Introduction

In today's fast-paced technological landscape, the testing of electronic components has become a cornerstone of product development and manufacturing. Quality control is not just a checkbox in the production process; it ensures reliability, safety, and performance in an increasingly competitive market. As companies strive for excellence, understanding industry standards and certifications becomes crucial to maintaining product integrity while navigating the complexities of supply chain digitization.

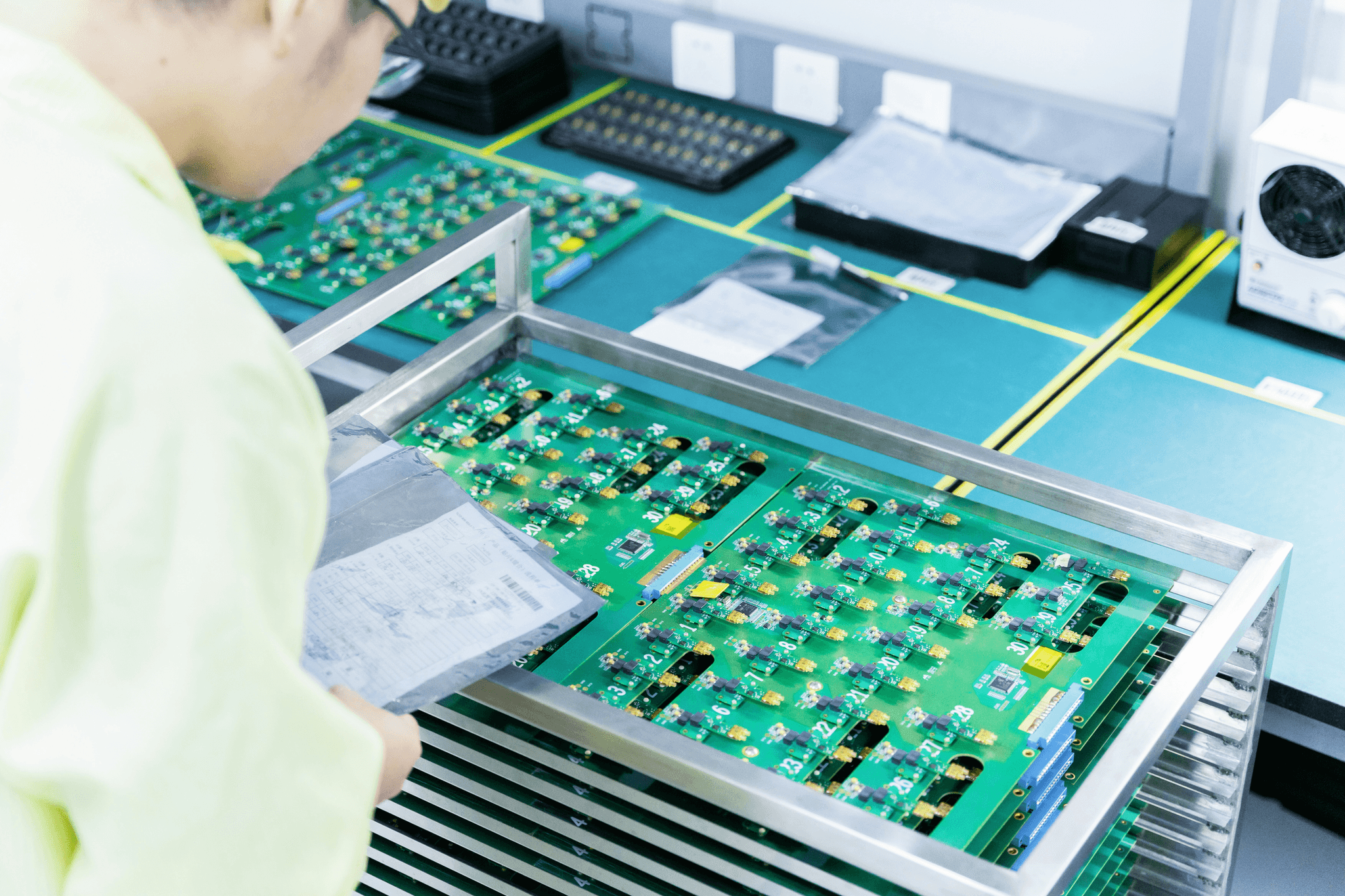

Importance of Testing Electronic Components

The testing of electronic components plays a vital role in ensuring that products meet both consumer expectations and regulatory requirements. Without rigorous testing protocols, manufacturers risk producing faulty products that can lead to significant financial losses and reputational damage. Additionally, effective quality control processes help identify potential issues early on, allowing companies to address them before they escalate into larger problems down the line.

Overview of Industry Standards

Industry standards provide a framework for the testing of electronic components, ensuring consistency and reliability across various sectors. These standards evolve through regular regulatory updates to address emerging technologies and practices in electronics manufacturing. Staying informed about these changes is essential for companies aiming to maintain compliance while optimizing their quality control measures.

Key Players in Testing Services

In the realm of electronic component testing, several key players dominate the landscape by offering specialized services tailored to meet industry demands. These organizations not only conduct thorough supplier audits but also assist manufacturers in navigating certification processes that are critical for market access. By collaborating with reputable testing service providers, companies can enhance their quality control efforts and streamline their supply chain digitization initiatives.

The Role of Quality Control in Testing

Quality control is the backbone of the testing of electronic components, ensuring that products meet stringent standards before they reach consumers. Without effective quality control measures, manufacturers risk delivering unreliable products that could lead to safety hazards and financial losses. By implementing rigorous testing protocols, companies can enhance their reputations and foster customer trust.

Ensuring Product Reliability

Product reliability is paramount in the electronics industry, where even minor failures can result in catastrophic consequences. Quality control processes involve systematic testing of electronic components to identify defects early, thus preventing costly recalls or repairs later on. By prioritizing reliability through meticulous testing practices, companies not only comply with certifications but also build long-term relationships with clients who value dependable products.

Impact on Supply Chain Digitization

The digitization of supply chains has transformed how quality control is implemented within the electronics sector. With advanced data analytics and real-time monitoring systems, manufacturers can track the quality of their components throughout the production process, leading to enhanced efficiency and reduced waste. This integration allows for quicker regulatory updates and compliance checks while also facilitating supplier audits that ensure adherence to quality standards.

Case Study: China Inspection Pro

China Inspection Pro serves as a prime example of effective quality control in action within the electronics industry. This organization specializes in conducting thorough inspections and certifications for various electronic components, helping businesses navigate complex regulatory landscapes. By leveraging technology and expertise in supplier audits, China Inspection Pro has successfully improved product reliability while promoting sustainability initiatives throughout its operations.

Understanding Certification Processes

Certification processes in the electronics industry are crucial for ensuring that products meet specific standards and regulations. These certifications not only enhance product credibility but also play a significant role in the testing of electronic components. As industries evolve, understanding the nuances of these certifications becomes paramount for manufacturers aiming to maintain quality control and compliance.

Types of Certifications in Electronics

In the realm of electronics, several key certifications stand out, including ISO 9001, UL certification, and CE marking. Each certification serves a distinct purpose; for instance, ISO 9001 focuses on quality management systems, while UL certification emphasizes safety standards for electronic devices. By obtaining these certifications, companies can demonstrate their commitment to quality control and provide assurance to customers regarding their products' reliability.

Moreover, specialized certifications like RoHS (Restriction of Hazardous Substances) are becoming increasingly important as sustainability takes center stage in manufacturing practices. These certifications not only validate compliance with environmental regulations but also highlight a company’s dedication to sustainable practices within their supply chain digitization efforts. Ultimately, understanding these various types of certifications is essential for navigating the complex landscape of electronic component testing.

Importance of Regulatory Updates

Regulatory updates play a critical role in shaping the certification landscape within the electronics industry. Staying informed about changes ensures that companies remain compliant with evolving standards which can directly impact their ability to market products globally. Regularly reviewing regulatory updates is vital not just for maintaining compliance but also for enhancing overall quality control measures.

Furthermore, these updates often reflect broader trends such as increased emphasis on sustainability and environmental responsibility in manufacturing processes. As regulations tighten around hazardous materials and waste management, businesses must adapt their testing protocols accordingly to meet new requirements while demonstrating commitment to sustainable practices. Ignoring regulatory updates can lead to costly penalties or product recalls—an outcome no manufacturer wants.

Navigating Compliance Challenges

Navigating compliance challenges is no small feat; it requires a strategic approach that incorporates thorough supplier audits and effective risk management strategies. Companies often face hurdles when trying to align existing processes with new regulations or when sourcing components from suppliers who may not meet required standards themselves. This makes it essential for businesses to conduct regular supplier audits that assess adherence to both quality control measures and certification requirements.

Additionally, organizations must be proactive in identifying potential compliance risks within their supply chains—especially as digitization continues reshaping how we manage supplier relationships today. By fostering open communication with suppliers about regulatory expectations and collaborating on solutions, companies can strengthen partnerships while ensuring adherence to necessary certifications across all levels of production. In this way, navigating compliance challenges becomes less about avoiding pitfalls and more about embracing opportunities for growth through enhanced collaboration.

Supplier Audits and Their Significance

Supplier audits play a crucial role in the testing of electronic components, ensuring that suppliers meet quality standards and regulatory requirements. These audits not only assess compliance but also help identify potential risks within the supply chain that could impact product reliability. By adopting effective audit practices, companies can enhance their quality control processes while fostering stronger relationships with their suppliers.

Best Practices for Conducting Audits

Conducting supplier audits effectively requires a well-structured approach that prioritizes transparency and communication. Start by establishing clear criteria based on industry standards and regulatory updates to guide the audit process, ensuring all necessary certifications are verified. Additionally, leveraging technology can streamline the auditing process, allowing for real-time data collection and analysis that supports informed decision-making regarding supplier performance.

Assessing Supplier Risk Management

Risk management is a fundamental aspect of supplier audits, particularly in the context of supply chain digitization. By evaluating a supplier's risk management strategies, companies can identify vulnerabilities that may affect the testing of electronic components or delay production timelines. Regular assessments not only mitigate risks but also provide insights into how suppliers adapt to changing regulations and market demands.

Strengthening Supplier Relationships

Supplier audits should not be viewed solely as compliance checks; they are opportunities to build trust and collaboration with key partners in your supply chain. Engaging suppliers in discussions about findings fosters an environment of continuous improvement where both parties can work together towards sustainability goals and enhanced quality control measures. Ultimately, nurturing these relationships leads to more resilient supply chains capable of adapting to future challenges.

Sustainable Testing Methods

In today's rapidly evolving landscape, the testing of electronic components requires a fresh perspective that embraces sustainability. The integration of sustainable practices into Quality Control not only addresses environmental concerns but also enhances the overall efficiency of the testing process. As organizations strive for greener operations, they find that sustainability can lead to significant cost savings and improved supplier relationships.

Integrating Sustainability into Quality Control

Integrating sustainability into Quality Control involves reevaluating traditional testing methods and adopting more eco-friendly practices. This shift can include utilizing energy-efficient equipment, reducing waste during the testing of electronic components, and employing sustainable materials in the development of test devices. By aligning their Quality Control processes with sustainability goals, companies can enhance their reputation while meeting regulatory updates and certifications that emphasize environmental responsibility.

Moreover, organizations are increasingly recognizing that sustainable practices in Quality Control contribute to supply chain digitization efforts. By implementing digital tools that track resource consumption and waste generation during testing, businesses can identify areas for improvement and reduce their carbon footprint effectively. Ultimately, this commitment to sustainability fosters a culture of continuous improvement in both product quality and environmental stewardship.

Green Practices in Electronic Testing

Green practices in electronic testing encompass a variety of strategies aimed at minimizing environmental impact while maintaining high standards for product reliability. One such practice is the adoption of non-toxic materials for component testing, which not only complies with regulatory updates but also aligns with consumer demand for safer products. Additionally, companies are increasingly investing in renewable energy sources to power their testing facilities, further reducing their ecological footprint.

Supplier audits play a crucial role in ensuring that partners adhere to green practices as well. By assessing suppliers’ commitment to environmental standards during audits, organizations can mitigate risks associated with non-compliance and strengthen relationships based on shared sustainability goals. This collaborative approach not only enhances trust between partners but also contributes to a more resilient supply chain.

Future Trends in Eco-Friendly Testing

The future of eco-friendly testing is bright as emerging technologies continue to reshape how we approach the testing of electronic components. Innovations such as AI-driven analytics will enable companies to optimize their processes by identifying inefficiencies and suggesting greener alternatives without compromising quality or accuracy. Furthermore, advancements in automation will streamline workflows while minimizing waste generated during tests.

As we look ahead, it's clear that regulatory updates will increasingly prioritize sustainability benchmarks within certifications related to electronic components. Companies will need to stay agile by adapting their Quality Control measures accordingly—ensuring compliance while embracing new green technologies as they emerge on the market. Ultimately, these trends point toward a future where sustainable practices become integral not just for compliance but also for driving competitive advantage.

Emerging Technologies in Testing

The landscape of testing electronic components is rapidly evolving, driven by innovations that enhance quality control and efficiency. As industries strive for sustainability and compliance with regulatory updates, emerging technologies play a pivotal role in shaping the future of testing. This section explores how AI, automation, and advanced methodologies are transforming the testing process.

AI and Machine Learning Applications

Artificial Intelligence (AI) and machine learning are revolutionizing the testing of electronic components by providing data-driven insights that improve accuracy and efficiency. These technologies can analyze vast amounts of data from previous tests to identify patterns, predict potential failures, and optimize testing procedures. By integrating AI into quality control processes, companies can significantly reduce errors while ensuring that their products meet necessary certifications.

Moreover, machine learning algorithms can adapt over time, refining their predictive capabilities based on real-time data from ongoing supplier audits. This adaptability not only enhances the reliability of electronic components but also streamlines supply chain digitization efforts by quickly identifying areas for improvement or compliance challenges. In an era where regulatory updates are frequent, leveraging AI ensures that organizations remain ahead in maintaining standards.

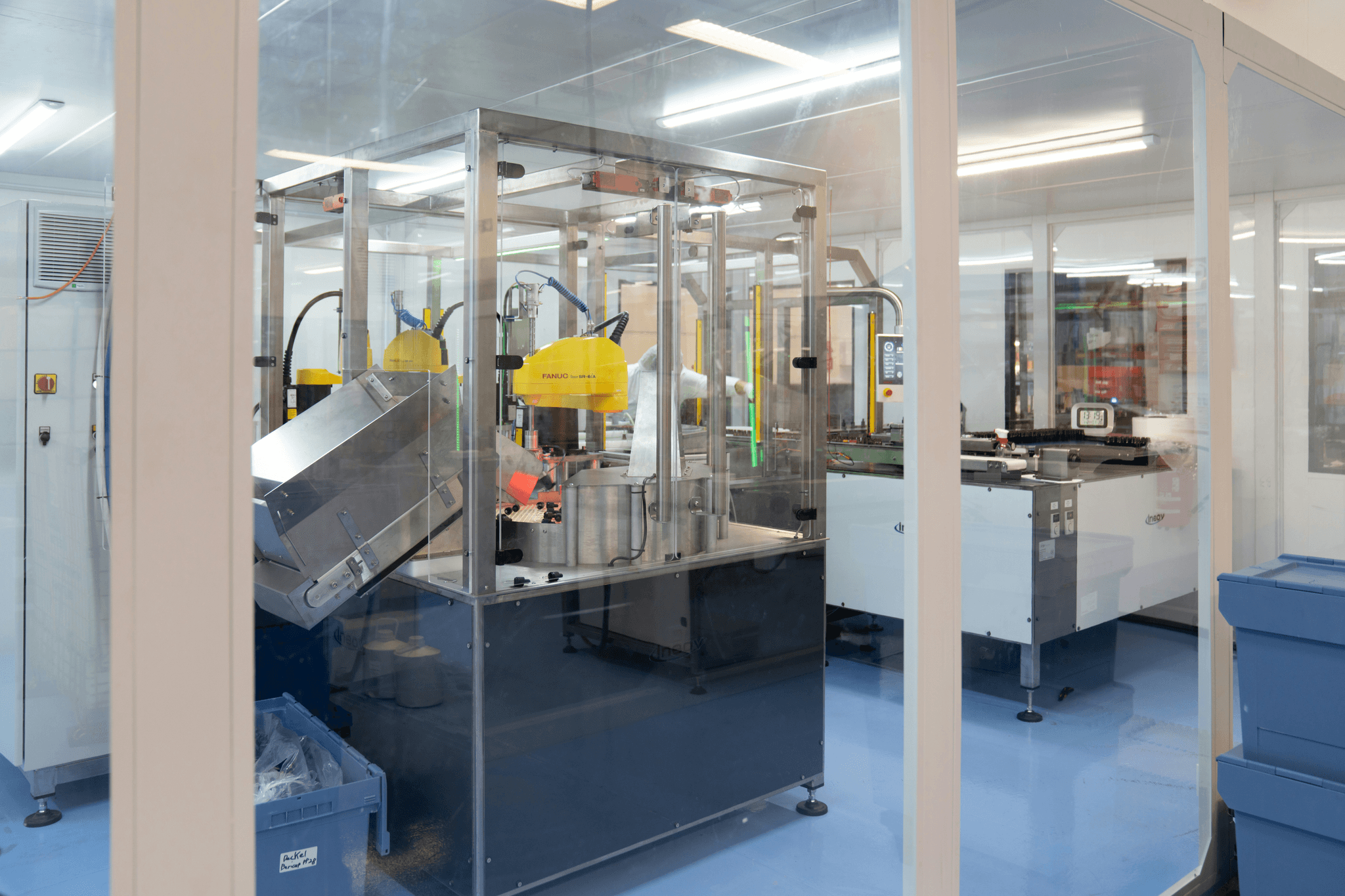

Automation in Testing Procedures

Automation has become a cornerstone in the modern approach to the testing of electronic components, allowing for faster turnaround times without sacrificing quality control. Automated systems can execute repetitive tasks with precision while minimizing human error—critical factors when adhering to stringent certifications required by regulators. As companies embrace automation within their processes, they find themselves better equipped to manage supplier audits effectively.

The integration of automated solutions also facilitates seamless documentation and reporting during tests, making it easier to navigate compliance challenges associated with regulatory updates. Furthermore, automated systems can be programmed to adhere to sustainable practices—reducing waste and energy consumption during testing phases while still meeting rigorous industry standards. Thus, automation not only boosts efficiency but also aligns with growing demands for sustainability in manufacturing.

Enhancing Accuracy and Efficiency

Emerging technologies are fundamentally enhancing both accuracy and efficiency within the realm of electronic component testing—a necessity given today's fast-paced market demands. Advanced tools equipped with sensors provide real-time monitoring capabilities during tests; this not only allows for immediate adjustments but also ensures adherence to quality control benchmarks throughout production cycles. The result is a more reliable product that meets or exceeds necessary certifications.

Additionally, improved accuracy reduces the likelihood of costly recalls or rework due to non-compliance with industry regulations—an increasingly critical aspect as businesses face tighter scrutiny from regulators worldwide. Companies implementing these advanced technologies often report significant improvements in their supply chain digitization efforts as well; enhanced tracking systems ensure transparency across all stages of production while bolstering supplier risk management strategies through rigorous audits based on accurate data analysis.

In conclusion, emerging technologies such as AI and automation are essential drivers behind advancements in the testing of electronic components—enabling companies to enhance quality control measures while fostering sustainable practices across their operations.

Conclusion

As we wrap up our exploration of the testing of electronic components, it’s crucial to recognize the multifaceted methods that ensure product reliability and compliance with industry standards. From rigorous quality control measures to comprehensive supplier audits, each aspect plays a vital role in maintaining high standards in electronics manufacturing. Moreover, navigating the complexities of certifications and regulatory updates is paramount for companies striving to stay competitive in a rapidly evolving market.

Summarizing Key Testing Methods

The testing of electronic components encompasses various methodologies designed to evaluate performance, safety, and durability. Techniques such as functional testing, stress testing, and environmental simulation are essential for ensuring that products meet the necessary quality control benchmarks. Additionally, integrating sustainable practices into these testing methods not only enhances product integrity but also aligns with the growing demand for eco-friendly solutions in supply chain digitization.

Importance of Continuous Improvement

In an industry characterized by rapid technological advancements, continuous improvement is not just a buzzword; it's a necessity. Regular updates on regulatory changes and certifications are critical to adapting quality control processes effectively. By fostering an environment that encourages innovation and embraces new practices—such as sustainable testing methods—companies can enhance their competitive edge while minimizing risks associated with supplier audits.

The Future of Electronic Component Testing

Looking ahead, the future of electronic component testing is poised for transformation through emerging technologies like AI and machine learning. These innovations promise to streamline processes and enhance accuracy in quality control measures while addressing sustainability concerns more effectively than ever before. As businesses navigate this shifting landscape filled with opportunities for growth and efficiency, staying abreast of regulatory updates will be essential for maintaining compliance within a global supply chain.