Introduction

In today's global marketplace, maintaining high standards of quality is paramount, especially for businesses sourcing products from China. With a reputation for both innovation and mass production, the importance of quality control in China cannot be overstated. Effective quality management ensures that products not only meet but exceed international standards, safeguarding brand reputation and customer satisfaction.

Importance of Quality Control in China

Quality control is essential in the manufacturing landscape of China, where diverse industries thrive and competition is fierce. Companies must implement robust quality assurance practices to mitigate risks associated with product defects and inconsistencies. By prioritizing QC quality control measures, businesses can enhance their operational efficiency and build lasting relationships with clients.

Key Role of Product Inspection Services

Product inspection services play a critical role in ensuring that goods meet specified standards before they reach consumers. These services act as a safety net, identifying potential issues during various stages of production through rigorous quality inspections. By leveraging these inspections, companies can foster trust among stakeholders and ensure compliance with international regulations.

Choosing the Right Inspection Company

Selecting the right inspection company is crucial for effective quality assurance and maintaining product integrity throughout the supply chain. Not all product inspection companies in China offer the same level of expertise or reliability; thus, thorough research is necessary to find a partner that aligns with your specific needs. A well-chosen inspection service can provide invaluable insights into your manufacturing processes while ensuring adherence to stringent quality management protocols.

Understanding Quality Control Fundamentals

Quality control and quality assurance are the cornerstones of effective manufacturing processes, especially in a dynamic landscape like China. The nuances of these concepts are essential for companies seeking to maintain high standards and ensure customer satisfaction. By understanding quality management principles, businesses can leverage the expertise of product inspection companies in China to enhance their operations.

Definitions of Quality Assurance and Quality Control

Quality assurance (QA) refers to the systematic processes and activities designed to ensure that products meet specified requirements throughout their development and production phases. In contrast, quality control (QC) focuses on the operational techniques and activities used to fulfill quality requirements during manufacturing. Together, QA and QC form an integrated approach that guarantees consistent product quality through rigorous standards set by various product inspection companies in China.

Differences Between Quality Assurance and Quality Control

While both quality assurance and quality control aim to improve product reliability, they differ significantly in focus and methodology. QA is proactive; it emphasizes preventing defects through planned processes before production begins, whereas QC is reactive; it involves inspecting products after they are manufactured to identify any issues that may arise. Understanding these differences is crucial for manufacturers looking to implement effective strategies with the help of QC quality control specialists from reputable product inspection companies in China.

Importance of Quality Management in Manufacturing

Quality management plays a pivotal role in ensuring that manufacturing processes are efficient, cost-effective, and capable of producing high-quality products consistently. By integrating both quality assurance inspections and robust QC practices, companies can mitigate risks associated with international trade while enhancing customer trust. Ultimately, effective quality management not only bolsters a company’s reputation but also positions it favorably within competitive markets dominated by leading product inspection companies in China.

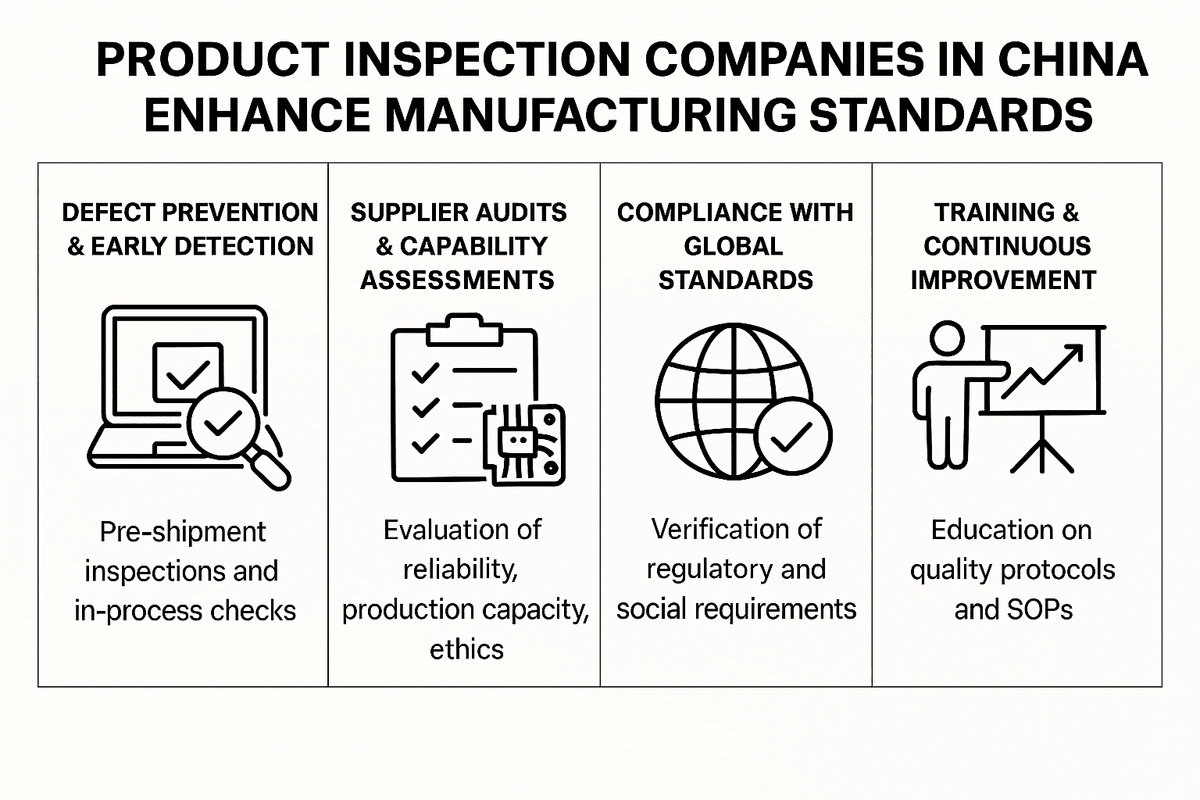

The Landscape of Product Inspection Companies in China

Navigating the realm of product inspection companies in China can feel like finding a needle in a haystack, especially for businesses looking to ensure quality control and quality assurance. With the vast number of firms available, it's crucial to understand which ones stand out and how they can support effective quality management. This section will explore leading inspection companies, highlight notable services from China Inspection Pro, and offer guidance on selecting the right partner for your needs.

Overview of Leading Inspection Companies

China is home to numerous product inspection companies that cater to diverse industries and standards. Some of the leading firms include SGS, Bureau Veritas, and Intertek, each known for their robust quality assurance protocols and comprehensive QC quality control processes. These companies provide a range of services from factory audits to detailed quality inspections, ensuring that products meet both domestic and international standards.

The competition among these inspection giants has led to significant advancements in technology and methodologies used in quality management. Many firms now leverage cutting-edge tools such as AI-driven analytics and real-time reporting systems to enhance their service offerings. Consequently, businesses can expect more reliable results that facilitate smoother international trade operations while maintaining high-quality standards.

Notable Services Offered by China Inspection Pro

China Inspection Pro has carved out a niche within the crowded landscape by offering tailored solutions designed to meet specific client needs. Their notable services encompass various stages of production including pre-production inspections, during production checks, and pre-shipment assessments—all vital components of effective quality assurance inspections. By focusing on these critical phases, they help clients mitigate risks associated with sourcing products from overseas manufacturers.

In addition to traditional inspection services, China Inspection Pro also provides specialized offerings such as factory audits and compliance testing for specific regulations or certifications required by different markets. Their expertise extends across multiple sectors including textiles, electronics, toys, and consumer goods—ensuring that clients receive well-rounded support throughout their supply chain journey. This comprehensive approach not only enhances product reliability but also fosters trust between manufacturers and buyers.

Choosing the Right Product Inspection Company

Selecting the right product inspection company is essential for achieving effective quality control in your manufacturing process. Start by assessing your specific needs: consider factors like industry type, volume requirements, and geographic location when researching potential partners among product inspection companies in China. It's important to look beyond just cost; evaluate their experience level with your particular products or sector as well as their reputation within the industry.

Additionally, seek out testimonials or case studies that showcase how previous clients have benefited from their services—this can provide valuable insights into their capabilities regarding quality management practices. Don’t hesitate to engage directly with potential partners; ask questions about their QC processes or inquire about technologies they employ during inspections for added clarity on what you can expect from them moving forward.

Types of Quality Inspections

In the realm of quality management, understanding the various types of inspections is crucial for manufacturers and importers alike. Quality control is not a one-size-fits-all process; it requires tailored approaches depending on different stages of production. This section delves into three key types of quality inspections that product inspection companies in China typically offer: pre-production, during production, and pre-shipment inspections.

Pre-production Inspection

Pre-production inspection is a vital step in the quality assurance process that occurs before manufacturing begins. This type of inspection involves assessing raw materials and components to ensure they meet specified standards and requirements. By engaging in this early phase, businesses can mitigate risks associated with poor-quality inputs, ultimately enhancing their overall quality control efforts.

During pre-production inspections, product inspection companies in China evaluate suppliers’ capabilities and verify compliance with industry standards. This proactive approach not only helps identify potential issues but also fosters a collaborative relationship between manufacturers and suppliers. When quality assurance is prioritized from the outset, it sets the stage for smoother production processes down the line.

During Production Inspection

Once manufacturing kicks off, during production inspections come into play to maintain quality assurance throughout the entire process. These inspections focus on monitoring production lines to ensure that products are being made according to specifications and within acceptable tolerances. By identifying defects or deviations early on, companies can address problems before they escalate into costly setbacks.

Product inspection companies in China provide real-time feedback during this phase, allowing manufacturers to make immediate corrections if needed. This ongoing scrutiny not only enhances product reliability but also reinforces a culture of quality management within factories. Ultimately, during production inspections serve as an essential checkpoint that aligns manufacturing practices with established quality control protocols.

Pre-shipment Inspection

Pre-shipment inspection is often seen as the final line of defense in ensuring product integrity before goods leave for international markets. This type of inspection involves a thorough examination of finished products to confirm they meet all agreed-upon specifications and standards prior to shipping. It acts as a safety net for importers by verifying that what they ordered matches what’s being sent.

Engaging reputable product inspection companies in China for pre-shipment inspections can significantly reduce risks associated with international trade such as returns or disputes over defective goods. These inspections typically include checks on packaging integrity, labeling accuracy, and overall presentation—all vital elements that impact customer satisfaction upon delivery. In essence, pre-shipment inspections bolster confidence in global trade by ensuring that products meet both regulatory requirements and consumer expectations.

Benefits of Quality Assurance Inspections

Quality assurance inspections play a pivotal role in ensuring that products meet established standards before they hit the market. With the rise of international trade, particularly involving product inspection companies in China, understanding these benefits is essential for businesses looking to maintain a competitive edge. From risk mitigation to cost savings, quality control and quality assurance practices are integral to successful manufacturing and distribution.

Risk Mitigation for International Trade

Risk mitigation is one of the most significant advantages of implementing quality assurance inspections. When dealing with product inspection companies in China, businesses can identify potential issues early in the production process, thus reducing the likelihood of costly recalls or legal disputes down the line. By prioritizing quality management through rigorous qc quality control measures, companies foster safer trading environments and enhance their reputations globally.

Moreover, with effective quality control and quality assurance strategies in place, businesses can navigate complex regulatory landscapes more efficiently. This proactive approach minimizes risks associated with non-compliance and helps ensure that products meet both domestic and international standards. Ultimately, investing in thorough quality inspections translates into smoother transactions and reduced uncertainties in global markets.

Enhancing Product Reliability and Trust

Another key benefit of quality assurance inspections is the enhancement of product reliability and trust among consumers. When customers see that a company consistently utilizes reputable product inspection companies in China for their qc quality control processes, it builds confidence in their offerings. Quality management doesn't just protect businesses; it also safeguards consumers by ensuring they receive safe and reliable products.

In an age where consumer trust is paramount, demonstrating commitment to high-quality standards can set a brand apart from competitors. Companies that prioritize thorough quality inspection protocols are more likely to cultivate loyal customer bases who appreciate transparency regarding product safety and reliability. In essence, effective quality assurance fosters brand credibility that resonates well beyond initial purchases.

Cost Savings Through Early Detection

Cost savings through early detection are perhaps one of the most appealing benefits of engaging with professional product inspection services before products reach consumers' hands. By identifying defects or inconsistencies during various stages—be it pre-production or during production—businesses can avoid expensive last-minute fixes or full-scale recalls later on. The financial implications of not addressing these issues early on can be staggering; thus integrating strict qc quality control measures saves money over time.

Additionally, investing in comprehensive quality assurance inspection processes often leads to improved operational efficiency within manufacturing facilities. Streamlining production lines based on feedback from inspections reduces waste while enhancing productivity levels overall—a win-win situation! Ultimately, these cost-saving measures contribute significantly to healthier profit margins as well as sustainable business practices.

The Process of Quality Inspection

Quality inspection is a critical component of quality management, especially in the realm of international trade. The process ensures that products meet specified standards before they reach consumers, minimizing risks associated with defects or non-compliance. Understanding the steps involved in quality control can help businesses choose the right product inspection companies in China to safeguard their interests.

Steps Involved in Quality Control

The journey of quality control begins with defining clear quality standards relevant to the product being manufactured. Once these standards are established, product inspection companies in China will typically conduct a series of inspections at various stages: pre-production, during production, and pre-shipment. Each step is designed to identify potential issues early on, allowing for timely interventions that save time and costs associated with rectifying defects later.

During the pre-production phase, initial samples are evaluated against specifications to ensure compliance before mass production starts. Next comes the during-production inspection (DPI), where inspectors monitor ongoing manufacturing processes for adherence to quality assurance practices and detect any deviations from expected outcomes. Finally, a pre-shipment inspection (PSI) is conducted to verify that finished goods meet all agreed-upon criteria before they leave the factory—this step is crucial for maintaining brand reputation and consumer trust.

Tools and Technologies Used for Inspections

Modern quality assurance inspections have evolved significantly thanks to advancements in technology. Product inspection companies in China now utilize a variety of tools ranging from simple checklists to sophisticated software solutions that facilitate real-time monitoring of production lines. These technologies help streamline the inspection process by enhancing accuracy and efficiency while ensuring compliance with international standards.

Some common tools include digital measuring instruments for assessing dimensions and tolerances, as well as automated systems that can track defects during manufacturing runs. Additionally, software platforms enable inspectors to compile data quickly and generate reports on-the-fly—this integration of technology into quality control processes represents a significant leap forward for effective quality management practices in manufacturing environments.

Reporting and Feedback Mechanisms

Once inspections are completed, it’s essential that findings are communicated clearly through structured reporting mechanisms. Quality assurance inspections typically generate detailed reports outlining any discrepancies found during evaluations along with recommendations for corrective actions needed before proceeding further down the supply chain. This feedback loop not only aids manufacturers but also builds trust between suppliers and clients by demonstrating commitment to maintaining high-quality standards.

Moreover, product inspection companies in China often provide follow-up assessments based on previous reports' findings to ensure continuous improvement over time—a hallmark of effective quality management systems. By fostering open communication channels about potential issues encountered during inspections, businesses can create an environment conducive to ongoing enhancements across all aspects related to quality control.

Conclusion

Quality control and quality assurance are not just buzzwords; they are the backbone of successful manufacturing, especially in a bustling hub like China. The significance of maintaining consistent product quality cannot be overstated, as it directly impacts customer satisfaction and brand reputation. By leveraging the expertise of product inspection companies in China, businesses can ensure that their products meet the highest standards before reaching the market.

Ensuring Consistent Product Quality

Ensuring consistent product quality is paramount for any business aiming to thrive in today’s competitive landscape. Quality management systems that incorporate both quality assurance and quality control help identify potential issues early, allowing for timely interventions. By implementing rigorous quality inspections at various stages of production, companies can maintain high standards and mitigate risks associated with defective products.

The Value of Third-Party Inspections

Third-party inspections offer an unbiased perspective on product quality that in-house teams may overlook due to familiarity or internal biases. Engaging reputable product inspection companies in China provides businesses with access to specialized knowledge and resources tailored to specific industries. This external validation not only enhances credibility but also strengthens relationships with international partners by demonstrating a commitment to quality assurance.

Building Trust in Global Trade Through Quality Control

In an era where global trade is more interconnected than ever, building trust is crucial for long-term business success. Quality control practices foster reliability among consumers and partners alike, ensuring that products meet expectations consistently across borders. By prioritizing quality assurance inspections, businesses can cultivate a reputation for excellence that resonates well beyond their immediate markets.