Introduction

In today's competitive marketplace, the importance of choosing the right inspection company cannot be overstated. Quality control is not just a checkbox on your production list; it’s a vital component that can make or break your business. With various inspection companies available, understanding how to select one that aligns with your specific needs is crucial for ensuring the production of quality goods and services.

Importance of Choosing the Right Inspection Company

Selecting the right inspection company can significantly impact your overall product quality and brand reputation. The wrong choice could lead to overlooked defects or compliance issues, which in turn could result in costly recalls or damaged relationships with customers. By investing time and effort into this decision, you are safeguarding your investment and enhancing customer satisfaction through reliable quality control measures.

Key Factors to Consider in Your Selection

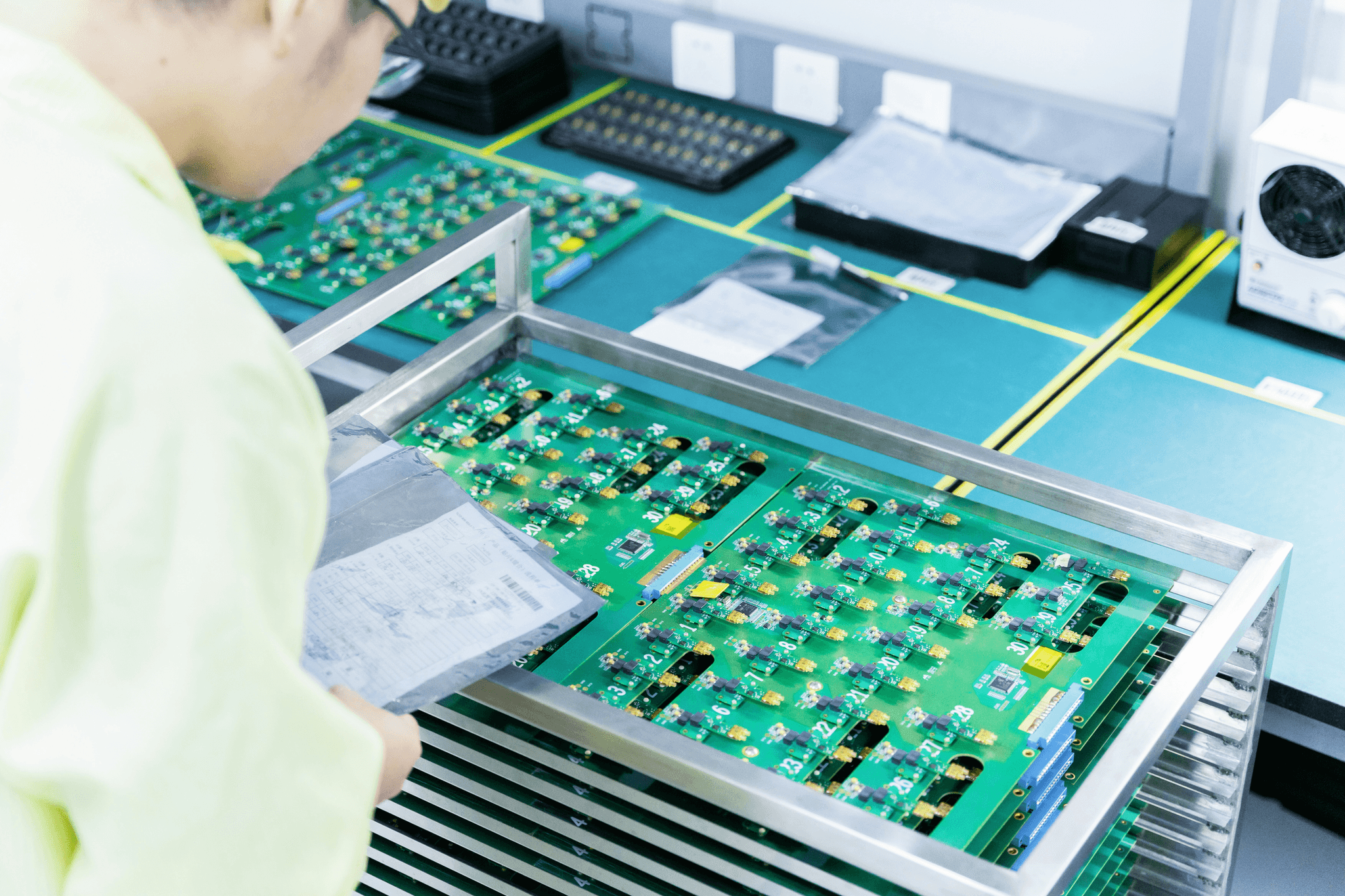

When evaluating potential inspection companies, several key factors should guide your decision-making process. Consider their expertise in areas such as social compliance auditing and visual inspection procedures, as these specialties can directly affect how well they align with your industry needs. Additionally, assessing their experience with testing of electronic components will help ensure they have the necessary skills to handle your specific products effectively.

The Impact of Quality Control on Your Business

Quality control plays an integral role in maintaining high standards throughout the production process, influencing everything from operational efficiency to customer loyalty. A rigorous approach to quality inspections not only minimizes risks associated with non-conformity reports but also fosters a culture of excellence within your organization. Ultimately, prioritizing quality control can lead to long-term success by establishing trust and reliability among consumers.

Understanding Different Types of Inspection Companies

When it comes to ensuring quality in production, not all inspection companies are created equal. Each company may have unique specializations that cater to specific industries or types of inspections. Understanding these differences can significantly impact the effectiveness of your quality control measures and the overall success of your business.

Specializations in Quality Control

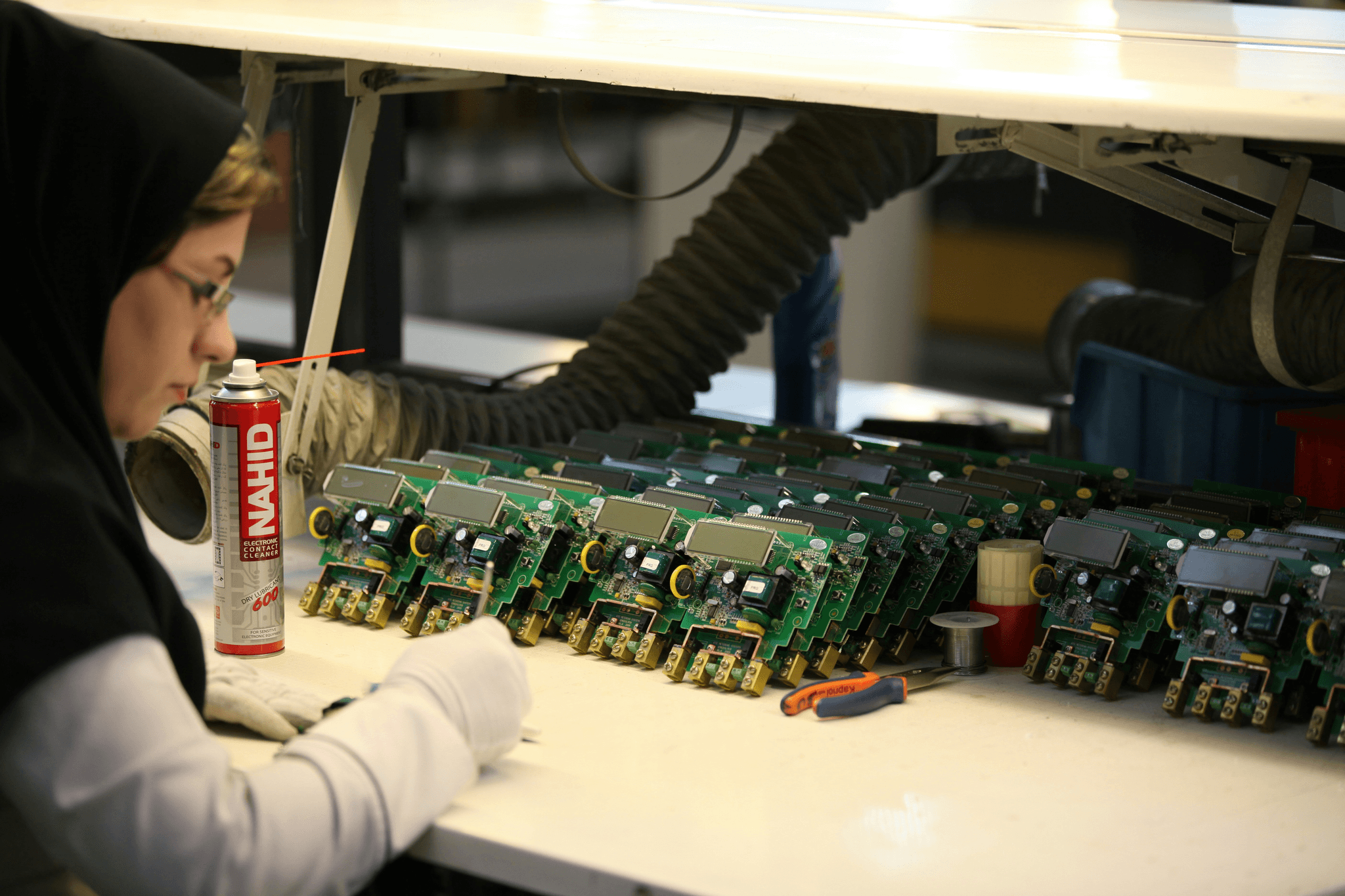

Inspection companies often specialize in various aspects of quality control, which allows them to provide tailored services that meet specific industry needs. For instance, some may focus on the testing of electronic components, ensuring that products meet stringent safety and performance standards. Others might concentrate on manufacturing processes, offering insights into how to enhance the production of quality goods and services while minimizing defects.

These specializations also extend to different methodologies employed during inspections. Whether it’s through rigorous testing protocols or advanced technology applications, understanding what each inspection company brings to the table is crucial for selecting a partner that aligns with your business goals.

Overview of Social Compliance Auditing

Social compliance auditing has become an essential aspect for many businesses looking to uphold ethical standards in their supply chains. This process ensures that manufacturers adhere to labor laws and social responsibility guidelines, making it a critical component for brands aiming for sustainability and ethical practices. By engaging with inspection companies that offer social compliance auditing, businesses can mitigate risks related to labor violations and enhance their brand reputation.

These audits often involve thorough assessments of working conditions, employee treatment, and adherence to local regulations. The findings from these audits can lead directly to improvements in operational practices and help create a more positive work environment—ultimately contributing to better productivity and product quality.

Importance of Visual Inspection Procedure

The visual inspection procedure is a fundamental part of any comprehensive quality control strategy employed by inspection companies. This method involves scrutinizing products visually before they reach consumers, allowing inspectors to identify defects or deviations from specifications early in the production process. By implementing robust visual inspections, companies can prevent non-conformity reports from piling up due to overlooked issues during manufacturing.

Moreover, visual inspections are particularly beneficial when testing electronic components where precision is paramount; even minor flaws can lead to significant failures down the line. Thus, investing time into effective visual inspection procedures not only enhances product reliability but also saves costs associated with recalls or rework—ensuring a smoother path toward delivering high-quality goods and services.

Assessing Credentials and Experience

When it comes to selecting the right inspection companies, credentials and experience are paramount. A company's qualifications can significantly influence the quality of their services, impacting everything from social compliance auditing to the testing of electronic components. Understanding what makes a company credible will help you make an informed decision that ultimately enhances the production of quality goods and services.

Importance of Industry Certifications

Industry certifications serve as a badge of honor for inspection companies, indicating adherence to established standards and practices. Certifications not only demonstrate a company's commitment to excellence but also assure clients that they are working with professionals who understand the nuances of quality control. Whether it's ISO certifications or specific accreditations related to visual inspection procedures, these credentials can be a game-changer in ensuring that you partner with a reliable service provider.

Evaluating Past Performance and Reviews

One of the best ways to gauge an inspection company's reliability is by evaluating their past performance through client reviews and case studies. Look for testimonials that highlight their expertise in areas such as social compliance auditing or detailed reporting on non-conformity reports—these insights can provide invaluable context about what you can expect. Additionally, don’t hesitate to ask for references; hearing directly from previous clients can illuminate how well they handle challenges like the testing of electronic components.

Key Questions to Ask Before Hiring

Before signing on the dotted line with any inspection company, it's crucial to ask some key questions that will clarify their capabilities and approach. Inquire about their experience with your specific industry or product types; this is particularly important if you're focused on sectors requiring rigorous quality checks like electronics or textiles. Also, don't forget to ask about how they handle non-conformity reports—understanding their process here will give you insight into how they manage issues during inspections, ensuring your production of quality goods and services remains uninterrupted.

What is QC Inspector and Their Role

Quality Control (QC) Inspectors play a crucial role in ensuring that products meet specific standards and regulations, thus safeguarding the integrity of inspection companies. They are responsible for conducting thorough examinations throughout the production process, from raw materials to finished goods. By identifying any discrepancies early on, QC Inspectors help maintain the production of quality goods and services.

Definition and Responsibilities

So, what is a QC Inspector? Essentially, they are professionals who specialize in evaluating products to ensure compliance with established quality standards. Their responsibilities include performing inspections at various stages of production, documenting findings, and collaborating with production teams to address any issues that arise. This role is vital not just for product quality but also for maintaining customer satisfaction and trust.

How QC Inspectors Enhance Product Quality

QC Inspectors enhance product quality by implementing rigorous testing protocols, particularly in sectors like electronics where precision is paramount. Through methods such as visual inspection procedures and functional testing of electronic components, they identify defects that could lead to non-conformity reports later on. Their keen eye for detail ensures that only products meeting high-quality benchmarks make it to market, which ultimately strengthens the reputation of the associated inspection companies.

The Role of QC Inspectors in Non-Conformity Reports

Understanding what a non-conformity report entails is essential when discussing the role of QC Inspectors. These reports document any deviations from established standards or specifications during inspections—essentially flagging issues before they escalate into larger problems. By addressing these non-conformities promptly, QC Inspectors help organizations adhere to social compliance auditing requirements and improve overall operational efficiency.

The Process of Quality Inspections

Quality inspections are crucial for ensuring that products meet the necessary standards before they reach consumers. Inspection companies play an essential role in this process, employing various methods and techniques to evaluate product quality effectively. Understanding the steps involved in quality inspections can help businesses appreciate how these evaluations contribute to the overall production of quality goods and services.

Steps in the Inspection Process

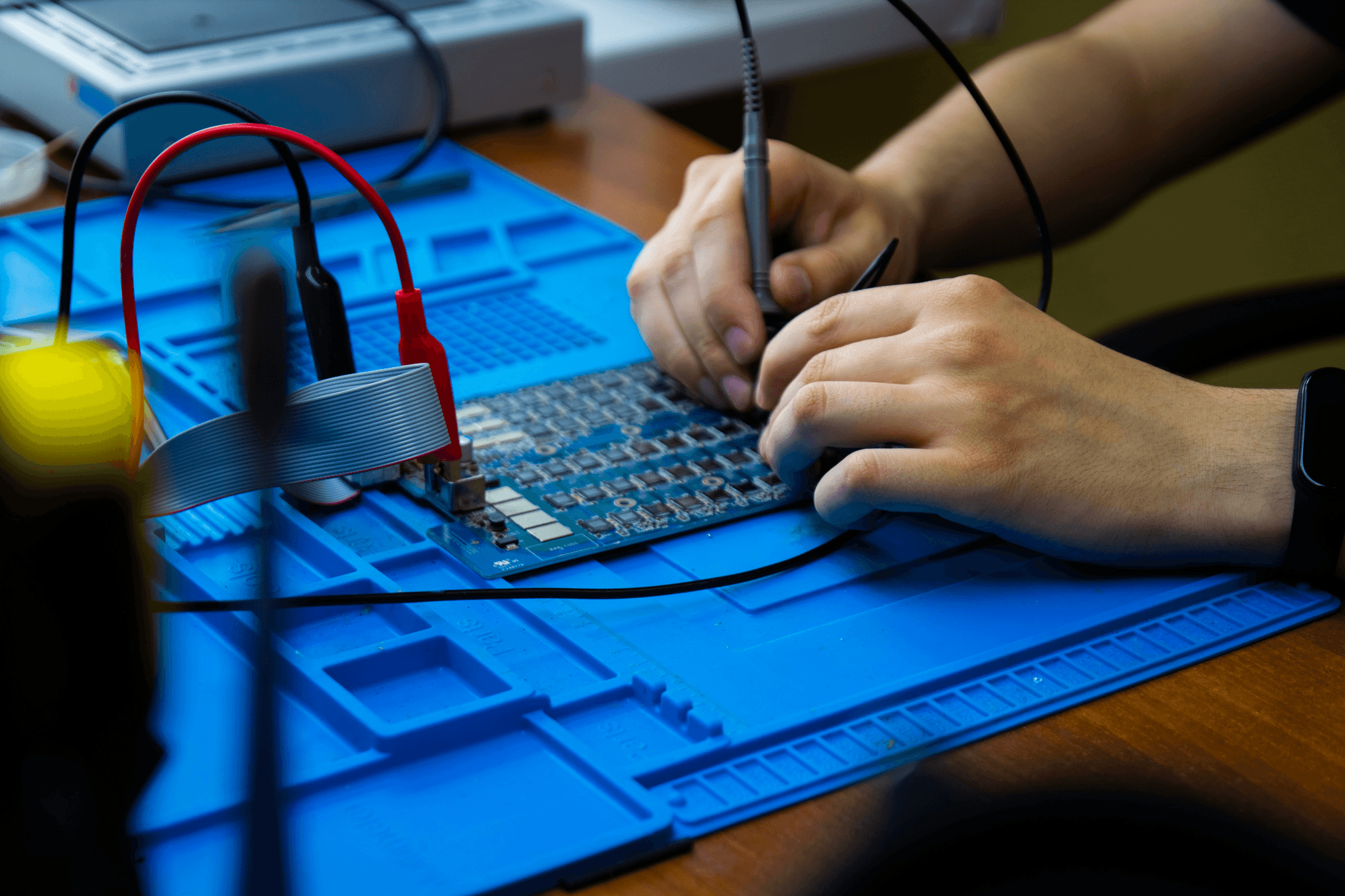

The inspection process typically begins with a pre-inspection meeting where expectations and requirements are discussed between the client and the inspection company. Following this, a thorough visual inspection procedure is conducted to identify any apparent defects or issues. After initial assessments, detailed testing of electronic components may take place, which includes checking for functionality, safety standards, and compliance with specifications.

Once inspections are complete, inspection companies compile their findings into a non-conformity report if any discrepancies are found. This document outlines specific areas where products do not meet required standards, providing valuable feedback to manufacturers. Finally, based on these insights, recommendations for corrective actions can be made to ensure future production aligns with quality expectations.

Common Techniques in Testing of Electronic Components

Testing of electronic components involves several techniques designed to assess performance and reliability under various conditions. One common method is functional testing, where components are subjected to operational simulations to ensure they perform as intended under real-world scenarios. Additionally, stress testing evaluates how these components withstand extreme conditions such as temperature changes or voltage fluctuations.

Another technique used by inspection companies is automated testing equipment (ATE), which allows for precise measurements and rapid evaluations of multiple samples simultaneously. This efficiency helps streamline the quality control process while maintaining high accuracy levels in detecting potential failures. Furthermore, visual inspections remain integral throughout this phase; inspectors look for physical defects that could lead to performance issues down the line.

How Inspection Companies Ensure Production of Quality Goods and Services

Inspection companies utilize a combination of rigorous testing methods and industry best practices to ensure that manufacturers produce quality goods and services consistently. By conducting thorough inspections at various stages of production—ranging from raw material assessments to final product evaluations—these companies help catch issues early before they escalate into larger problems that could affect consumer safety or satisfaction.

Moreover, social compliance auditing is often part of their offerings; it ensures that factories adhere not only to product standards but also ethical labor practices during production processes. This holistic approach reinforces brand integrity while fostering trust among consumers who increasingly value corporate responsibility alongside product quality. Ultimately, when businesses partner with reputable inspection companies equipped with skilled QC inspectors, they enhance their ability to deliver superior products that meet market demands.

Choosing Local vs. International Inspection Companies

When it comes to selecting inspection companies, the choice between local and international firms can significantly impact your quality control processes. Each option has its unique strengths that can align with different business needs. Understanding these differences is crucial for ensuring the production of quality goods and services.

Benefits of Local Knowledge

Local inspection companies bring a wealth of regional knowledge that can be invaluable in the quality control process. They understand local regulations, cultural nuances, and market expectations, which can enhance their effectiveness in social compliance auditing. Additionally, their familiarity with local suppliers often leads to more precise evaluations during visual inspection procedures.

Choosing a local firm can also facilitate quicker communication and response times, which is vital when issues arise during inspections or testing of electronic components. This immediacy allows businesses to address potential non-conformities swiftly before they escalate into larger problems. Furthermore, local inspectors may have established relationships with manufacturers, enhancing trust and cooperation throughout the inspection process.

Lastly, engaging with local inspection companies fosters community ties and supports regional economies while ensuring that your products meet both national and international standards for quality control. The personal touch that comes from a local firm often leads to better collaboration when addressing what is a non-conformity report.

Advantages of Global Expertise

On the flip side, international inspection companies offer expansive expertise that transcends borders—ideal for businesses operating on a global scale or sourcing materials from various countries. These firms are equipped to handle complex supply chains and diverse regulatory environments effectively due to their vast experience in social compliance auditing across different markets. Their understanding of global standards ensures consistency in quality across all production sites.

Moreover, international firms often have access to advanced technologies and methodologies for testing of electronic components that may not be available locally. This technological edge can significantly enhance the efficiency and accuracy of inspections while ensuring adherence to rigorous quality benchmarks worldwide. For businesses aiming for global reach, partnering with an experienced international player could be essential for maintaining high-quality production standards.

However, it’s important not to overlook potential challenges such as time zone differences or varying communication styles when working with global partners; these factors could impact timely responses needed during critical stages like what is a non-conformity report resolution or immediate corrective actions after inspections.

China Inspection Pro: A Leader in Quality Assurance

One standout option in the realm of international inspection companies is China Inspection Pro—a leader renowned for its exceptional service offerings tailored specifically for businesses sourcing from China or other Asian countries. With expertise spanning various industries including electronics manufacturing, they excel at providing thorough inspections that ensure compliance with both local regulations and global standards alike.

China Inspection Pro specializes in visual inspection procedures designed to identify defects early on—crucial when dealing with intricate electronic components where even minor flaws can lead to significant issues down the line. Their team comprises highly trained QC inspectors who are well-versed in what constitutes acceptable quality levels across multiple sectors; this reduces risks associated with product recalls or customer dissatisfaction due to non-compliance issues highlighted in what is a non-conformity report.

In conclusion, whether you lean towards local knowledge or global expertise depends largely on your specific business needs—each has its merits worth considering carefully before making your choice among inspection companies.

Conclusion

In the world of business, the choice of inspection companies can make or break your operations. Selecting the right partner for quality control is not just a box-ticking exercise; it’s an investment in your brand's reputation and longevity. By keeping key factors in mind, you set yourself up for success and ensure that your products meet the highest standards.

Final Tips for Selecting Inspection Companies

When evaluating inspection companies, prioritize those with proven industry experience and relevant certifications. Don't hesitate to ask about their expertise in social compliance auditing and visual inspection procedures; these are crucial aspects of maintaining product integrity. Additionally, reviewing past performance through testimonials or case studies can provide insight into how they handle testing of electronic components and other goods.

It's also wise to consider their approach to non-conformity reports—understanding how they manage discrepancies can reveal a lot about their quality control processes. Look for companies that are transparent about their methodologies and willing to share their results with you. After all, a good inspection company should be as invested in your success as you are.

The Value of Quality Control in Business Success

Quality control is not just a regulatory requirement; it’s essential for building trust with customers and ensuring repeat business. When businesses prioritize quality inspections, they significantly reduce the risk of defective products reaching the market, which can lead to costly recalls or damage to brand reputation. Furthermore, effective testing of electronic components ensures that your products perform reliably, enhancing customer satisfaction.

Moreover, implementing thorough visual inspection procedures helps catch potential issues before they escalate into larger problems down the line. This proactive approach saves time and resources while promoting a culture of excellence within your organization. Ultimately, investing in quality control translates into higher profitability and sustained growth.

Taking Action: Finding Your Ideal Inspection Partner

Now that you’re equipped with knowledge about what is QC inspector roles and responsibilities, it’s time to take action! Begin by creating a list of potential inspection companies based on recommendations or online research—don’t forget to check reviews! Narrow down your options by asking targeted questions regarding their experience with social compliance auditing and non-conformity reports.

Once you've shortlisted candidates, set up meetings or calls to discuss your specific needs concerning production of quality goods and services. This will help you gauge whether they understand your industry nuances and if they're genuinely interested in being part of your journey toward excellence. Remember: choosing an ideal inspection partner is not just about meeting minimum requirements; it's about fostering a relationship that enhances both parties' success!