Introduction

In the fast-paced world of manufacturing and production, the importance of quality inspection tables cannot be overstated. These essential tools play a pivotal role in ensuring that products meet stringent quality standards before they reach consumers. By integrating effective quality control services, businesses can streamline their processes and enhance their reputation as reliable quality suppliers.

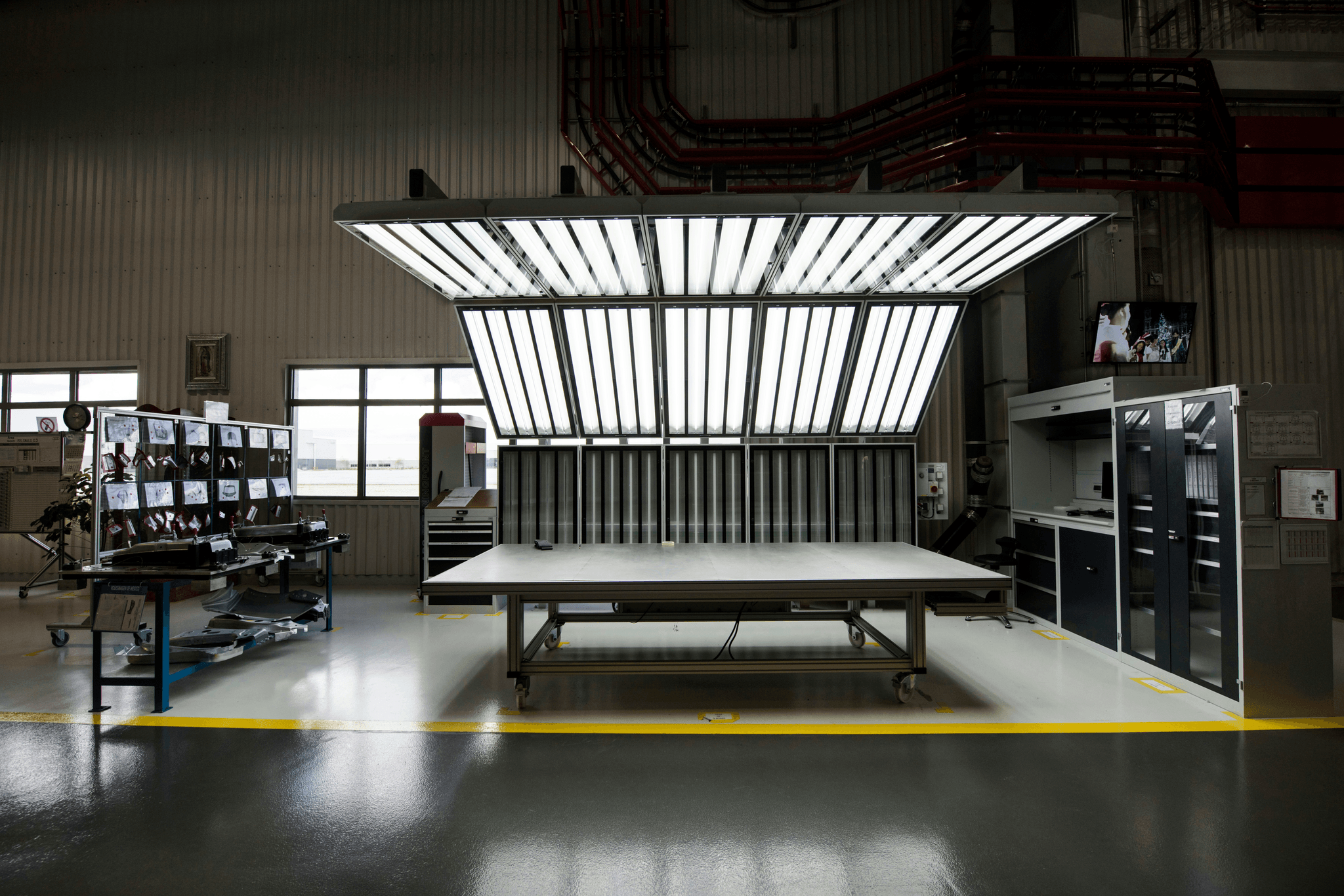

Importance of Quality Inspection Tables

Quality inspection tables serve as the backbone of any robust quality control system. They provide a dedicated space for thorough inspections, allowing teams to identify defects and inconsistencies early in the production cycle. This proactive approach not only saves time and money but also fosters trust among customers who expect nothing less than perfect quality solutions.

Why Durability Matters

Durability is a critical factor when selecting a quality inspection table, as these surfaces endure constant use in demanding environments. A durable table withstands wear and tear while maintaining precision, ensuring that inspections are both accurate and efficient over time. Investing in high-quality materials means fewer replacements and repairs, ultimately leading to enhanced productivity for businesses relying on consistent quality control services.

Versatility in Quality Control

Versatility is another hallmark of an effective quality inspection table; it should adapt to various tasks across different industries seamlessly. Whether it's accommodating multiple inspection types or fitting into limited workspaces, a versatile design maximizes functionality without sacrificing performance. This adaptability allows organizations to implement comprehensive quality solutions tailored to their specific needs while maintaining high standards across the board.

Overview of Quality Inspection Tables

These tables serve a critical purpose: providing a stable, well-organized surface for inspecting products and components. By streamlining the inspection process, they help maintain high standards and minimize errors, ultimately leading to better quality solutions.

Definition and Purpose

A quality inspection table is specifically designed to facilitate thorough inspections of various products during manufacturing or assembly processes. Its primary purpose is to offer inspectors a dedicated space where they can assess items for defects or inconsistencies efficiently. By using these tables, businesses can enhance their overall quality control efforts and ensure that only the best products reach consumers.

Key Features to Look For

When selecting a quality inspection table, it's essential to consider several key features that can enhance its functionality. Look for adjustable height options that cater to different users and tasks, ensuring comfort during prolonged use. Additionally, built-in lighting and magnification tools can significantly improve visibility and detail during inspections, making it easier for quality suppliers to identify issues early on.

Types of Quality Inspection Tables

There are various types of quality inspection tables available on the market today, each tailored to specific needs within different industries. For instance, some tables are designed with modular components that allow customization based on unique inspection requirements. Others may incorporate integrated technology like digital displays or software connectivity for real-time data tracking—an invaluable asset in modern quality control services.

Materials That Stand the Test of Time

Selecting the right material is not just about aesthetics; it directly impacts the efficiency of quality control services and how well these tables can withstand rigorous use. In this section, we will explore the merits of steel versus aluminum, the importance of surface finishes, and how to choose a material that meets your specific needs.

Steel vs. Aluminum: A Comparison

Steel and aluminum are two popular materials used in crafting quality inspection tables, each with its own set of advantages and drawbacks. Steel is renowned for its strength and durability, making it ideal for heavy-duty applications where stability is paramount in quality control services. On the other hand, aluminum is lightweight and resistant to corrosion, which makes it suitable for environments where mobility or frequent relocation is necessary.

When weighing your options between steel and aluminum for a quality inspection table, consider factors such as weight capacity requirements and exposure to elements like moisture or chemicals. While steel might offer superior load-bearing capabilities, aluminum’s portability can be a game-changer in dynamic workspaces that demand flexibility. Ultimately, your choice should align with both your operational needs and long-term maintenance considerations.

The Role of Surface Finishes

Surface finishes play a crucial role in enhancing both the appearance and functionality of quality inspection tables made from various materials like steel or aluminum. A well-applied finish can provide additional protection against scratches, rusting, or other forms of wear that could compromise a table's integrity over time. For instance, powder coating on steel surfaces not only adds an aesthetically pleasing layer but also extends the lifespan by offering resistance against harsh conditions.

Moreover, surface treatments can also improve hygiene standards in industries where cleanliness is paramount—think food processing or pharmaceuticals—by providing non-porous surfaces that are easier to clean. When choosing a finish for your quality inspection table, it's essential to consider both functional requirements as well as visual appeal; after all, who says you can't have beauty alongside brawn?

Choosing the Right Material for Your Needs

Choosing the right material for your quality inspection table involves more than just picking between steel or aluminum; it requires an assessment of your specific operational demands and environment conditions where these tables will be utilized. Factors such as weight capacity requirements, frequency of movement needed within workspaces, environmental exposure (like humidity or chemicals), and even aesthetic preferences play significant roles in this decision-making process.

Consulting with reputable quality suppliers who understand industry standards can provide invaluable insights into which materials best meet your unique needs while ensuring compliance with applicable regulations in quality control services. Remember that investing time upfront into selecting appropriate materials will pay dividends down the line through increased efficiency and reduced maintenance costs associated with high-quality solutions tailored specifically for you.

Designing for Versatility

A well-designed quality inspection table can adapt to various tasks and environments, making it an invaluable asset in any quality control setting. By focusing on customization options, multi-functional use cases, and space-saving solutions, businesses can maximize their quality control services while ensuring efficiency and effectiveness.

Customization Options Available

Customization is key when selecting a quality inspection table that meets your specific needs. Many manufacturers offer adjustable heights, interchangeable work surfaces, and modular components that allow you to tailor the table to your workflow. This flexibility ensures that your quality inspection processes are not only efficient but also comfortable for operators who rely on these tables daily.

Additionally, customization extends beyond physical attributes; you can often choose from a variety of colors and finishes to align with your brand identity or workplace aesthetics. Whether it's adding specialized fixtures for tools or integrating technology like barcode scanners or digital displays, a customized quality inspection table enhances functionality while promoting a streamlined workflow. Ultimately, investing in customization options leads to improved quality solutions that cater specifically to your operational requirements.

Multi-functional Use Cases

Quality inspection tables are no longer just static workstations; they have evolved into multi-functional hubs capable of handling various tasks across different industries. From assembly lines in manufacturing plants to detailed inspections in laboratories, these tables play a crucial role in maintaining product integrity and compliance with industry standards. Their adaptability allows teams to perform everything from routine checks to complex assessments efficiently.

For example, some businesses utilize their quality inspection tables for training new employees by providing hands-on experience with real products under supervision. Others may incorporate them into packing stations where final inspections occur before shipping products out the door. This versatility not only maximizes the utility of each table but also reinforces the importance of rigorous quality control services throughout every phase of production.

Space-Saving Solutions for Small Work Areas

In today’s fast-paced world, many businesses face space constraints that challenge their operational efficiency—especially when it comes to implementing effective quality control services. Fortunately, designing a versatile quality inspection table can help overcome these limitations through innovative space-saving solutions. Compact designs with foldable features or mobile bases enable easy relocation without sacrificing functionality.

Moreover, wall-mounted options or stacking systems allow companies operating in small work areas to optimize their available space effectively while still maintaining high standards for product inspections and testing procedures. These clever design choices ensure that even limited environments can support robust workflows without compromising on the essential aspects of maintaining product quality and compliance with regulations.

Quality Control Services You Can Trust

In today's competitive marketplace, the need for reliable quality control services has never been more critical. Quality inspection tables play a pivotal role in ensuring that products meet stringent standards before they reach consumers. By integrating these tables into their operations, companies can enhance their overall service quality and reputation.

How Quality Inspection Tables Enhance Services

Quality inspection tables are not just tools; they are essential components of a robust quality control system. These tables provide a dedicated space for thorough inspections, allowing workers to identify defects and inconsistencies effectively. With organized layouts and specific features tailored for various industries, quality inspection tables streamline the inspection process, making it quicker and more efficient.

The benefits extend beyond mere functionality; they also improve worker morale by providing a well-designed workspace that promotes focus and productivity. When employees have the right tools at their disposal, including high-quality inspection tables, they can perform their tasks with greater accuracy and confidence. This leads to fewer errors in production and ultimately results in higher customer satisfaction.

Moreover, by implementing effective quality control services through these tables, businesses can reduce waste and minimize costs associated with rework or returns. In essence, investing in a quality inspection table is investing in your company's reputation and bottom line.

The Role of China Inspection Pro

When it comes to sourcing reliable quality solutions, China Inspection Pro stands out as a reputable partner for many businesses worldwide. They specialize in offering comprehensive inspection services tailored to meet diverse industry needs while emphasizing the importance of using high-quality materials like those found in premium quality inspection tables. Their expertise ensures that inspections are conducted efficiently without compromising on standards.

China Inspection Pro brings an array of benefits to the table—pun intended! Their trained inspectors utilize advanced techniques alongside top-notch equipment to ensure that every product meets or exceeds expected specifications before leaving the factory floor. By collaborating with such skilled professionals, companies can rest assured that their products are thoroughly vetted through superior quality control services.

Furthermore, partnering with China Inspection Pro allows businesses access to vital insights into market trends and potential pitfalls within their supply chain processes. This knowledge not only enhances product reliability but also fosters lasting relationships between manufacturers and suppliers based on trust and commitment to excellence.

Building Relationships with Quality Suppliers

Establishing strong relationships with quality suppliers is crucial for maintaining consistent product integrity over time. A reliable supplier will prioritize transparency regarding material sourcing and production processes while also being receptive to feedback about how their products—like quality inspection tables—can be improved further for optimal performance within your operations.

Building these partnerships requires open communication channels where both parties feel comfortable discussing expectations surrounding delivery timescales or any potential issues encountered during manufacturing processes related directly back down onto those essential quality control services provided by your team members using those very same tools!

Additionally, fostering such relationships encourages collaboration on future projects aimed at enhancing overall efficiency across both organizations involved—ultimately leading toward better outcomes for customers who rely heavily upon these trusted providers' capabilities when it comes down selecting appropriate solutions tailored precisely according each unique situation faced daily within various industries today!

Real-World Applications and Success Stories

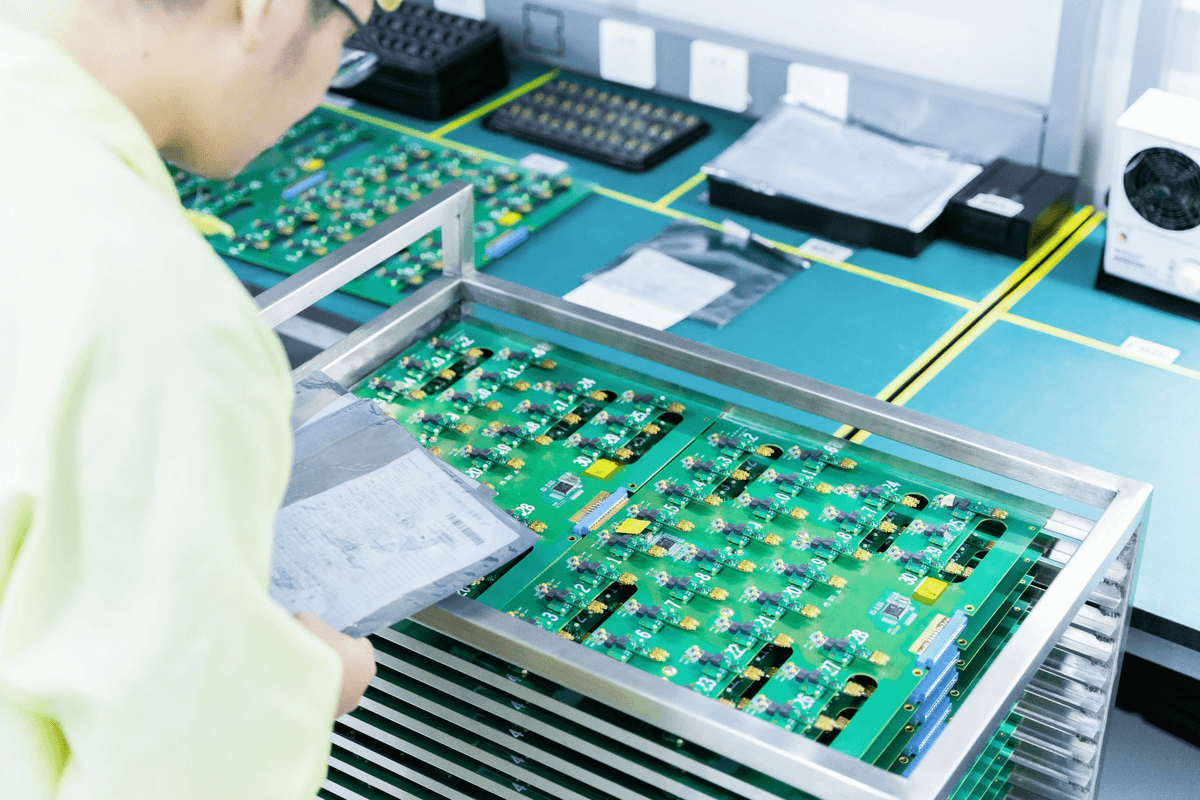

Quality inspection tables are not just a trend; they are integral to various industries aiming to enhance their quality control services. From manufacturing plants to electronics assembly lines, these tables provide the necessary support for meticulous quality inspection processes. Organizations that invest in quality solutions often find themselves reaping the benefits of improved efficiency and reduced error rates.

Industries Benefiting from Quality Solutions

Manufacturing, automotive, aerospace, and electronics industries have all embraced quality inspection tables as essential tools in their operations. In manufacturing, these tables help ensure that products meet stringent standards before reaching consumers. The automotive industry relies on quality inspection for safety and performance, while aerospace demands precision that only dedicated quality control services can provide.

Moreover, the electronics sector utilizes quality inspection tables to handle delicate components that require careful examination. By leveraging these specialized surfaces, companies can streamline their workflows and maintain high-quality outputs. Ultimately, investing in a robust quality inspection table translates into enhanced reliability across various sectors.

Case Studies of Effective Implementation

A notable case study comes from a leading automotive manufacturer that integrated custom-designed quality inspection tables into its production line. This implementation allowed them to reduce defects by 30% within the first quarter of use due to improved visibility during inspections and streamlined processes for identifying issues early on. With this success story in mind, many organizations are recognizing how tailored solutions can drive substantial improvements.

Another example is an electronics company that faced challenges with component damage during inspections. By switching to specialized quality inspection tables with padded surfaces and adjustable heights, they reduced damage rates by over 25%. These real-world applications underscore how crucial it is to choose the right equipment for effective quality control services.

Testimonials from Satisfied Customers

Customers consistently praise their investments in quality solutions like customizable quality inspection tables. One customer stated, Since implementing our new table system, our team has seen a remarkable increase in productivity while maintaining high-quality standards. This sentiment echoes throughout numerous testimonials highlighting how these tools have transformed operations.

Another satisfied user noted, Our previous setup was cumbersome; now we have versatile workspaces that adapt easily to different projects. Such feedback illustrates how essential it is for businesses to prioritize flexibility when selecting a quality supplier for their needs. The positive experiences shared by customers reinforce the notion that investing in proper equipment pays off significantly over time.

Conclusion

In the fast-paced world of manufacturing and production, maximizing efficiency is crucial, and quality inspection tables play a pivotal role in achieving that goal. By providing a dedicated space for thorough quality inspection, these tables streamline processes and reduce errors. Investing in a high-quality inspection table not only enhances productivity but also fosters a culture of quality control services that resonate throughout an organization.

Maximizing Efficiency with Quality Inspection Tables

Quality inspection tables are designed to optimize workflows and ensure that products meet stringent standards before reaching the market. When equipped with the right features, such as adjustable heights and integrated storage solutions, they become indispensable tools for any quality control team. The result is a seamless integration into various operational environments, allowing for swift identification of defects and ensuring consistent output.

Future Trends in Quality Control

As industries evolve, so too do the technologies and methodologies surrounding quality control services. The future will likely see an increased reliance on automation and data analytics to enhance the capabilities of quality inspection tables. Innovations such as smart sensors and AI-driven analytics will provide real-time feedback, enabling businesses to adapt quickly to emerging challenges while maintaining high standards in product quality.

The Path to Improved Product Quality

The journey toward improved product quality begins with selecting reliable quality suppliers who understand the importance of robust inspection processes. By leveraging effective quality solutions—such as versatile inspection tables—organizations can establish rigorous standards that elevate their offerings above competitors'. Ultimately, this commitment to excellence not only satisfies customers but also builds lasting brand loyalty.