Introduction

In the world of coffee making, quality is paramount. Whether you’re brewing a cup in a Manual Coffee Machine or an Electric Coffee Machine, understanding the potential Quality Defects in Commercial Coffee Makers can save you from a bitter experience. With various types of machines available, including Stovetop Coffee Machines, it’s essential to recognize and address typical coffee machine quality defects to ensure your daily brew is as delightful as possible.

Understanding Quality Defects in Coffee Makers

Quality defects can manifest in many ways across different types of coffee makers. For instance, a Manual Coffee Machine may struggle with brewing consistency if its components are not up to par, while an Electric Coffee Machine might face electrical failures that pose safety hazards. By familiarizing yourself with these issues, you can better appreciate how they impact not just the taste of your coffee but also the longevity and reliability of your equipment.

Importance of Inspection Checklists

Regularly reviewing these lists allows you to catch typical coffee machine quality defects early on—whether they arise from heat distribution issues or misaligned heating elements in electric models. This proactive approach not only enhances safety but also maximizes the performance and lifespan of your beloved coffee makers.

Ensuring Optimal Performance for Your Machines

To ensure optimal performance for your machines, consistent maintenance is key across all types—from Manual and Electric Coffee Machines to Stovetop varieties. By routinely inspecting parts and addressing any signs of wear or damage, you can mitigate common quality defects that threaten your brewing experience. Ultimately, investing time in maintenance and inspections will lead to better-tasting coffee and less frustration over faulty machines.

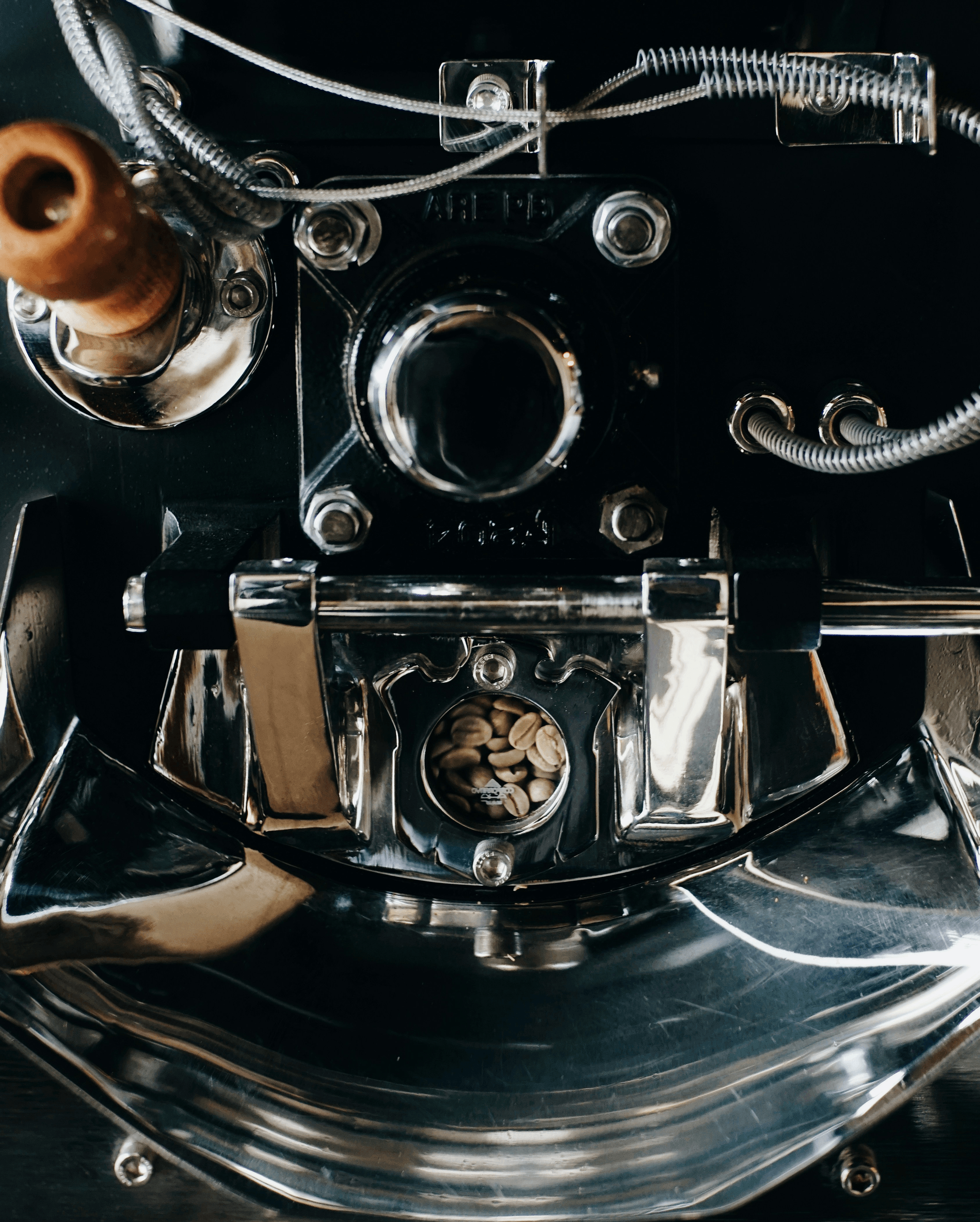

Common Quality Defects in Manual Coffee Machines

The quality defects in commercial coffee makers are often reflected in the manual models as well, where user control and craftsmanship play pivotal roles. Understanding these defects not only enhances the brewing experience but also ensures that your morning ritual is free from hiccups.

Issues with Brewing Consistency

Brewing consistency is one of the most common quality defects found in manual coffee machines. Variations in grind size, water temperature, and brewing time can lead to a cup of coffee that tastes more like a game of roulette than a reliable morning pick-me-up. If your manual coffee machine isn’t calibrated correctly or lacks uniformity in its brewing process, you might find yourself stuck with an unpredictable cup that swings from delightful to disastrous.

Problems with Heat Distribution

Another significant issue lies in heat distribution within these machines. Uneven heating can result in under-extraction or over-extraction of flavors from the coffee grounds, leading to an imbalanced brew. Inconsistent heat distribution is among typical coffee machine quality defects that can frustrate even the most patient barista wannabes; after all, no one wants a lukewarm cup when they’re craving a robust espresso.

Durability Concerns with Components

Durability concerns are particularly relevant when discussing manual coffee machines; after all, they rely heavily on physical components for optimal performance. Parts such as filters and carafes often wear out faster than expected due to frequent use and exposure to heat, compromising both functionality and safety over time. Addressing these durability issues early on can save you from future headaches and ensure that your manual machine remains a reliable companion for years to come.

Typical Coffee Machine Quality Defects in Electric Models

Electric coffee machines are a marvel of modern convenience, but they aren’t without their fair share of quality defects. From electrical failures to pressure inconsistencies, these issues can turn your morning ritual into a frustrating experience. Let's dive into some common problems that plague electric coffee machines and how they relate to the broader category of quality defects in commercial coffee makers.

Electrical Failures and Safety Hazards

One of the most alarming quality defects in electric coffee machines is electrical failure, which can lead to safety hazards that no one wants to deal with before their first cup of joe. These failures can manifest as faulty wiring or malfunctioning components, creating risks like short circuits or even fire hazards. Regular inspections are crucial for identifying these electrical issues early on, ensuring that your electric coffee machine operates safely and effectively.

In the realm of commercial coffee makers, such electrical defects can cause significant downtime and loss of business. Nobody wants to face an unexpected closure because their equipment has decided it’s time for a vacation! By paying attention to these potential pitfalls, you can keep your electric coffee machine—and your customers—happy and safe.

Inconsistent Pressure Problems

Another typical quality defect in electric models is inconsistent pressure during brewing, which leads to subpar extraction and an unsatisfying cup of coffee. This issue often arises from blockages in the pump or malfunctions within the pressure system itself, leaving you with weak or overly bitter brews instead of the rich flavors you crave. Consistent pressure is vital for achieving that perfect cup; without it, your electric coffee machine may feel like it's just going through the motions.

For commercial operations relying on high-quality beverages, addressing pressure inconsistencies is non-negotiable. If you're serving customers who expect top-notch espresso or drip coffee every time, investing time into understanding these faults will pay off handsomely in customer satisfaction (and repeat business). So keep an eye out for those rogue pressure fluctuations!

Misalignment of Heating Elements

Misalignment of heating elements is yet another pesky issue that can plague electric coffee machines—especially if they’ve seen better days! When heating elements aren’t positioned correctly, it can result in uneven heat distribution throughout the brewing process. This misalignment not only affects flavor but also contributes to longer brew times and wasted energy—a double whammy for efficiency.

In both manual and commercial settings alike, addressing this defect ensures optimal performance from your equipment while maximizing energy use—a win-win situation! Regular maintenance checks will help catch any misalignments before they become major headaches down the line. After all, nobody wants a cold cup when they’re expecting something piping hot!

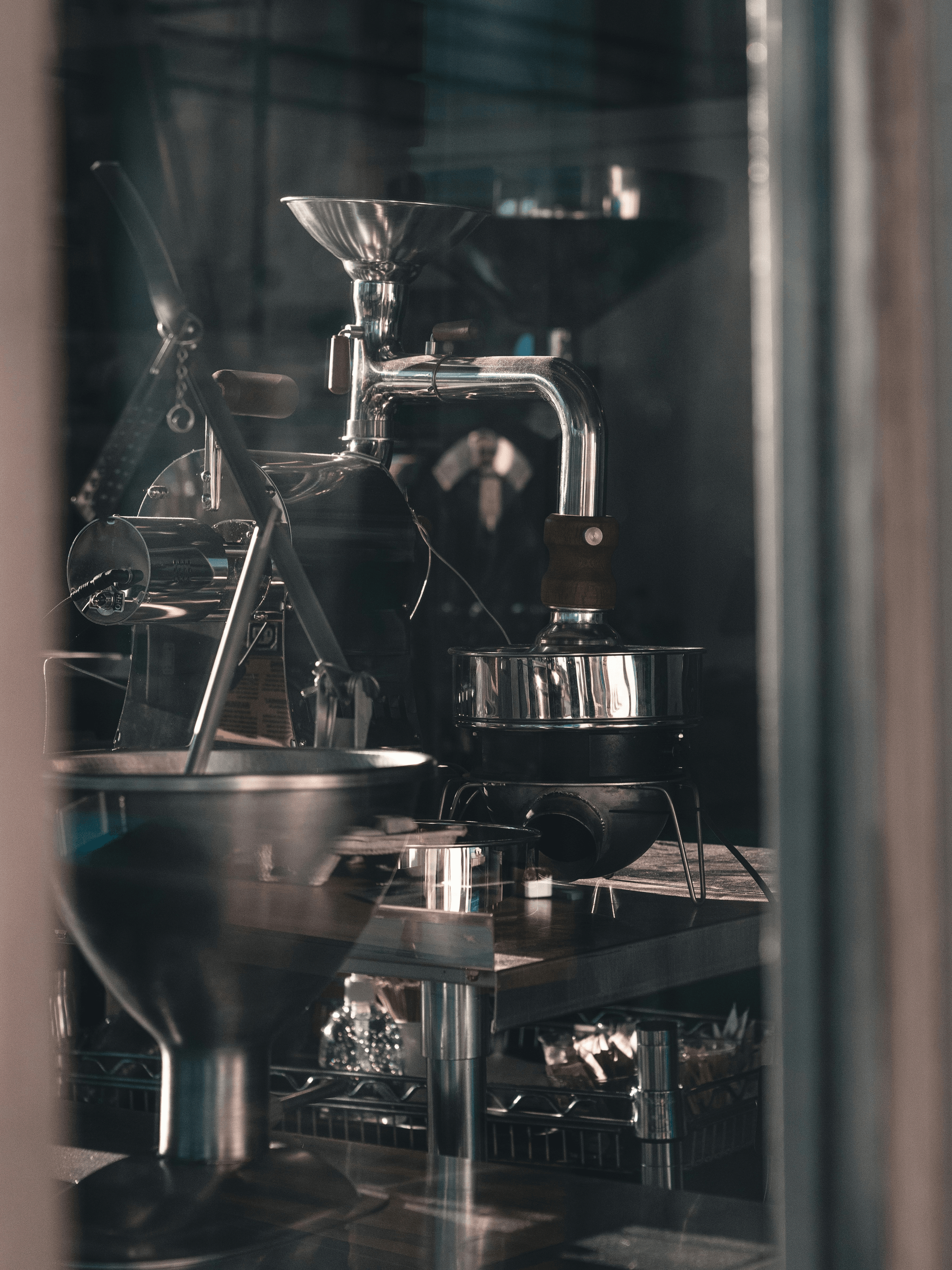

Quality Defects in Stovetop Coffee Machines

Stovetop coffee machines, beloved for their simplicity and rich flavor, are not immune to quality defects. While they may seem straightforward, even the best stovetop models can suffer from issues that compromise the brewing experience. Understanding these defects is crucial for both consumers and manufacturers alike to ensure optimal performance and satisfaction.

Inefficient Water Flow

One of the most common quality defects in stovetop coffee machines is inefficient water flow. This issue can arise from clogs or improper assembly, leading to uneven extraction and a less-than-stellar cup of coffee. When water flows too slowly or not at all, it can ruin the brewing process entirely, leaving you with a bitter or weak brew that no one wants to sip.

Moreover, inefficient water flow can also indicate potential problems in other areas of the machine. For instance, if the filter is blocked or if there are issues with seals, these could lead to leaks or further inefficiencies down the line. Regular inspection of your manual coffee machine can help catch these issues before they escalate into more significant problems.

Difficulty in Achieving Proper Brew Time

Another notable defect associated with stovetop coffee machines is difficulty in achieving proper brew time. The ideal brewing time is essential for extracting flavors effectively; however, inconsistencies often plague users due to various factors such as heat distribution and water flow rates. If your electric coffee machine doesn’t maintain a steady temperature throughout the brewing cycle, you might find yourself waiting longer than necessary for that perfect cup.

This challenge often leads users to overcompensate by adjusting their cooking times manually—a risky game that could result in burnt grounds or under-extracted flavors. In essence, relying on trial and error rather than precise measurements diminishes the joy of making coffee altogether! To mitigate this issue, investing in high-quality components and regularly checking your stovetop model's functionality is vital.

Material Quality and Safety Issues

Lastly, material quality stands as a significant concern when discussing typical coffee machine quality defects among stovetop models. Many consumers may overlook this aspect while shopping but choosing poorly made materials can lead to safety hazards such as overheating or chemical leaching into your brew. High-quality metals not only enhance durability but also ensure that no harmful substances interfere with your morning ritual.

Additionally, subpar materials can impact how well a stovetop coffee machine retains heat—affecting both efficiency and taste over time. Ensuring that you select models made from safe materials will promote longevity while safeguarding your health during each brewing session! Always look out for certifications indicating compliance with safety standards when purchasing any commercial coffee maker.

Preventative Measures for Quality Issues

Regular maintenance, the use of quality parts, and early detection of potential issues can significantly enhance the longevity and performance of your coffee machines. Whether you’re dealing with a Manual Coffee Machine, Electric Coffee Machine, or Stovetop Coffee Machine, these preventative measures are essential.

Regular Maintenance Tips

Regular maintenance is crucial for preventing Typical Coffee Machine Quality Defects from becoming major headaches. For instance, cleaning your coffee maker regularly not only removes residue but also ensures that components function optimally. Additionally, descaling your machines periodically helps prevent mineral buildup that can affect brewing consistency across all types of coffee makers.

Inspecting seals and gaskets in Manual Coffee Machines can prevent leaks and ensure proper pressure during brewing. For Electric Coffee Machines, checking electrical connections and ensuring that filters are clean will help maintain consistent performance. Meanwhile, Stovetop Coffee Machines benefit from regular checks on the water flow system to ensure that every cup brewed is as delightful as the last.

Importance of Using Quality Parts

Using quality parts is non-negotiable when it comes to minimizing Quality Defects in Commercial Coffee Makers. Cheap or subpar components can lead to a cascade of issues—from inconsistent brew times in Electric Coffee Machines to heat distribution problems in Manual models. Investing in high-grade replacement parts not only enhances durability but also ensures safety across all machine types.

For those operating Stovetop Coffee Machines, using quality materials like stainless steel can prevent rust and degradation over time. This not only contributes to better flavor extraction but also maintains the integrity of your equipment for years to come. Remember: when it comes to coffee machines, you often get what you pay for—so don’t skimp on quality!

How to Identify Early Warning Signs

Identifying early warning signs can save you from facing severe Quality Defects in Commercial Coffee Makers down the line. Keep an eye out for unusual noises or inconsistent brewing times as these could indicate deeper issues within your Electric or Manual models. If you notice any leaks or excessive steam escaping from your Stovetop Coffee Machine, it’s time for some immediate troubleshooting.

Pay attention to changes in taste as well; if your coffee suddenly tastes off or bitter despite using fresh beans and clean water, this could be a sign of underlying problems with heat distribution or component wear-and-tear across any type of machine you're using. Lastly, make a habit of inspecting all visible parts regularly; a little vigilance goes a long way toward prolonging the life and performance of your beloved coffee maker.

The Role of Professional Inspections

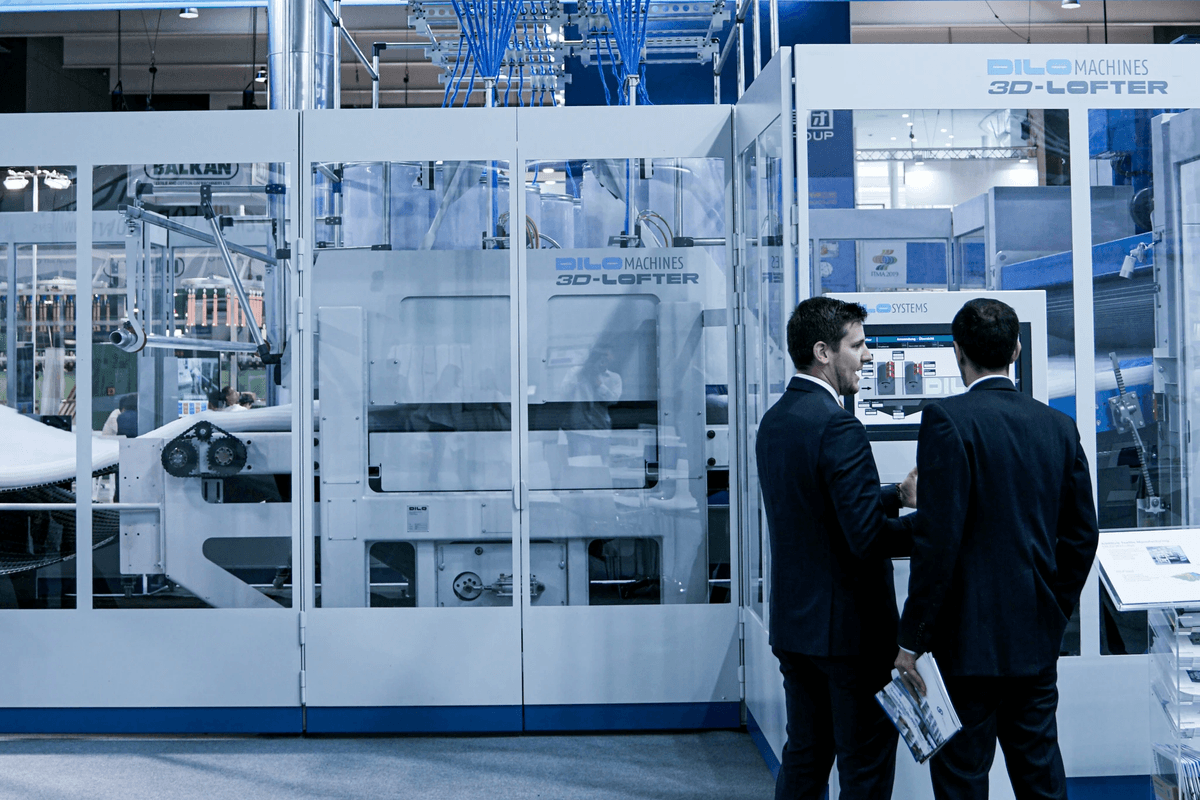

When it comes to ensuring the quality and longevity of coffee machines, professional inspections play a pivotal role. Hiring experts like China Inspection Pro can significantly reduce the risk of encountering typical coffee machine quality defects in commercial settings. These inspections not only enhance product reliability but also provide peace of mind for manufacturers and consumers alike.

Benefits of Hiring China Inspection Pro

One major benefit of hiring China Inspection Pro is their extensive experience in identifying quality defects in commercial coffee makers. Their team is well-versed in the nuances between manual coffee machines, electric coffee machines, and stovetop coffee machines, making them an invaluable asset during inspections. Additionally, they help streamline the inspection process, which can save time and reduce costly delays in production.

Another advantage is that these professionals utilize advanced tools and techniques to detect even the subtlest issues that may lead to significant problems down the line. By addressing potential quality defects early on, manufacturers can avoid costly recalls or repairs later in the product lifecycle. This proactive approach not only enhances customer satisfaction but also bolsters brand reputation by ensuring high-quality products reach the market.

Lastly, working with China Inspection Pro means you’re tapping into a network of industry contacts and resources that can further support your production goals. They provide insights into best practices for maintaining equipment and offer recommendations for sourcing high-quality parts that minimize future defects. In an industry where every cup counts, having a reliable inspection partner can make all the difference.

Understanding the Inspection Process

The inspection process conducted by professionals typically involves several key steps designed to meticulously evaluate each type of coffee maker for quality defects. Initially, inspectors will conduct a visual examination to identify any obvious flaws or inconsistencies across manual coffee machines, electric coffee machines, or stovetop models. This first step is crucial as it sets the stage for more detailed assessments.

Following this initial review, inspectors perform functional tests to ensure that each machine operates as intended under various conditions—checking factors such as brewing consistency and heat distribution across different models. For instance, they might simulate user scenarios to uncover issues related to pressure inconsistencies or material safety concerns specific to stovetop coffee machines or electric variants. This hands-on approach helps verify that each unit meets performance standards before reaching consumers.

Finally, inspectors compile their findings into comprehensive reports detailing any identified quality defects along with recommendations for improvement or remediation strategies. These reports serve as essential documentation not only for manufacturers but also for compliance purposes with industry regulations governing commercial appliances like coffee makers.

Ensuring Compliance with Industry Standards

Ensuring compliance with industry standards is paramount when evaluating quality defects in commercial coffee makers; it protects both consumers and manufacturers alike from potential hazards associated with subpar products. Professional inspections help verify adherence to safety guidelines set forth by organizations such as UL (Underwriters Laboratories) or CE (Conformité Européenne). By meeting these standards, companies can assure customers that their manual coffee machines and electric counterparts are safe for everyday use.

Moreover, compliance enhances marketability by instilling confidence among retailers who want assurance that they are offering reliable products free from typical quality machine defects like electrical failures or misaligned heating elements. Inspectors often keep abreast of changing regulations within the industry so they can provide accurate guidance on what constitutes compliant manufacturing practices—ensuring your products don’t just meet current standards but are also prepared for future changes.

In conclusion, engaging professional inspection services significantly mitigates risks associated with typical coffee machine quality defects while promoting adherence to vital safety standards within an increasingly competitive market landscape—ultimately leading towards improved consumer trust and satisfaction over time.

Conclusion

In our exploration of quality defects in coffee makers, we've uncovered a range of issues that can affect both manual and electric models, as well as stovetop varieties. From brewing inconsistencies to electrical failures, understanding these typical coffee machine quality defects is essential for ensuring your coffee maker performs at its best. As we've seen, regular inspections and maintenance can help mitigate these issues and extend the life of your beloved brewing machines.

Recap of Typical Quality Defects

Quality defects in commercial coffee makers can manifest in various ways across different types of machines. Manual coffee machines often struggle with brewing consistency and durability concerns, while electric models may face electrical failures or misalignment of heating elements. Stovetop coffee machines aren't immune either; they can suffer from inefficient water flow and material safety issues that impact the overall brewing experience.

Importance of a Thorough Inspection Checklist

A thorough inspection checklist is crucial for identifying potential quality defects in commercial coffee makers before they lead to bigger problems. By systematically evaluating each component—from the heating elements to the pressure systems—you can catch early signs of wear or malfunction. This proactive approach not only saves time and money but also ensures that your manual, electric, or stovetop coffee machine operates smoothly for years to come.

Enhancing Coffee Machine Longevity and Performance

To enhance the longevity and performance of your coffee maker, it's vital to implement regular maintenance practices tailored to each type—be it a manual coffee machine or an electric one. Using high-quality parts during repairs significantly reduces the likelihood of recurring typical coffee machine quality defects that could disrupt your daily brew ritual. Ultimately, investing time in proper care will reward you with consistently great-tasting coffee and a dependable machine you can rely on.