Introduction

In a world where food safety is paramount, understanding food packaging testing is crucial for manufacturers, suppliers, and consumers alike. Food packaging serves as the first line of defense against contamination and spoilage, making rigorous testing essential to ensure that materials are safe and effective. As we delve into the complexities of this field, we will uncover how third party inspection services play a vital role in maintaining high standards of quality and compliance.

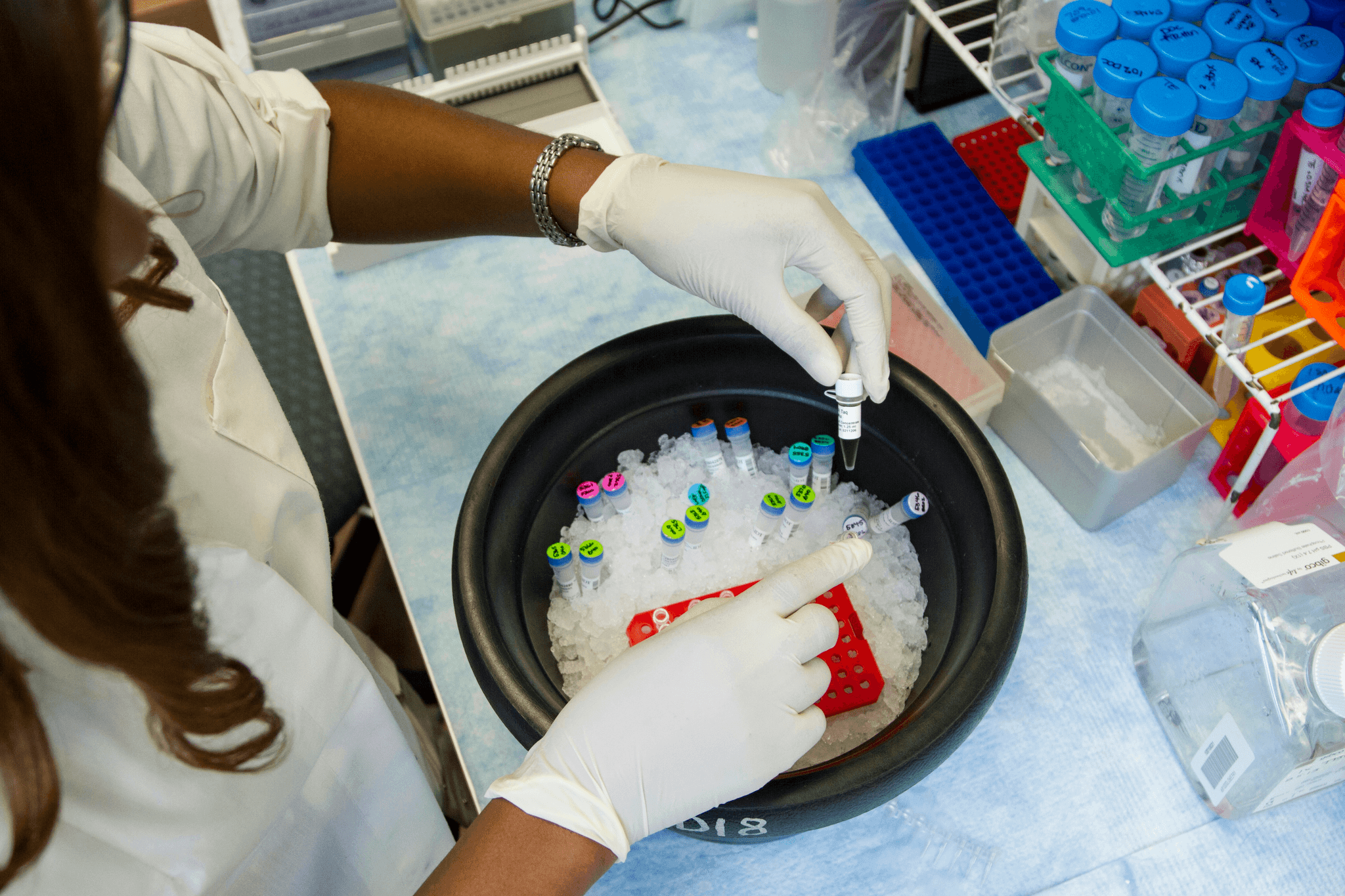

Understanding Food Packaging Testing

Food packaging testing encompasses a variety of assessments designed to evaluate the safety and integrity of materials used in packaging food products. This process involves rigorous examination to identify potential hazards that could compromise consumer health or product quality. By adhering to established protocols and standards, manufacturers can ensure their products meet regulatory requirements while also satisfying consumer expectations for safety.

Importance of Safety in Food Packaging

The importance of safety in food packaging cannot be overstated; it directly impacts public health and trust in food products. Unsafe packaging materials can lead to contamination, spoilage, or even toxic reactions when they come into contact with food items. By prioritizing safety through comprehensive testing methods, businesses not only protect consumers but also uphold their brand reputation within a competitive marketplace.

Role of Third Party Inspection Services

Third party inspection services offer an unbiased perspective on the quality and safety of food packaging materials, acting as an essential safeguard against potential risks associated with supplier quality roles and responsibilities. These agencies conduct thorough assessments based on industry standards, ensuring compliance with regulations while providing valuable insights into manufacturing quality inspection processes. By utilizing a reputable third party inspection agency list, companies can streamline their operations while enhancing consumer confidence through verified safety measures.

Overview of Food Packaging Testing

Food packaging testing serves as a critical safeguard in ensuring that the materials used to contain our food are safe, effective, and compliant with industry standards. In an era where consumer awareness regarding safety is at an all-time high, understanding the essential standards and regulations that govern food packaging is paramount. This section will explore these aspects, shedding light on why rigorous testing is indispensable for both manufacturers and consumers.

Essential Standards and Regulations

The landscape of food packaging testing is shaped by a myriad of essential standards and regulations designed to protect public health. Organizations such as the FDA (Food and Drug Administration) in the United States or EFSA (European Food Safety Authority) in Europe establish guidelines that dictate what materials can be used in food contact applications. Compliance with these regulations not only ensures safety but also enhances brand reputation, making it crucial for suppliers to be well-versed in their roles and responsibilities regarding quality assurance.

Moreover, third party inspection services play a pivotal role in verifying compliance with these standards through rigorous assessments. They help manufacturers navigate the complex web of regulations while ensuring that their products adhere to safety protocols before reaching consumers. By regularly consulting the third party inspection agency list, businesses can identify reputable organizations equipped to conduct comprehensive evaluations of their food packaging materials.

Types of Tests Conducted

When it comes to food packaging testing, various types of tests are conducted to assess different aspects of packaging performance and safety. These tests include migration testing, which evaluates how substances from packaging materials may transfer into food under specific conditions; physical testing that examines durability; and mechanical testing focused on structural integrity during handling and transportation. Each type of test serves a unique purpose but collectively ensures that products meet established safety benchmarks.

Additionally, shelf-life evaluation techniques are employed to determine how long products maintain their quality under varying storage conditions—an essential factor for both manufacturers and retailers alike. Understanding these diverse types of tests allows suppliers to take proactive measures in meeting compliance requirements while safeguarding consumer health through effective manufacturing quality inspection practices.

Why Testing is Crucial for Safety

Testing plays an indispensable role in maintaining safety within the food supply chain by identifying potential risks before they reach consumers' hands. With increasing scrutiny from regulatory bodies and heightened consumer expectations regarding product quality, thorough examination through food packaging testing has never been more vital. It not only protects public health but also builds trust between brands and consumers—a trust built on transparency about supplier quality roles and responsibilities.

In this context, third party inspection services serve as an additional layer of assurance by providing unbiased evaluations that reinforce adherence to safety protocols. Their expertise helps mitigate risks associated with non-compliance or substandard materials while enhancing overall product integrity—ultimately leading towards safer consumption experiences for everyone involved.

Key Players in Food Packaging Testing

In the world of food packaging testing, several key players ensure that products meet safety and quality standards. Understanding their roles is crucial for anyone involved in the supply chain, from manufacturers to consumers. This section will explore the vital contributions of third-party inspection agencies, supplier quality roles and responsibilities, and a spotlight on China Inspection Pro.

The Role of Third Party Inspection Agencies

Third party inspection agencies are the gatekeepers of food packaging testing, ensuring compliance with various regulations and standards. These organizations conduct unbiased evaluations, providing an essential layer of trust between manufacturers and consumers. By utilizing third party inspection services, companies can confidently assure their customers that their packaging meets safety requirements.

These agencies perform a variety of tests on food packaging materials to evaluate factors such as migration potential, physical integrity, and overall safety. Their expertise is invaluable in identifying potential risks before products hit the shelves. Moreover, by being listed on a reputable third party inspection agency list, these organizations enhance their credibility in the industry.

In an increasingly global market where regulations can vary widely, third party inspection agencies play a critical role in harmonizing safety practices across borders. They help businesses navigate complex regulatory landscapes while ensuring that food packaging testing remains consistent and reliable. Ultimately, these agencies contribute significantly to consumer confidence by guaranteeing that only safe products reach the market.

Supplier Quality Roles and Responsibilities

Supplier quality roles and responsibilities are pivotal in maintaining high standards throughout the food packaging supply chain. Suppliers must adhere to stringent guidelines regarding material sourcing and production processes to ensure compliance with food safety regulations. This responsibility extends beyond just providing materials; it involves active participation in ongoing quality assurance efforts.

Effective communication between suppliers and manufacturers is essential for successful food packaging testing outcomes. Suppliers should be well-versed in applicable regulations so they can provide necessary documentation during inspections or audits conducted by third-party agencies. When suppliers take ownership of their quality roles, it reduces risks associated with non-compliance and enhances overall product integrity.

Additionally, implementing robust supplier quality management systems can streamline processes related to manufacturing quality inspection protocols. This proactive approach helps identify potential issues early on before they escalate into costly problems down the line—ultimately safeguarding both brand reputation and consumer health.

A Look at the China Inspection Pro

China Inspection Pro has emerged as a prominent player within the realm of food packaging testing services tailored specifically for businesses operating in or sourcing from China. With a strong focus on ensuring compliance with international standards while navigating local regulatory complexities, this agency offers invaluable support for companies looking to maintain high-quality benchmarks throughout their production processes.

What sets China Inspection Pro apart is its comprehensive suite of services that encompass everything from factory audits to detailed product inspections—all designed around enhancing manufacturing quality inspection practices among Chinese suppliers. Their team possesses deep knowledge about both domestic laws and global requirements governing food packaging materials—making them an indispensable partner for any business seeking reliable insights into local markets.

By choosing an agency like China Inspection Pro from your third party inspection agency list, you gain access not only to expert evaluations but also tailored solutions aimed at mitigating risks associated with importing goods from overseas markets—leading ultimately toward enhanced consumer trust through rigorous adherence to established safety measures surrounding food packaging testing.

Common Testing Methods for Food Packaging

When it comes to food packaging testing, a variety of methods are employed to ensure safety and compliance. These methods help identify potential hazards and assess the overall integrity of packaging materials. Understanding these common testing techniques is essential for anyone involved in supplier quality roles and responsibilities.

Migration Testing Explained

Migration testing is a crucial aspect of food packaging testing that examines how substances from the packaging material may transfer into the food product itself. This process assesses whether harmful chemicals or additives could migrate from the package into the food, potentially posing health risks to consumers. By utilizing third party inspection services, manufacturers can validate that their products meet stringent safety standards, ensuring consumer confidence.

The results from migration tests inform suppliers about any necessary adjustments in materials or design to minimize risks. Regulatory bodies often require these tests before granting approval for new packaging solutions. Thus, migration testing is not just a formality; it’s an essential step in safeguarding public health.

Physical and Mechanical Testing

Physical and mechanical testing evaluates the structural integrity of food packaging materials under various conditions. This includes assessing factors such as tensile strength, puncture resistance, and seal integrity—critical elements that determine how well a package can protect its contents during transportation and storage. Third party inspection agencies often conduct these tests to provide unbiased evaluations that manufacturers can trust.

These tests also help identify weaknesses in packaging designs that could lead to product spoilage or contamination over time. By adhering to rigorous physical and mechanical standards, companies can enhance their manufacturing quality inspection processes significantly. Ultimately, this type of testing contributes greatly to ensuring that consumers receive products in optimal condition.

Shelf-Life Evaluation Techniques

Shelf-life evaluation techniques focus on determining how long packaged foods remain safe for consumption while maintaining their quality attributes like taste, texture, and nutritional value. This involves simulating various environmental conditions—such as temperature fluctuations and humidity levels—to observe how they affect the food over time within its packaging. Proper shelf-life assessments are vital for suppliers in understanding when their products might start degrading.

By employing third party inspection services for shelf-life studies, companies gain objective insights into their product's longevity which helps them make informed decisions about marketing timelines and inventory management strategies. Additionally, this information plays a significant role in regulatory compliance since many jurisdictions require documented evidence of shelf-life data before products hit shelves.

In conclusion, understanding these common testing methods not only equips manufacturers with vital knowledge but also reinforces their commitment to safety through effective supplier quality roles and responsibilities.

Challenges in Food Packaging Safety

The landscape of food packaging safety is fraught with challenges that can jeopardize both consumer health and brand integrity. One of the most pressing issues is identifying potential risks associated with materials and processes used in food packaging testing. These risks can arise from chemical migration, contamination, or even physical defects, making it essential for companies to adopt a proactive approach to mitigate them.

Identifying Potential Risks

When it comes to food packaging testing, identifying potential risks is akin to finding a needle in a haystack. The myriad of materials used—plastics, papers, metals—each come with their own set of challenges and safety concerns. Companies must conduct thorough assessments that include migration testing and other analytical methods to detect harmful substances before they reach consumers.

Moreover, the complexity increases when considering various environmental factors that could affect packaging integrity over time. For instance, temperature fluctuations during transit can lead to material degradation or compromised seals, which may not be immediately apparent without rigorous manufacturing quality inspection processes in place. Therefore, understanding supplier quality roles and responsibilities becomes crucial; suppliers must be aware of these potential pitfalls and work closely with third party inspection services to ensure compliance.

Keeping Up with Regulations

Navigating the labyrinthine world of regulations surrounding food packaging safety can feel like trying to read an ancient scroll without a Rosetta Stone. With guidelines constantly evolving across different jurisdictions, keeping up-to-date is not just advisable; it’s essential for compliance and consumer trust. Third party inspection agencies play an invaluable role here by providing insights into current regulations while also offering services that help manufacturers meet these standards effectively.

Regulatory bodies often introduce new requirements based on emerging scientific research or consumer advocacy efforts aimed at improving safety standards in food packaging testing. This dynamic environment necessitates ongoing education for all stakeholders involved—from manufacturers to suppliers—to ensure they adhere to best practices while minimizing risks associated with non-compliance. Failing to stay informed could result not only in financial penalties but also damage reputations built over years.

Ensuring Supplier Compliance

Ensuring supplier compliance is another hurdle that companies face within the framework of food packaging safety challenges. Suppliers are integral players whose materials directly impact the quality and safety of packaged products; thus, their adherence to established guidelines cannot be overlooked. Regular audits conducted by third party inspection agencies are vital for maintaining oversight on supplier practices while also fostering accountability among all parties involved.

In addition, establishing clear communication channels regarding expectations helps clarify supplier quality roles and responsibilities within the larger ecosystem of food production and distribution. By actively engaging suppliers through training programs or workshops focused on regulatory updates and best practices in manufacturing quality inspection, companies can significantly reduce risks associated with non-compliance down the line. Ultimately, ensuring robust supplier partnerships is key for creating safer food packaging solutions that consumers can trust.

How to Choose a Third Party Inspection Agency

Choosing the right third party inspection agency is crucial for ensuring the safety and compliance of your food packaging testing. With a plethora of options available, it can be daunting to sift through the third party inspection agency list to find one that meets your specific needs. However, understanding what to look for can simplify this process and help you make an informed decision.

Evaluating the Third Party Inspection Agency List

When evaluating the third party inspection agency list, start by checking their credentials and certifications. Look for agencies that are accredited by recognized bodies, as this often indicates a commitment to quality and adherence to industry standards in food packaging testing. Additionally, consider their experience in your specific sector; agencies with a proven track record in food packaging are more likely to understand the nuances involved in supplier quality roles and responsibilities.

Another important factor is customer feedback; reviews from previous clients can reveal much about an agency's reliability and effectiveness. Pay attention to how they handle challenges or issues that arise during inspections—this speaks volumes about their professionalism and dedication. Ultimately, compiling a shortlist based on these criteria will set you on the right path toward selecting a competent inspection partner.

Key Qualities to Look For

Not all third party inspection services are created equal, so it's essential to identify key qualities that distinguish top-tier agencies from mediocre ones. First and foremost, look for expertise in food packaging testing; they should have staff with relevant qualifications and experience in conducting various types of tests effectively. Furthermore, excellent communication skills are vital; you want an agency that keeps you informed throughout the process while being responsive to your queries.

Another quality worth noting is flexibility; your chosen agency should be willing to adapt their services based on your unique requirements or unexpected challenges that may arise during inspections. Additionally, consider their technological capabilities—agencies utilizing advanced testing methods can deliver more accurate results faster than those relying solely on traditional approaches. By focusing on these attributes, you'll be better equipped to select an agency that aligns with your goals.

The Importance of Manufacturing Quality Inspection

Manufacturing quality inspection plays a pivotal role in ensuring that food packaging meets safety standards before reaching consumers' hands. This process not only verifies compliance with regulations but also helps identify potential risks associated with materials used in packaging—an essential aspect of food packaging testing. By investing time into thorough inspections conducted by qualified third party agencies, companies can significantly reduce liability issues while enhancing overall product integrity.

Moreover, effective manufacturing quality inspections contribute directly to consumer confidence; when customers trust that products have been rigorously tested for safety and compliance, they are more likely to remain loyal brand advocates. This loyalty translates into long-term business success as satisfied customers share their positive experiences with others—word-of-mouth marketing at its finest! Therefore, prioritizing high-quality manufacturing inspections should be non-negotiable for any organization committed to excellence.

Conclusion

In the ever-evolving landscape of food packaging testing, the future promises to be both challenging and exciting. As consumer awareness grows, the demand for stringent safety measures and compliance will only increase. Innovations in technology and testing methods will play a crucial role in ensuring that food packaging meets the highest standards of quality and safety.

The Future of Food Packaging Testing

The future of food packaging testing is set to embrace cutting-edge technologies such as artificial intelligence and automation, which can streamline processes and enhance accuracy. Third party inspection services will likely become more integral, providing an additional layer of trust in an industry that demands transparency. As regulations continue to evolve globally, staying updated on the third party inspection agency list will be essential for manufacturers looking to maintain compliance.

Enhancing Consumer Confidence Through Safety

Consumer confidence hinges on the assurance that products are safe from harmful substances, making effective food packaging testing indispensable. By prioritizing supplier quality roles and responsibilities, companies can foster a culture of accountability that resonates with consumers. When customers know their favorite products undergo rigorous safety checks, it reinforces their trust in brands committed to quality.

Final Thoughts on Quality and Compliance

In conclusion, maintaining high standards in food packaging testing is not just about compliance; it's about safeguarding public health and enhancing brand reputation. Manufacturers must prioritize manufacturing quality inspection as a means to ensure that every product leaving their facility meets or exceeds expectations. As we look ahead, collaboration between stakeholders—manufacturers, suppliers, and third party inspection agencies—will be vital for achieving long-term success in ensuring safe food packaging.