Introduction

In the ever-evolving landscape of manufacturing, maintaining quality is paramount. AQL sampling plans serve as a crucial tool for quality control, ensuring that products meet established standards before they reach consumers. By understanding these plans, companies can streamline their quality inspection processes and enhance overall product reliability.

Understanding AQL Sampling Plans

AQL, or Acceptable Quality Level, is a statistical measure used in quality control to determine the maximum number of defective items considered acceptable in a sample batch. These sampling plans are designed to minimize risk while maximizing efficiency during the inspection process. Quality control companies leverage AQL sampling plans to ensure that their clients receive products that meet specified quality standards without excessive costs.

Importance of Quality Control

Quality control is vital for any business aiming to maintain customer satisfaction and brand reputation. It encompasses various processes and methodologies, including rigorous quality inspections that identify defects before products reach the market. Implementing effective quality control measures not only reduces waste but also fosters trust between manufacturers and consumers, ultimately leading to increased profitability.

Key Elements of a C=0 Sampling Plan

A C=0 sampling plan is characterized by its strict criteria: no defective items are allowed in the sampled lot. This approach emphasizes zero tolerance for defects and requires meticulous inspection protocols that can be effectively managed with manufacturing quality inspection software. By adopting a C=0 plan, organizations can significantly elevate their quality assurance efforts and ensure consistent product excellence.

What is AQL Sampling?

AQL sampling, or Acceptable Quality Level sampling, is a statistical quality control method used to determine the maximum number of defective items that can be considered acceptable in a batch of products. It serves as a crucial tool for quality control companies aiming to maintain high standards in their manufacturing processes. By establishing AQL sampling plans, organizations can effectively balance the cost of inspection with the need for quality assurance.

Definition and Purpose

At its core, AQL sampling provides a framework for evaluating the quality of products through random sampling rather than inspecting every single item. The purpose is to identify defects while minimizing inspection costs and time, making it an efficient choice for manufacturers. This method allows companies to set limits on acceptable defects while ensuring that customer satisfaction remains intact.

Common Uses in Quality Inspection

AQL sampling is widely utilized across various industries during quality inspections to assess product conformity before shipment. From electronics to textiles, businesses leverage these plans to evaluate batches efficiently and make informed decisions about acceptance or rejection based on predetermined criteria. Moreover, this approach helps streamline operations by reducing the need for exhaustive inspections without compromising product quality.

The Role of AQL in Manufacturing

In manufacturing environments, AQL plays a pivotal role in maintaining consistent quality control throughout production cycles. By integrating AQL sampling into their processes, manufacturers can proactively identify potential issues early on and implement corrective actions swiftly. Additionally, using manufacturing quality inspection software enhances the effectiveness of these plans by automating data collection and analysis, further supporting better decision-making regarding product quality.

The Significance of AQL C=0

In the realm of quality control, AQL C=0 stands out as a pivotal standard that emphasizes zero tolerance for defects. This approach is particularly crucial in industries where safety and reliability are non-negotiable, such as pharmaceuticals and aerospace. By adopting AQL C=0 criteria, companies can enhance their reputation for quality while minimizing costly recalls or rework.

Understanding C=0 Criteria

The C=0 criteria in AQL sampling plans signify that no defective items are acceptable in a sample batch during quality inspection. Under this scheme, if even one defect is found, the entire lot may be rejected, prompting manufacturers to adopt stricter quality control measures. This rigorous approach ensures that products meet the highest standards before they reach consumers, ultimately fostering trust and satisfaction.

Impact on Quality Control

Implementing AQL C=0 has a profound impact on overall quality control processes within manufacturing environments. It compels quality control companies to refine their inspection techniques and invest in advanced manufacturing quality inspection software that can efficiently detect defects early in production. As a result, organizations not only improve product reliability but also enhance operational efficiency by reducing waste associated with defective goods.

Benefits for Quality Control Companies

Quality control companies leveraging the AQL C=0 standard enjoy several key benefits that set them apart from competitors. First and foremost, adhering to this stringent criterion allows these firms to market themselves as leaders in quality assurance, attracting clients who prioritize excellence in their supply chains. Additionally, by utilizing robust QA inspections supported by technology and thorough training for quality control inspectors, these companies can achieve higher customer satisfaction rates and foster long-term partnerships with manufacturers.

Step-by-Step Implementation

Implementing AQL sampling plans effectively requires a structured approach that aligns with your quality control objectives. This section breaks down the essential steps to ensure your quality inspection processes are both efficient and effective. By following these guidelines, you can enhance the reliability of your quality control measures.

Assessing Your Quality Needs

Before diving into AQL sampling plans, it's crucial to assess your specific quality needs. Understanding the nature of your products and the expectations of your customers will guide you in determining the appropriate level of scrutiny required during inspections. Quality control companies often recommend conducting a thorough analysis of past defects and customer feedback to identify areas where quality improvements are necessary.

This assessment will help you define what constitutes acceptable quality levels for your manufacturing processes. Consider factors such as production volume, product complexity, and regulatory requirements that might influence your quality control strategy. By aligning AQL sampling with these needs, you can create a tailored approach that enhances overall product integrity.

Selecting the Right AQL Level

Once you've assessed your quality needs, it's time to select the right AQL level for your products. The Acceptable Quality Level (AQL) is crucial because it defines the maximum number of defects allowed in a sample before rejecting an entire batch during quality inspections. Choosing an appropriate AQL level requires balancing risk and cost; too lenient an AQL might lead to customer dissatisfaction, while too strict could inflate costs unnecessarily.

Commonly used AQL levels range from 0.1% for critical items to 2% or more for less critical products, depending on industry standards and customer expectations. Collaborating with experienced professionals in quality control can provide insights into which levels best suit different scenarios within manufacturing environments. Remember that selecting an appropriate AQL level is not just about compliance; it’s about fostering trust with customers by consistently delivering high-quality products.

Establishing Inspection Protocols

With clear objectives set through assessing needs and selecting an AQL level, the next step is establishing robust inspection protocols tailored for effective QA inspections. These protocols should outline detailed procedures for how inspections will be conducted, including sample sizes, testing methods, and documentation processes necessary for maintaining transparency in quality control practices.

Utilizing manufacturing quality inspection software can streamline this process by automating data collection and reporting tasks associated with inspections—making it easier to track compliance over time while minimizing human error during evaluations. Additionally, incorporating regular training sessions for your quality control inspectors ensures they stay updated on best practices while honing their skills in identifying defects accurately.

By implementing well-defined inspection protocols supported by technology and training initiatives, you'll not only improve consistency but also foster a culture of continuous improvement within your organization regarding its commitment to high-quality standards.

Choosing Quality Control Software

In today's fast-paced manufacturing environment, selecting the right quality control software is crucial for effective quality inspection processes. With a plethora of options available, it's essential to identify features that align with your specific needs, particularly when utilizing AQL sampling plans. This choice can significantly impact the efficiency and accuracy of your quality control practices.

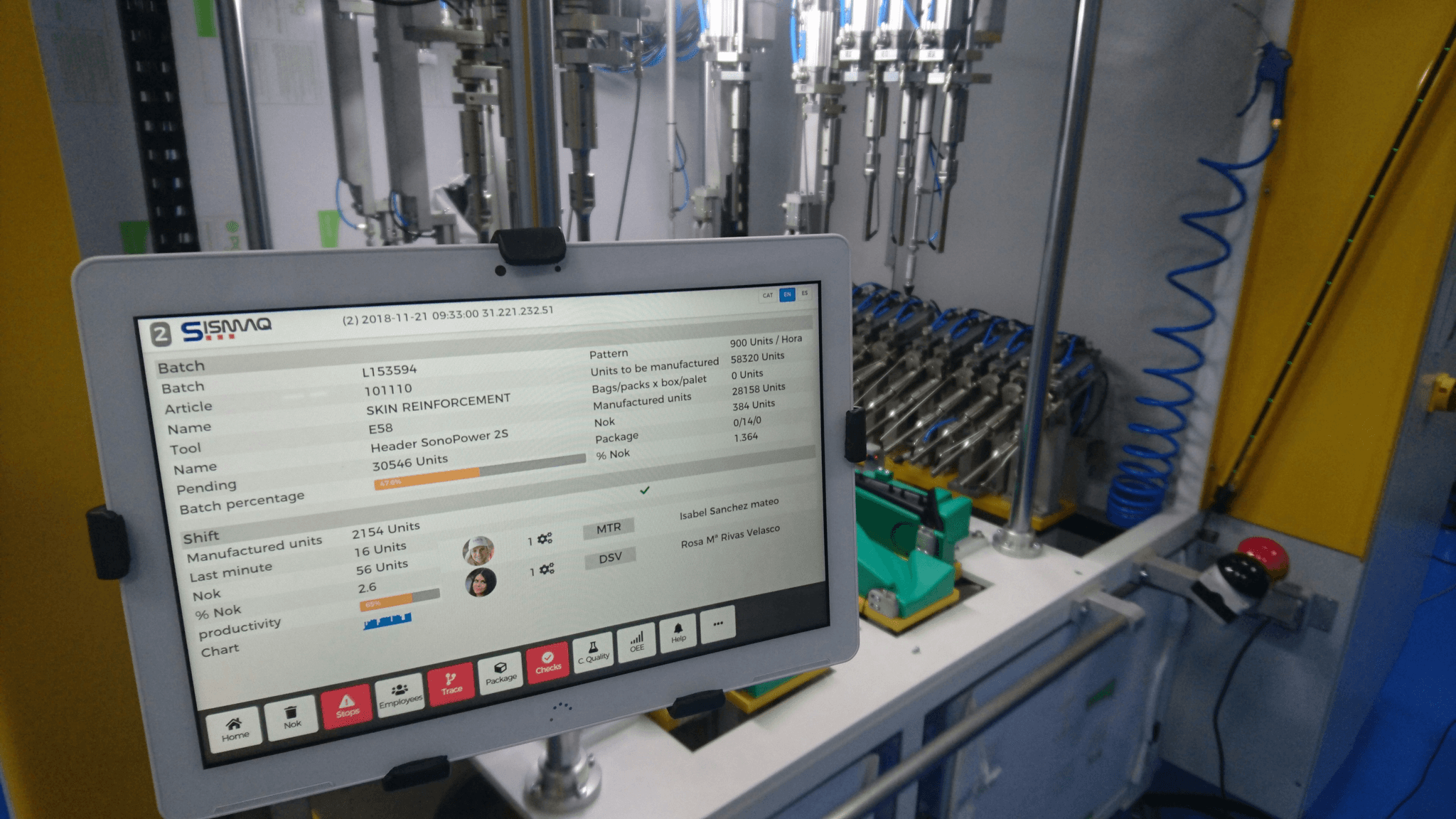

Features of Manufacturing Quality Inspection Software

When evaluating manufacturing quality inspection software, several key features should be prioritized to ensure optimal performance. First and foremost, robust reporting capabilities are essential; they allow quality control companies to track defects and analyze trends over time effectively. Additionally, user-friendly interfaces streamline the training process for new quality control inspectors, enabling them to navigate the system with ease.

Another critical feature is real-time data collection, which ensures that any issues detected during AQL sampling plans can be addressed immediately. Integration with existing systems is also vital; seamless connectivity allows for smoother workflows and enhances overall productivity in QA inspections. Lastly, customizable dashboards provide insights tailored to your unique quality control needs, helping teams make informed decisions swiftly.

Integrating Software with AQL Sampling

Integrating your chosen software with AQL sampling methodologies can elevate your quality inspection processes significantly. This integration allows for automated calculations and assessments based on predefined AQL levels, reducing human error during inspections. Moreover, it enables real-time monitoring of compliance with established standards while facilitating swift adjustments when deviations occur.

Additionally, a well-integrated system supports data analysis related to historical inspection results derived from AQL sampling plans. By leveraging this data, companies can refine their inspection protocols and improve overall product quality over time. The synergy between software tools and AQL methodologies empowers organizations to maintain rigorous standards without sacrificing efficiency.

Popular Tools for Effective QA Inspections

There are several popular tools available that cater specifically to the needs of QA inspections within manufacturing settings using AQL sampling plans. One standout option is Minitab—a statistical analysis tool that offers robust features for managing data from various inspection processes while supporting compliance with industry standards. Another notable choice is InfinityQS—this software specializes in statistical process control (SPC) and provides real-time insights into production performance.

For those seeking a cloud-based solution, Qualio offers an intuitive platform designed specifically for managing quality documentation and ensuring compliance across various sectors in manufacturing environments. Each of these tools enhances the capabilities of quality control companies by streamlining their processes related to inspections while fostering a culture of continuous improvement among their teams of inspectors.

Training Your Quality Control Inspector

Training your quality control inspector is vital for maintaining high standards in quality inspection and ensuring that aql sampling plans are effectively implemented. A well-trained inspector not only identifies defects but also contributes to the overall improvement of manufacturing processes. Investing in the right training programs can lead to significant benefits for quality control companies and their clients.

Key Skills for Inspectors

Quality control inspectors must possess a blend of technical skills, analytical thinking, and attention to detail. Familiarity with aql sampling plans is crucial, as it enables them to apply appropriate inspection techniques based on predefined acceptance criteria. Additionally, strong communication skills are essential for conveying findings clearly and collaborating with production teams to address any quality issues.

Inspectors should also be adept at using manufacturing quality inspection software, which streamlines the process of documenting inspections and analyzing data trends. This proficiency allows them to quickly identify patterns that could indicate systemic issues within manufacturing processes. Furthermore, problem-solving skills enable inspectors to propose effective solutions when discrepancies arise during qa inspections.

Best Practices for QA Training

Implementing best practices in QA training ensures that quality control inspectors are equipped with the necessary knowledge and skills to perform their duties effectively. Training programs should include both theoretical knowledge about aql sampling and hands-on experience with real-world scenarios encountered during inspections. This combination helps reinforce learning and prepares inspectors for the challenges they may face on the job.

Incorporating regular workshops or refresher courses can keep inspectors updated on industry standards, new technologies, and evolving methodologies in quality control. Engaging inspectors in discussions about common pitfalls during qa inspections fosters a culture of continuous improvement within the team. Moreover, mentorship opportunities can provide newer inspectors with guidance from seasoned professionals who have navigated similar challenges.

Continuous Improvement in Inspection Skills

Continuous improvement is crucial in maintaining high-quality standards within any organization focused on quality control. Encouraging inspectors to seek feedback after each inspection fosters an environment where they can learn from their experiences and refine their techniques over time. Regular performance evaluations can highlight areas needing development while celebrating achievements that motivate further growth.

Additionally, leveraging technology such as manufacturing quality inspection software not only facilitates easier tracking of inspector performance but also aids in identifying trends that require attention or adjustment in training methods. Quality control companies should prioritize creating pathways for professional development by offering certifications or specialized training related to aql sampling plans or advanced inspection techniques. By investing in ongoing education, organizations ensure their teams remain competitive and adept at tackling new challenges presented by evolving industry standards.

Conclusion

In the ever-evolving landscape of manufacturing, ensuring consistent quality control is paramount. AQL sampling plans provide a framework for maintaining high standards in product quality, which is essential for customer satisfaction and brand reputation. By implementing effective quality inspection protocols, companies can minimize defects and enhance their overall operational efficiency.

Ensuring Consistent Quality Control

Consistent quality control hinges on the effective application of AQL sampling plans that guide businesses in identifying acceptable defect levels during inspections. These plans empower quality control companies to systematically evaluate products, ensuring they meet established standards before reaching consumers. Ultimately, this proactive approach not only safeguards a company’s reputation but also fosters long-term relationships with customers who value reliability.

The Role of China Inspection Pro

China Inspection Pro stands out as a leader in the realm of quality control by offering comprehensive solutions tailored to meet diverse manufacturing needs. Their expertise in AQL sampling and commitment to rigorous quality inspection processes make them an invaluable partner for businesses aiming to maintain high-quality outputs. With advanced manufacturing quality inspection software, they streamline inspections and enhance communication between manufacturers and clients, ensuring transparency throughout the process.

Future of AQL Sampling in Industry

The future of AQL sampling in industry looks bright as more companies recognize its significance in bolstering their quality control efforts. As technology continues to advance, integrating sophisticated data analytics into AQL sampling plans will likely enhance their effectiveness further by providing real-time insights into production processes. Quality control inspectors equipped with these tools will be better positioned to uphold standards and adapt swiftly to changing market demands.