Introduction

In the ever-evolving landscape of manufacturing, the significance of streamlined inspections cannot be overstated. As industries strive for higher efficiency and quality, the integration of automated inspection processes has emerged as a pivotal solution. By embracing advanced technologies in quality inspection in manufacturing, companies can not only enhance their production processes but also tackle the challenges inherent in maintaining rigorous quality control.

The Importance of Streamlined Inspections

Streamlined inspections are essential for ensuring that products meet stringent standards throughout the production process. In an era where consumer expectations are at an all-time high, manufacturers must prioritize quality control in industries to remain competitive. Implementing effective process inspection strategies helps to identify defects early, reducing waste and ensuring that only top-notch products reach the market.

Key Benefits of Automation

Automation in inspection processes offers a multitude of benefits that significantly impact overall productivity and efficiency. Automated inspection systems not only enhance accuracy but also minimize human error, leading to more reliable results in quality control. Furthermore, with visual inspection systems integrated into production lines, manufacturers can achieve faster throughput while maintaining consistent standards across all products.

Challenges in Quality Control

Despite advancements in technology, challenges still persist within the realm of quality control in industries. Many organizations struggle with integrating new automated inspection tools into existing workflows without disrupting operations or incurring additional costs. Additionally, ensuring that teams are adequately trained on these new systems is crucial; otherwise, even the best visual inspection systems may fall short of their potential benefits if not utilized effectively.

Understanding Process Inspection

In the ever-evolving landscape of manufacturing, understanding process inspection is crucial for maintaining high standards of quality control. This section delves into the definitions and roles of various inspection methods, particularly focusing on automated inspection systems and their integration with industrial control solutions. By grasping these concepts, manufacturers can ensure a more efficient production process.

Defining Quality Inspection in Manufacturing

Quality inspection in manufacturing serves as the backbone of product reliability and customer satisfaction. It encompasses a range of activities aimed at evaluating products at different stages of the production process to ensure they meet specified standards. By implementing effective quality inspection protocols, manufacturers can identify defects early on, reducing waste and enhancing overall efficiency.

Role of Visual Inspection Systems

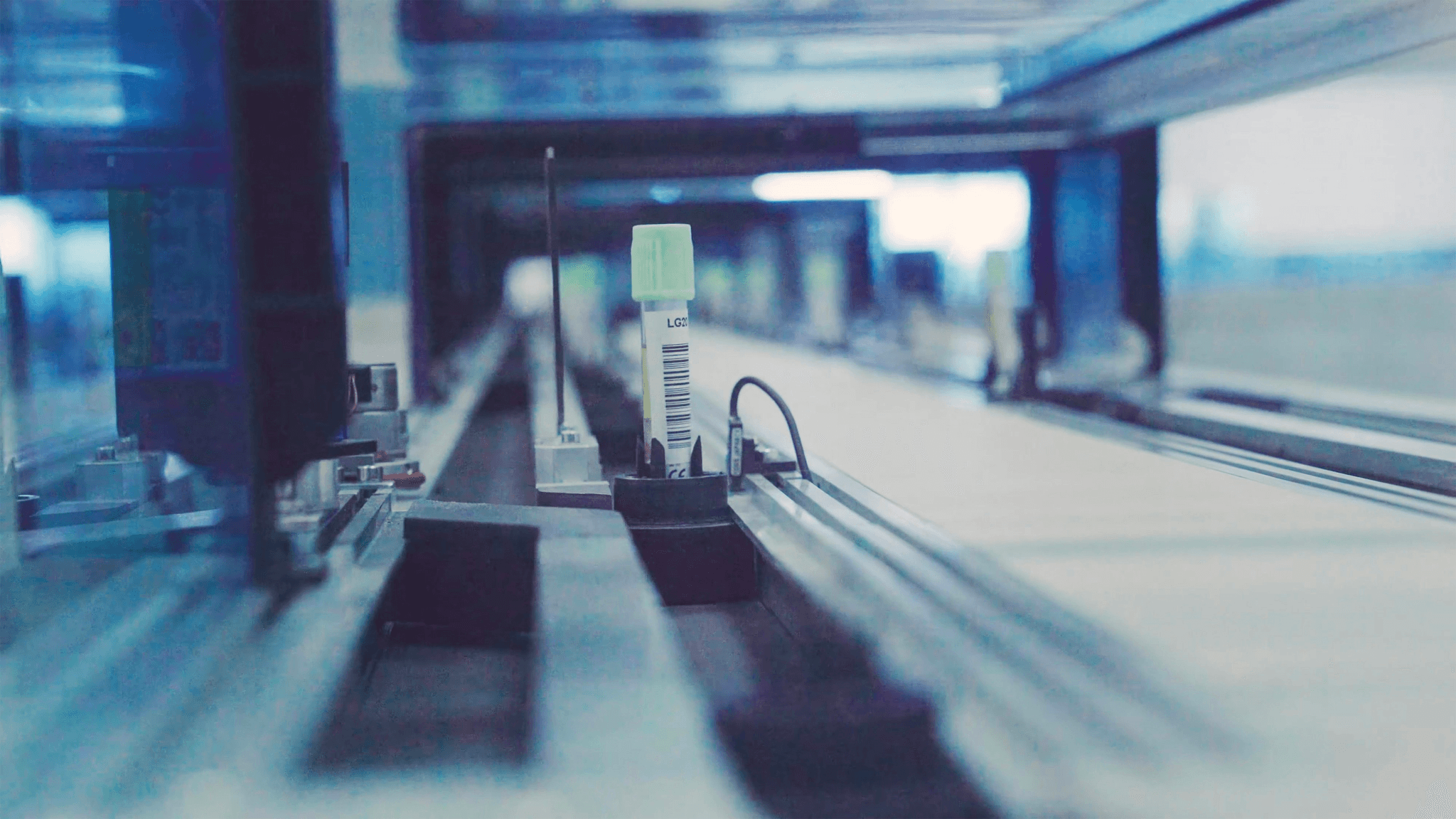

Visual inspection systems have revolutionized how quality control is executed in industries today. These automated inspection tools utilize advanced imaging technology to detect flaws that might be invisible to the naked eye, ensuring that only products meeting stringent criteria proceed through the production process. By integrating visual inspection systems into existing workflows, companies can significantly enhance their quality control measures while minimizing human error.

Integrating Industrial Control Solutions

Integrating industrial control solutions with automated inspection processes is essential for achieving seamless operations within manufacturing environments. These solutions allow for real-time monitoring and adjustments during production, ensuring that any deviations from quality standards are promptly addressed. By harmonizing automated inspection with industrial controls, manufacturers can create a more agile production process that not only meets but exceeds quality expectations.

Benefits of Automated Inspection

Automated inspection is revolutionizing the landscape of quality control in industries, offering a plethora of benefits that traditional methods simply can't match. By leveraging advanced technologies such as visual inspection systems and industrial control solutions, companies are enhancing their process inspection capabilities like never before. This not only leads to improved product quality but also creates a more efficient production process overall.

Enhancing Accuracy in Quality Control

One of the most significant advantages of automated inspection is its ability to enhance accuracy in quality control. Automated systems utilize high-resolution cameras and sophisticated algorithms to detect defects that might elude the human eye during manual inspections. As a result, quality inspection in manufacturing becomes more reliable, reducing the risk of faulty products reaching consumers and bolstering brand reputation.

Moreover, these visual inspection systems are programmed to follow stringent criteria without fatigue or bias, ensuring that every product is evaluated against consistent standards. This level of precision minimizes human error and allows for real-time adjustments to be made during the production process, ultimately leading to higher-quality outputs. In industries where safety and compliance are paramount, such accuracy can be a game-changer.

Reducing Time and Labor Costs

In addition to improving accuracy, automated inspection significantly reduces time and labor costs associated with quality control processes. Manual inspections can be time-consuming and often require multiple personnel for thorough evaluations; however, automated systems streamline this by performing rapid assessments with minimal human intervention. This efficiency not only speeds up the production process but also frees up valuable resources that can be allocated elsewhere within the organization.

The integration of industrial control solutions allows for seamless data collection and analysis, enabling businesses to identify bottlenecks quickly and optimize their operations further. Consequently, companies benefit from lower operational costs while maintaining high standards in quality inspection in manufacturing practices. The bottom line? More productivity with less overhead—what's not to love?

Improving Consistency in Production Process

Consistency is crucial when it comes to maintaining product quality across large-scale production processes; this is where automated inspection truly shines. By employing visual inspection systems within an industrial control framework, manufacturers ensure that each item produced meets predefined specifications without deviation over time. This uniformity not only enhances customer satisfaction but also builds trust in brand reliability.

Automated inspections provide continuous monitoring throughout the production process rather than isolated checks at specific intervals; this means any deviations can be caught early on before they escalate into larger issues down the line. Additionally, as these systems learn from past data through machine learning algorithms, they continuously improve their detection capabilities—ensuring that even subtle defects do not slip through unnoticed over time. Ultimately, this fosters an environment where excellence becomes standard practice rather than an exception.

Choosing the Right Technology

In today's fast-paced manufacturing landscape, selecting the right technology for quality inspection is crucial. With advancements in automated inspection and industrial control systems, manufacturers need to be discerning about their choices. The right visual inspection systems can significantly enhance the overall production process and ensure robust quality control in industries.

Evaluating Visual Inspection Systems

When evaluating visual inspection systems, it’s essential to consider both accuracy and efficiency. These systems should seamlessly integrate into your existing process inspection framework while providing real-time feedback on product quality. A thorough assessment of various options based on specific manufacturing needs will help identify the best fit for enhancing quality control in industries.

Moreover, look for features such as high-resolution imaging and intelligent algorithms that can detect even the subtlest defects. The ability to customize these visual inspection systems ensures they align with your unique production process requirements. By investing time in evaluation, you can avoid costly mistakes and improve overall operational efficiency.

How to Integrate Automated Inspection Tools

Integrating automated inspection tools into your existing workflow can seem daunting, but it doesn't have to be! Start by mapping out your current process inspection steps and identifying areas where automation could save time or reduce errors. This strategic approach will allow you to pinpoint how automated inspection can complement human oversight rather than replace it entirely.

Training staff on these new tools is vital; they must understand not only how to operate them but also their role in maintaining quality control in industries. Encourage an environment of collaboration between human operators and machines for optimal results. As you implement these tools, remember that continuous monitoring and adjustments will enhance their effectiveness over time.

The Impact of Industrial Control Systems

Industrial control systems play a pivotal role in ensuring that automated inspection aligns with broader production goals. These sophisticated frameworks facilitate seamless communication between different components of the manufacturing process, allowing for real-time data collection and analysis during quality inspections. By integrating industrial control solutions with visual inspection systems, manufacturers can achieve unprecedented levels of precision and consistency.

Furthermore, a well-implemented industrial control system helps streamline workflows by minimizing downtime caused by manual checks or errors in quality inspections. This synergy between automated tools and industrial controls ultimately leads to improved product excellence across all stages of production processes. Embracing this technology not only enhances efficiency but also fosters a culture of continuous improvement within organizations.

Best Practices for Implementation

Implementing automated inspection systems in manufacturing is not just about technology; it’s about creating a seamless integration within your production process. A well-structured strategy can streamline your process inspection, ensuring that quality control in industries remains robust and effective. By focusing on the right methodologies, you can enhance both efficiency and accuracy in quality inspection.

Streamlining Your Process Inspection Strategy

To streamline your process inspection strategy, start by mapping out every step of your production process. Identify critical points where quality inspection in manufacturing can be enhanced through automated inspection tools, such as visual inspection systems that detect defects early on. This proactive approach minimizes the risk of errors and fosters a culture of continuous improvement.

Next, consider integrating industrial control solutions that allow for real-time monitoring and feedback during inspections. This ensures that any deviations from quality standards are caught swiftly, reducing waste and rework costs significantly. By leveraging data analytics from these systems, you can refine your process further to meet evolving industry standards.

Lastly, don’t overlook the importance of collaboration among teams involved in the production process. Encouraging open communication between operators, engineers, and quality assurance personnel will lead to more effective problem-solving strategies during inspections. The synergy between human insight and automated solutions is key to achieving excellence in quality control.

Training Your Team on New Technologies

Training is an essential component when implementing new technologies like automated inspection systems. Ensure that all team members understand how these visual inspection systems operate and how they fit into the larger framework of quality control in industries. Knowledge transfer not only boosts confidence but also empowers employees to utilize these tools effectively.

Consider developing a comprehensive training program that includes hands-on sessions with the technology as well as theoretical knowledge about its benefits for process inspection. Regular workshops or refresher courses will keep everyone updated on advancements in automation technologies relevant to their roles within the production process.

Moreover, fostering a mindset of adaptability among employees will help them embrace changes more readily when new industrial control solutions are introduced or existing ones are upgraded. An informed team is crucial for maximizing the potential of automated inspections while maintaining high standards in quality control.

Continuous Improvement and Feedback Loops

Establishing continuous improvement protocols is vital for maintaining high-quality standards through automated inspections over time. Implementing feedback loops allows teams to evaluate performance metrics regularly and adjust processes accordingly based on real-world outcomes from visual inspection systems used during production runs.

Encourage team members to share insights gained from their experiences with both successes and challenges encountered during inspections—this collaborative approach drives innovation within your organization’s quality control practices across various industries.

Additionally, consider adopting methodologies like Six Sigma or Lean Manufacturing principles tailored specifically for enhancing quality inspection in manufacturing processes through automation techniques—these frameworks promote systematic improvements while minimizing waste effectively over time.

Case Studies in Success

In the world of manufacturing, success stories abound when it comes to implementing automated inspection systems. These case studies not only highlight the effectiveness of visual inspection systems but also provide valuable lessons that can be applied across various industries. By examining real-life applications, we can glean insights into how quality inspection in manufacturing can be transformed through innovative approaches.

Lessons from China Inspection Pro

China Inspection Pro serves as an exemplary model for adopting automated inspection technologies within the manufacturing sector. This company revolutionized its process inspection by integrating advanced industrial control solutions that significantly enhanced their quality control measures. The implementation of automated inspection has led to increased accuracy and efficiency, proving that investing in technology pays off in terms of product excellence.

One notable lesson learned is the importance of adaptability; China Inspection Pro continuously refines its processes based on feedback and performance data from their visual inspection systems. This iterative approach ensures they remain at the forefront of quality control in industries where precision is paramount. By embracing change and leveraging automation, they have set a benchmark for others looking to improve their production processes.

Real-World Applications of Automated Inspection

Across various sectors, real-world applications of automated inspection are reshaping manufacturing landscapes and redefining standards for quality control in industries such as automotive, electronics, and food production. For instance, an automotive manufacturer successfully integrated a suite of visual inspection systems that not only streamlined their process inspection but also reduced defects significantly during production runs. This led to improved customer satisfaction and a notable decrease in warranty claims.

In electronics manufacturing, companies have adopted automated inspection tools to ensure every component meets stringent quality standards before assembly. By utilizing these technologies, they have minimized human error while enhancing consistency throughout the production process. The shift towards automation has proven essential for maintaining competitive advantages in fast-paced markets where precision is critical.

Enhancing Quality Control in Industries

The enhancement of quality control across industries hinges on effective implementation strategies for automated inspections and industrial controls. Companies that prioritize these elements often see substantial improvements in their overall operational efficiency and product reliability. Moreover, integrating visual inspection systems into existing workflows allows organizations to detect issues early on—before they escalate into costly problems down the line.

A prime example can be found within the pharmaceutical industry where strict compliance with safety regulations necessitates flawless quality control measures. Automated inspections help maintain rigorous standards by ensuring each batch is thoroughly evaluated against predetermined criteria without compromising speed or accuracy during production processes. As more industries recognize these benefits, we can expect a broader shift towards automation as a standard practice for achieving excellence in quality assurance.

Conclusion

In the ever-evolving landscape of manufacturing, achieving efficiency through effective inspection is paramount. Streamlined processes not only save time and resources but also enhance the overall quality of products. By embracing automated inspection technologies, industries can significantly reduce errors and ensure that every aspect of the production process meets stringent quality standards.

Driving Efficiency with Effective Inspection

The heart of any successful manufacturing operation lies in its approach to process inspection. Implementing robust visual inspection systems allows companies to catch defects early, minimizing waste and rework. As a result, organizations can maintain a smoother production process while ensuring that quality control remains at the forefront.

Moreover, integrating advanced industrial control solutions into quality inspection in manufacturing enables real-time monitoring and adjustments. This proactive approach not only fosters efficiency but also instills confidence among stakeholders regarding product reliability. Ultimately, driving efficiency through effective inspection practices leads to enhanced productivity and profitability.

Future Trends in Automated Inspection

The future of automated inspection is bright, with technology advancing at an unprecedented pace. Emerging trends indicate a shift towards more sophisticated visual inspection systems that leverage artificial intelligence and machine learning for improved accuracy. These innovations will empower manufacturers to adapt rapidly to changes in production processes while maintaining high standards of quality control in industries.

Additionally, as automation becomes more prevalent, we can expect an increase in collaborative robots (cobots) working alongside human inspectors. This synergy will enhance the capabilities of traditional quality inspections by combining human intuition with machine precision. The integration of such technologies promises not just improvements in efficiency but also a transformative impact on how industries approach process inspection.

Ensuring Product Excellence through Quality Control

Ensuring product excellence is no longer just about meeting minimum standards; it requires a commitment to continuous improvement within quality control frameworks. By adopting automated inspection tools, manufacturers can establish rigorous benchmarks that consistently exceed customer expectations. This dedication to excellence fosters brand loyalty and enhances reputation within competitive markets.

Furthermore, feedback loops created by data collected during automated inspections allow for ongoing refinement of both products and processes. Companies that prioritize this iterative approach are better positioned to respond swiftly to market demands while maintaining high-quality outputs across their production lines. In conclusion, integrating modern techniques into quality control ensures that product excellence remains not just an aspiration but a tangible outcome.