Introduction

In the glimmering world of jewelry, quality control is the unsung hero that ensures every piece shines not just in appearance but in integrity. Jewelry Quality Control Inspection is essential for maintaining the standards that consumers expect, particularly when it comes to imitation jewelry, which often faces scrutiny for its materials and craftsmanship. By understanding how to properly evaluate quality, manufacturers can safeguard their reputation and ensure customer satisfaction.

Understanding Jewelry Quality Control

Jewelry Quality Control Inspection involves a systematic approach to evaluating the quality of jewelry products throughout the manufacturing process. This includes assessing materials, craftsmanship, and overall design to ensure they meet established standards. By implementing rigorous quality control measures, manufacturers can identify potential issues early on and rectify them before reaching the consumer.

Importance of Quality in Imitation Jewelry

The importance of quality in imitation jewelry cannot be overstated; it directly influences consumer perceptions and purchasing decisions. High-quality imitation pieces can rival their genuine counterparts in beauty while being more accessible financially. Conversely, subpar products not only disappoint customers but can also tarnish brand reputation—a risk no company wants to take.

Key Factors in Quality Control Inspection

Several key factors play a pivotal role in effective Jewelry Quality Control Inspection processes. These include visual assessments, material testing for durability, and meticulous evaluation of workmanship and finish. By focusing on these elements during inspections, manufacturers can ensure that their imitation jewelry not only meets industry standards but also delights consumers with its aesthetic appeal.

Standards for Imitation Jewelry

In the world of imitation jewelry, establishing rigorous standards is essential for maintaining quality and consumer trust. Quality metrics serve as the backbone of Jewelry Quality Control Inspection, allowing manufacturers to evaluate their products against specific criteria. By defining these metrics, businesses can ensure consistency and reliability in their offerings, ultimately leading to a more satisfied customer base.

Defining Quality Metrics

Quality metrics in imitation jewelry encompass a range of factors including material composition, durability, and aesthetic appeal. These metrics are crucial for effective Jewelry Quality Control Inspection as they provide measurable benchmarks that can guide manufacturers in assessing their products. By focusing on these defined quality indicators, brands can enhance their reputation and reduce the likelihood of defects slipping through the cracks.

Industry-Specific Benchmarks

Different segments within the imitation jewelry market may have unique benchmarks tailored to their target demographics and style preferences. For instance, fashion-forward brands might prioritize trend alignment and vibrant color palettes, while classic designs may focus more on timeless elegance and craftsmanship. Establishing industry-specific benchmarks not only aids in Jewelry Quality Control Inspection but also helps brands position themselves competitively within the marketplace.

The Role of Certification

Certification plays a pivotal role in reinforcing quality standards across the imitation jewelry industry. Accredited bodies evaluate products based on predefined criteria related to materials and craftsmanship before granting certification status. This not only enhances customer confidence but also streamlines Jewelry Quality Control Inspection processes by providing an additional layer of assurance that products meet established quality standards.

Inspection Techniques for Manufacturers

When it comes to Jewelry Quality Control Inspection, manufacturers must adopt a multifaceted approach to ensure their products meet the highest standards. This section delves into various inspection techniques that can significantly enhance the quality of imitation jewelry. By implementing effective inspection processes, manufacturers can identify defects early and maintain their reputation in a competitive market.

Visual Inspection Processes

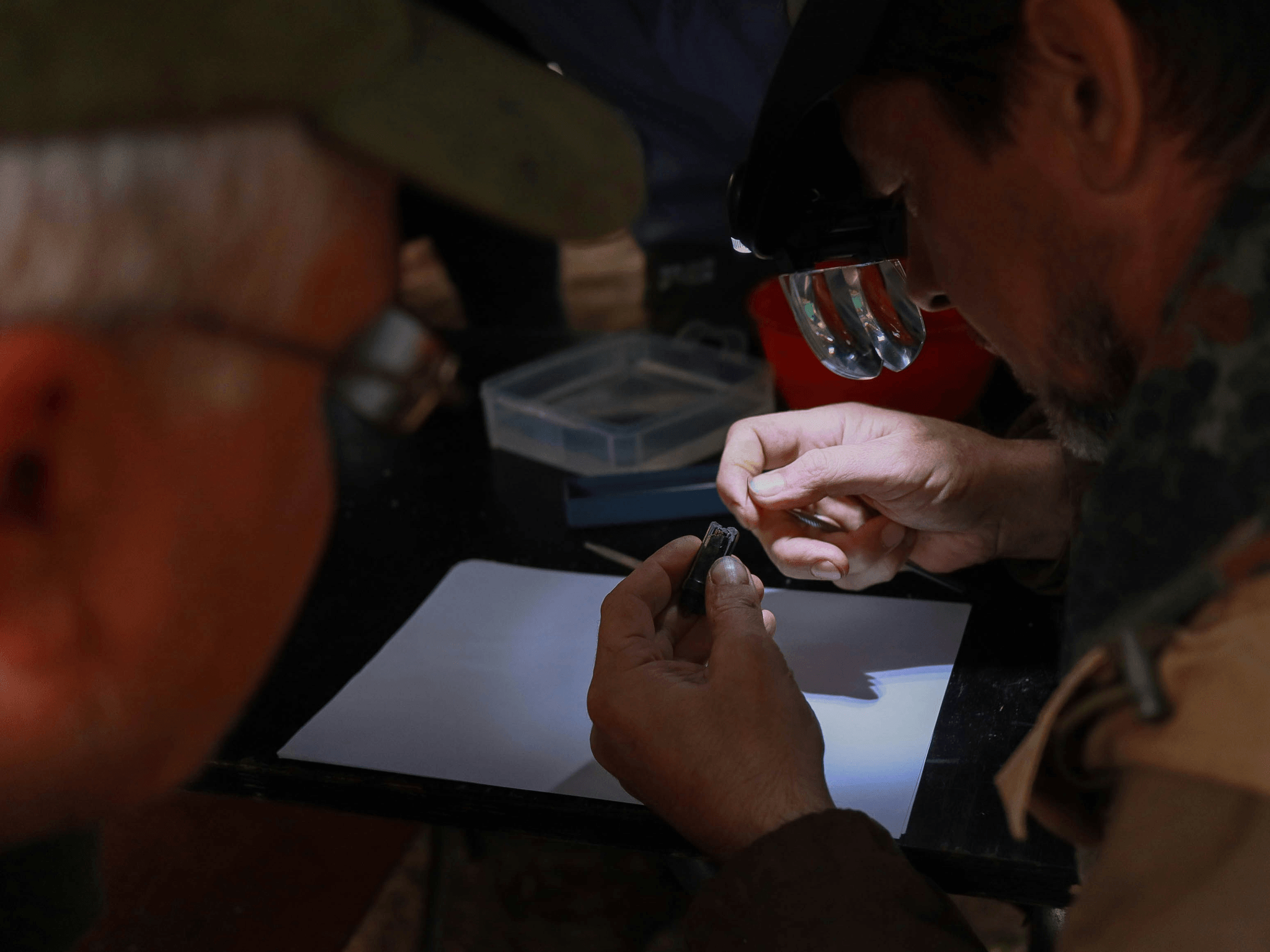

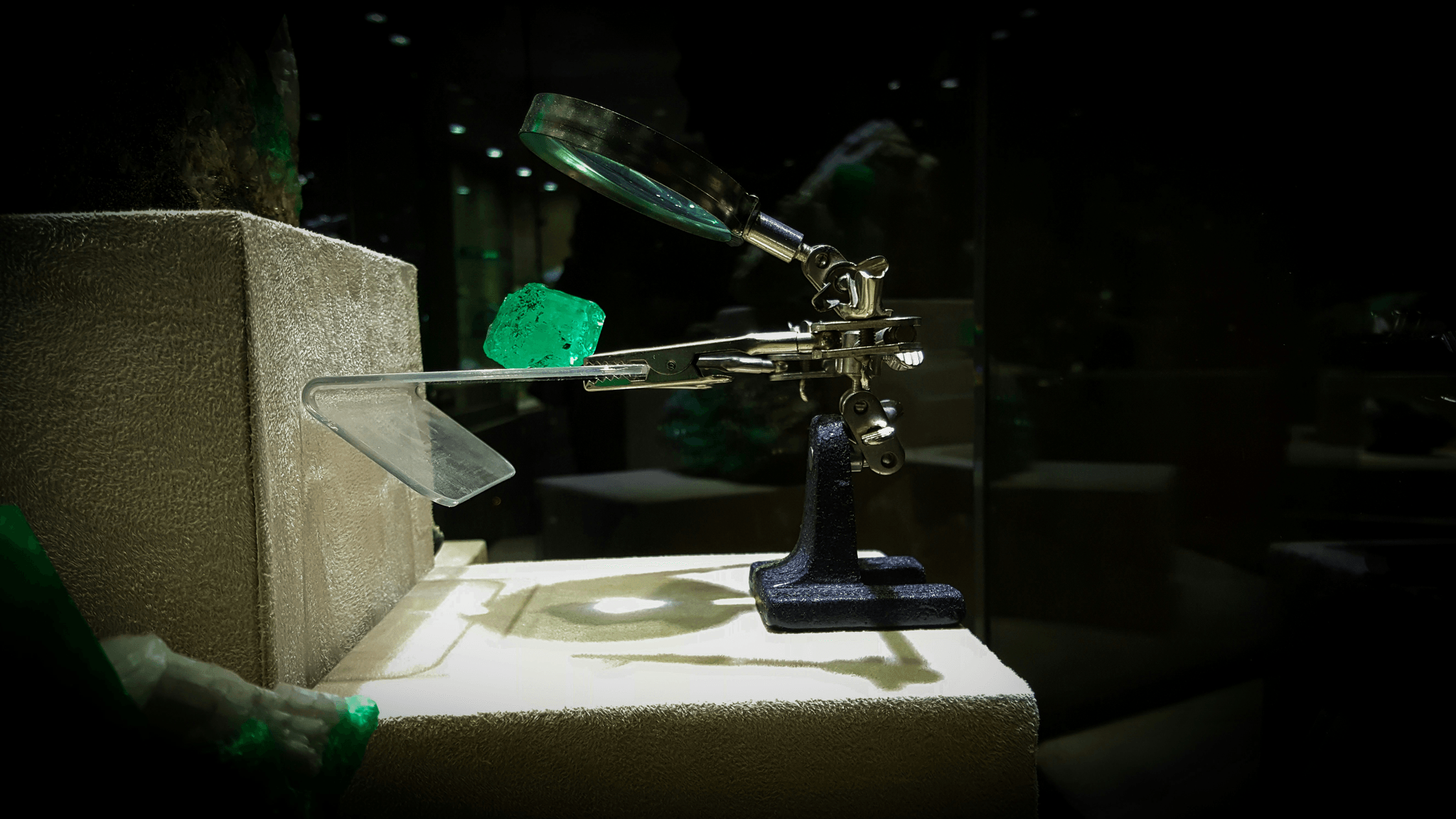

Visual inspection processes are fundamental in Jewelry Quality Control Inspection, allowing inspectors to assess the overall appearance of imitation jewelry. This technique involves scrutinizing pieces for any visible flaws such as scratches, discoloration, or inconsistencies in design. An experienced inspector can often spot issues that might not be apparent during other forms of testing, making this an invaluable step in maintaining quality.

To conduct a thorough visual inspection, it's essential to have proper lighting and magnification tools at hand. Inspectors should examine each piece from multiple angles and under different lighting conditions to ensure no defect goes unnoticed. By prioritizing visual inspections, manufacturers can catch potential problems before they reach consumers, thus safeguarding their brand's integrity.

Testing Materials for Durability

Durability testing is another critical aspect of Jewelry Quality Control Inspection that assesses how well materials withstand wear and tear over time. Different materials used in imitation jewelry have varying levels of resilience; therefore, understanding these properties is vital for ensuring product longevity. Common tests include scratch resistance assessments and exposure to environmental factors like moisture and UV light.

Manufacturers often use standardized tests to evaluate material performance under controlled conditions. For example, conducting a tensile strength test can reveal how much stress a piece can endure before breaking or deforming. By rigorously testing materials for durability, manufacturers not only enhance product quality but also build consumer trust by delivering reliable items.

Assessing Workmanship and Finish

Assessing workmanship and finish is crucial within the realm of Jewelry Quality Control Inspection as it reflects on the craftsmanship behind each piece of jewelry. Inspectors examine details such as solder joints, stone settings, and surface finishes to ensure they meet industry standards for quality. A well-finished piece not only looks appealing but also signifies reliability and attention to detail.

A thorough assessment may involve checking for uniformity across multiple pieces produced from the same batch; inconsistencies could indicate underlying production issues that need addressing immediately. Moreover, evaluating workmanship helps identify areas where training or improvements may be necessary within manufacturing processes—ultimately leading to enhanced quality control practices overall. By focusing on both workmanship and finish during inspections, manufacturers reinforce their commitment to excellence in imitation jewelry production.

Tools for Effective Quality Control

In the world of imitation jewelry, ensuring top-notch quality is paramount. To achieve this, manufacturers need to leverage a variety of tools and technologies designed specifically for Jewelry Quality Control Inspection. By utilizing these advanced methods, companies can identify defects early in the production process and maintain high standards.

Utilizing Advanced Inspection Technology

Advanced inspection technology has revolutionized Jewelry Quality Control Inspection by introducing precision and efficiency into the process. Techniques such as 3D scanning, X-ray fluorescence (XRF), and digital microscopy allow inspectors to detect minute flaws that may go unnoticed during traditional inspections. By integrating these technologies into their workflows, manufacturers can ensure that every piece meets stringent quality metrics.

Moreover, automation in inspection processes reduces human error and speeds up production timelines, leading to quicker market readiness without compromising on quality. The data collected from these advanced tools also helps in analyzing trends over time, enabling manufacturers to adapt their processes based on historical performance. Ultimately, investing in cutting-edge technology enhances overall product integrity while boosting consumer confidence in imitation jewelry.

Importance of Sample Testing

Sample testing is a critical aspect of Jewelry Quality Control Inspection that cannot be overlooked. By examining a representative sample from each batch produced, manufacturers can assess the overall quality without needing to inspect every single piece individually—saving time and resources while still ensuring standards are met. This method allows for early detection of potential issues before they escalate into larger problems affecting entire production runs.

Additionally, sample testing provides valuable insights into material durability and craftsmanship consistency across different pieces. It acts as a safeguard against subpar products reaching consumers' hands, which could tarnish brand reputation significantly. In essence, regular sample testing is not just about compliance; it's about cultivating trust with customers who expect reliable quality from their jewelry purchases.

Essential Equipment for Inspectors

Every Jewelry Quality Control Inspection team should be equipped with essential tools that facilitate thorough evaluations of imitation jewelry pieces. Items such as magnifying loupes for detailed visual checks and hardness testers for assessing material durability are crucial for identifying defects quickly and accurately. Furthermore, using calipers or micrometers ensures precise measurements are taken during inspections.

Investing in high-quality equipment not only streamlines the inspection process but also empowers inspectors to deliver consistent results across various product lines. Regular calibration of these tools is equally vital to maintain accuracy over time; after all, even the best equipment can become unreliable if not properly maintained! With well-equipped inspectors on board, manufacturers can uphold rigorous standards throughout their production cycles.

Common Defects in Imitation Jewelry

Imitation jewelry, while often more affordable than its fine counterparts, can suffer from a range of defects that compromise its quality and appeal. Understanding these common flaws is crucial for manufacturers aiming to uphold high standards through effective Jewelry Quality Control Inspection. By identifying and addressing these issues early on, brands can enhance their reputation and ensure customer satisfaction.

Identifying Material Flaws

Material flaws in imitation jewelry can manifest in various ways, such as discoloration, brittleness, or improper alloy compositions. These imperfections not only affect the aesthetic appeal but also the durability of the pieces. A rigorous Jewelry Quality Control Inspection process should include tests for material integrity to ensure that items meet industry standards and consumer expectations.

Another common material flaw is the use of subpar coatings or finishes that may chip or wear off quickly. Inspectors must be vigilant about assessing surface treatments to prevent tarnishing or fading over time. By focusing on material quality during inspections, manufacturers can significantly reduce returns and boost customer confidence in their products.

Recognizing Design and Craftsmanship Issues

Design and craftsmanship are pivotal elements in determining the overall quality of imitation jewelry. Common issues include misaligned components, uneven finishes, and poorly executed settings that detract from a piece's visual appeal. Effective Jewelry Quality Control Inspection should involve detailed scrutiny of design elements to ensure they align with brand standards.

Additionally, craftsmanship problems like rough edges or inadequate soldering can lead to discomfort when wearing jewelry items. Inspectors need to pay attention not just to aesthetics but also functionality during inspections to catch these potential pitfalls early on. Ultimately, ensuring high-quality design and craftsmanship will set a brand apart in a crowded marketplace.

The Impact of Poor Quality on Brand Reputation

The repercussions of poor-quality imitation jewelry extend far beyond unsatisfied customers; they can severely damage a brand's reputation over time. When consumers encounter defective products, they are likely to share their experiences through reviews or social media platforms—an instant recipe for bad publicity! This makes it imperative for businesses to prioritize Jewelry Quality Control Inspection as part of their manufacturing process.

Moreover, consistent quality failures can lead to increased returns and warranty claims, which ultimately affect profit margins negatively. Brands that neglect quality control risk losing loyal customers who may turn elsewhere for more reliable options—after all, trust is hard-earned but easily lost! By investing in thorough inspection processes upfront, manufacturers safeguard their reputation while fostering long-term relationships with consumers.

Partnering with Professionals

In the world of imitation jewelry, quality control is not just an afterthought; it's a necessity. Partnering with professionals who specialize in Jewelry Quality Control Inspection can elevate your product standards to new heights. By leveraging their expertise, manufacturers can ensure that every piece meets or exceeds consumer expectations.

The Role of Quality Control Experts

Quality control experts play a pivotal role in maintaining the integrity of imitation jewelry products. They bring a wealth of knowledge about industry standards and best practices, ensuring that each item undergoes rigorous inspection processes. From assessing material durability to evaluating craftsmanship, these professionals are essential for identifying potential flaws before they reach consumers.

Moreover, their experience allows them to implement tailored inspection protocols that suit specific production needs. This not only enhances the overall quality but also reduces costs associated with returns and rework due to defects. Ultimately, having quality control experts on your team fosters a culture of excellence that resonates throughout your brand.

Benefits of Collaborating with China Inspection Pro

Collaborating with China Inspection Pro offers numerous advantages for those in the imitation jewelry sector. This organization specializes in Jewelry Quality Control Inspection and has established itself as a trusted partner for manufacturers worldwide. Their extensive network and local expertise allow for efficient inspections that save time and resources while ensuring compliance with international standards.

Additionally, China Inspection Pro utilizes state-of-the-art technology and methodologies to provide detailed reports on product quality. These insights empower businesses to make informed decisions about production adjustments or enhancements needed for optimal performance in the market. With such partnerships, companies can focus on innovation while leaving quality assurance in capable hands.

Implementing Continuous Improvement Strategies

The journey towards impeccable jewelry quality doesn't end with initial inspections; it requires ongoing commitment through continuous improvement strategies. By regularly reviewing inspection results and feedback from consumers, businesses can identify trends and areas needing enhancement within their production processes. This proactive approach ensures that every iteration of imitation jewelry reflects higher standards than the last.

Engaging quality control experts facilitates this process by providing valuable insights into industry advancements and emerging best practices in Jewelry Quality Control Inspection procedures. They can help design training programs for staff to foster a mindset geared toward excellence at all levels of production. Ultimately, this commitment not only improves product quality but also strengthens brand reputation among discerning consumers.

Conclusion

In the world of imitation jewelry, elevating standards is not just a goal; it's a necessity. With consumers becoming increasingly discerning, the need for rigorous Jewelry Quality Control Inspection processes has never been more critical. By adopting higher quality metrics and adhering to industry benchmarks, manufacturers can ensure their products stand out in a crowded market.

Elevating Standards in Imitation Jewelry

To elevate standards in imitation jewelry, manufacturers must embrace comprehensive quality control measures that go beyond the basics. This includes implementing robust Jewelry Quality Control Inspection protocols that scrutinize every detail from materials to craftsmanship. By doing so, brands can foster a reputation for excellence that resonates with consumers seeking both style and reliability.

How Quality Control Impacts Consumer Trust

Quality control is the backbone of consumer trust in any industry, but it holds particular significance in imitation jewelry. When customers see consistent excellence through rigorous Jewelry Quality Control Inspection processes, they are more likely to return and recommend the brand to others. In an era where word-of-mouth travels fast—thanks to social media—maintaining high-quality standards can make or break a brand's reputation.

Next Steps for Effective Quality Management

To implement effective quality management strategies, businesses should start by reviewing their current Jewelry Quality Control Inspection practices and identifying areas for improvement. Collaborating with professionals who specialize in quality assurance can provide fresh insights and techniques tailored to the unique challenges of imitation jewelry production. Ultimately, committing to continuous improvement will not only enhance product quality but also solidify customer loyalty over time.