Introduction

In the world of footwear, quality defects are more than just minor inconveniences; they can significantly impact both manufacturers and consumers alike. From excessive wax, oil, or glue issues to peeling materials, understanding the various types of quality defects is crucial for maintaining high standards in shoe production. By recognizing these flaws early on, companies can not only save costs but also enhance customer satisfaction and brand loyalty.

Understanding Quality Defects in Shoes

Quality defects in shoes can be broadly categorized into different zones for effective classification—most notably Zone 1 and Zone 2 for defect classifications. Zone 1 often includes surface-level issues like abrasion marks or excessive wax that may not affect structural integrity but can tarnish a shoe's overall appearance. Meanwhile, Zone 2 focuses on more severe concerns such as weak adhesive or broken stitches that could compromise the footwear’s durability and performance.

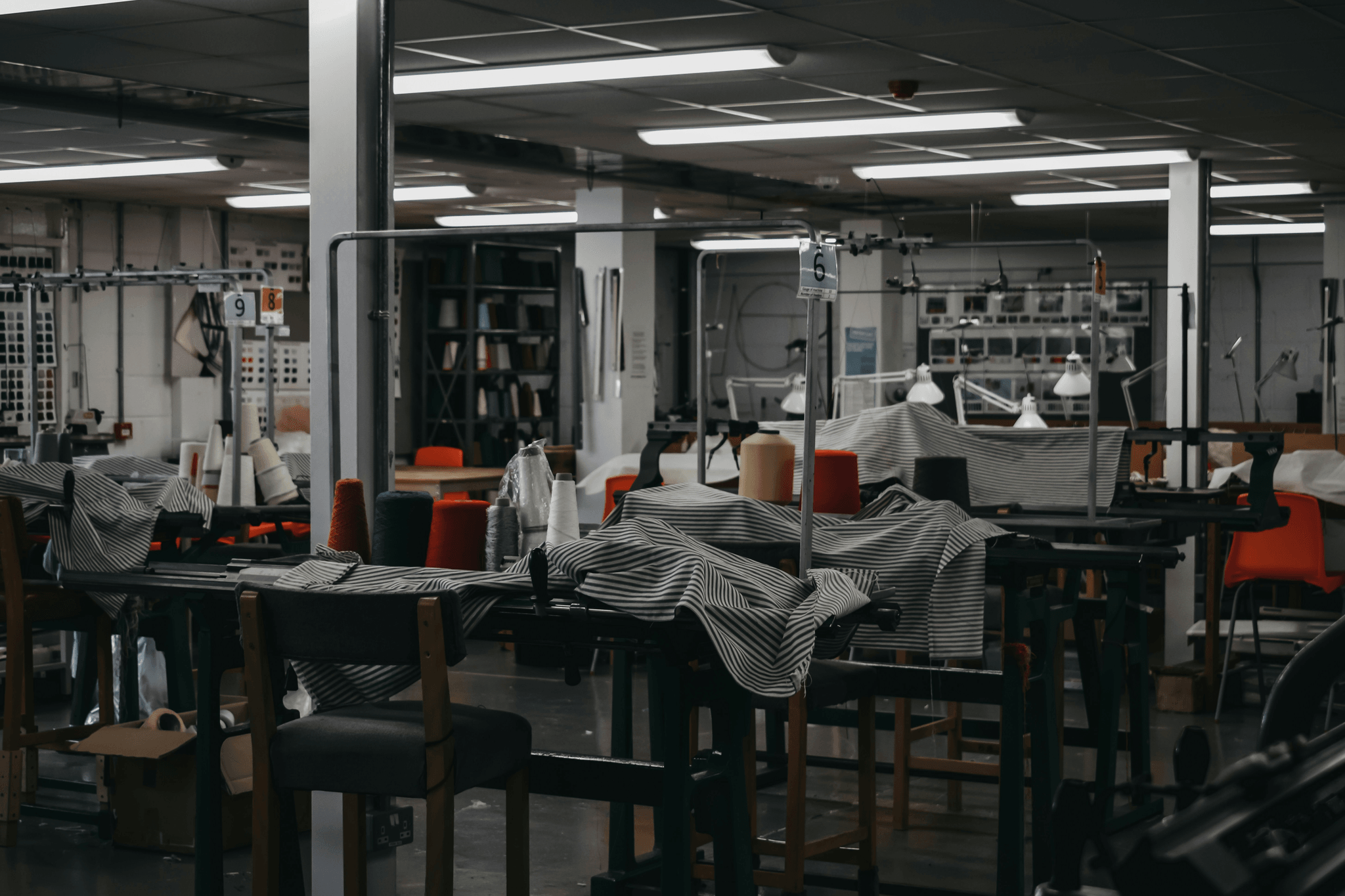

The Importance of Quality Control

Quality control serves as the backbone of any successful footwear manufacturing process, ensuring that each pair meets established standards before reaching consumers. Without rigorous quality checks, issues like inaccurate sizing or sharp metal contamination could slip through the cracks, leading to customer dissatisfaction and increased return rates. By implementing robust quality control measures, manufacturers can minimize these risks while fostering a culture of excellence within their teams.

Identifying Defects Early On

Identifying defects early on is essential for preventing larger problems down the line; after all, an ounce of prevention is worth a pound of cure! Regular inspections help catch issues such as peeled materials or abrasion marks before they escalate into costly recalls or reputational damage. With advancements in technology and inspection methods, brands now have more tools at their disposal than ever to ensure that quality defects are caught swiftly and efficiently.

Common Quality Defects

When it comes to footwear, quality defects can make or break a brand's reputation. Understanding these flaws and their classifications is crucial for manufacturers and consumers alike. By identifying common quality defects early on, businesses can ensure customer satisfaction while maintaining their market position.

Zone 1 and Zone 2 for Defect Classifications

In the realm of quality control, defects are often categorized into two primary zones: Zone 1 and Zone 2. Zone 1 encompasses critical defects that directly affect the shoe's functionality or safety, such as weak adhesive or broken stitches that could lead to catastrophic failures. On the other hand, Zone 2 includes less severe issues like surface blemishes or minor aesthetic flaws that may not compromise performance but could still impact consumer perception.

Classifying quality defects into these zones allows manufacturers to prioritize their inspection processes effectively. For instance, addressing issues in Zone 1 should be a top priority due to their potential impact on user safety and satisfaction. By focusing on these classifications, brands can streamline their quality control efforts and reduce the likelihood of costly returns stemming from serious quality defects.

Excessive Wax, Oil, or Glue Issues

One of the most common offenders in the world of quality defects is excessive wax, oil, or glue used during production. While these substances are often necessary for finishing touches and ensuring durability, over-application can lead to unsightly residues that detract from a shoe’s overall appearance. Not only do these issues affect visual appeal, but they can also create slippery surfaces that compromise user safety.

Manufacturers need to strike a balance when it comes to applying waxes and adhesives; too much can result in a product that's more trouble than it's worth. Customers expect shoes that not only look good but also perform well without any sticky surprises lurking beneath the surface. Addressing excessive wax or glue issues proactively will help brands maintain high standards while minimizing customer complaints about quality defects.

Peeled Materials and Their Impact

Peeled materials are another common issue faced by footwear manufacturers and retailers alike—one that should never be underestimated when discussing quality defects. This defect often arises from poor adhesion between layers of material due to inadequate application of adhesives during production processes like bonding leather to soles or lining fabric with cushioning foam. When materials peel away from each other after just a few wears, it not only affects aesthetic appeal but also diminishes the overall lifespan of the shoe.

The impact of peeled materials extends beyond mere disappointment; it can lead customers straight back to return counters with dissatisfaction written all over their faces—a situation every brand wants to avoid! To combat this problem effectively requires diligent attention during manufacturing stages as well as robust testing protocols before shoes hit store shelves. By tackling peeled materials head-on through rigorous inspections and using high-quality adhesives designed for durability under various conditions (think heat resistance), brands will enhance both product longevity and customer loyalty.

Structural Integrity Concerns

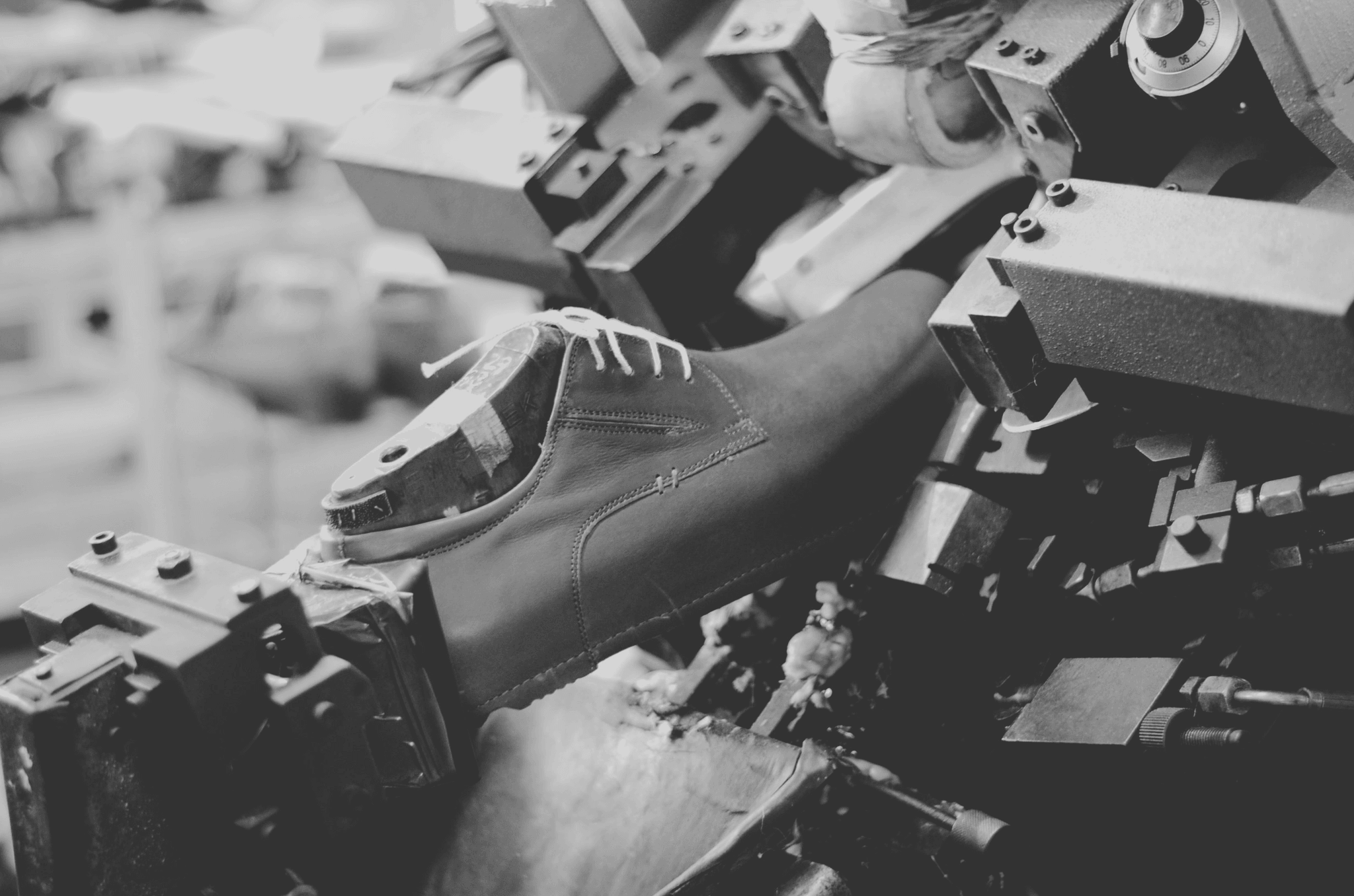

When it comes to footwear, structural integrity is non-negotiable. Quality defects like weak adhesive and broken stitches can undermine the very purpose of shoes—providing comfort and support. Understanding these issues, especially in Zone 1 and Zone 2 for defect classifications, is crucial for both manufacturers and consumers alike.

Weak Adhesive and Broken Stitches

Weak adhesive can lead to catastrophic failures in shoe construction, causing soles to separate from the upper materials. Broken stitches not only compromise durability but also create potential hotspots for further quality defects, such as peeled materials or excessive wax accumulation. In both cases, the result is a shoe that may look fine on the outside but fails miserably under pressure.

Consequences of Poor Construction

The consequences of poor construction are far-reaching; shoes with weak adhesive or broken stitches often lead to customer dissatisfaction and a spike in returns due to inaccurate sizing or other issues that arise from structural flaws. A single pair of poorly constructed shoes can tarnish a brand's reputation, leading consumers to question overall quality control measures employed during production. Moreover, if customers encounter sharp metal contamination hazards due to these defects, it could result in serious safety concerns that extend beyond mere aesthetics.

How to Spot Structural Defects

Spotting structural defects requires a keen eye and some know-how; consumers should look for signs of weak adhesive by checking for any gaps between components or uneven surfaces where excess glue has been applied. Inspecting stitching closely can reveal broken stitches—look for loose threads or inconsistent patterns that signal potential failure points down the line. Additionally, being aware of common quality defects like abrasion marks on the surface will help identify problems before they escalate into costly returns or safety issues.

Size Matters: The Perils of Inaccurate Sizing

In the world of footwear, accurate sizing is paramount. Poorly sized shoes are a significant contributor to quality defects, leading to customer dissatisfaction and increased return rates. When consumers encounter inaccurate sizing, they not only experience discomfort but also lose trust in the brand, which can have long-lasting effects on sales.

Implications of Sizing Errors

Sizing errors can lead to a multitude of issues that ripple throughout the supply chain. For instance, if a shoe is labeled as a size 10 but fits more like an 11 due to manufacturing inconsistencies, it falls into Zone 1 and Zone 2 for defect classifications. This discrepancy not only frustrates customers but also leads to wasted resources in returns and exchanges, ultimately impacting profitability.

Customer Satisfaction and Returns

Customer satisfaction hinges on finding the perfect fit; when shoes don’t measure up, it often results in returns that could have been avoided with better quality control measures in place. Excessive wax or glue used during production might mask underlying sizing flaws temporarily but will not save a brand from negative reviews when customers realize their new kicks are too tight or too loose. Moreover, high return rates due to inaccurate sizing can tarnish a company’s reputation and lead to financial losses over time.

Solutions for Accurate Sizing

To combat the perils of inaccurate sizing, brands must prioritize rigorous testing protocols before shoes hit the market. Implementing advanced measurement technologies can help ensure that each pair adheres to standardized sizes and minimizes defects related to weak adhesive or broken stitches that could affect fit over time. Additionally, clear communication about size variations across different styles can empower consumers to make informed choices while reducing the likelihood of disappointment stemming from poor sizing practices.

Contamination Risks

Contamination risks in shoe production can lead to serious quality defects that compromise both safety and customer satisfaction. Among these risks, sharp metal contamination poses a significant hazard, potentially injuring workers and customers alike. Understanding how to identify and mitigate these risks is essential for maintaining high standards of quality control.

Sharp Metal Contamination Hazards

Sharp metal contamination hazards are a pressing concern in the footwear industry. These contaminants can originate from various sources, such as machinery, tools, or even leftover materials from the manufacturing process. If not detected early on—especially in Zone 1 and Zone 2 for defect classifications—these sharp objects can lead to severe injuries or product recalls, ultimately affecting brand reputation.

Safety Standards in Shoe Production

Safety standards in shoe production are designed to prevent incidents related to contamination risks like sharp metal hazards. Regulatory bodies outline strict guidelines that manufacturers must adhere to ensure the safety of their products. By following these standards diligently, companies can minimize the occurrence of quality defects while also protecting their workers and consumers from potential harm.

Prevention Techniques

Preventing contamination risks requires a proactive approach focused on quality control measures throughout the manufacturing process. Regular inspections should be performed to identify any sharp metal pieces or other contaminants before they become an issue—this is especially crucial when dealing with excessive wax, oil, or glue that may obscure visibility during checks. Training employees on proper handling techniques and maintaining clean work environments are also effective strategies for reducing contamination-related quality defects.

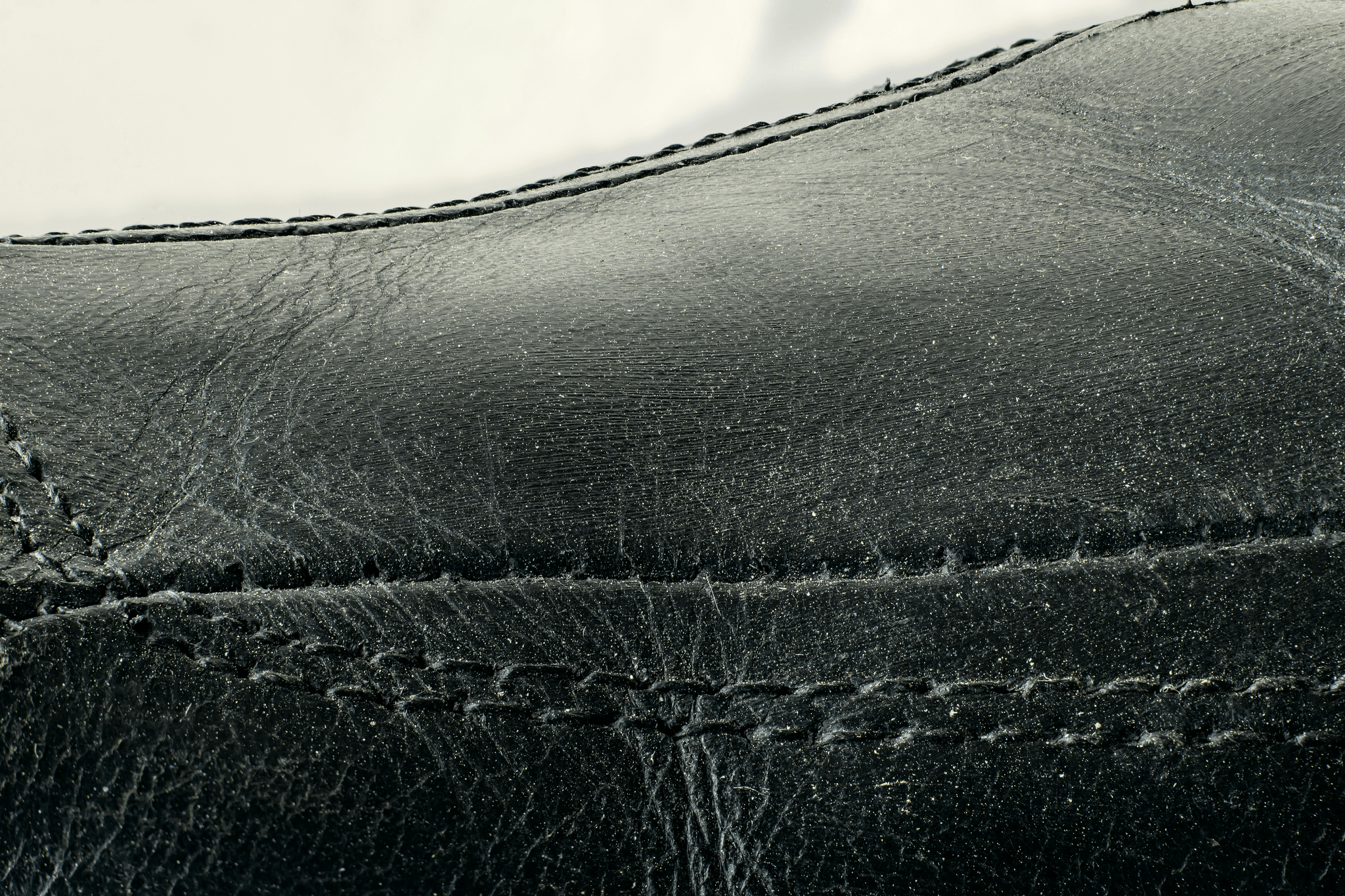

Surface Quality Defects

Surface quality defects can be the Achilles' heel of any shoe brand, and a significant contributor to customer dissatisfaction. Among these defects, abrasion marks stand out as particularly troublesome, often arising from mishandling during production or transportation. These marks not only mar the aesthetic appeal of the footwear but can also indicate deeper issues related to the materials used—think excessive wax, oil, or glue that could lead to more serious quality defects down the line.

The Problem with Abrasion Marks

Abrasion marks are those unsightly scratches or scuffs that can turn a beautiful pair of shoes into an instant no thanks for consumers. These marks often signal poor handling practices or inadequate protective packaging during shipping—issues that fall squarely in Zone 1 and Zone 2 for defect classifications. When customers see these imperfections upon unboxing their new kicks, it raises immediate concerns about overall quality control and craftsmanship.

How Surface Defects Affect Sales

The impact of surface defects like abrasion marks on sales cannot be overstated; they are akin to a bad first impression on a date. Customers who encounter visible flaws may question the durability and reliability of the product, leading to increased returns and negative reviews—two things every brand dreads. Therefore, addressing surface quality defects is not just about aesthetics; it’s about safeguarding your bottom line by ensuring customer satisfaction and loyalty.

Quality Control Measures

To combat surface quality defects effectively, implementing stringent quality control measures is essential. Regular inspections should focus on identifying issues such as abrasion marks before shoes hit retail shelves; this includes assessing for excessive wax, oil, or glue residue that might contribute to surface imperfections. Additionally, training staff on proper handling techniques can drastically reduce damage during transit and improve overall product integrity—keeping weak adhesive or broken stitches from becoming part of your shoe's story.

Professional Inspections: A Quality Assurance Approach

In the world of footwear, professional inspections serve as a crucial line of defense against quality defects that can undermine brand reputation and customer satisfaction. Employing experts to conduct thorough evaluations ensures that issues like excessive wax, oil, or glue are identified before shoes hit the market. Additionally, these inspections can spotlight structural concerns such as weak adhesive or broken stitches which may not be immediately visible but could lead to significant problems down the line.

The Role of China Inspection Pro

China Inspection Pro plays a pivotal role in maintaining high standards in shoe production by providing specialized inspection services tailored to the footwear industry. Their trained professionals are adept at identifying common quality defects, including peeled materials and abrasion marks, utilizing Zone 1 and Zone 2 for defect classifications to streamline their assessments. By focusing on meticulous evaluations, they ensure that manufacturers adhere to safety standards while minimizing contamination risks from sharp metal contamination during production.

Benefits of Third-Party Inspections

Engaging third-party inspection services offers numerous benefits beyond what internal checks can provide. For one, these independent evaluations bring an unbiased perspective that helps manufacturers address potential issues like inaccurate sizing before products reach consumers. Furthermore, third-party inspections enhance credibility in the eyes of customers who increasingly demand transparency regarding quality defects; knowing that a reliable entity has verified product integrity builds trust and loyalty.

Building Trust Through Quality Assurance

Quality assurance through professional inspections is integral in establishing long-term relationships with customers who prioritize quality over quantity. When brands proactively address potential pitfalls such as excessive wax or glue residue and ensure accurate sizing through rigorous checks, they foster an environment of reliability and satisfaction among consumers. Ultimately, investing in thorough inspections not only mitigates risks associated with quality defects but also paves the way for stronger brand loyalty and repeat business.

Conclusion

In the fast-paced world of footwear production, recognizing the impact of quality defects is paramount. Quality defects can lead to dissatisfied customers, increased returns, and a tarnished brand reputation. By understanding how issues like excessive wax, oil, or glue can compromise a shoe’s integrity, manufacturers can take proactive steps to enhance their quality control processes.

Recognizing the Impact of Quality Defects

Quality defects manifest in various forms, from excessive wax and glue to structural issues like weak adhesive and broken stitches. Each defect not only affects the aesthetic appeal of shoes but also their safety and durability. When peeled materials are present or sizing is inaccurate, customers may face discomfort or even injury, leading them to question their purchase decisions.

Strategies for Detecting Shoe Defects

Implementing effective strategies for detecting shoe defects is crucial for maintaining high standards in production. Utilizing Zone 1 and Zone 2 for defect classifications allows manufacturers to systematically identify and categorize issues early on. Regular inspections focusing on contamination risks such as sharp metal contamination and surface quality defects like abrasion marks can significantly reduce the likelihood of defective products reaching consumers.

The Future of Quality Control in Footwear

The future of quality control in footwear lies in leveraging technology and data analytics to enhance detection methods further. As manufacturers increasingly adopt automated systems for identifying quality defects, they will be better equipped to address problems related to inaccurate sizing or construction flaws proactively. By fostering a culture of continuous improvement and accountability regarding quality control practices, the industry can ensure that consumers receive only the best products.