Introduction

In the world of manufacturing and production, maintaining high standards is crucial for success. The Acceptable Quality Level (AQL) formula serves as a fundamental tool in quality control, providing a systematic approach to evaluate product quality. By understanding AQL sampling techniques, businesses can ensure that their products meet acceptable standards before reaching consumers.

What is the Acceptable Quality Level Formula

The acceptable quality level formula quantifies the maximum number of defective items considered acceptable in a sample batch during quality inspection. This statistical method helps companies determine whether to accept or reject a lot based on predefined criteria. Essentially, it bridges the gap between product quality and consumer satisfaction by establishing clear thresholds for defects.

Importance of AQL in Quality Control

The importance of AQL in quality control cannot be overstated; it provides a structured framework that enhances consistency and reliability in product evaluation. Quality inspection companies utilize this formula to minimize risks associated with defective goods, ultimately safeguarding brand reputation and customer trust. Moreover, employing the AQL formula ensures compliance with industry standards, making it an indispensable component of effective quality management systems.

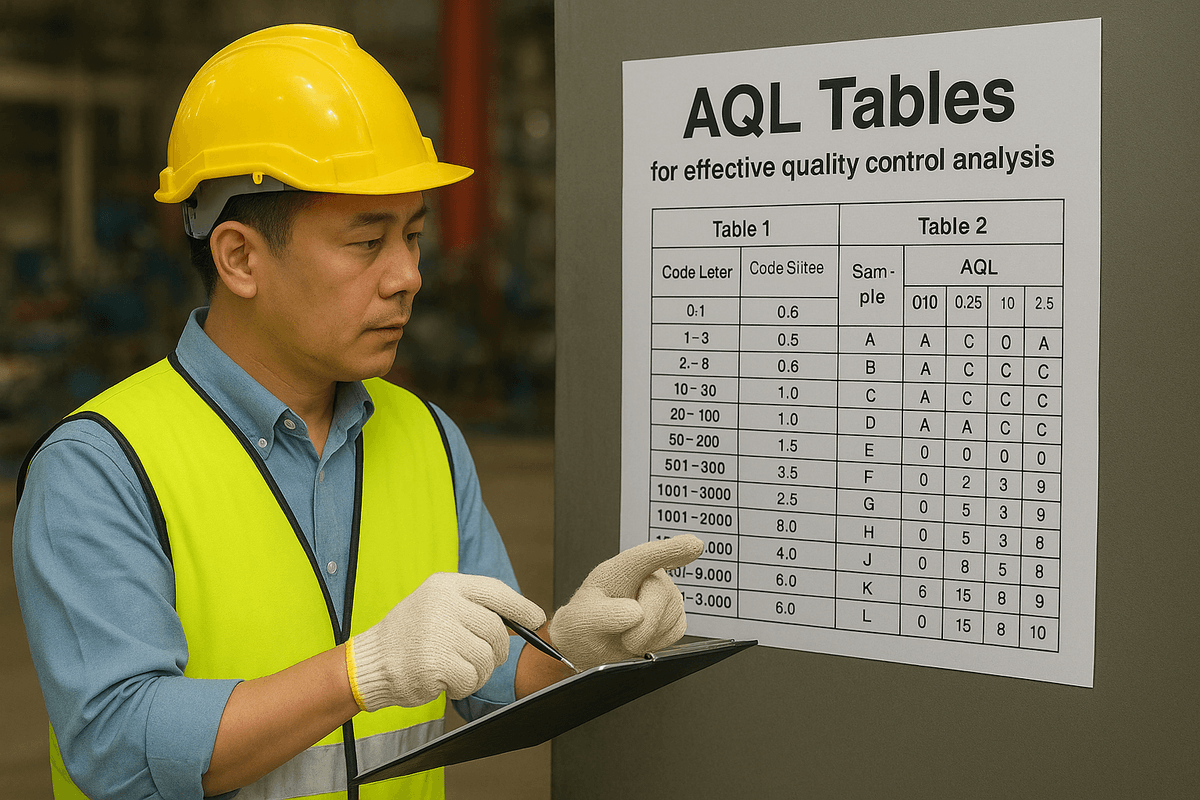

How AQL Sampling Works

AQL sampling works by selecting random samples from a larger batch and assessing them against the acceptable quality level set by the manufacturer or industry standards. This process involves using an AQL chart or table to determine sample sizes and acceptance numbers based on predetermined defect rates. By implementing these methods effectively, businesses can streamline their quality assurance practices while reducing costs associated with extensive inspections.

Defining the Acceptable Quality Level Formula

The Acceptable Quality Level (AQL) formula is a cornerstone in the realm of quality control, providing a systematic approach to sampling and inspection. By defining acceptable limits for defects in products, it helps businesses ensure that their offerings meet customer expectations without incurring excessive costs associated with perfect quality. This balance between quality and cost is essential for maintaining competitiveness, especially in industries where product standards are paramount.

Key Components of the AQL Formula

The AQL formula comprises several key components that work together to establish acceptable defect levels. At its core, it defines the maximum number of defective items allowed in a sample size before rejecting an entire batch. This involves parameters such as lot size, sample size, and acceptance number, which all play vital roles in determining whether a batch passes or fails inspection.

Understanding these components is crucial for quality control companies that utilize AQL sampling methods effectively. By mastering these elements, businesses can create tailored inspection plans that align with their specific needs and industry standards. Moreover, leveraging an AQL calculator can streamline this process by providing quick calculations based on varying inputs.

Different Types of AQL Tables

AQL tables are indispensable tools used by quality inspection companies to facilitate decision-making during the sampling process. These tables categorize various acceptable quality levels into different classes based on the product type and industry requirements. Commonly used types include general inspection tables and special inspection tables—each designed for specific scenarios depending on factors like risk tolerance and production volume.

Each table provides clear guidance on how many samples should be inspected from a given lot size and what constitutes an acceptable number of defects within those samples. Understanding how to navigate these AQL charts can significantly enhance efficiency during inspections while minimizing potential errors that could lead to costly rejections or recalls later on.

Real-world Applications of AQL

In real-world scenarios, the application of the acceptable quality level formula extends across various industries—from manufacturing to food safety—demonstrating its versatility in ensuring product integrity. For instance, electronics manufacturers often rely on stringent AQL standards due to high consumer expectations regarding performance and reliability; even minor defects can lead to significant failures down the line.

Similarly, in sectors like textiles or automotive parts production, implementing effective AQL sampling techniques helps maintain consistent product quality while managing costs efficiently. As businesses increasingly adopt data-driven approaches through tools like an AQL calculator and comprehensive charts or tables for reference, they enhance their ability to make informed decisions quickly—ultimately leading to improved customer satisfaction.

The Role of Quality Inspection Companies

In today’s competitive market, quality inspection companies play a pivotal role in maintaining product standards and ensuring compliance with the acceptable quality level formula (AQL). These companies specialize in evaluating products before they reach consumers, thus safeguarding brand reputation and customer satisfaction. By implementing systematic quality control measures, such as AQL sampling and utilizing AQL calculators, businesses can significantly reduce the risk of defects.

How China Inspection Pro Enhances Quality Control

China Inspection Pro stands out among quality inspection companies by providing tailored solutions that enhance overall quality control. Their expertise in the acceptable quality level formula allows them to design specific AQL tables that cater to various industries, ensuring that products meet both international standards and client expectations. With their advanced techniques in AQL sampling, they help businesses identify potential issues early on, saving time and resources while boosting confidence in product integrity.

Benefits of Professional Quality Inspection

Engaging professional quality inspection services yields numerous benefits for businesses looking to uphold high standards. First off, these services provide an objective assessment of product quality using well-established methods like the AQL chart to determine acceptable defect rates. Additionally, by relying on experienced inspectors who utilize sophisticated AQL calculators and follow rigorous protocols, companies can mitigate risks associated with poor-quality products entering the market.

Choosing the Right Quality Inspection Partner

Selecting the right quality inspection partner is crucial for any business committed to excellence. It's essential to evaluate potential partners based on their knowledge of the acceptable quality level formula and experience with various AQL tables relevant to your industry. Moreover, consider their ability to adapt AQL sampling techniques according to your specific needs; this flexibility can make all the difference in achieving optimal results.

Understanding AQL Sampling Techniques

In the world of quality control, understanding AQL sampling techniques is crucial for ensuring that products meet the acceptable quality level formula. AQL sampling allows companies to inspect a representative sample of products rather than examining every single item, making it a practical approach in various industries. By employing effective AQL sampling methods, businesses can maintain high standards without incurring excessive costs or delays.

Overview of AQL Sampling Methods

A variety of AQL sampling methods exist to help quality inspection companies assess product quality efficiently. The most common techniques include simple random sampling, systematic sampling, and stratified sampling, each offering unique advantages depending on the production context. Using an appropriate method ensures that the sample accurately reflects the overall quality level of a batch while minimizing bias and maximizing reliability.

Strategies for Effective AQL Sampling

To achieve optimal results with AQL sampling, it’s essential to implement effective strategies tailored to your specific needs. First, clearly define your acceptable quality level formula by determining the maximum number of defective items allowed in your sample size. Next, utilize an aql calculator to determine the appropriate sample size based on factors such as lot size and desired confidence levels; this step is critical for accurate assessments.

Additionally, regularly review and update your aql chart or table based on historical data and trends in product defects; this practice will enhance decision-making over time. Ensuring proper training for staff involved in inspections is also vital so they understand how to conduct thorough evaluations while adhering to established protocols.

Common Pitfalls in AQL Sampling

Despite its effectiveness, several common pitfalls can undermine the integrity of AQL sampling processes if not addressed properly. One frequent mistake is failing to select a representative sample; if certain segments are overlooked or underrepresented during inspections, this can lead to misleading conclusions about product quality. Quality inspection companies must also avoid relying solely on statistical tools like an aql calculator without considering practical aspects such as production variability.

Another pitfall is neglecting documentation; maintaining accurate records of inspections and findings helps ensure accountability and facilitates continuous improvement within quality control systems. Lastly, overlooking employee training can result in inconsistent application of procedures—quality assurance relies heavily on knowledgeable personnel who understand both the principles behind an acceptable quality level formula and how to execute them effectively.

Utilizing the AQL Calculator

In today's quality control landscape, the AQL calculator has emerged as a vital tool for manufacturers and quality inspection companies alike. This nifty device simplifies the process of determining acceptable quality levels by providing quick calculations based on predefined parameters. By leveraging an acceptable quality level formula, businesses can ensure they maintain high standards while efficiently managing their resources.

How to Use an AQL Calculator Effectively

Using an AQL calculator effectively requires a solid understanding of its key components, including lot size, sample size, and acceptance number. First, input your lot size—the total number of items in your batch—into the calculator. Next, select the appropriate sample size based on your production volume and desired confidence level to ensure that your aql sampling is both practical and reliable.

Once you've entered these values, you can determine the maximum number of defects allowed in your sample using the acceptance number derived from an AQL table or chart. This step is crucial because it directly influences your quality inspection outcomes; too lenient an acceptance number may lead to subpar products slipping through the cracks. Therefore, familiarize yourself with various AQL tables so you can make informed decisions tailored to your specific industry needs.

Interpreting Results from the AQL Calculator

Interpreting results from an AQL calculator can be straightforward if you know what to look for in terms of pass/fail metrics. Once you've calculated the acceptance number based on your inputs, compare it against actual defect counts found during inspections or testing phases. If defects exceed this threshold, it's time to reevaluate either your production processes or consider engaging with professional quality inspection companies for further analysis.

Moreover, understanding how different factors influence results is essential for continuous improvement within your operations. For instance, if you're frequently hitting or exceeding rejection rates indicated by the acceptable quality level formula, it might signal underlying issues in manufacturing or supplier reliability that need addressing urgently. Regularly revisiting these calculations ensures that you're not only compliant but also striving for excellence in product delivery.

Integrating AQL Calculators into Quality Assurance Practices

Integrating an AQL calculator into existing quality assurance practices can streamline processes and enhance overall effectiveness in managing product standards. Start by training staff on how to use these calculators alongside traditional methods like visual inspections and statistical sampling techniques; this creates a comprehensive approach toward maintaining acceptable quality levels across all products produced.

Additionally, coupling an AQL calculator with robust data analytics tools allows businesses to track trends over time—enabling proactive adjustments before problems escalate into larger issues that could jeopardize customer satisfaction or brand reputation. Quality control companies often recommend setting up routine audits where results from calculators are reviewed alongside findings from physical inspections; this holistic view helps identify areas needing improvement more swiftly.

Finally, don’t forget about documentation! Keeping detailed records of calculations and outcomes not only supports compliance efforts but also fosters transparency within teams working towards shared goals related to product excellence—all while reinforcing a culture dedicated to continuous improvement based on solid data foundations.

Navigating AQL Charts and Tables

Understanding how to effectively navigate AQL charts and tables is crucial for anyone involved in quality control. The acceptable quality level formula provides a framework for determining acceptable limits of defects in a sample, which can be visualized through these charts and tables. Quality inspection companies often rely on these tools to streamline the sampling process and enhance decision-making.

Understanding AQL Charts at a Glance

AQL charts are designed to present complex statistical data in an easily digestible format, making them invaluable for quality inspection processes. These charts typically display various sample sizes alongside corresponding acceptance numbers, allowing users to quickly assess the acceptable quality level formula at play. By understanding how to read these charts, professionals can make informed decisions regarding product acceptance or rejection based on predefined standards.

Practical Use Cases of AQL Tables

AQL tables serve as practical guides in diverse scenarios within the realm of quality control companies. For instance, manufacturers can utilize these tables when determining the appropriate sample size for inspections based on their production volume and desired defect levels. Additionally, retailers may refer to AQL tables when assessing incoming shipments from suppliers, ensuring that they meet their acceptable quality level criteria before being stocked.

How AQL Charts Assist in Decision-Making

A crucial aspect of effective quality inspection is timely decision-making, and this is where AQL charts truly shine. By presenting clear thresholds for acceptability based on the acceptable quality level formula, these charts help streamline discussions among teams involved in product evaluation. Quality inspection companies can leverage this information not only to make quick decisions but also to justify those decisions with data-driven insights backed by solid statistical evidence.

Conclusion

In a world where quality can make or break a business, the Acceptable Quality Level (AQL) formula stands as a beacon for effective quality control. It simplifies the often complex landscape of quality inspection by providing clear guidelines on acceptable defect rates. By leveraging AQL sampling and reliable tools like the AQL calculator, companies can streamline their processes and enhance overall product quality.

Simplifying Quality Control with AQL

The acceptable quality level formula serves as a straightforward method for determining how many defects are permissible in a batch of products. This clarity allows businesses to focus their efforts on what truly matters—delivering high-quality products while managing costs effectively. Quality inspection companies utilize AQL charts and tables to ensure that inspections are both efficient and effective, reducing ambiguity in quality control.

Enhancing Product Quality through AQL

By implementing the acceptable quality level formula, organizations can significantly enhance their product quality. The strategic use of AQL sampling helps pinpoint potential issues before they escalate into larger problems, allowing for timely interventions. Moreover, partnering with professional quality inspection companies ensures that businesses not only meet but exceed industry standards through rigorous checks based on well-established AQL parameters.

The Future of Quality Inspection and AQL

Looking ahead, the role of the acceptable quality level formula in shaping the future of quality inspection is undeniable. As industries evolve and consumer expectations rise, reliance on sophisticated tools like the AQL calculator will become increasingly crucial for maintaining competitive advantage. With advancements in technology and data-driven insights from AQL charts and tables, businesses will be better equipped to navigate challenges in quality control while consistently delivering superior products.