Introduction

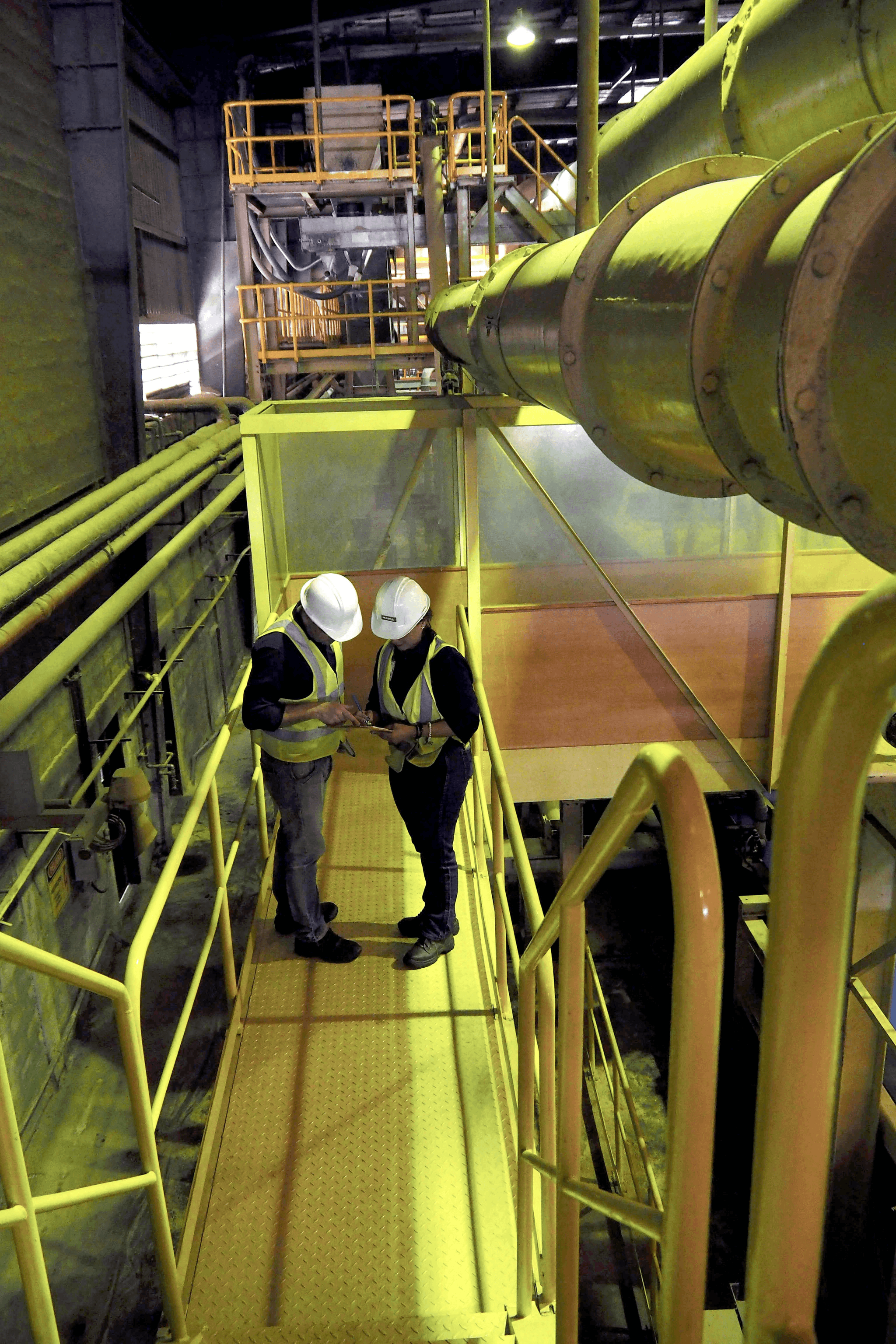

In the world of industrial operations, the importance of regular machinery inspection cannot be overstated. These inspections are essential to ensure that equipment remains in optimal working condition, minimizing downtime and costly repairs. By establishing a consistent frequency of inspection, organizations can proactively address potential issues before they escalate into significant problems.

Importance of Regular Machinery Inspection

Regular machinery inspection is a vital practice that safeguards both the equipment and the workforce. It helps in identifying wear and tear, preventing unexpected breakdowns that could disrupt production schedules. Furthermore, routine inspections enhance safety measures by ensuring all equipment functions correctly and complies with industry standards.

Common Machinery Issues and Their Impact

Machinery can face various issues such as misalignments, leaks, or electrical faults that can lead to severe operational setbacks. These common problems not only affect productivity but can also pose serious safety hazards for employees working nearby. Understanding these risks highlights the necessity for thorough equipment inspections to mitigate potential dangers.

Benefits of Using a Comprehensive Checklist

Utilizing a comprehensive machinery inspection checklist streamlines the inspection process by ensuring no critical aspect is overlooked. This systematic approach allows inspectors to focus on key areas such as mechanical components, electrical systems, and safety features effectively. Moreover, having a checklist fosters accountability among team members while promoting consistent maintenance practices across all machinery types.

Structural Integrity

Regular assessments not only prolong the lifespan of machinery but also prevent costly breakdowns that can halt production. Utilizing a comprehensive machinery inspection checklist allows for systematic evaluations, ensuring no critical area is overlooked.

Assessing Frames and Supports

Frames and supports are the backbone of any piece of machinery, bearing the weight and stress during operation. During machinery inspections, it's essential to check for any visible cracks, corrosion, or misalignments that could compromise stability. Conducting these assessments with a defined frequency of inspection helps identify potential issues before they escalate into significant problems.

Checking for Signs of Fatigue

Fatigue in structural components can lead to catastrophic failures if not addressed promptly during equipment inspections. Look for signs such as unusual wear patterns or deformation in critical areas; these often indicate that components are nearing their limits. Regular checks using a well-structured machinery inspection checklist will help catch fatigue early, ensuring safety and operational efficiency.

Importance of Load Capacity

Understanding the load capacity is crucial in maintaining safe operation levels for all types of machinery. Exceeding this capacity can lead to structural failure or even accidents on-site, making regular inspections vital to confirm compliance with manufacturer specifications. By incorporating load capacity evaluations into your routine equipment inspections, you safeguard both personnel and investment while enhancing overall productivity.

Mechanical Components

Althorough machinery inspection checklist will help pinpoint potential problems before they escalate into costly repairs or downtime. Regular equipment inspections should include an assessment of gears, bearings, belts, and lubrication systems to maintain efficiency and safety.

Inspecting Gears and Bearings

Gears and bearings are often the unsung heroes of machinery; they handle heavy loads while operating at high speeds. A comprehensive machinery inspection should focus on signs of wear such as scoring, pitting, or unusual noise during operation. Regular inspections help determine the frequency of inspection needed for these components based on their usage intensity—after all, a little preventive maintenance can save a lot of headaches down the line.

Evaluating Belt Tension and Condition

Belt tension is crucial for maintaining efficient power transmission in any mechanical system. During equipment inspections, check for proper tension levels; too loose or too tight can lead to premature wear or failure. Additionally, inspect belts for cracks or fraying—these issues can compromise performance if not addressed promptly through regular machinery inspection.

Ensuring Proper Lubrication

Lubrication is the lifeblood of any mechanical system; it reduces friction and prevents overheating among moving parts. An effective machinery inspection checklist must include checks for oil levels and the condition of lubricants used in various components like gears and bearings. Consistent evaluation ensures that lubrication intervals are adhered to based on equipment usage patterns—the right frequency of inspection can make all the difference in extending equipment life.

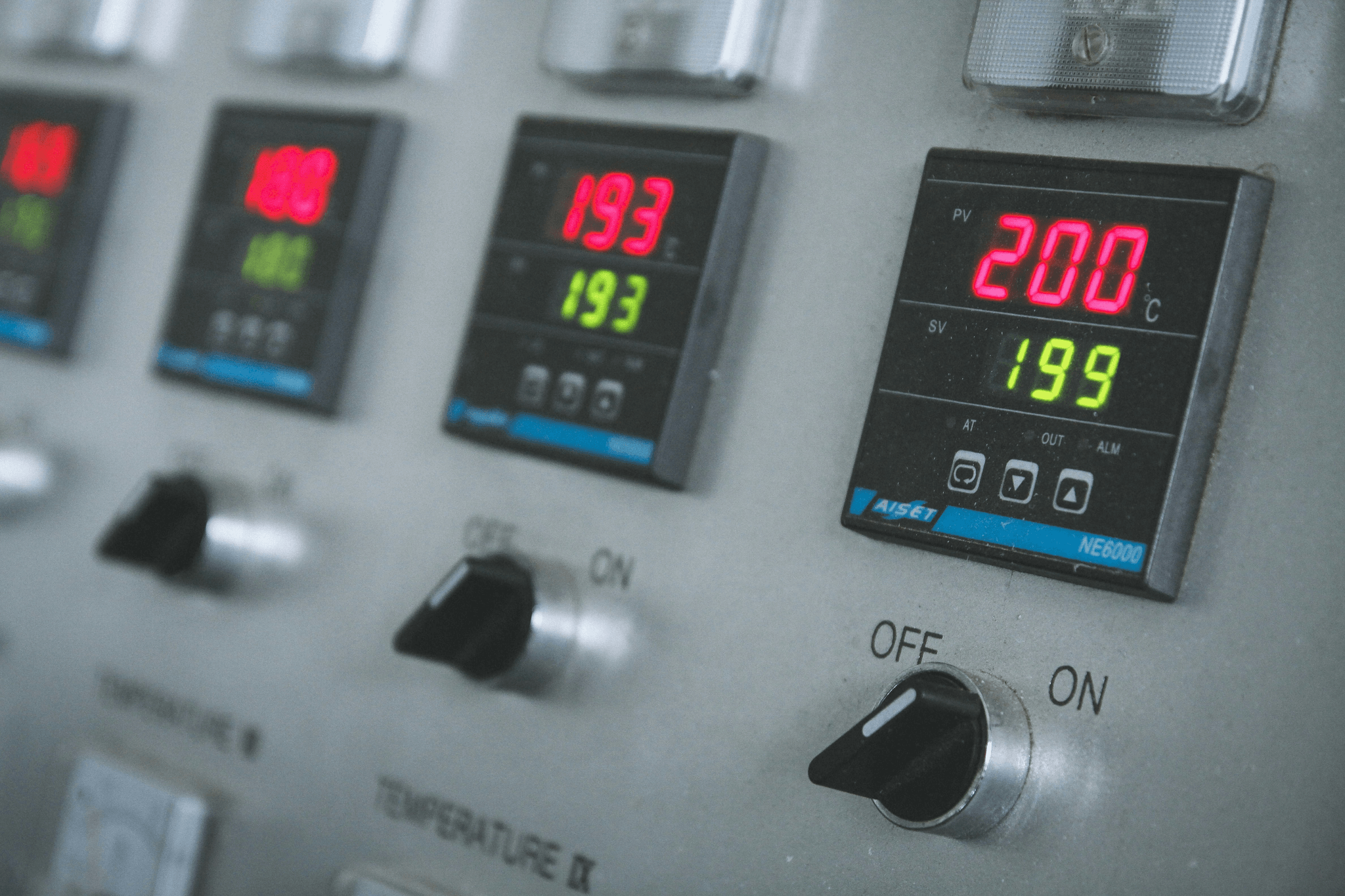

Electrical Systems

When it comes to machinery inspection, electrical systems are often the unsung heroes that keep everything running smoothly. Neglecting these components can lead to catastrophic failures, safety hazards, and costly downtime. Therefore, a thorough inspection of electrical systems should be a staple in any machinery inspection checklist.

Examining Wiring and Connections

Examining wiring and connections is like checking the veins of your machinery; they’re crucial for delivering power where it’s needed most. Look for any signs of wear, fraying, or corrosion that could compromise performance or safety. Regular equipment inspections should include verifying that all connections are secure and free from moisture or debris, ensuring optimal conductivity.

In addition to visual checks, consider the frequency of inspection for wiring based on environmental factors like humidity and temperature fluctuations. If your machinery operates in harsh conditions, more frequent inspections may be warranted to catch potential issues before they escalate. Remember, a small oversight in this area can lead to significant operational disruptions down the line.

Testing Circuit Integrity

Testing circuit integrity is another critical aspect of electrical systems during machinery inspections. This involves using specialized tools to measure voltage levels and ensure circuits are functioning as intended without interruptions or leaks. A robust machinery inspection checklist will include steps for identifying any inconsistencies that could indicate underlying problems.

Moreover, understanding how often you should conduct these tests can help you stay ahead of potential failures. For instance, if your equipment is utilized heavily or operates under extreme conditions, increasing the frequency of circuit integrity tests might be necessary for maintaining reliability. After all, proactive measures can save you from reactive repairs that come with hefty price tags.

Identifying Electrical Hazards

Identifying electrical hazards isn't just about ensuring compliance; it's about protecting lives and preserving equipment integrity during inspections. Look out for exposed wires, overloaded circuits, or malfunctioning safety devices that could pose risks to operators and maintenance personnel alike. A thorough approach to this part of your machinery inspection will not only enhance safety but also extend the lifespan of your equipment.

Additionally, incorporating regular training sessions on recognizing electrical hazards into your maintenance routine can empower staff with knowledge to act swiftly if issues arise during equipment inspections. The importance of fostering a culture focused on safety cannot be overstated—it's key in preventing accidents before they happen! Ultimately, prioritizing hazard identification ensures everyone goes home safe at the end of their shift.

Safety Features

When it comes to machinery inspection, safety features are paramount. These components not only protect the operators but also ensure that the equipment runs smoothly without unexpected interruptions. Regular equipment inspections should include a thorough review of all safety mechanisms, as neglecting them can lead to serious accidents and costly downtime.

Reviewing Emergency Stops

Emergency stops are crucial in any machinery setup, acting as a lifeline during unforeseen circumstances. During your machinery inspection, it’s vital to test these systems regularly to ensure they function correctly when needed most. Remember, the frequency of inspection for emergency stops should be consistent; after all, you wouldn’t want to find out they’re not working when seconds count!

Ensuring Proper Guards and Shields

Guards and shields serve as the first line of defense against potential hazards in machinery operation. Inspecting these features is an essential part of your machinery inspection checklist; any gaps or damages can expose workers to risks that could have been easily mitigated. Ensure that these protective barriers are intact and properly positioned at all times—after all, a small oversight can lead to big consequences.

Checking Safety Alarms and Indicators

Safety alarms and indicators act as the alert system for any irregularities during operation, making their functionality critical in maintaining a safe work environment. During equipment inspections, check that all alarms sound correctly and indicators light up as intended; this simple step can prevent accidents before they happen! Regular checks on these systems will enhance overall safety compliance while providing peace of mind for operators.

Hydraulic and Pneumatic Systems

When it comes to machinery inspection, hydraulic and pneumatic systems are often the unsung heroes that keep equipment running smoothly. These systems rely on fluid power to perform essential functions, making their integrity crucial for overall machinery performance. Regular equipment inspections in this area can prevent costly failures and ensure operational efficiency.

Inspecting Hoses and Fittings

Hoses and fittings are the lifelines of hydraulic and pneumatic systems, so they deserve a thorough inspection during your machinery inspection checklist. Look for signs of wear, such as cracks or bulges in hoses, which can lead to leaks or catastrophic failures if left unchecked. Additionally, ensure that fittings are tight and free from corrosion; loose or damaged connections can compromise system pressure and performance.

Evaluating Fluid Levels and Quality

Fluid levels should be checked regularly as part of your frequency of inspection schedule to ensure optimal operation of hydraulic and pneumatic systems. Low fluid levels can lead to overheating or insufficient pressure, while contaminated fluids can cause wear on components over time. Use a clean sampling method to evaluate fluid quality; this will help you catch any issues before they escalate into major problems.

Testing Pressure Relief Valves

Pressure relief valves are critical safety features that need regular testing during machinery inspections to prevent over-pressurization accidents. These valves should open at their designated pressure settings; failure to do so could result in serious equipment damage or even injury. Incorporating pressure relief valve testing into your machinery inspection checklist not only complies with safety regulations but also enhances overall system reliability.

Compliance with Regulations

Ensuring compliance with regulations is crucial for maintaining safety and operational efficiency in any machinery operation. Regular machinery inspection not only helps in adhering to these standards but also protects the investment made in equipment. A well-structured machinery inspection checklist can guide operators through the necessary steps to meet industry requirements.

Understanding Industry Standards

Industry standards serve as the backbone of safe and effective machinery operation, dictating everything from design specifications to maintenance practices. Familiarity with these standards is essential for anyone involved in equipment inspections, as they outline the minimum safety and performance criteria that must be met. Regular training on these standards ensures that personnel are up-to-date with compliance requirements, which can vary by industry and region.

Role of China Inspection Pro

China Inspection Pro plays a pivotal role in ensuring that companies adhere to local and international regulations regarding machinery inspection. Their expertise helps organizations navigate complex compliance landscapes while providing valuable insights into best practices for equipment inspections. By collaborating with such professionals, businesses can bolster their adherence to regulations, ultimately leading to enhanced safety and reduced liability.

Ensuring Documentation and Reporting

Documentation is a vital component of compliance, serving as proof of regular inspections and maintenance activities performed on machinery. A comprehensive approach involves not just completing a machinery inspection checklist but also ensuring that all findings are documented clearly for future reference and audits. This meticulous record-keeping allows businesses to track the frequency of inspections over time, making it easier to identify trends or issues that may need addressing.

Conclusion

In conclusion, the importance of regular machinery inspection cannot be overstated. By focusing on key areas such as structural integrity, mechanical components, electrical systems, safety features, and hydraulic and pneumatic systems, we can significantly reduce the risk of equipment failures. Utilizing a comprehensive machinery inspection checklist ensures that no stone is left unturned during these vital assessments.

Recap of Key Inspection Areas

Throughout our exploration of machinery inspections, we highlighted several critical areas that warrant attention. From assessing the frames and supports for structural integrity to evaluating electrical systems for potential hazards, each component plays a pivotal role in overall equipment health. Regular equipment inspections using a detailed checklist not only enhance safety but also improve operational efficiency.

Importance of Professional Oversight

While self-inspections are beneficial, the value of professional oversight in machinery inspection cannot be ignored. Trained professionals bring expertise and a fresh perspective that can uncover issues that might go unnoticed by untrained eyes. This level of scrutiny is especially crucial given the frequency of inspection required to maintain compliance with industry standards and regulations.

Taking Action on Inspection Findings

Once inspections are complete and findings documented, taking action is paramount to ensure ongoing safety and functionality. Addressing identified issues promptly helps prevent minor problems from escalating into major breakdowns or accidents. Implementing an effective plan based on your machinery inspection results will not only safeguard your equipment but also contribute to a culture of continuous improvement within your organization.