Introduction

In the world of agriculture, the role of quality control in fertilizer is paramount to ensuring optimal crop production and sustainability. Fertilizer Quality Control Services are essential for maintaining the standards that farmers depend on to nourish their soils and maximize yields. By implementing rigorous Fertilizer Inspection and Audit Services, manufacturers can guarantee that their products meet both regulatory requirements and farmer expectations.

Understanding Fertilizer Quality Control

Fertilizer quality control involves a comprehensive set of processes designed to ensure that fertilizers meet specific standards for effectiveness and safety. This includes everything from raw material sourcing to final product testing, with a particular emphasis on Fertilizer Testing in Laboratory settings. Understanding these processes allows stakeholders to identify potential issues early, thereby safeguarding both agricultural productivity and environmental health.

Importance of Consistent Quality in Manufacturing

Consistent quality in manufacturing is not just a regulatory requirement; it's a cornerstone of agricultural success. When fertilizers are produced with high-quality standards, farmers can trust that they are applying products that will enhance soil health and promote robust crop growth. The role of quality control in fertilizer manufacturing ensures that each batch adheres to established guidelines, ultimately supporting better farming practices.

Key Players in Quality Assurance

Quality assurance in the fertilizer industry involves multiple key players who work collaboratively to uphold standards across the supply chain. Manufacturers, regulatory bodies, and independent testing facilities all have vital roles in ensuring compliance with safety regulations and performance benchmarks. By engaging with specialized Fertilizer Quality Control Services, these stakeholders can navigate the complexities of fertilizer inspection while fostering trust within the agricultural community.

The Role of Quality Control in Fertilizer

Quality control in fertilizer production is not just a buzzword; it's the backbone of successful crop yields and sustainable agricultural practices. The role of quality control in fertilizer ensures that products meet specific standards and perform as expected, which ultimately leads to healthier plants and better harvests. By implementing robust quality control processes, manufacturers can prevent defects, reduce waste, and enhance customer satisfaction.

Overview of Quality Control Processes

The quality control processes in fertilizer manufacturing are multi-faceted, involving various stages from raw material selection to final product testing. These processes include thorough inspections and audits to ensure that each batch adheres to established specifications. Fertilizer inspection and audit services play a crucial role here by providing an independent assessment of the manufacturing process, ensuring compliance with both local and international quality standards.

Additionally, continuous monitoring throughout production helps identify any deviations from desired quality levels early on. This proactive approach not only minimizes risks but also enhances overall efficiency in the manufacturing process. Ultimately, effective quality control processes contribute significantly to the reliability of fertilizers available in the market.

Common Quality Control Techniques

Several techniques are commonly employed in fertilizer quality control to maintain high standards throughout production. One prevalent method is fertilizer testing in laboratory settings, where samples undergo rigorous analysis for nutrient composition and contaminants. This scientific approach allows manufacturers to confirm that their products deliver the promised benefits while adhering to safety regulations.

Another common technique involves sensory evaluations where trained personnel assess physical attributes such as color, texture, and solubility of fertilizers before they hit the market. Furthermore, on-site inspections during production help ensure that equipment is functioning correctly and that operational practices align with best practices for safety and efficacy. These combined techniques help reinforce the role of quality control in fertilizer manufacturing.

Importance of Compliance with Standards

Compliance with industry standards is paramount for maintaining credibility within the agricultural sector; it assures farmers that they are purchasing reliable products for their crops. Adhering to established guidelines—whether set by local regulatory bodies or international organizations—ensures that fertilizers meet necessary performance criteria while safeguarding environmental health. Fertilizer Quality Control Services often assist manufacturers by providing guidance on compliance requirements tailored to specific markets.

Moreover, non-compliance can lead not only to subpar crop yields but also potential legal ramifications for producers who fail to meet regulatory expectations. In an age where consumers are increasingly concerned about sustainability practices in agriculture, maintaining compliance has never been more critical for business viability and reputation management within this competitive industry landscape. Thus, understanding compliance's importance reinforces why investing in robust quality assurance measures is essential for all stakeholders involved.

Techniques for Quality Assessment

Quality assessment in fertilizer production is crucial to ensure that the end product meets agricultural needs and regulatory standards. The role of quality control in fertilizer encompasses various techniques, including laboratory testing, field trials, and the integration of technology. By employing these methods, manufacturers can guarantee the efficacy and safety of their fertilizers.

Laboratory Testing Methods

Laboratory testing methods are foundational in Fertilizer Quality Control Services, providing a scientific basis for assessing nutrient content and purity. These tests often include chemical analyses to determine macronutrient and micronutrient levels, alongside assessments for contaminants that could harm crops or soil health. Regular Fertilizer Testing in Laboratory settings ensures that products adhere to established standards, helping manufacturers avoid costly recalls or compliance issues.

Additionally, laboratory tests can help identify the physical properties of fertilizers such as solubility and particle size distribution. This information is invaluable for understanding how a fertilizer will behave once applied in the field. Ultimately, robust laboratory testing not only supports quality assurance but also enhances consumer trust in fertilizer products.

Field Trials and Performance Evaluation

Field trials serve as a practical extension of laboratory findings by assessing how fertilizers perform under real-world conditions. These trials involve applying different fertilizers across various agricultural settings to evaluate their impact on crop yield and health over time. The insights gained from these performance evaluations are vital for refining product formulations and ensuring they meet farmers' needs.

Moreover, conducting field trials allows manufacturers to gather data on nutrient availability in different soil types and climates—factors that can significantly influence crop outcomes. By integrating feedback from these evaluations into their processes, companies enhance their Fertilizer Quality Control Services while also fostering better relationships with farmers who rely on effective fertilization strategies.

Use of Technology for Quality Monitoring

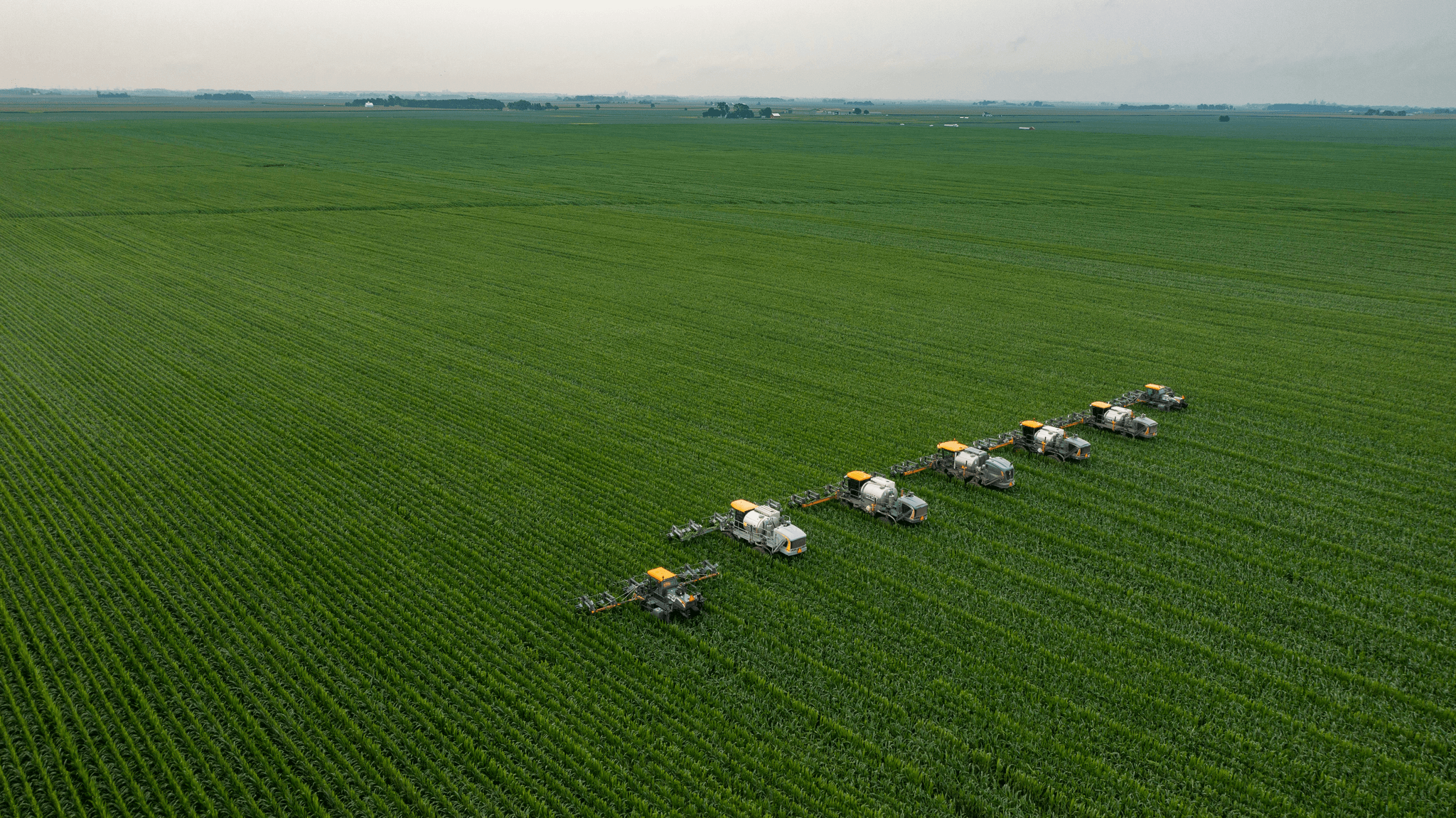

The integration of technology into quality monitoring has revolutionized how fertilizers are assessed throughout production cycles. Advanced tools like sensors, drones, and data analytics platforms facilitate real-time monitoring of fertilizer quality during manufacturing processes as well as application stages in agriculture. This technological approach helps maintain consistent product quality while reducing human error associated with traditional methods.

Moreover, digital platforms enable seamless communication between manufacturers and farmers regarding Fertilizer Inspection and Audit Services—ensuring both parties remain informed about compliance with established standards. As technology continues to evolve, its role in enhancing the efficiency of quality control processes will become increasingly significant.

Regulatory Frameworks and Guidelines

Navigating the complex landscape of fertilizer quality control requires a keen understanding of regulatory frameworks and guidelines. These regulations are essential to ensure that fertilizers meet safety, efficacy, and environmental standards. By adhering to these frameworks, manufacturers can guarantee the integrity of their products while fostering trust among consumers.

Understanding Global Regulations

Global regulations governing fertilizer quality are designed to protect both agricultural productivity and environmental health. Different countries have varying requirements, but many align with international standards to facilitate trade and ensure product safety. The role of quality control in fertilizer is paramount here; it ensures compliance with these regulations while promoting sustainable practices.

In many regions, fertilizers must undergo rigorous testing before they can be marketed. This includes Fertilizer Quality Control Services that evaluate nutrient content and potential contaminants. Understanding these global regulations helps manufacturers navigate the maze of compliance while ensuring their products contribute positively to agricultural practices worldwide.

Role of Organizations like ISO and ASTM

Organizations such as ISO (International Organization for Standardization) and ASTM International play a crucial role in establishing standards for fertilizer quality control. They provide guidelines that help manufacturers implement effective Fertilizer Inspection and Audit Services, ensuring that products meet specific criteria for safety and performance. Adhering to these standards not only enhances product credibility but also minimizes risks associated with substandard fertilizers.

ISO standards focus on various aspects of production, including quality management systems that enhance operational efficiency. Meanwhile, ASTM develops technical specifications for materials used in fertilizers, which is vital for maintaining consistent quality across different batches. By aligning with these organizations' guidelines, companies can improve their overall processes while reinforcing the importance of the role of quality control in fertilizer production.

Compliance with Local and International Standards

Compliance with local and international standards is non-negotiable for any manufacturer aiming to thrive in today’s competitive market. Fertilizer testing in laboratory settings is often a requirement for demonstrating compliance with both local regulations and international benchmarks set by organizations like ISO or ASTM. This rigorous approach not only safeguards public health but also ensures that farmers receive high-quality products capable of maximizing crop yields.

Moreover, understanding local laws is crucial; they may impose additional requirements beyond global norms due to regional environmental concerns or agricultural practices. Manufacturers must invest in robust Fertilizer Quality Control Services to stay ahead of evolving regulations while delivering safe products consistently. Ultimately, compliance fosters a culture of accountability within the industry—one where both manufacturers and farmers benefit from high-quality fertilizers tailored to specific needs.

The Impact of Quality on Agriculture

Quality in fertilizer production is not just a buzzword; it’s a cornerstone for successful agriculture. The role of quality control in fertilizer directly influences crop yield, nutrient availability, and the overall health of the soil. When manufacturers prioritize Fertilizer Quality Control Services, they set the stage for agricultural success.

How Quality Affects Crop Yield

The relationship between fertilizer quality and crop yield is as undeniable as the sun rising each morning. High-quality fertilizers ensure that plants receive essential nutrients in the right proportions, which can lead to bountiful harvests. Conversely, subpar products can stunt growth and reduce yields significantly, making the role of quality control in fertilizer an essential focus for manufacturers.

Farmers rely on Fertilizer Inspection and Audit Services to guarantee that they are applying effective products to their fields. With reliable quality assessments, farmers can make informed decisions about their fertilization strategies, ultimately boosting productivity. This symbiotic relationship between quality control and crop yield underscores why rigorous testing—such as Fertilizer Testing in Laboratory settings—is vital.

Nutrient Availability and Soil Health

Quality fertilizers play a crucial role in maintaining nutrient availability within the soil ecosystem. When fertilizers are manufactured with strict adherence to quality standards, they enhance soil health by providing balanced nutrition that supports microbial life and promotes organic matter decomposition. This connection illustrates how vital Fertilizer Quality Control Services are for sustainable agricultural practices.

Moreover, poor-quality fertilizers can lead to nutrient imbalances that harm soil structure over time. A healthy soil environment is paramount for plant growth; hence ensuring high-quality inputs through proper inspection processes becomes non-negotiable for farmers aiming for long-term success. By investing in Fertilizer Inspection and Audit Services, stakeholders help maintain this delicate balance essential for thriving crops.

Economic Implications for Farmers

The economic landscape of farming is heavily influenced by the quality of fertilizers used in cultivation practices. High-quality fertilizers not only improve crop yields but also enhance profitability by minimizing wastage and reducing input costs over time—an aspect every farmer appreciates! When farmers utilize effective Fertilizer Testing in Laboratory facilities before application, they effectively safeguard their investments against potential losses due to inferior products.

Additionally, when farmers experience higher yields from using top-notch fertilizers backed by stringent quality control measures, they can achieve better market prices for their produce. This creates a ripple effect that benefits local economies as well; increased productivity often leads to more jobs within agricultural sectors and related industries. Thus emphasizing how critical it is to prioritize the role of quality control in fertilizer manufacturing.

In summary, maintaining high standards through effective Fertilizer Quality Control Services isn't just about compliance—it's about fostering an agricultural ecosystem where both crops thrive and farmers prosper economically.

Innovations in Fertilizer Quality Management

In the ever-evolving agricultural landscape, innovations in fertilizer quality management are crucial for ensuring optimal crop yields and sustainable farming practices. With the increasing demand for high-quality fertilizers, the role of quality control in fertilizer production has never been more significant. Manufacturers are leveraging advanced technologies and methodologies to enhance their Fertilizer Quality Control Services, ensuring that products meet stringent industry standards.

Advances in Manufacturing Technologies

The fertilizer industry is witnessing a technological revolution that enhances manufacturing processes and product consistency. Automated systems and precision engineering play a vital role in quality control, allowing for real-time monitoring of production parameters. This not only streamlines operations but also ensures that Fertilizer Inspection and Audit Services can effectively identify any discrepancies before they affect product quality.

Moreover, innovations such as controlled-release fertilizers and nano-fertilizers are changing how nutrients are delivered to crops, improving efficiency and reducing waste. These advancements require rigorous testing protocols, which underscores the importance of robust Fertilizer Testing in Laboratory settings to ensure efficacy and safety. Ultimately, these manufacturing advancements contribute significantly to maintaining high standards in fertilizer quality management.

Use of Data Analytics for Quality Improvement

Data analytics is transforming how manufacturers approach quality control in fertilizers by providing actionable insights derived from vast amounts of data collected during production processes. By analyzing trends and patterns related to fertilizer performance, companies can fine-tune their formulations to meet specific agricultural needs more effectively. This proactive approach enhances the role of quality control in fertilizer by identifying potential issues before they escalate into larger problems.

Additionally, integrating predictive analytics allows manufacturers to anticipate changes in market demands or regulatory requirements, ensuring compliance with local and international standards consistently. The continuous feedback loop created through data analysis helps refine Fertilizer Quality Control Services by enabling timely adjustments based on real-world performance metrics. As a result, farmers benefit from improved products tailored for optimal crop yield outcomes.

Collaborations with Companies like China Inspection Pro

Collaborative efforts between manufacturers and specialized firms like China Inspection Pro are pivotal for enhancing fertilizer quality management practices globally. These partnerships leverage expertise in Fertilizer Inspection and Audit Services to ensure that all products adhere strictly to established guidelines while also meeting customer expectations for performance and safety. Such collaborations emphasize the importance of comprehensive oversight throughout the supply chain.

Furthermore, working alongside inspection agencies fosters transparency within the industry by promoting best practices among producers worldwide—ultimately leading to better-quality fertilizers reaching farmers' fields. By incorporating third-party evaluations into their processes, manufacturers can bolster their credibility while reinforcing the role of quality control in fertilizer production as an essential component of agricultural success. This synergy not only enhances product integrity but also contributes positively to farmers' economic viability through improved crop outputs.

Conclusion

In the ever-evolving world of agriculture, the role of quality control in fertilizer cannot be overstated. Consistent quality ensures that farmers receive products that meet their needs, ultimately leading to better crop yields and healthier soil. Quality control not only safeguards manufacturers' reputations but also reinforces trust within the agricultural supply chain.

Summary of Quality Control Importance

Quality control is fundamental in maintaining the integrity of fertilizers throughout their lifecycle. Fertilizer Quality Control Services play a pivotal role in ensuring compliance with industry standards and regulations, which are critical for both manufacturers and consumers. By implementing robust Fertilizer Inspection and Audit Services, companies can mitigate risks associated with subpar products while enhancing their market position.

Future Trends in Fertilizer Quality

As we look to the future, innovations in fertilizer quality management are set to redefine industry standards. The integration of advanced technologies such as data analytics will facilitate more precise Fertilizer Testing in Laboratory settings, allowing for quicker identification of quality issues before they reach the market. Additionally, a growing emphasis on sustainability will drive demand for fertilizers that not only perform well but also minimize environmental impact.

Recommendations for Manufacturers and Farmers

Manufacturers should prioritize establishing comprehensive quality control measures that encompass all aspects of production—from sourcing raw materials to final product delivery. Engaging with specialized Fertilizer Quality Control Services can provide valuable insights into current best practices and compliance requirements. For farmers, staying informed about the latest innovations in fertilizer testing and quality assurance will empower them to make better choices for their crops and ultimately enhance their productivity.