Introduction

In the world of manufacturing, maintaining quality while managing costs is a balancing act that requires precision and strategy. One of the critical tools in achieving this balance is the Acceptable Quality Level (AQL) standard, which serves as a benchmark for determining the maximum number of defective items considered acceptable in a batch. Understanding AQL is essential for manufacturers who strive to deliver products that meet customer expectations without breaking the bank.

Understanding Acceptable Quality Level

The Acceptable Quality Level (AQL) is a statistical measure used to quantify the level of defects that can be tolerated in a production lot. Essentially, it sets the threshold for quality assurance, guiding manufacturers on how many defects are permissible before a batch is deemed unacceptable. By defining these standards, companies can streamline their quality control processes and ensure consistency across their products.

Importance of AQL in Manufacturing

The importance of AQL in manufacturing cannot be overstated; it acts as a crucial link between cost efficiency and product quality. Implementing an appropriate AQL standard helps businesses minimize losses due to defective goods while maximizing customer satisfaction through reliable products. In an increasingly competitive market, adhering to AQL standards not only enhances reputation but also fosters trust among consumers and stakeholders alike.

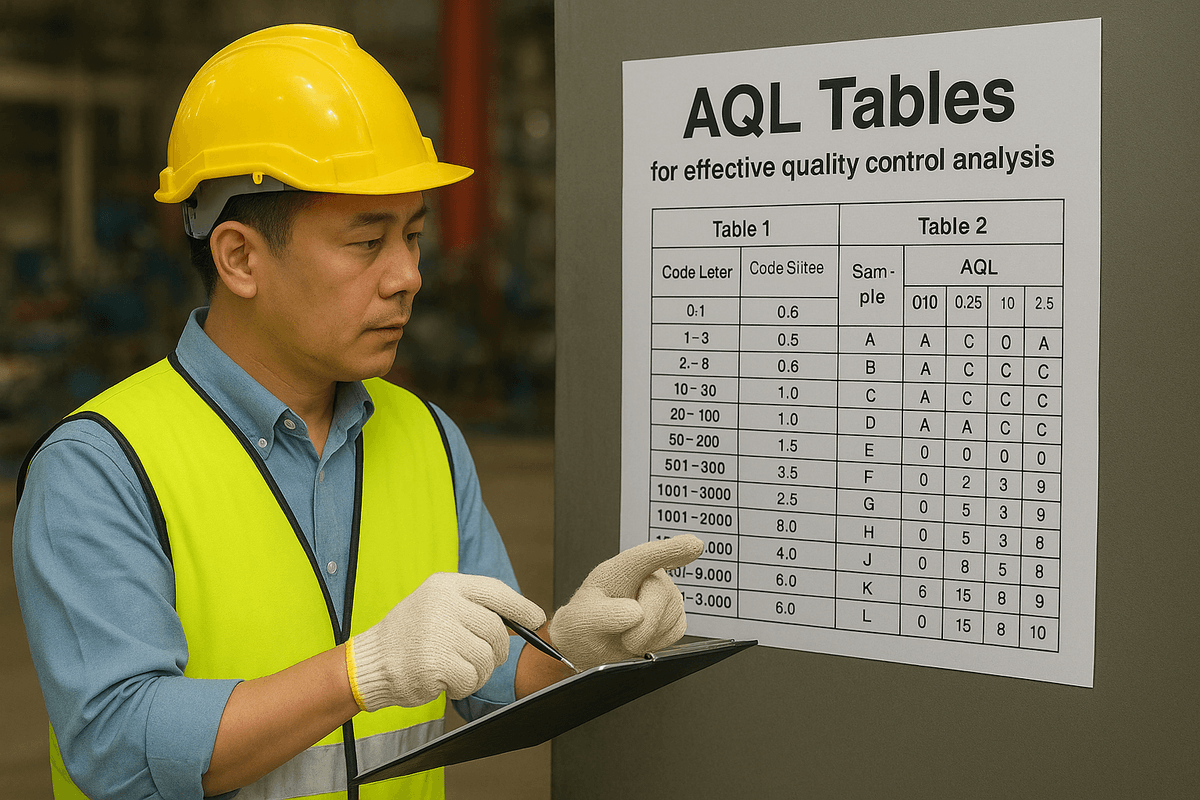

Key Concepts of Quality Control

Quality control encompasses various methodologies aimed at ensuring that products meet specified requirements and standards before they reach consumers. The key concepts include inspection procedures, statistical sampling techniques, and continuous improvement practices—all of which work harmoniously with AQL standards to uphold product integrity. By integrating these principles into their operations, manufacturers can effectively mitigate risks associated with poor quality and enhance overall operational efficiency.

The Basics of AQL

Understanding the fundamentals of Acceptable Quality Level (AQL) is crucial for any manufacturer aiming for excellence. AQL standards provide a framework for determining the maximum number of defective items considered acceptable in a sample batch. This concept plays a pivotal role in ensuring that products meet quality expectations while also maintaining efficiency in production.

Defining AQL Standards

AQL standards are essentially benchmarks that define acceptable levels of defects in manufactured goods. These standards are typically expressed as a percentage, indicating how many defective units can be tolerated within a given sample size before the entire batch is rejected. For example, an AQL standard of 1% means that out of 100 items inspected, one defective item would be permissible; anything more would trigger further scrutiny or rejection.

The beauty of these standards lies in their flexibility; they can be tailored to fit different industries and product types. Whether it’s electronics, textiles, or automotive parts, defining clear AQL standards helps manufacturers maintain consistency and reliability in their output. Ultimately, these standards serve as a guiding light for quality control processes across various sectors.

AQL Measurement Techniques

Measuring adherence to AQL standards involves several techniques designed to assess product quality efficiently and accurately. One common method is statistical sampling, where random samples from production batches are inspected to determine defect rates without examining every single item—saving time and resources while still ensuring quality assurance. Techniques like the double sampling plan or sequential sampling can also be employed to refine results further and minimize risk.

In addition to traditional inspection methods, modern technology has introduced advanced measurement techniques such as automated inspection systems and artificial intelligence-driven analytics. These innovations allow manufacturers to gather real-time data on defect rates and adjust production processes accordingly—ensuring that the defined AQL standard is consistently met over time. By employing these measurement techniques effectively, organizations can enhance their overall quality assurance strategies.

The Role of AQL in Quality Assurance

AQL plays an integral role in quality assurance by acting as both a guideline and a benchmark for evaluating product integrity throughout the manufacturing process. By adhering to established AQL standards, companies can systematically identify defects before they escalate into larger issues that could impact customer satisfaction or brand reputation. Moreover, implementing rigorous quality checks based on these standards fosters trust among consumers who expect reliable products.

Furthermore, maintaining compliance with relevant AQL guidelines not only enhances product quality but also aligns with industry regulations—ultimately contributing to operational efficiency and cost savings over time. In today’s competitive market landscape, businesses cannot afford to overlook the importance of robust quality assurance practices grounded in clearly defined AQL standards. Thus, understanding this relationship between AQL and overall product excellence is key for any organization striving for success.

AQL in Action: Real-World Applications

In the world of manufacturing, understanding how to effectively implement Acceptable Quality Level (AQL) standards is crucial for maintaining product quality and efficiency. This section delves into real-world applications of AQL, showcasing how leading companies leverage these standards to enhance their manufacturing processes. By examining case studies from Toyota, Apple, and Samsung, we can glean valuable insights into the practical implications of AQL standards in diverse industries.

Case Study: Toyota Production System

Toyota is synonymous with quality and efficiency, largely due to its innovative production system that integrates AQL standards seamlessly into its operations. The Toyota Production System (TPS) emphasizes continuous improvement and waste reduction while adhering to specific AQL benchmarks. By employing rigorous sampling techniques aligned with AQL standards, Toyota ensures that only products meeting their high-quality thresholds make it through the production line.

In practice, this means that each component undergoes a thorough inspection process based on predetermined AQL levels before assembly. The result? Not only does Toyota maintain a stellar reputation for reliability but also significantly reduces costs associated with defects and rework. Their commitment to quality control through robust AQL practices serves as a model for manufacturers worldwide.

How Apple Implements AQL Standards

Apple's approach to quality control is another prime example of effective AQL application in the tech industry. The company employs stringent AQL standards throughout its supply chain management process to ensure that each product meets its high-quality expectations before reaching consumers. By setting clear guidelines based on industry-specific AQL metrics, Apple can maintain consistency across its vast array of products.

To achieve this level of quality assurance, Apple collaborates closely with suppliers to establish mutual understanding and adherence to these standards. Regular audits and inspections are conducted using established sampling procedures derived from the relevant AQL guidelines, ensuring any deviations are promptly addressed. This proactive stance not only enhances product quality but also fortifies Apple's brand reputation as a leader in innovation.

Insights from Samsung's Quality Control

Samsung has carved out a niche in global markets by prioritizing exceptional product quality through robust adherence to AQL standards across all manufacturing phases. Their commitment is evident in their comprehensive testing protocols which integrate various statistical methods for measuring compliance with established tolerances defined by their specific AQL frameworks. This meticulous attention to detail allows Samsung to manage supplier variability effectively while ensuring end products meet consumer expectations.

Moreover, Samsung’s use of advanced technology aids in monitoring production processes against set AQL benchmarks consistently. They employ automated systems that provide real-time feedback on quality levels during manufacturing runs—an invaluable asset for quickly identifying potential issues before they escalate into costly problems down the line. As such, Samsung exemplifies how integrating modern technology with traditional quality control principles can lead to superior outcomes grounded firmly in established aql standard practices.

Common AQL Standards Explained

When it comes to maintaining product quality, understanding common AQL standards is crucial for manufacturers. These standards provide a framework for assessing acceptable quality levels in various industries, ensuring that products meet customer expectations while minimizing waste and costs. Let’s dive into some of the most recognized AQL standards and how they shape quality control practices.

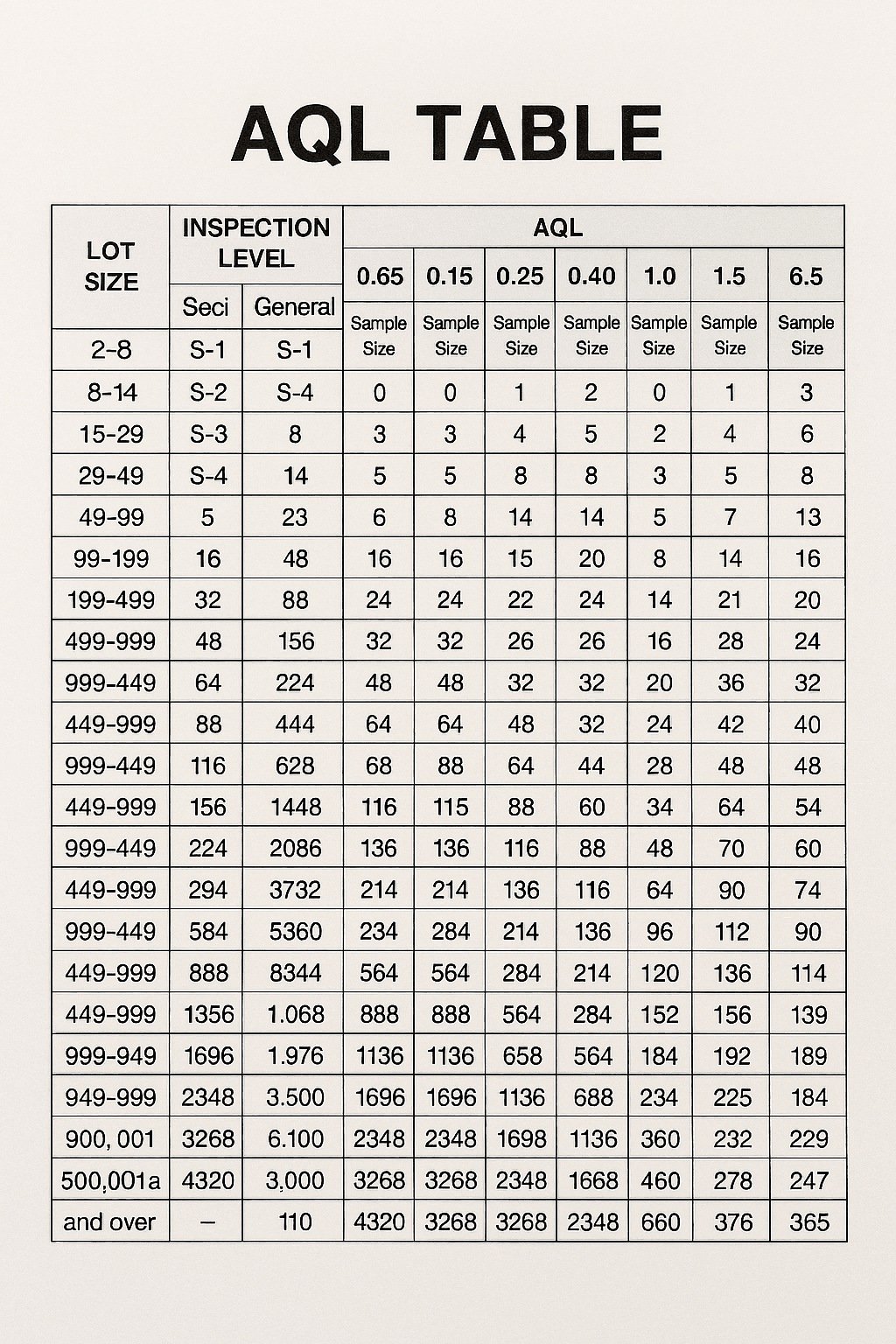

ANSI/ASQC Z1.4 Guidelines

The ANSI/ASQC Z1.4 guidelines are among the most widely adopted AQL standards in the United States. This standard outlines sampling procedures that help organizations determine whether to accept or reject a batch of products based on predefined acceptance numbers and sample sizes. By employing these guidelines, companies can effectively balance the risks of accepting defective items against the costs associated with inspection, ensuring a streamlined quality assurance process.

The beauty of ANSI/ASQC Z1.4 lies in its flexibility; it allows manufacturers to choose their sampling plans based on the size of their production lot and their desired level of confidence in product quality. In practice, this means that businesses can tailor their approach to fit specific needs while adhering to industry norms—an essential aspect when striving for compliance with an AQL standard.

Moreover, these guidelines not only serve as a benchmark for product acceptance but also foster continuous improvement by encouraging companies to analyze defects systematically and implement corrective actions where necessary.

ISO 2859-1 Sampling Procedures

ISO 2859-1 is another prominent AQL standard that provides detailed sampling procedures for inspection by attributes. This international standard is designed to assess whether a batch meets specified quality levels through statistical sampling techniques, making it an invaluable tool for global manufacturers seeking consistency across borders. With its structured approach, ISO 2859-1 helps businesses minimize risks associated with defective products while maximizing efficiency in their inspection processes.

One key feature of ISO 2859-1 is its focus on different inspection levels and plans tailored to various types of production scenarios—be it large-scale manufacturing or smaller batches. This adaptability ensures that companies can find an appropriate balance between thoroughness and practicality when applying AQL standards across diverse operational environments.

Implementing ISO 2859-1 not only aids in maintaining product excellence but also enhances communication within supply chains by providing clear expectations regarding quality assurance practices among stakeholders worldwide.

Industry-Specific AQL Examples

While ANSI/ASQC Z1.4 and ISO 2859-1 lay down general frameworks for acceptable quality levels, many industries have developed specific adaptations of these AQL standards tailored to their unique needs. For example, the electronics industry often utilizes stricter AQL thresholds due to high consumer expectations regarding performance and reliability—defective components can lead not just to financial losses but also significant reputational damage.

In contrast, industries like textiles may adopt more lenient AQL standards since variations in fabric texture or color might not significantly impact overall functionality or aesthetic appeal from a consumer standpoint. This illustrates how understanding specific industry nuances is essential when applying any given AQL standard effectively while still achieving desired outcomes related to cost-efficiency and customer satisfaction.

Ultimately, recognizing these industry-specific applications allows businesses to implement targeted quality control measures that resonate with both operational goals and market demands—a win-win situation indeed!

Challenges in Maintaining AQL

Maintaining an acceptable quality level (AQL) in manufacturing can be a daunting task, particularly as businesses strive to meet customer expectations while keeping costs in check. The delicate balance between cost and quality often leads to tough decisions that can impact the overall integrity of products. Companies must navigate these challenges carefully, ensuring that their adherence to AQL standards does not compromise their financial viability.

Balancing Cost and Quality

Finding the sweet spot between cost and quality is akin to walking a tightrope for many manufacturers. Adopting stringent aql standards can drive up production costs, which may discourage companies from fully implementing necessary quality control measures. However, cutting corners on quality can lead to defective products that ultimately harm brand reputation and customer satisfaction—an outcome no business wants.

Manufacturers often face pressure from stakeholders to minimize expenses while still delivering high-quality products that meet or exceed aql standards. This conflict can result in compromises that undermine the very essence of quality assurance practices. Therefore, it's crucial for organizations to develop strategic approaches that allow them to maintain competitive pricing without sacrificing product excellence.

Addressing Supplier Variability

Supplier variability presents another significant challenge when it comes to maintaining AQL standards across the board. Different suppliers may have varying levels of adherence to quality protocols, leading to inconsistencies in raw materials or components used in production processes. This variability can make it difficult for manufacturers to ensure that every batch meets established aql standards.

To mitigate this issue, companies must invest time and resources into establishing strong relationships with suppliers who prioritize quality as highly as they do. Regular audits and performance evaluations can help identify potential discrepancies before they affect product output significantly. By fostering collaboration with suppliers and setting clear expectations regarding aql standards, manufacturers can enhance overall consistency in their supply chain.

The Impact of Global Supply Chains

In today's interconnected world, global supply chains add another layer of complexity when it comes to maintaining AQL standards. With components sourced from various countries, each with its own regulatory requirements and cultural attitudes towards quality control, achieving uniformity becomes increasingly challenging. Manufacturers must navigate these complexities while ensuring compliance with international aql standards.

Moreover, fluctuations in political climates or economic conditions across different regions can disrupt supply chains and impact product availability or quality levels unexpectedly. Companies must remain agile and adaptable while continuously monitoring their suppliers' performance against established AQL benchmarks globally. By implementing robust risk management strategies within their supply chains, businesses can better safeguard against potential disruptions affecting product integrity.

How China Inspection Pro Enhances AQL

In the realm of quality control, China Inspection Pro stands out by providing tailored solutions that elevate the Acceptable Quality Level (AQL) for manufacturers. Their professional quality inspection services are designed to ensure that products meet stringent aql standards, enabling businesses to maintain high-quality outputs while minimizing defects. By leveraging their expertise, companies can navigate the complexities of quality assurance with confidence.

Professional Quality Inspection Services

China Inspection Pro offers a comprehensive suite of professional quality inspection services that cater to various industries. These services are meticulously aligned with established aql standards, ensuring that every product undergoes rigorous testing and evaluation before reaching consumers. With a focus on transparency and reliability, their inspectors meticulously assess products at different stages of production, helping clients identify potential issues early on and adhere to quality benchmarks.

Furthermore, these inspections are not merely about ticking boxes; they provide insightful data that can be used to enhance manufacturing processes. By employing advanced technologies and methodologies aligned with aql standards, China Inspection Pro ensures that clients receive actionable feedback tailored to their specific needs. This proactive approach not only fosters trust between manufacturers and consumers but also drives continuous improvement in product quality.

Actionable Recommendations for Improvement

One of the standout features of China Inspection Pro is their commitment to delivering actionable recommendations for improvement based on inspection outcomes. After conducting thorough evaluations in line with aql standards, they provide detailed reports highlighting areas needing attention and suggesting practical solutions. This helps manufacturers implement changes swiftly and effectively, ultimately boosting overall product quality.

Moreover, these recommendations often include insights into optimizing production processes or enhancing supplier relationships—both vital components in achieving consistent adherence to aql standards. By fostering an environment of collaboration and open communication between all parties involved in the supply chain, businesses can better manage risks associated with variability in product quality. Such initiatives not only improve compliance but also contribute positively to brand reputation.

Navigating Complex Regulatory Requirements

Navigating complex regulatory requirements can be daunting for manufacturers striving to meet international aql standards; however, China Inspection Pro excels in this area as well. Their team is well-versed in various regulatory frameworks across different markets, ensuring clients remain compliant without sacrificing efficiency or effectiveness during production cycles. This expertise is invaluable for companies looking to expand globally while maintaining high-quality benchmarks.

Additionally, they provide training sessions aimed at educating staff about relevant regulations related to AQL compliance—empowering teams with knowledge crucial for maintaining high-quality outputs consistently. With this support system in place, businesses can confidently tackle regulatory challenges while focusing on what they do best: producing exceptional products that meet consumer expectations regarding quality and safety.

In conclusion, by partnering with China Inspection Pro and leveraging their professional services aligned with established aql standards, manufacturers can significantly enhance their approach toward quality control—ensuring product excellence every step of the way.

Conclusion

In wrapping up our exploration of Acceptable Quality Level (AQL), it’s clear that its role in manufacturing is more crucial than ever. As industries evolve and consumer expectations rise, the AQL standard serves as a vital benchmark for quality control, ensuring products meet specific thresholds of excellence. The future of AQL in manufacturing promises innovation, adaptability, and a continuous commitment to quality.

The Future of AQL in Manufacturing

The future of the AQL standard looks bright as technology continues to advance within the manufacturing sector. With automation and AI-driven analytics on the rise, manufacturers can expect enhanced precision in measuring quality levels, making it easier to adhere to AQL standards. Furthermore, integrating real-time data into production processes will allow companies to react swiftly to any deviations from these standards, ultimately improving overall product quality.

Best Practices for Quality Control

To maintain high-quality outputs while adhering to the AQL standard, companies should adopt best practices that foster a culture of quality throughout their operations. First and foremost, regular training for employees on quality control processes is essential; an informed workforce is key to consistent results. Additionally, implementing robust feedback loops ensures that any issues are promptly addressed and improvements are continually made based on insights gathered from both internal audits and customer feedback.

Ensuring Product Excellence with AQL Standards

Ensuring product excellence through the application of AQL standards requires a proactive approach in every phase of production. Companies must regularly review their inspection processes and refine them based on emerging industry trends and technologies that affect quality assurance methods. By committing to ongoing evaluation and adaptation of their practices around the AQL standard, manufacturers can not only meet but exceed customer expectations—ultimately leading to greater brand loyalty and market success.