Introduction

In the fast-paced world of construction and manufacturing, regular equipment inspections are not just a box to tick; they are vital for ensuring safety, efficiency, and longevity. These inspections serve as a proactive measure to identify potential hazards before they escalate into costly problems. In an industry where quality in construction is paramount, neglecting equipment inspections can lead to dire consequences.

The Importance of Regular Equipment Inspections

Regular equipment inspections play a crucial role in maintaining operational integrity and safeguarding worker safety. They help ensure that machinery is functioning correctly and complies with industry regulations, thus reducing the risk of accidents on site. Moreover, a valid inspection certificate serves as proof that equipment has been thoroughly evaluated by qualified personnel, instilling confidence in both workers and management.

What Equipment Inspections Ensure

Equipment inspections ensure compliance with legal standards while also verifying that all machinery operates at optimal performance levels. By systematically checking each component of the equipment, inspectors can detect wear and tear or any malfunctions early on, minimizing downtime and repair costs. This proactive approach not only protects investments but also enhances overall productivity within an organization.

Benefits Beyond Compliance

While compliance with regulations is essential, the benefits of regular equipment inspections extend far beyond just avoiding fines or legal issues. Companies that prioritize these inspections often experience improved operational efficiency due to fewer breakdowns and enhanced worker safety—leading to lower insurance premiums over time. Additionally, organizations can bolster their reputation by demonstrating their commitment to quality control methods like social compliance audits and thorough footwear inspection processes.

Understanding Equipment Inspections

When we talk about equipment inspections, we're diving into a crucial aspect of maintaining safety and efficiency in various industries. These inspections are systematic evaluations of equipment to ensure they meet safety standards and operational requirements. By understanding what these inspections entail, businesses can better appreciate their role in quality control and compliance.

Definition of Equipment Inspections

Equipment inspections are thorough assessments designed to evaluate the condition and functionality of machinery or tools used in various sectors, including construction and manufacturing. Essentially, these evaluations help identify any potential issues before they escalate into significant problems that could affect safety or productivity. In the realm of quality in construction, regular equipment inspections serve as a backbone for ensuring that all machinery operates safely and efficiently.

Overview of the Inspection Process

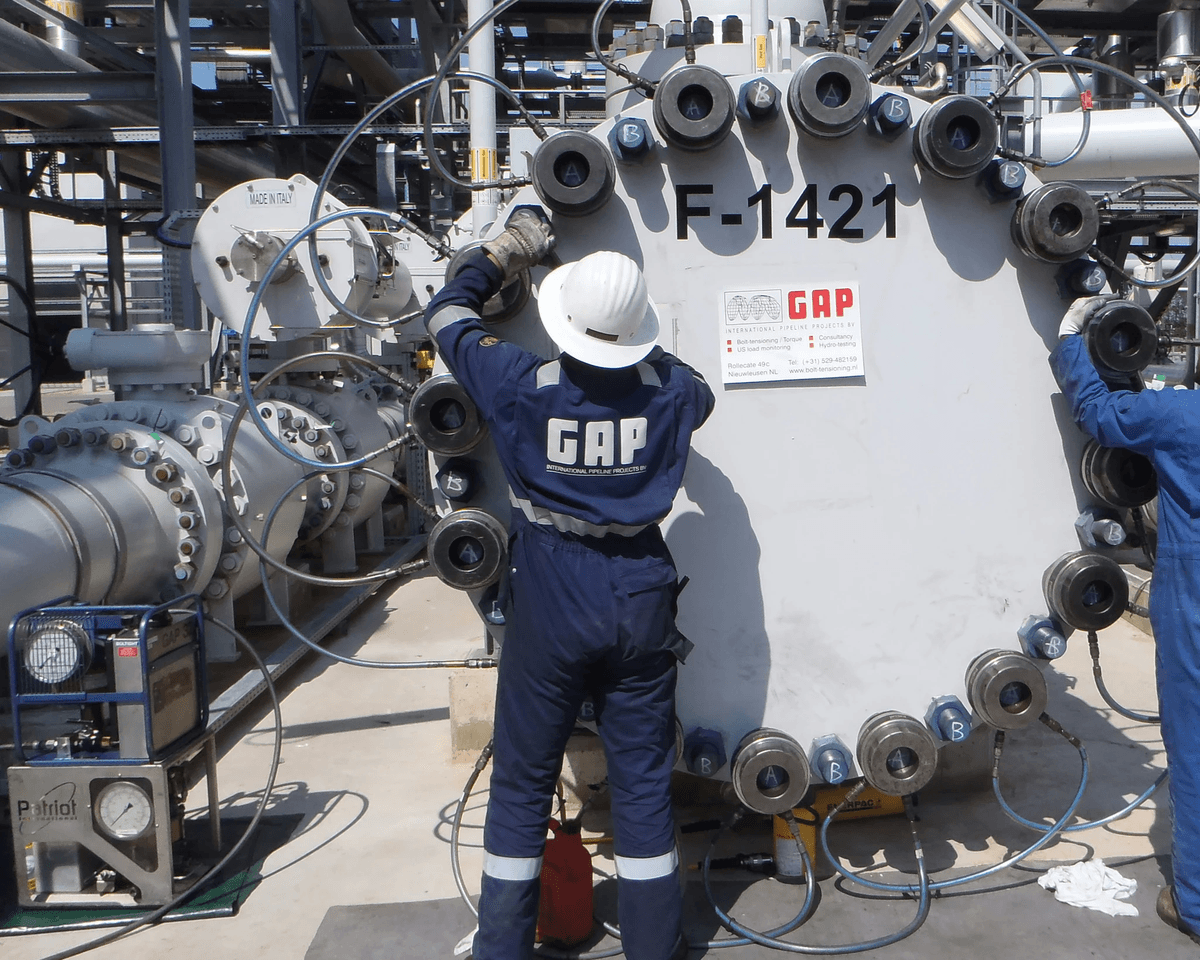

The inspection process typically begins with a detailed checklist tailored to the specific type of equipment being evaluated. Trained professionals from a reputable QC company conduct these checks, examining each component methodically to ensure compliance with industry standards. Following this assessment, an inspection certificate is issued, documenting the findings and affirming that the equipment meets necessary regulations.

Key Components of an Inspection Certificate

An inspection certificate is not just a piece of paper; it's a vital document that summarizes the results of an equipment inspection. Key components include details such as the type of equipment inspected, date of inspection, findings regarding its condition, and any recommendations for maintenance or repair. Importantly, this certificate serves as proof that due diligence has been exercised—crucial for legal compliance and essential for those asking what is a social compliance audit? when assessing overall operational integrity.

The Role of Quality Control in Inspections

In the realm of equipment inspections, quality control (QC) plays a pivotal role in ensuring that all machinery and tools meet safety and performance standards. By employing various quality control methods, inspectors can systematically evaluate equipment to identify any potential issues before they escalate into serious problems. This proactive approach not only safeguards workers but also enhances the overall efficiency of operations, making it an essential component of any inspection process.

Quality Control Methods in Equipment Inspections

Quality control methods in equipment inspections are diverse and tailored to meet specific industry needs. Common techniques include visual inspections, functional testing, and the use of specialized measurement tools to assess equipment performance accurately. Furthermore, employing a systematic approach through checklists ensures that all critical components are evaluated thoroughly, leading to more reliable inspection certificates that reflect true equipment conditions.

Additionally, QC companies often implement statistical process controls to analyze data collected during inspections. This allows for identifying trends and potential areas for improvement over time, ensuring that equipment remains compliant with regulations and operational standards. By consistently applying these quality control methods during inspections, businesses can prevent costly downtimes caused by unexpected equipment failures.

How QC Companies Enhance Inspection Reliability

QC companies enhance inspection reliability by leveraging their expertise and experience within the field of equipment inspections. They utilize trained professionals who are well-versed in industry standards and regulatory requirements, which translates into accurate assessments for clients seeking inspection certificates. Moreover, these companies often employ advanced technologies such as drones or imaging systems to conduct thorough evaluations that traditional methods might miss.

The integration of technology not only improves accuracy but also speeds up the inspection process while maintaining high-quality results. Additionally, QC companies provide ongoing training for their inspectors to stay updated on the latest compliance regulations and best practices in quality assurance. This commitment to continuous improvement ensures that clients receive consistent service with dependable outcomes every time they engage a QC company for their inspection needs.

The Importance of Quality in Construction

Quality is paramount in construction; it is not just about meeting deadlines but ensuring safety and durability through rigorous equipment inspections as well. High-quality construction relies heavily on using well-maintained machinery—after all, no one wants a crane malfunctioning mid-lift! Regularly scheduled inspections help mitigate risks associated with poor-quality construction practices while enhancing overall project efficiency.

Moreover, understanding what is a social compliance audit becomes crucial when considering how quality impacts labor practices within construction sites too. These audits ensure not only adherence to safety regulations but also ethical treatment of workers involved in construction projects—further highlighting the importance of quality across multiple dimensions within this sector. Ultimately, investing time and resources into quality assurance leads to better project outcomes while fostering trust among stakeholders involved.

Compliance and Regulatory Standards

In the realm of equipment inspections, compliance with regulatory standards is paramount. These standards ensure that all equipment meets safety and operational requirements, thereby protecting workers and enhancing quality in construction. Understanding these regulations can help organizations avoid pitfalls associated with non-compliance.

What is a Social Compliance Audit?

A social compliance audit is an evaluation process that assesses an organization’s adherence to social standards, including labor rights and workplace safety. This type of audit often intersects with equipment inspections, as it examines whether the tools and machinery used are compliant with regulations that protect employee welfare. Essentially, it’s about ensuring that companies not only meet legal requirements but also uphold ethical practices in their operations.

Legal Requirements for Equipment Inspections

Legal requirements for equipment inspections vary by industry but generally mandate routine checks to ensure safety and functionality. These laws compel businesses to obtain an inspection certificate that verifies compliance with established guidelines, thus safeguarding both employees and the public. Failure to adhere to these legalities can lead to significant penalties, including fines or even shutdowns.

Consequences of Non-Compliance

The consequences of non-compliance in equipment inspections can be severe and multifaceted. Companies may face hefty fines or legal action if they fail to meet regulatory standards, which can tarnish their reputation in the industry. Moreover, neglecting proper inspections can lead to accidents on-site, jeopardizing worker safety and resulting in costly operational disruptions.

Enhancing Safety and Efficiency

In the fast-paced world of construction and manufacturing, the importance of regular equipment inspections cannot be overstated. These inspections not only help ensure compliance with regulations but also play a pivotal role in enhancing safety and operational efficiency. By understanding the risks associated with neglecting inspections, businesses can make informed decisions that protect their workforce and bottom line.

Safety Risks of Neglecting Inspections

Neglecting equipment inspections can lead to catastrophic failures that compromise worker safety. When machinery is not regularly checked, it may develop faults that go unnoticed until it's too late, resulting in accidents or injuries on site. Furthermore, an inspection certificate serves as a crucial document verifying that all safety protocols have been followed, which can significantly reduce liability in case of incidents.

The risks extend beyond just physical injuries; they can also impact morale and productivity within teams. Workers operating faulty equipment may feel anxious or unsafe, leading to decreased efficiency and increased turnover rates. Therefore, prioritizing regular equipment inspections is not just about compliance—it's about fostering a safe work environment where employees can thrive.

Impact on Operational Efficiency

Operational efficiency is often directly linked to the condition of machinery used in processes like construction or manufacturing. Regular equipment inspections help identify potential issues before they escalate into costly breakdowns or downtime, thus keeping projects on schedule. In fact, companies that invest in quality control methods for their equipment often find themselves reaping the rewards in terms of enhanced productivity and reduced maintenance costs.

Moreover, when teams know their tools are reliable thanks to thorough inspections by a reputable qc company, they can focus more on their tasks rather than worrying about potential failures. This peace of mind translates into smoother operations and better overall performance for any organization involved in quality in construction or similar fields.

Case Studies: Success Due to Regular Inspections

Several case studies highlight the transformative effects of adhering to strict inspection protocols within various industries. For instance, a major construction firm implemented routine equipment inspections across all its job sites after facing multiple delays due to unexpected machine failures; this proactive approach resulted in a 30% reduction in downtime over six months! With each inspection backed by an official inspection certificate, the company could confidently assure clients of its commitment to quality.

Similarly, another company specializing in footwear production saw significant improvements after integrating regular equipment checks into their workflow—reducing defects by 25% while increasing production speed by 15%. These success stories demonstrate how consistent adherence to inspection practices not only safeguards against risks but also enhances overall operational effectiveness.

Choosing the Right Inspection Partner

Selecting the right inspection partner is crucial for ensuring that your equipment inspections meet all necessary standards and deliver reliable results. With a plethora of QC companies available, it can be daunting to determine which one aligns best with your needs. A thorough evaluation based on specific factors will help streamline this decision-making process and enhance the quality in construction.

Factors to Consider When Selecting a QC Company

When searching for a reputable QC company, start by examining their experience and expertise in equipment inspections relevant to your industry. Look for companies that provide comprehensive inspection certificates that clearly outline their findings, methodologies, and compliance with regulatory standards. Additionally, consider their approach to quality control methods; a company that utilizes advanced techniques will likely yield more reliable results.

Another essential factor is the company's reputation within the industry—client testimonials and case studies can provide insight into their past performance. Ensure they are familiar with what is social compliance audit requirements if applicable to your operations, as this can significantly affect your business's credibility. Lastly, evaluate their customer service; an accessible and responsive team can make all the difference when issues arise or questions need answering.

How China Inspection Pro Stands Out

China Inspection Pro has carved out a niche in providing top-tier equipment inspections through its commitment to quality and reliability. Their inspectors are highly trained professionals who understand not only the technical aspects of inspections but also the importance of delivering clear inspection certificates that clients can trust. By employing innovative quality control methods tailored specifically for various industries, they ensure thorough assessments every time.

What sets China Inspection Pro apart is its focus on building long-term relationships with clients through transparent communication and consistent results—qualities that are vital in today's fast-paced market environment. They also keep abreast of evolving regulations related to equipment inspections and social compliance audits, ensuring you remain compliant without breaking a sweat. With an impressive track record of successful partnerships across multiple sectors, it's no wonder they stand out among QC companies.

The Value of Expert Footwear Inspection

When it comes to specialized sectors like footwear production, expert footwear inspection becomes indispensable in maintaining high-quality standards throughout manufacturing processes. These inspections not only assess material quality but also verify adherence to safety regulations—a crucial aspect considering potential hazards associated with faulty products or non-compliance issues like what is social compliance audit entails.

Engaging professionals who specialize in footwear inspection means you're investing in peace of mind; these experts utilize proven quality control methods designed specifically for evaluating footwear items at various stages of production. Regular inspections ensure any discrepancies are caught early on, saving time and costs down the line while enhancing overall operational efficiency within your supply chain management practices.

In conclusion, choosing the right inspection partner is paramount for achieving optimal results from equipment inspections while elevating quality across all processes involved—from manufacturing through delivery—ultimately benefiting both businesses and consumers alike.

Conclusion

In conclusion, regular equipment inspections are not just a box to tick; they are essential for maintaining safety, efficiency, and compliance in any operation. By understanding what equipment inspections entail and the significance of an inspection certificate, businesses can ensure that they are not only meeting regulatory requirements but also enhancing their operational standards. The role of a quality control (QC) company cannot be overstated in this context, as they provide the expertise needed to uphold quality in construction and beyond.

Key Takeaways on Equipment Inspections

One key takeaway is that equipment inspections play a crucial role in identifying potential issues before they escalate into costly problems. An inspection certificate serves as proof of compliance and reliability, instilling confidence among stakeholders about the safety standards being upheld. Additionally, understanding what is a social compliance audit emphasizes the broader implications of equipment inspections on ethical practices within industries.

Long-Term Benefits of Regular Inspections

The long-term benefits of regular inspections extend far beyond mere compliance; they contribute significantly to operational efficiency and risk management. By routinely engaging in thorough footwear inspection or other equipment evaluations, companies can reduce downtime caused by unforeseen mechanical failures or safety incidents. Ultimately, these proactive measures lead to increased productivity and lower overall costs over time.

Elevating Quality through Consistent Practices

Elevating quality through consistent practices involves integrating robust quality control methods into the inspection process itself. Companies that prioritize regular equipment inspections foster a culture of excellence that resonates throughout their operations—leading to superior products and services for clients. When stakeholders see a commitment to maintaining high standards through effective QC partnerships, it boosts trust and enhances brand reputation.