Introduction

In the fast-paced world of manufacturing and trade, ensuring product quality is paramount. Quality control serves as the backbone of successful operations, safeguarding businesses from costly errors and dissatisfied customers. Among the various methods employed to uphold quality standards, pre shipment inspection stands out as a critical checkpoint before products reach their final destination.

The Importance of Quality Control

Quality control is not just a buzzword; it’s a vital practice that can make or break a business. By implementing effective quality checks, companies can identify defects early in the production process, reducing waste and enhancing customer satisfaction. In today’s competitive market, robust quality control measures are essential for maintaining brand reputation and achieving long-term success.

What is Pre Shipment Inspection?

Pre shipment inspection refers to the systematic evaluation of products before they leave the manufacturer’s facility for delivery. This process involves thorough quality checks to ensure that items meet specified standards and client requirements. By conducting pre shipment inspections, businesses can mitigate risks associated with defective goods entering the supply chain.

Benefits of Quality Checks

Quality checks provide numerous benefits that extend beyond mere compliance; they enhance overall operational efficiency as well. Regular quality auditing helps identify trends in production issues while fostering a culture of continuous improvement within manufacturing processes. Ultimately, investing in rigorous quality control practices leads to increased customer loyalty and higher profit margins for businesses committed to excellence.

Understanding Quality Control

Quality control is a systematic process that ensures products meet specific standards and requirements before they reach the market. It encompasses various activities, including quality inspections and pre-shipment inspections, which are designed to identify defects or inconsistencies in products. By implementing effective quality checks, businesses can enhance their reputation and customer satisfaction.

Definition and Key Components

At its core, quality control refers to the measures taken to ensure that a product or service adheres to defined quality standards. Key components of quality control include inspection, testing, and auditing processes that help identify areas for improvement. These elements work together to create a robust framework that supports consistent quality checks in manufacturing.

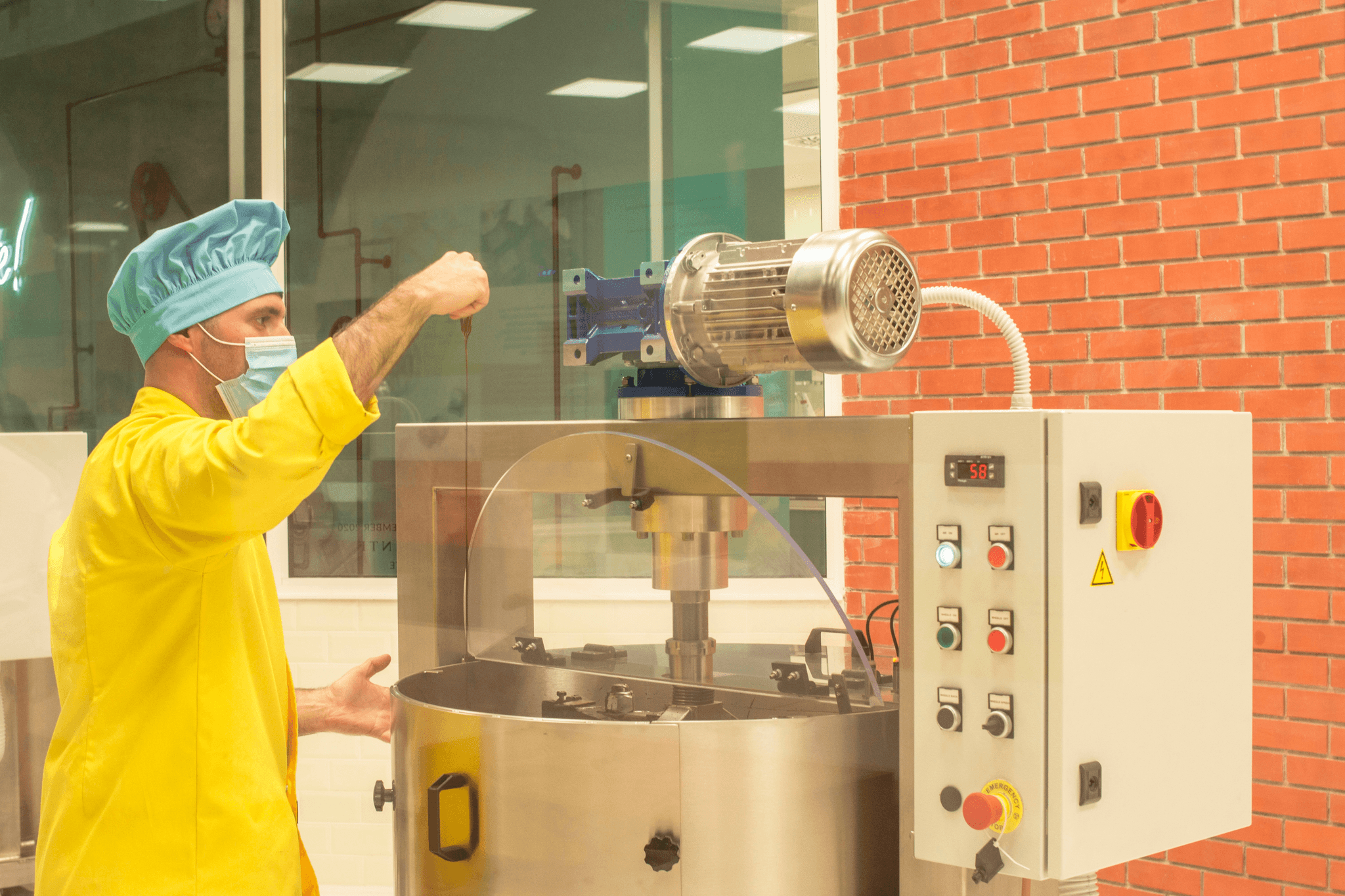

Role of a Quality Control Inspector

The role of a quality control inspector is pivotal in maintaining high standards throughout the production process. Inspectors are responsible for conducting thorough evaluations of products during various stages of manufacturing, ensuring compliance with established guidelines. Their keen eye for detail helps catch potential issues early on, thus reducing the likelihood of costly recalls or customer complaints.

Quality Control in Manufacturing

Quality control in manufacturing involves implementing practices that consistently produce high-quality goods while minimizing defects. This includes establishing standardized procedures for production and conducting regular audits to assess adherence to these standards. By prioritizing quality checks in manufacturing processes, companies not only improve their final products but also enhance operational efficiency and reduce waste.

The Process of Pre Shipment Inspection

Pre shipment inspection is a critical step in quality control that ensures products meet specified standards before they reach the customer. This process not only safeguards the buyer's investment but also enhances brand reputation by minimizing defects and ensuring compliance with regulations. By implementing effective quality checks during this stage, businesses can prevent costly returns and maintain customer satisfaction.

Steps Involved in Pre Shipment Inspection

The pre shipment inspection process typically begins with a thorough review of the product specifications and quality standards established by the buyer. Inspectors then conduct a visual examination of the goods, assessing factors such as appearance, functionality, and packaging. Following this initial assessment, random sampling is performed to evaluate product performance through rigorous testing methods, ensuring that all items adhere to quality control measures.

Once inspections are complete, inspectors compile detailed reports outlining their findings related to quality checks in manufacturing. These reports serve as crucial documentation for both buyers and suppliers, providing transparency throughout the supply chain. Ultimately, these steps collectively ensure that only high-quality products are shipped to customers.

Role of Inspectors in Quality Checks

Quality control inspectors play a pivotal role in maintaining standards during pre shipment inspections. They act as the bridge between manufacturers and buyers by verifying that products meet specified criteria before leaving the factory floor. Their expertise allows them to identify potential issues early on, enabling manufacturers to address problems proactively rather than reactively.

Inspectors utilize various techniques for effective quality auditing, including visual assessments and functional tests tailored to specific products. They not only check for compliance with industry standards but also assess overall workmanship and packaging integrity during their evaluations. By performing these duties diligently, quality control inspectors help ensure that businesses can deliver consistent value to their customers.

Common Challenges Faced

Despite its importance, pre shipment inspection often comes with its own set of challenges in maintaining effective quality control practices. One common issue is communication gaps between manufacturers and inspectors; misunderstandings regarding specifications can lead to discrepancies during inspections or missed defects altogether. Additionally, time constraints may pressure inspectors to rush through assessments, potentially compromising thoroughness.

Another challenge lies in variations across production batches; even minor changes can affect overall product quality unexpectedly during manufacturing processes. Furthermore, cultural differences may impact how inspections are perceived or conducted globally—what’s considered acceptable in one region might not align with another’s standards for quality checks in manufacturing. Navigating these challenges requires adaptability and strong collaboration among all parties involved.

Quality Checks in Manufacturing

Quality checks in manufacturing are the backbone of ensuring that products meet specified standards before they reach consumers. By implementing effective quality control measures, businesses can minimize defects and enhance customer satisfaction. This section dives into techniques for effective quality auditing, tools employed, and the critical importance of maintaining consistency in quality.

Techniques for Effective Quality Auditing

Effective quality auditing involves a systematic approach to evaluate processes and products against established criteria. Techniques such as statistical sampling, process mapping, and root cause analysis are essential for identifying areas needing improvement within the production line. By utilizing these methods, quality control inspectors can provide actionable insights that drive continuous improvement and ensure that pre shipment inspection processes are thorough and reliable.

Another technique is the implementation of Six Sigma principles, which focus on reducing variation and enhancing product reliability through data-driven decision-making. Regular training sessions for employees involved in quality checks can also foster a culture of quality awareness throughout the organization. As a result, organizations not only comply with industry standards but also build a reputation for excellence through their commitment to rigorous quality controls.

Tools and Technologies Used

The landscape of quality control in manufacturing has evolved significantly with advancements in technology. Modern tools such as automated inspection systems, data analytics software, and digital dashboards have transformed how companies perform their quality inspections. These technologies enable real-time monitoring of production processes, allowing for immediate corrective actions when deviations from standards occur.

Moreover, tools like non-destructive testing (NDT) equipment help inspectors assess product integrity without causing damage—critical during pre shipment inspection stages where preserving product condition is paramount. Additionally, mobile applications streamline communication between teams involved in quality checks by providing instant access to inspection reports and feedback loops, enhancing overall efficiency within the audit process.

Importance of Consistency in Quality

Consistency is key when it comes to successful quality checks in manufacturing; it ensures that every product meets predetermined specifications regardless of when or where it was produced. A consistent approach to quality control not only builds trust with customers but also reduces costs associated with returns or reworks due to defects. The role of a dedicated quality control inspector becomes crucial here—ensuring uniformity across all stages from raw materials to finished goods.

Furthermore, establishing standard operating procedures (SOPs) helps maintain this consistency by providing clear guidelines on how inspections should be conducted across various processes within an organization. Regular audits reinforce these practices by identifying any lapses or deviations from established protocols before they escalate into larger issues affecting production output or customer satisfaction levels. Ultimately, consistency in quality leads to enhanced brand loyalty—a powerful asset for any business aiming for long-term success.

Case Studies of Quality Control Success

Quality control is not just a buzzword; it’s a game-changer for businesses across various industries. Successful case studies highlight how effective quality checks and pre shipment inspection can lead to significant improvements in product reliability and customer satisfaction. By examining these real-world examples, we can gain valuable insights into the importance of rigorous quality control processes.

Real-World Examples of Quality Control

One notable example comes from the electronics industry, where a leading manufacturer implemented stringent quality checks in manufacturing to reduce defects in their products. By employing skilled quality control inspectors to conduct thorough pre shipment inspections, they managed to decrease returns by 30%, significantly boosting their reputation among consumers. Another case involves a clothing company that adopted quality auditing practices, resulting in improved fabric durability and overall garment performance, ultimately increasing customer loyalty.

In the automotive sector, a major car manufacturer enhanced its assembly line processes through regular quality inspections at each stage of production. This proactive approach allowed them to identify issues early on and resolve them before reaching the consumer market, showcasing how essential quality control is in maintaining brand integrity. These examples illustrate that when companies prioritize quality control and pre shipment inspection, they not only improve product outcomes but also strengthen their market position.

Lessons Learned from Quality Audits

The lessons learned from these successful audits emphasize the necessity of integrating quality checks throughout the manufacturing process rather than treating them as an afterthought. One key takeaway is that early detection of defects can save companies both time and money; addressing issues during production is far less costly than handling returns or customer complaints later on. Additionally, fostering a culture of accountability among employees regarding quality standards encourages everyone to take ownership of their work.

Another important lesson is the value of continuous improvement based on audit findings; businesses should regularly review their processes and adapt as needed to stay competitive in an ever-evolving marketplace. Implementing feedback loops allows organizations to refine their quality controls continually while ensuring compliance with industry standards. Ultimately, embracing these lessons leads to enhanced efficiency and effectiveness across all aspects of operations.

Impact of Quality Inspections on Businesses

The impact of robust quality inspections extends well beyond immediate financial benefits; it shapes long-term business sustainability as well. Companies that invest in thorough pre shipment inspection protocols often see enhanced brand loyalty and increased market share due to consistently high-quality products reaching consumers’ hands. Furthermore, positive customer experiences driven by effective quality checks can lead to word-of-mouth referrals—a powerful marketing tool that no amount of advertising can replicate.

Moreover, organizations with strong emphasis on quality control tend to cultivate better relationships with suppliers who appreciate working with partners committed to excellence. This collaboration fosters an environment where both parties are motivated to uphold high standards throughout the supply chain—ultimately benefiting everyone involved from manufacturers down to end-users. In summary, prioritizing comprehensive quality inspections not only improves product integrity but also contributes significantly toward building lasting business success.

Choosing the Right Inspection Service

Selecting the right inspection service is crucial for maintaining quality control and ensuring that your products meet standards before they hit the market. With so many options available, businesses must navigate through various factors to find a service that aligns with their needs. A well-chosen inspection service can significantly enhance your quality checks and streamline the pre shipment inspection process.

Criteria for Selecting a Quality Control Service

When it comes to choosing a quality control service, several criteria should be considered to ensure optimal results. First, evaluate their experience and expertise in conducting quality inspections specific to your industry; this is vital for effective quality auditing. Additionally, look for a service that employs certified quality control inspectors who are familiar with international standards and regulations.

Another important factor is the technology and tools utilized by the inspection service; advanced equipment can lead to more accurate assessments during quality checks in manufacturing. Furthermore, consider customer reviews and case studies demonstrating their success in improving product quality through previous collaborations. Finally, transparency in pricing and reporting practices will help you gauge their reliability as partners in your quest for top-notch quality control.

Insights on China Inspection Pro

China Inspection Pro stands out as a leading choice for businesses seeking reliable pre shipment inspection services in China. Their team of experienced quality control inspectors is well-versed in various industries, ensuring thorough assessments tailored to client specifications. By leveraging state-of-the-art technology and methodologies, they provide comprehensive reports detailing every aspect of the quality checks performed.

What sets China Inspection Pro apart is their commitment to customer satisfaction; they prioritize clear communication throughout the entire process of quality auditing. They also offer flexible scheduling options that accommodate clients' timelines while maintaining rigorous standards of excellence in all inspections conducted. This blend of adaptability and professionalism makes them an ideal partner for any business aiming to enhance its product offerings through effective quality control.

Long-Term Benefits of Professional Inspection

Investing in professional inspection services yields long-term benefits that extend beyond immediate compliance with standards; it fosters a culture of continuous improvement within organizations focused on maintaining high-quality products. Regular pre shipment inspections not only minimize risks associated with defective goods but also build trust with customers who expect consistent product excellence from brands they choose.

Moreover, implementing robust quality checks can lead to significant cost savings over time by reducing returns, enhancing customer satisfaction, and boosting brand reputation—essential elements for sustained business growth. As companies become more adept at integrating these practices into their operations, they will likely see not just improvements in product performance but also increased efficiency across all aspects of manufacturing processes.

Conclusion

In the ever-evolving landscape of business, maximizing product quality through inspections is not just a luxury; it’s a necessity. Quality control and pre shipment inspection serve as vital checkpoints that ensure products meet established standards before they reach consumers. By implementing robust quality checks, businesses can significantly reduce the risk of defects and enhance customer satisfaction.

Maximizing Product Quality Through Inspections

Quality inspections are essential to maintaining high standards in manufacturing processes. They act as a safety net, catching potential issues early in production, which ultimately saves time and resources. By prioritizing quality control, companies can foster a reputation for reliability and excellence in their products.

The Role of Quality Control in Business Success

Quality control is integral to business success; it influences everything from customer loyalty to operational efficiency. Companies that invest in thorough quality checks in manufacturing often find themselves reaping the rewards through increased sales and reduced returns. Moreover, having a dedicated quality control inspector ensures ongoing adherence to industry standards, which can be the difference between thriving and merely surviving in competitive markets.

Future Trends in Quality Inspection Services

As technology continues to advance, the future of quality inspection services looks promising with innovations like AI-driven analytics and real-time monitoring systems on the horizon. These advancements will enable more efficient quality auditing processes while reducing human error associated with traditional methods. Businesses that embrace these future trends will likely see enhanced performance and greater adaptability within their quality control frameworks.