Introduction

However, ensuring that your outdoor furniture is safe and durable requires more than just a cursory glance; it demands a thorough Outdoor Furniture Inspection. This process not only guarantees quality and longevity but also safeguards against potential hazards that could arise from subpar products.

Importance of Thorough Outdoor Furniture Inspection

A meticulous Outdoor Furniture Inspection is essential for identifying any defects or weaknesses in the materials and construction of your furniture. From the assembly check according to the instruction manual to assessing moisture content, each step plays a critical role in maintaining safety standards. Ignoring these checks could lead to accidents, costly repairs, or even injuries—especially when children are involved.

Key Tests for Quality Assurance

To ensure your outdoor furniture stands the test of time and weather, several key tests must be performed as part of an effective inspection regimen. These include static loading check procedures that evaluate weight capacity, impact check for chairs that determine resilience under pressure, and coating adhesive check by 3M tape to assess surface adhesion quality. Each of these tests contributes to a comprehensive understanding of how well your furniture will perform in real-world conditions.

Unveiling Risks and Responsibilities

Understanding the risks associated with inadequate inspections is crucial for both manufacturers and consumers alike. Failing to conduct proper testing can lead not only to product failures but also legal liabilities if injuries occur due to negligence in ensuring safety standards—especially concerning outdoor furniture for children. By committing to rigorous testing methods like moisture content checks and impact assessments, we embrace our responsibility toward creating safer outdoor environments for everyone.

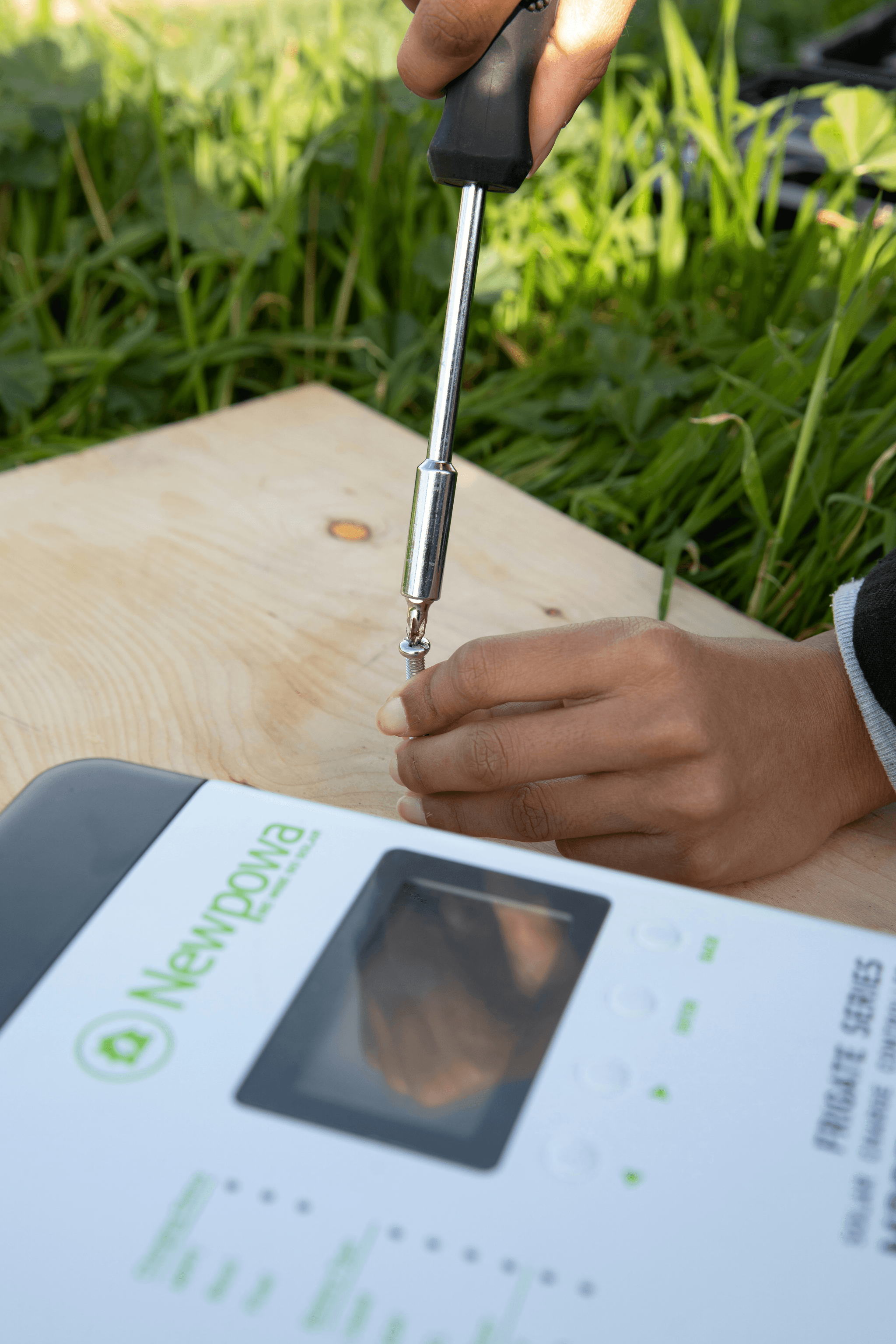

Assembly Check According to Instruction Manual

Proper assembly ensures not only the longevity of your furniture but also its safety and functionality. A well-assembled piece can withstand various tests, including static loading checks and impact checks for chairs, ultimately enhancing user experience.

Ensuring Correct Assembly Practices

Correct assembly practices are vital in outdoor furniture inspection, as they lay the groundwork for durability and safety. Following the provided instructions meticulously guarantees that each component fits together as intended, reducing the risk of structural failure during use. Moreover, ensuring correct assembly practices can prevent costly repairs or replacements down the line.

Importance of Following Manufacturer Instructions

Following manufacturer instructions is paramount in outdoor furniture inspection because these guidelines are crafted based on rigorous testing and engineering principles. Each piece of furniture may have unique requirements that ensure its stability under various conditions, such as static loading checks or moisture content checks. Ignoring these instructions could lead to improper assembly and potential hazards, especially when considering outdoor furniture for children.

Common Assembly Mistakes to Avoid

Common assembly mistakes can easily derail your outdoor furniture inspection efforts if you're not careful. One frequent error is skipping steps or misinterpreting diagrams, which can compromise structural integrity during impact checks for chairs or coating adhesive checks by 3M tape. Additionally, using incorrect tools or forcing parts together can lead to damage; always double-check before tightening screws and bolts!

Static Loading Check

When it comes to Outdoor Furniture Inspection, one of the critical tests is the static loading check. This assessment helps determine whether furniture can withstand the weight it’s designed to support without compromising safety or integrity. Proper evaluation ensures that outdoor furniture not only meets consumer expectations but also adheres to industry standards.

Understanding Weight Capacity Standards

Weight capacity standards are essential benchmarks in Outdoor Furniture Inspection, establishing how much weight a piece of furniture can safely hold. These standards vary based on materials, design, and intended use; thus, being aware of them is crucial for both manufacturers and consumers. Ignoring these guidelines can lead to accidents or premature wear and tear, making it vital to understand these limits before purchasing.

How Static Loading Impacts Durability

The static loading check reveals much about how outdoor furniture will endure over time. When a piece fails this test, it may not just collapse under pressure but could also suffer from structural fatigue that affects its longevity. Therefore, understanding how static loading impacts durability is key in ensuring that your investment in outdoor furniture remains solid and reliable through various conditions.

Testing Procedures for Accurate Results

Conducting a thorough static loading check involves specific testing procedures designed for accurate results in Outdoor Furniture Inspection. Typically, this includes applying gradual weight until the maximum capacity is reached while monitoring for any signs of distress or failure in the structure. Utilizing standardized methods ensures that results are consistent and trustworthy—after all, nobody wants their patio chair to become an unexpected launch pad!

Impact Check for Chairs

When it comes to outdoor furniture inspection, the impact check for chairs is crucial. This assessment determines how well a chair can withstand sudden forces, ensuring safety and longevity in various conditions. Evaluating chair resilience to impact not only protects users but also maintains the integrity of your outdoor space.

Evaluating Chair Resilience to Impact

Evaluating chair resilience involves understanding how materials respond to sudden pressure or weight. Chairs must endure everything from playful kids jumping on them to heavy winds knocking them over, making this evaluation essential for outdoor furniture inspection. A well-designed chair should absorb shock effectively and return to its original shape without damage.

Techniques for Impact Testing

Several techniques can be employed during the impact check for chairs, with drop tests being one of the most common methods. This approach simulates real-world scenarios where a user might fall or drop something onto the chair's surface. Another method includes using weighted objects that mimic human weight, allowing inspectors to measure how much force the chair can handle before showing signs of distress.

Real-World Implications of Impact Testing

The implications of thorough impact testing are significant in everyday life, particularly when it comes to outdoor furniture for children. A chair that passes rigorous impact checks is more likely to remain safe and functional over time, reducing the risk of accidents during family gatherings or playdates in your backyard. Ultimately, understanding these real-world implications reinforces why proper outdoor furniture inspection is vital—not just for aesthetics but also for safety and durability.

Outdoor Furniture for the Child

When it comes to outdoor furniture for children, safety is paramount. Ensuring that these pieces meet rigorous safety standards can prevent accidents and injuries while allowing kids to enjoy the great outdoors. Conducting a thorough Outdoor Furniture Inspection is essential to certify that all items, from picnic tables to lounge chairs, are safe and suitable for little ones.

Safety Standards for Children's Outdoor Furniture

Children's outdoor furniture must adhere to specific safety standards designed to protect young users. These include regulations regarding sharp edges, stability, and the use of non-toxic materials. By conducting an Assembly Check according to the instruction manual, manufacturers can ensure that each piece meets these critical requirements before reaching consumers.

Moreover, compliance with safety standards not only protects children but also gives parents peace of mind when selecting outdoor furniture. The Static Loading Check plays a vital role here by assessing weight capacity and ensuring that structures can withstand playful antics without tipping over or collapsing. This thorough inspection process helps guarantee that children’s outdoor furniture is both fun and safe.

Assessing Material Safety and Stability

When evaluating children's outdoor furniture, assessing material safety and stability is crucial in an Outdoor Furniture Inspection process. Materials should be durable enough to handle rough play while being free from harmful chemicals or sharp components that could pose risks during use. Regular Moisture Content Checks are also important since high humidity levels can lead to mold growth or structural weaknesses in wooden furniture.

Additionally, examining how well materials hold up against various weather conditions ensures longevity and functionality over time. For instance, plastic may be lightweight but should not easily tip over during windy days; thus, performing an Impact Check for Chairs becomes essential in determining resilience against falls or bumps typical in children's playtime scenarios.

Recommended Testing for Kid-Friendly Designs

To ensure kid-friendly designs stand up to the rigors of childhood adventures, several recommended testing methods should be employed during the inspection process. First off, implementing a comprehensive Coating Adhesive Check by 3M tape allows manufacturers to evaluate whether finishes are securely bonded and resistant to peeling or chipping—a common issue with less durable products.

In addition to adhesive checks, incorporating Static Loading Checks helps identify any potential weaknesses in structure under typical weight loads encountered when multiple children are playing together on one piece of furniture. Lastly, conducting Impact Checks for Chairs will reveal how well these items withstand everyday wear-and-tear as kids climb on them or push them around during playtime activities.

By combining these testing methods—safety standard adherence with material assessments—manufacturers can confidently produce outdoor furniture designed specifically for children’s needs while ensuring their enjoyment remains worry-free!

Moisture Content Check

Outdoor furniture is often exposed to varying weather conditions, making moisture content a critical aspect of quality assurance during outdoor furniture inspection. Maintaining the right moisture levels in materials ensures durability and longevity, preventing issues such as warping or mold growth. Therefore, understanding moisture content checks is essential for anyone involved in outdoor furniture assembly checks and inspections.

Importance of Moisture Levels in Materials

Moisture levels significantly influence the structural integrity of outdoor furniture. High moisture content can lead to degradation of materials, while excessively low levels might render them brittle and prone to cracking. For manufacturers and consumers alike, keeping track of these levels during outdoor furniture inspection can save time and money by preventing premature wear and tear.

Effects of Humidity on Outdoor Furniture

Humidity plays a crucial role in the overall performance of outdoor furniture. High humidity can cause wood to swell or metal components to rust, while low humidity may lead to shrinkage or cracking in composite materials. By performing regular moisture content checks as part of your outdoor furniture inspection routine, you can mitigate these risks effectively.

Methods for Accurate Moisture Measurement

To ensure accuracy in measuring moisture content, various methods can be employed during an outdoor furniture inspection. One common approach is using a moisture meter that provides precise readings on material saturation levels. Additionally, conducting static loading checks before finalizing assembly ensures that all components withstand environmental stressors while maintaining appropriate moisture levels.

Coating Adhesive Check by 3M Tape

This is where the Coating Adhesive Check by 3M Tape comes into play, offering a reliable method for evaluating surface adhesion standards. A strong adhesive bond not only enhances the aesthetic appeal of outdoor furniture but also contributes significantly to its longevity and overall performance.

Evaluating Surface Adhesion Standards

Evaluating surface adhesion standards involves testing how well the coating adheres to various materials used in outdoor furniture. Manufacturers typically have specific adhesion benchmarks that their products should meet to ensure safety and durability. Inadequate adhesion can lead to peeling or flaking, which not only detracts from the visual appeal but can also pose risks during usage, especially in children’s outdoor furniture.

Significance of Coating Quality

Coating quality plays a pivotal role in Outdoor Furniture Inspection as it directly affects both appearance and functionality. High-quality coatings protect against environmental factors such as UV rays, moisture, and temperature fluctuations, which are particularly crucial for outdoor settings. Additionally, poor-quality coatings may fail under stress from static loading checks or impact tests for chairs, leading to premature wear and tear.

Practical Testing Techniques and Interpretation

Practical testing techniques for assessing coating adhesive strength often involve using 3M tape as a simple yet effective tool for measurement. The process is straightforward: apply a strip of tape over the coated area, press firmly, then quickly pull it away at a consistent angle while observing any peeling or residue left behind. The results provide valuable insights into whether further steps are needed in quality assurance or if the furniture meets necessary standards before being marketed.

Conclusion

In wrapping up our exploration of outdoor furniture inspection, it's clear that a meticulous approach is essential for ensuring the longevity and safety of your outdoor investments. We’ve discussed various critical testing methods, including the assembly check according to the instruction manual, static loading check, impact check for chairs, moisture content check, and coating adhesive check by 3M tape. Each of these tests plays a pivotal role in safeguarding against potential risks while enhancing the overall quality of outdoor furniture.

Recap of Essential Testing Methods

To ensure your outdoor furniture stands the test of time and usage, thorough inspections are non-negotiable. The assembly check (according to instruction manual) ensures that each piece is put together correctly, minimizing risks associated with improper construction. Additionally, conducting a static loading check helps determine whether your furniture can withstand expected weight without compromising durability—essential for both comfort and safety.

The impact check for chairs evaluates how well they can endure everyday wear and tear from use or accidental bumps. For families with children, understanding outdoor furniture for the child becomes even more crucial; ensuring that materials are safe and stable protects our little ones during playtime. Lastly, regular moisture content checks prevent damage from humidity fluctuations while a coating adhesive check by 3M tape guarantees that surfaces remain intact despite exposure to the elements.

Importance of Professional Inspection Services

While DIY checks can be beneficial, enlisting professional inspection services elevates your outdoor furniture inspection process significantly. Experts bring specialized knowledge about industry standards and testing protocols that ensure comprehensive assessments across all areas—from assembly checks to moisture content evaluations. By relying on professionals for tasks such as static loading checks and impact tests for chairs, you gain peace of mind knowing that every aspect has been scrutinized.

Moreover, professional inspectors often have access to advanced tools and techniques not typically available to consumers—providing more accurate results during coating adhesive checks by 3M tape or other assessments vital for child-friendly designs in outdoor furniture. Their expertise also extends to advising on best practices moving forward—ensuring proper maintenance routines are established based on specific materials used in your furnishings.

Commitment to Quality with China Inspection Pro

Their commitment to thorough inspections means you’re not just buying furniture; you’re securing peace of mind knowing everything has been checked meticulously—from assembly practices all the way through moisture content analysis. With their guidance on essential testing methods like impact checks or coating adhesive evaluations using 3M tape at your disposal, you can confidently furnish your outdoors without worry.

In conclusion, prioritizing these key aspects will not only enhance your enjoyment but also extend the lifespan of your outdoor investments—making every sunny afternoon spent lounging feel just right!