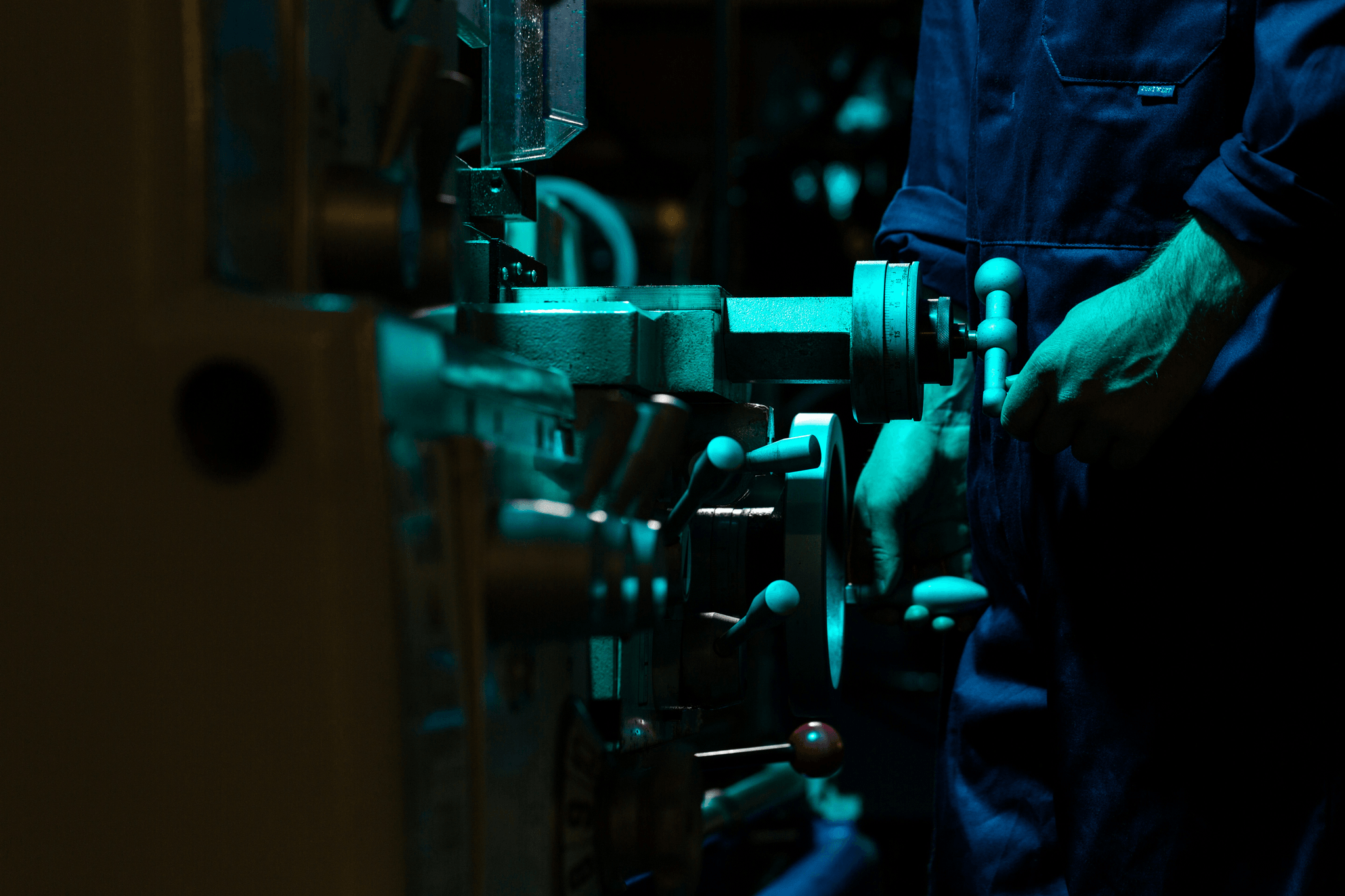

Visual Inspections and Functional Testing

Visual inspections are often the first line of defense in identifying potential issues with equipment. This involves a thorough examination of machinery for any visible signs of wear, damage, or malfunction without disassembling the unit. Functional testing complements visual inspections by assessing whether the equipment operates as intended, ensuring that everything from levers to lights is working properly—because nothing says “safety first” like knowing your gear is functional!

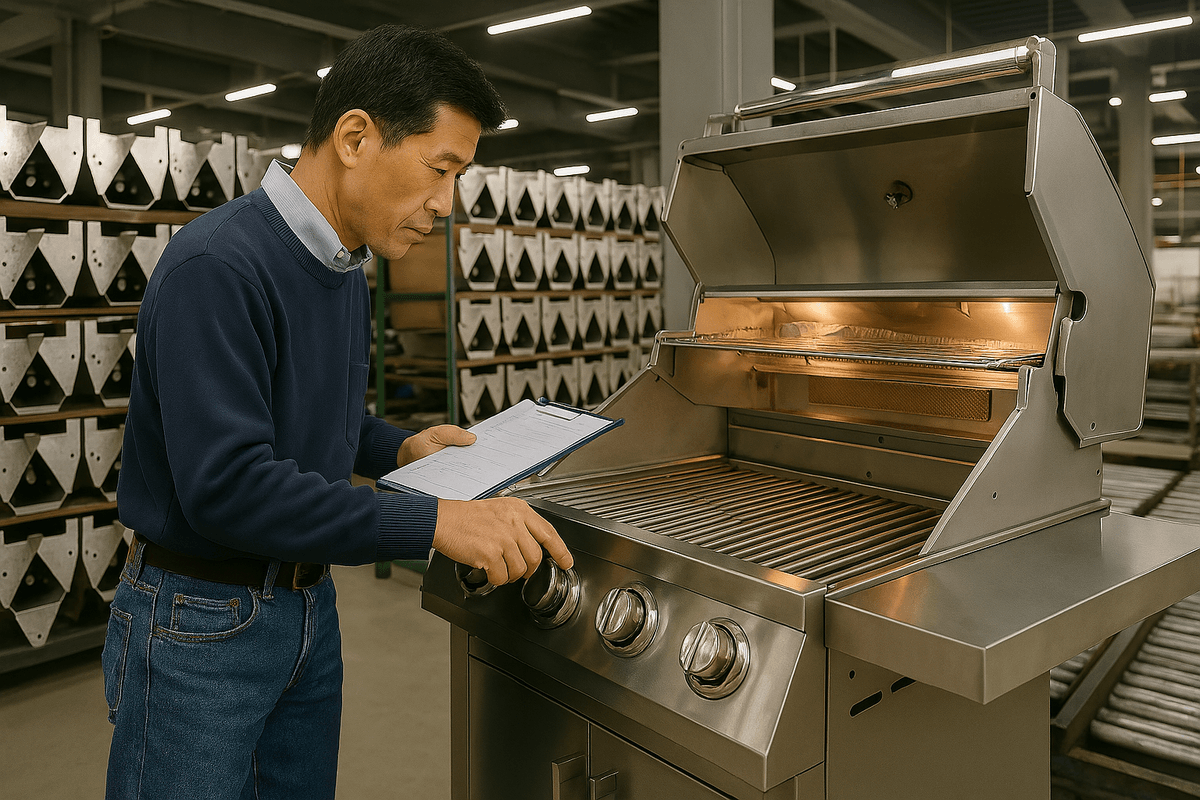

Routine Maintenance Checks

Routine maintenance checks are systematic evaluations performed at regular intervals to ensure that all components are functioning optimally. These checks often include cleaning, lubricating parts, and replacing worn items before they lead to more significant problems down the road. By adhering to these scheduled inspections, businesses can mitigate risks associated with unexpected breakdowns—reinforcing why equipment inspections are vital for operational success.

Periodic vs. Non-Periodic Inspections

Understanding the difference between periodic and non-periodic inspections helps organizations tailor their inspection strategies effectively. Periodic inspections occur at predetermined intervals based on manufacturer recommendations or regulatory requirements, ensuring consistent oversight over time. In contrast, non-periodic inspections may be triggered by specific events such as accidents or unusual performance issues; this flexibility allows teams to respond quickly when challenges arise in their equipment inspection processes.

Equipment Inspection Challenges

Navigating the world of equipment inspections is not all smooth sailing; there are a few challenges that can throw a wrench in the works. From compliance with safety regulations to managing costs, each obstacle requires careful consideration and strategic planning. Understanding these challenges is crucial for ensuring effective inspections and maintaining operational efficiency.

Navigating Compliance and Safety Regulations

One of the most daunting aspects of equipment inspections is navigating compliance and safety regulations. These regulations are designed to protect workers and promote safe practices, but they can often be complex and overwhelming. Staying updated on local, national, and industry-specific standards is essential for answering the question: Why are equipment inspections important? Without proper adherence to these regulations, organizations risk facing legal repercussions or costly fines.

Moreover, non-compliance can lead to serious accidents or equipment failures that could have been prevented through regular inspections. To tackle this challenge effectively, companies should invest in training their staff on regulatory requirements while also consulting with experts who specialize in compliance issues. This proactive approach not only simplifies the inspection process but also reinforces the importance of regular equipment checks.

Addressing Human Error

Human error is another significant challenge that plagues equipment inspections, often compromising their effectiveness. Inspectors may overlook critical issues due to fatigue or lack of proper training, leading to potentially dangerous situations down the line. By understanding why equipment inspections are important, organizations can emphasize the need for thoroughness in every inspection phase.

To mitigate human error, companies should implement rigorous training programs that focus on best practices for conducting inspections. Regular assessments and refresher courses can help keep inspectors sharp and aware of potential pitfalls during evaluations. Furthermore, technology can play a pivotal role in reducing human error by providing checklists or digital tools that guide inspectors through each step of the process.

Managing Inspection Costs

Managing inspection costs is yet another hurdle that organizations face when it comes to maintaining their equipment inspection schedules. While it might be tempting to cut corners by skipping routine checks or relying solely on visual assessments, this approach could lead to more significant expenses down the road due to unplanned downtime or repairs. Companies must recognize that investing in comprehensive types of equipment inspections ultimately pays off by enhancing safety and efficiency.

To balance costs effectively while still adhering to best practices for equipment inspections, businesses should establish a clear budget for both routine maintenance checks and emergency services as needed. Prioritizing preventative measures over reactive ones will save money in the long run while ensuring compliance with regulations related to safety standards. Additionally, collaborating with experienced partners like China Inspection Pro can help streamline processes without breaking the bank.

When Should You Conduct Equipment Inspections?

Determining the right timing for equipment inspections is crucial to ensuring safety, compliance, and operational efficiency. The question When should you conduct equipment inspections? is not just about scheduling; it involves understanding the nuances of your operations and the types of equipment in use. A well-planned inspection schedule can save time, money, and headaches down the line.

Establishing an Inspection Schedule

Creating a robust inspection schedule is foundational to effective maintenance practices. Regular inspections should be based on manufacturer recommendations, industry standards, and operational demands. By establishing a systematic approach to equipment inspections, organizations can ensure that safety protocols are consistently met while addressing any potential wear and tear proactively.

Incorporating both routine checks and more detailed evaluations into your schedule will help mitigate risks associated with equipment failure. Remember that different types of equipment may require varying frequencies of inspections; heavy machinery might need more frequent checks compared to office equipment. Ultimately, a well-structured inspection schedule contributes significantly to answering the question: Why are equipment inspections important?

Identifying Triggers for Inspections

While a regular schedule is essential, there are specific triggers that necessitate immediate attention through an inspection. These triggers can include unusual noises from machinery, unexpected performance drops, or changes in operating conditions—basically anything that raises a red flag about equipment functionality or safety. Recognizing these signs early can prevent minor issues from escalating into costly downtime or hazardous situations.

Additionally, significant events such as after an accident or following extreme weather conditions should prompt immediate assessments of all affected machinery. These triggers serve as critical reminders that even the best-laid plans for routine inspections must remain flexible to adapt to real-world challenges—an aspect often highlighted in discussions about equipment inspection challenges.

Balancing Regular and Emergency Inspections

Finding the right balance between regular and emergency inspections can be tricky yet vital for maintaining operational integrity. While regular inspections provide a solid foundation for identifying potential issues before they arise, emergency inspections allow teams to respond swiftly when something goes awry unexpectedly. Striking this balance ensures not only compliance with regulations but also enhances overall workplace safety.

To manage this effectively, consider implementing a tiered approach where routine checks cover most bases while reserving resources for urgent situations that may require immediate action. This strategy helps alleviate some common equipment inspection challenges by ensuring adequate preparedness without overextending resources unnecessarily. Ultimately, being proactive rather than reactive leads to improved outcomes in both safety and efficiency.

Equipment Inspection Best Practices

When it comes to equipment inspection, best practices can make all the difference between a smooth operation and a costly mishap. Adopting effective strategies not only enhances safety but also ensures compliance with regulations and prolongs equipment life. By focusing on training, technology, and expert partnerships, organizations can navigate the complexities of why are equipment inspections important?

Training and Certification of Inspectors

Training and certification of inspectors is crucial in maintaining high standards in equipment inspection. Well-trained inspectors bring a wealth of knowledge to the table, allowing them to identify potential issues before they escalate into serious problems. Moreover, a rigorous certification process ensures that inspectors are up-to-date with the latest safety regulations and best practices related to types of equipment inspections.

Incorporating regular training sessions keeps inspectors sharp and aware of new technologies or methodologies that may enhance their effectiveness. This proactive approach not only mitigates risks but also addresses one of the significant equipment inspection challenges—human error. Organizations that prioritize inspector training often see improved operational efficiency as well as enhanced safety outcomes.

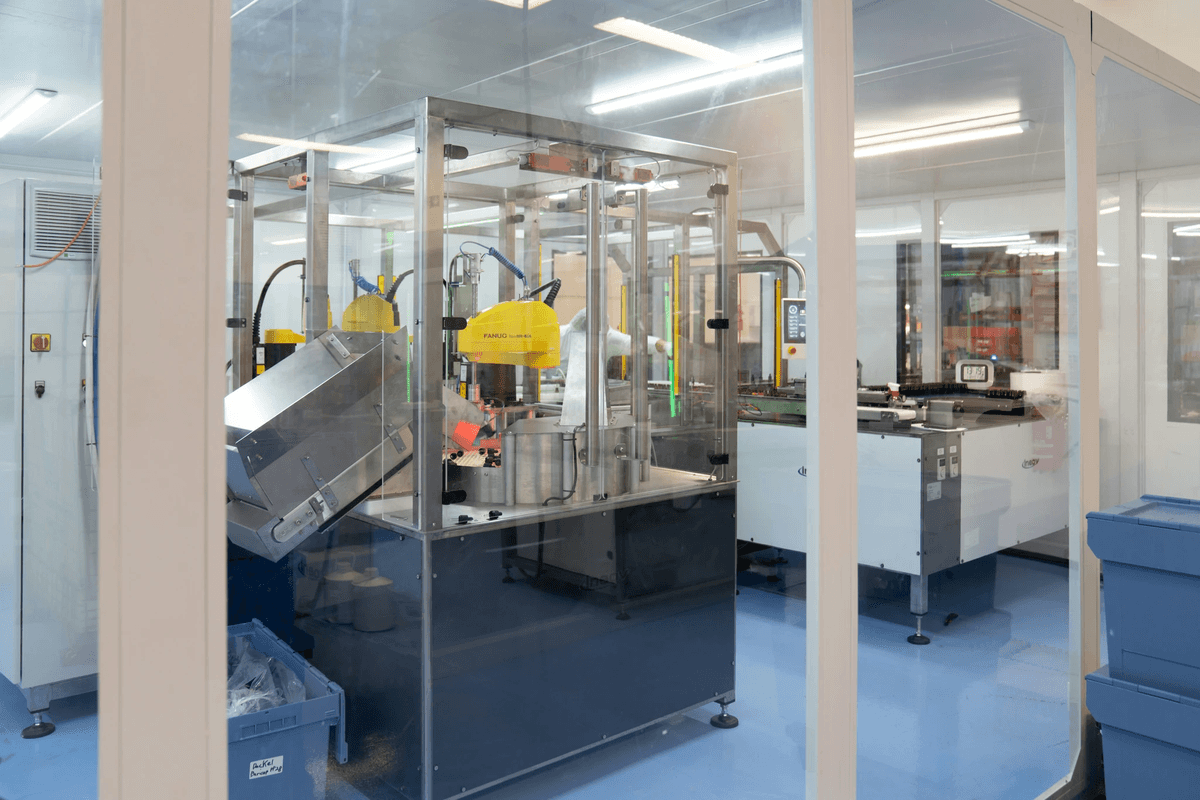

Utilizing Technology for Inspections

The integration of technology into equipment inspections has revolutionized how organizations approach safety and compliance. Tools such as drones, infrared cameras, and mobile apps streamline the inspection process by providing real-time data analysis and enhancing accuracy. This technological edge allows companies to conduct more thorough evaluations while reducing the time spent on each inspection.

Moreover, utilizing technology helps address some common equipment inspection challenges like managing costs and minimizing downtime during inspections. Automated systems can schedule routine checks based on usage patterns or manufacturer recommendations, answering the question: when should you conduct equipment inspections? By leveraging these advanced tools, organizations can ensure their equipment remains in peak condition without unnecessary interruptions.

Partnering with Experts like China Inspection Pro

Partnering with industry experts such as China Inspection Pro can significantly elevate your approach to equipment inspections. These professionals bring extensive experience in various types of equipment inspections, ensuring compliance with local regulations while maintaining high safety standards. Collaborating with experts allows companies to focus on their core operations while leaving intricate inspection processes in capable hands.

Additionally, experts help navigate complex regulatory environments which is often one of the major hurdles faced during inspections—addressing those pesky equipment inspection challenges head-on! By working together with seasoned professionals who understand why are equipment inspections important?, organizations gain peace of mind knowing their assets are being monitored effectively.

In summary, adopting best practices for your next round of equipment inspection will set you up for success by enhancing safety measures while extending machinery longevity. With proper training for inspectors, innovative technologies at your disposal, and strategic partnerships in place—you're well-equipped to tackle any challenge that comes your way!

Conclusion

In the realm of operational efficiency and safety, equipment inspections stand as a pivotal component. The significance of these inspections cannot be overstated; they not only ensure compliance with regulations but also enhance the longevity of equipment. Ultimately, a robust inspection regime fosters a culture of safety and reliability across industries.

The Overall Impact of Inspections

When pondering why equipment inspections are important, consider their far-reaching effects on both safety and productivity. Regular inspections can drastically reduce the likelihood of accidents, which in turn minimizes costly downtime and maintenance expenses. Moreover, by adhering to established types of equipment inspections—be it visual checks or functional testing—organizations can maintain high operational standards while avoiding legal repercussions.

Future Trends in Equipment Inspections

Looking ahead, the landscape of equipment inspection is set for transformation through technological advancements. Innovations such as AI-driven predictive analytics and remote monitoring tools are expected to streamline the inspection process, making it more efficient than ever before. Additionally, as industries face evolving challenges related to compliance and safety regulations, embracing these technologies will help tackle common equipment inspection challenges head-on.

Final Thoughts on Safety and Compliance

In conclusion, prioritizing equipment inspection best practices is essential for any organization aiming for long-term success. By establishing a clear schedule for when to conduct equipment inspections and ensuring that personnel are well-trained in spotting potential issues, businesses can cultivate a proactive safety culture. Ultimately, investing time and resources into effective equipment inspections not only safeguards employees but also fortifies an organization’s reputation in an increasingly competitive landscape.