Introduction

In the realm of manufacturing and production, understanding the difference between quality control and inspection can be a game changer. Quality control refers to the systematic processes that ensure products meet specific standards, while quality inspection focuses on evaluating those products after they have been created. By grasping these concepts, businesses can enhance their quality management strategies and ultimately boost customer satisfaction.

Understanding Quality Control and Inspection

Quality control is a proactive approach that aims to prevent defects in products through various techniques and methodologies. It encompasses a wide range of practices within company quality control frameworks, ensuring that every step of the production process adheres to established standards. On the other hand, quality inspection serves as a final checkpoint that assesses whether finished goods meet predefined criteria before they reach consumers.

Why This Difference Matters

Recognizing the difference between quality control and inspection is crucial for any organization aiming for excellence in their operations. While quality control focuses on prevention, ensuring issues are addressed before they escalate, quality inspection identifies problems after production has occurred. This distinction not only impacts product reliability but also influences overall efficiency and cost-effectiveness in manufacturing processes.

Common Misconceptions About Quality Management

Many people conflate quality management with merely conducting inspections or following checklists; however, this oversimplification overlooks critical elements such as continuous improvement and employee training within company quality control systems. It's essential to understand that effective quality management involves a holistic approach that integrates both proactive measures like quality control and reactive assessments like quality inspection. By dispelling these misconceptions, organizations can foster a culture of excellence where both prevention and detection play vital roles in achieving superior product outcomes.

Defining Quality Control

Quality control is a fundamental aspect of manufacturing that ensures products meet specific standards and requirements. It involves systematic processes aimed at preventing defects and maintaining quality throughout production. Understanding the role of quality control in manufacturing is essential for companies striving to enhance their quality management practices.

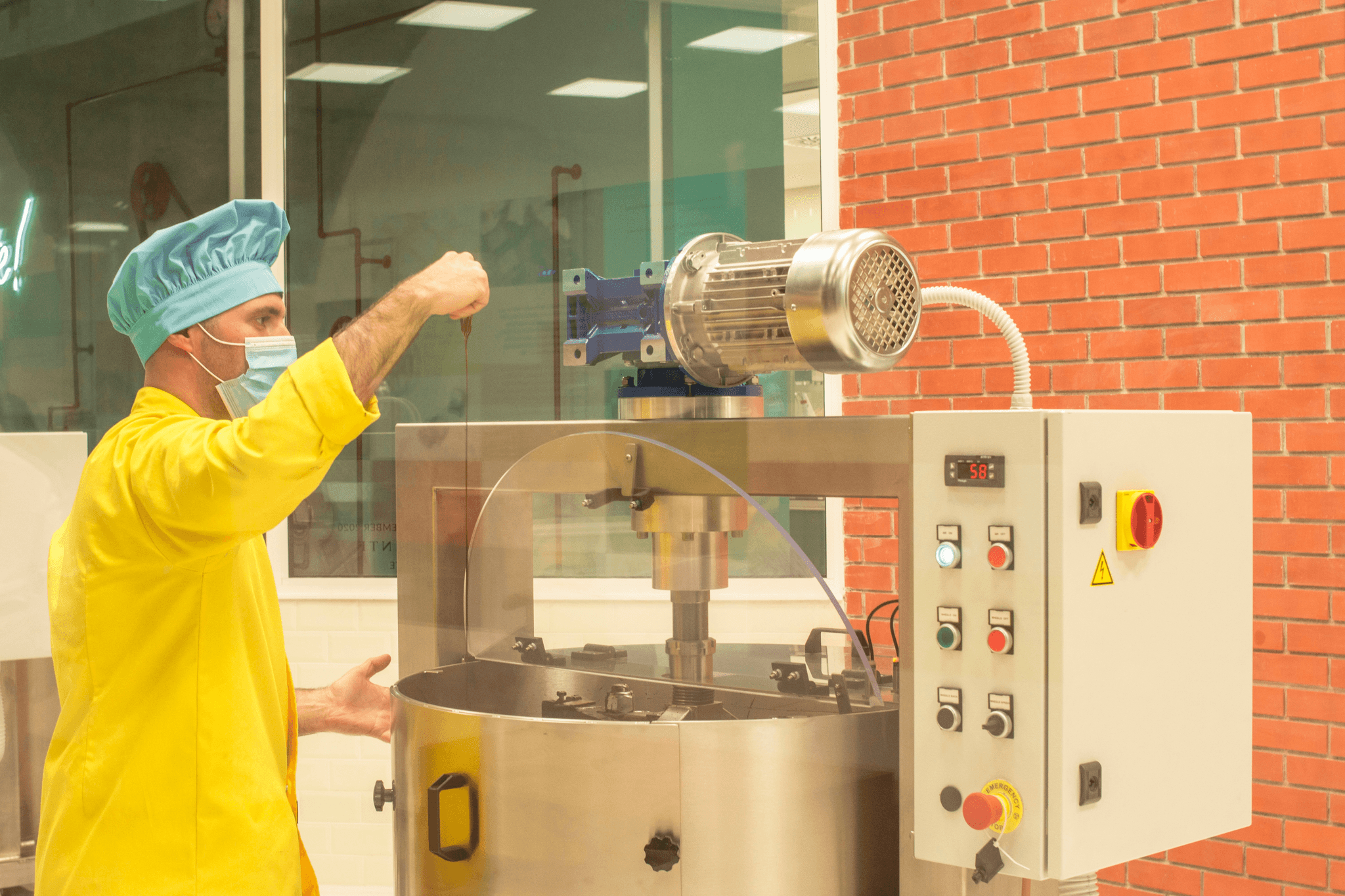

The Role of Quality Control in Manufacturing

In manufacturing, quality control serves as the gatekeeper, ensuring that products adhere to established specifications before they reach consumers. This proactive approach not only minimizes waste but also enhances customer satisfaction by delivering reliable products. By focusing on the difference between quality control and inspection, businesses can better allocate resources to prevent issues rather than merely detecting them post-production.

Key Techniques in Company Quality Control

To implement effective company quality control, various techniques come into play, such as statistical process control (SPC), Six Sigma methodologies, and Total Quality Management (TQM). These techniques help identify areas for improvement and optimize processes to maintain high-quality standards consistently. By integrating these methods into their operations, companies can significantly reduce errors and enhance overall efficiency in their manufacturing processes.

Importance of Quality Management Systems

Quality management systems (QMS) are crucial for any organization aiming to improve its product offerings continuously. A robust QMS provides a structured framework for managing quality across all levels of production and helps ensure compliance with industry regulations. By understanding the significance of QMS within the context of both quality control and inspection, companies can foster an environment where excellence becomes the norm rather than the exception.

What is Quality Inspection?

Quality inspection is a critical component of the overall quality management framework within any organization. It focuses on evaluating products to ensure they meet established standards and specifications before reaching the market. While often confused with quality control, understanding the difference between quality control and inspection can clarify their distinct roles in maintaining product integrity.

Types of Quality Inspection Processes

There are several types of quality inspection processes that companies can implement to maintain high standards in manufacturing. These include incoming material inspections, in-process inspections during production, and final product inspections before shipment. Each type serves a unique purpose, ensuring that every stage of production adheres to company quality control measures and meets customer expectations.

Incoming material inspections verify that raw materials conform to required specifications before they enter the manufacturing process. In-process inspections monitor production stages to catch defects early, while final product inspections serve as a last line of defense against subpar items reaching consumers. By employing these various types of quality inspection processes, businesses can significantly reduce errors and enhance their overall quality management efforts.

How Quality Inspection Ensures Product Standards

Quality inspection plays an essential role in ensuring that products meet both regulatory requirements and consumer expectations. By systematically checking for defects or deviations from specified standards, companies can prevent faulty products from entering the marketplace. This proactive approach not only protects customers but also safeguards a company's reputation by maintaining high levels of trust and satisfaction.

Through rigorous testing methods—such as visual checks, functional tests, and measurements—quality inspection guarantees compliance with industry standards and internal benchmarks alike. This process ultimately contributes to improved product reliability and performance while minimizing returns or complaints from customers due to defective items. The emphasis on thorough quality inspection reinforces the importance of effective quality management practices across all sectors.

Tools and Technologies in Quality Inspection

In today's fast-paced manufacturing environment, utilizing advanced tools and technologies for quality inspection has become indispensable for achieving optimal results in company quality control efforts. Automated systems like vision inspection technology enable real-time monitoring for defects at various stages of production with unparalleled accuracy. Additionally, data analytics software provides insights into trends over time, allowing organizations to refine their processes further.

Other innovative tools include non-destructive testing (NDT) methods such as ultrasonic or X-ray inspections that allow manufacturers to assess materials without causing damage—ensuring both safety and compliance with stringent industry guidelines. Furthermore, mobile applications facilitate on-the-go reporting by inspectors, streamlining communication between teams involved in maintaining product standards throughout the supply chain.

By embracing these cutting-edge technologies within their quality management strategies, businesses can enhance efficiency while ensuring adherence to rigorous standards—ultimately bridging the gap between expectation and reality regarding product performance.

Key Differences Between Quality Control and Inspection

When diving into the world of quality management, it's crucial to understand the difference between quality control and inspection. While both aim to enhance product quality, they operate in distinct realms with unique objectives. Recognizing these differences can significantly impact a company's approach to maintaining high standards in manufacturing.

Focus Areas: Prevention vs. Detection

The primary distinction lies in their focus areas: quality control emphasizes prevention, while quality inspection is all about detection. Quality control seeks to establish processes and systems that prevent defects from occurring in the first place, thereby ensuring that products meet predetermined standards before reaching the consumer. On the other hand, quality inspection serves as a safety net, identifying defects or non-conformities after production has occurred.

In essence, company quality control is proactive—aiming to cultivate an environment where issues are nipped in the bud before they manifest. Conversely, quality inspection reacts to problems that may have slipped through the cracks during production. This fundamental difference shapes how organizations implement their strategies for maintaining high-quality outputs.

Timing: Before vs. After Production

Timing plays a pivotal role in distinguishing between these two approaches; one acts before production while the other takes place afterward. Quality control measures are integrated into manufacturing processes from start to finish—think of it as building a robust foundation for your product's success right from inception. This ensures that any potential issues are addressed early on, leading to fewer complications down the line.

In contrast, quality inspection typically occurs after production has completed its course—like a final exam for your products before they hit the market. This timing difference means that while inspections can catch errors post-production, they don't prevent them from happening initially—a crucial consideration for companies aiming for excellence in their offerings.

Outcomes: Metrics, Reports, and Recommendations

The outcomes of these practices also vary significantly; each provides valuable insights but serves different purposes within quality management frameworks. Quality control focuses on establishing metrics and benchmarks that guide ongoing improvements within manufacturing processes; think of it as setting up a scoreboard for continuous performance evaluation. These metrics help companies refine their operations over time by identifying areas needing enhancement.

In contrast, quality inspections yield reports detailing findings related to product conformity or non-conformity after assessment—essentially providing feedback on what went wrong or right during production runs. These reports often include recommendations for corrective actions but do not provide insight into preventive measures taken beforehand like those found with effective company quality control systems.

Understanding these key differences between quality control and inspection allows businesses to make informed decisions about which strategies best suit their operational needs and goals.

Real-World Applications and Examples

In the world of manufacturing and product development, understanding the difference between quality control and inspection is crucial for achieving excellence. Leading brands have adopted robust quality control systems that not only ensure compliance with standards but also enhance their reputation in the market. These companies recognize that effective quality management goes beyond mere compliance; it fosters innovation, efficiency, and customer satisfaction.

Quality Control in Leading Brands

Leading brands such as Toyota and Apple epitomize the importance of company quality control in manufacturing processes. Toyota's renowned Toyota Production System emphasizes waste reduction while ensuring high-quality output through continuous improvement practices known as Kaizen. Similarly, Apple employs rigorous quality control measures throughout its supply chain to maintain its high standards, ensuring every product meets consumer expectations before hitting the shelves.

By investing in advanced techniques like Six Sigma and Total Quality Management (TQM), these brands create a culture of accountability where every employee contributes to maintaining quality standards. The integration of data analytics into their quality control processes allows them to anticipate potential issues before they escalate, showcasing how proactive approaches can significantly reduce defects and enhance overall product quality. This strategic focus on company quality control not only minimizes costs associated with returns but also builds lasting customer loyalty.

Quality Inspection with China Inspection Pro

When sourcing products from overseas manufacturers, companies often turn to specialized services like China Inspection Pro for effective quality inspection solutions. This service provides a comprehensive range of inspection processes tailored to meet specific client needs, ensuring that products adhere to international standards before shipment. By utilizing experienced inspectors who understand both local manufacturing practices and global requirements, businesses can mitigate risks associated with poor-quality goods entering their supply chains.

Quality inspection plays a pivotal role in identifying defects or deviations from specifications after production has occurred, emphasizing the critical timing aspect when comparing it to proactive quality control measures. With tools such as visual inspections, functional testing, and material verification at their disposal, China Inspection Pro helps businesses maintain high-quality output while navigating complex international trade environments. This partnership exemplifies how integrating effective quality inspection into workflows can safeguard a company's reputation by delivering products that consistently meet or exceed customer expectations.

Case Studies: Success Stories in Quality Management

Several case studies highlight how embracing both quality control and inspection leads to remarkable improvements in operational efficiency and customer satisfaction across various industries. For instance, a major electronics manufacturer implemented an integrated approach combining rigorous company quality control protocols with systematic inspections at different production stages—resulting in a 30% reduction in defect rates within just six months.

Another noteworthy example involves a textile company that faced significant challenges due to inconsistent product standards during manufacturing runs. By adopting comprehensive training programs focused on both preventive measures (quality control) and corrective actions (quality inspection), they transformed their operations into one marked by reliability and excellence—ultimately boosting sales by 25% over the following year.

These success stories underline the synergy between effective quality management strategies: when organizations recognize the difference between quality control and inspection—and leverage both effectively—they position themselves for sustained growth while enhancing their competitive edge in an increasingly demanding marketplace.

Choosing the Right Approach for Your Business

When it comes to navigating the intricate landscape of quality management, selecting the right approach for your business is crucial. The difference between quality control and inspection can significantly impact your operational efficiency and product reliability. By understanding these differences, you can better tailor a strategy that aligns with your specific needs.

Tailoring Quality Control Strategies to Your Needs

Every company has unique challenges and goals, making it essential to customize quality control strategies accordingly. Assessing your specific production processes will help identify areas where quality control can be most effective in manufacturing. Whether you're focused on streamlining operations or enhancing product consistency, a tailored approach ensures that your company quality control measures are both practical and impactful.

To achieve this customization, consider implementing industry best practices while also adapting them to fit your organizational culture. Regularly revisiting and refining these strategies will allow you to keep pace with evolving market demands and technological advancements in quality management. Remember, an effective quality control system isn’t just about compliance; it’s about fostering a proactive mindset that prioritizes excellence.

Integrating Quality Inspection into Your Workflow

Integrating quality inspection into your workflow is another vital aspect of a comprehensive quality management strategy. Quality inspection serves as the final checkpoint before products reach customers, ensuring they meet established standards. By embedding this process within your production line, you create a seamless flow that enhances both efficiency and accountability.

Utilizing modern tools and technologies can streamline this integration, allowing for real-time monitoring of product standards during manufacturing processes. This proactive approach not only helps detect issues early but also facilitates continuous improvement in company quality control efforts across all stages of production. Ultimately, integrating thorough inspection processes fosters a culture of accountability that resonates throughout the organization.

Common Challenges and Solutions in Quality Management

Quality management isn’t without its challenges; companies often face obstacles such as resource constraints or resistance to change when implementing new strategies for quality control or inspection processes. One common issue is miscommunication between departments regarding expectations for product standards; addressing this requires clear guidelines and regular training sessions focused on the importance of both quality control and inspection methods.

Another challenge lies in balancing cost-effectiveness with high-quality output; businesses must find innovative solutions that do not compromise on their commitment to excellence while remaining competitive in pricing. Leveraging technology can be an effective solution here—automated systems can enhance accuracy without significantly increasing costs associated with manual inspections or oversight.

In conclusion, navigating the complexities of choosing the right approach for your business necessitates a keen understanding of both quality control strategies tailored to meet specific needs and integrating robust inspection processes into workflows seamlessly while addressing common challenges proactively.

Conclusion

In today's competitive market, the importance of quality cannot be overstated. Companies that prioritize quality management not only enhance their reputation but also ensure customer satisfaction and loyalty. Understanding the difference between quality control and inspection is crucial for businesses aiming to thrive in a landscape where consumers demand excellence.

The Importance of Quality in Today’s Market

Quality is the cornerstone of any successful business strategy. In an era where customers are more informed than ever, maintaining high standards in product offerings can set a company apart from its competitors. Emphasizing quality management practices helps organizations build trust and reliability, which are essential for long-term success.

Enhancing Efficiency Through Quality Control

Implementing effective quality control measures leads to increased operational efficiency within manufacturing processes. By focusing on proactive strategies rather than reactive ones, companies can minimize waste and reduce costs associated with defects or recalls. Ultimately, robust company quality control systems enable businesses to streamline production while ensuring that products meet or exceed industry standards.

Building a Culture of Quality and Excellence

Creating a culture centered around quality requires commitment from all levels of an organization. Encouraging employees to take ownership of their work fosters an environment where continuous improvement is valued and pursued actively. When businesses integrate both quality control and inspection into their workflows, they lay the groundwork for sustainable excellence that resonates throughout their operations.