Introduction

In today's competitive landscape, manufacturing quality inspection stands as a pillar of success for businesses aiming to thrive. The process of quality assurance is not merely a checkbox on a production list; it’s an essential strategy that enhances product reliability and fosters consumer trust. By prioritizing rigorous quality control, companies can ensure they deliver products that meet or exceed customer expectations, ultimately shaping their brand reputation.

The Importance of Manufacturing Quality Inspection

Manufacturing quality inspection is critical in safeguarding the integrity of products before they reach consumers. It serves as a proactive measure to identify flaws and defects early in the production process, minimizing risks associated with subpar products. By implementing effective quality assurance practices, manufacturers can significantly reduce costs related to returns and repairs, making it an investment worth pursuing.

How Quality Control Boosts Brand Reputation

Quality control plays a pivotal role in establishing and maintaining a strong brand reputation. When customers consistently receive high-quality products, their trust in the brand solidifies, leading to repeat business and positive word-of-mouth referrals. This cycle of trust not only enhances customer loyalty but also differentiates brands in crowded markets where quality assurance is paramount.

The Financial Benefits of Quality Assurance

Investing in quality assurance yields substantial financial benefits for manufacturers over time. Early defect detection through robust manufacturing quality inspection processes can save companies significant amounts by reducing waste and rework costs. Furthermore, delivering reliable products bolsters customer satisfaction and retention rates, translating into long-term profitability that far outweighs initial investments in quality control measures.

Understanding Manufacturing Quality Inspection

Manufacturing quality inspection is a critical component of the production process that ensures products meet established standards and specifications. Its primary purpose is to identify defects before they reach consumers, safeguarding both brand integrity and customer satisfaction. By integrating rigorous quality assurance practices, manufacturers can enhance their operational efficiency while minimizing costs associated with product recalls and dissatisfied customers.

Definition and Purpose of Quality Inspection

Quality inspection refers to the systematic examination of products at various stages of production to ensure they adhere to predefined quality standards. The purpose of this inspection is twofold: first, it aims to detect any deviations from quality norms early in the manufacturing process; second, it serves as a preventive measure against potential failures that could arise post-production. Ultimately, effective manufacturing quality inspection not only protects consumer interests but also bolsters the reputation of brands committed to delivering high-quality products.

Key Processes in Quality Control

Quality control encompasses several key processes that work together to maintain high standards throughout the manufacturing cycle. These processes typically include incoming material inspections, in-process checks during production, and final product evaluations before shipment. Each step plays a vital role in ensuring that quality assurance practices are upheld—this is where QA quality comes into play—by identifying issues early on and implementing corrective actions as necessary.

The Role of Quality Assurance in Manufacturing

Quality assurance (QA) serves as a proactive approach within manufacturing, focusing on preventing defects rather than just detecting them after they occur. It involves establishing robust systems and protocols that guide all aspects of production—from design through delivery—to ensure consistent adherence to quality standards. By prioritizing quality assurance over mere compliance with regulations, manufacturers can foster an environment where continuous improvement becomes part of their culture, ultimately leading to superior products and enhanced customer loyalty.

The Impact of Quality Assurance on Products

Quality assurance plays a pivotal role in determining the overall success of manufactured products. By integrating robust quality inspection processes, manufacturers can significantly enhance product reliability and safety, reduce defects, and ensure compliance with industry standards. This not only elevates the quality of products but also fosters consumer trust and loyalty.

Enhancing Product Reliability and Safety

Manufacturing quality inspection is essential for enhancing product reliability and safety. When manufacturers implement rigorous quality assurance measures, they proactively identify potential issues that could compromise product integrity or user safety. This commitment to quality ensures that consumers receive products that meet or exceed their expectations, ultimately leading to higher satisfaction rates.

Moreover, consistent quality control helps prevent costly recalls due to safety hazards caused by defective products. By investing in qa quality practices from the outset, companies can mitigate risks associated with poor-quality items entering the market. Thus, the relationship between manufacturing quality inspection and product reliability becomes evident—higher standards lead to safer outcomes for consumers.

Reducing Defects Through Rigorous Inspection

Rigorous inspection processes are at the heart of effective quality assurance quality practices aimed at reducing defects in manufactured goods. By employing advanced techniques during manufacturing quality inspection, businesses can catch flaws early in production rather than after they've reached consumers’ hands. This proactive approach not only minimizes waste but also saves time and resources that would otherwise be spent addressing customer complaints.

Additionally, a strong emphasis on quality control enables manufacturers to create a culture of excellence within their teams. Employees become more aware of their roles in maintaining high standards, leading to a decrease in human error and an overall improvement in product outcomes. Ultimately, reducing defects through stringent inspections reinforces a brand’s reputation for delivering high-quality goods.

Compliance with Industry Standards and Regulations

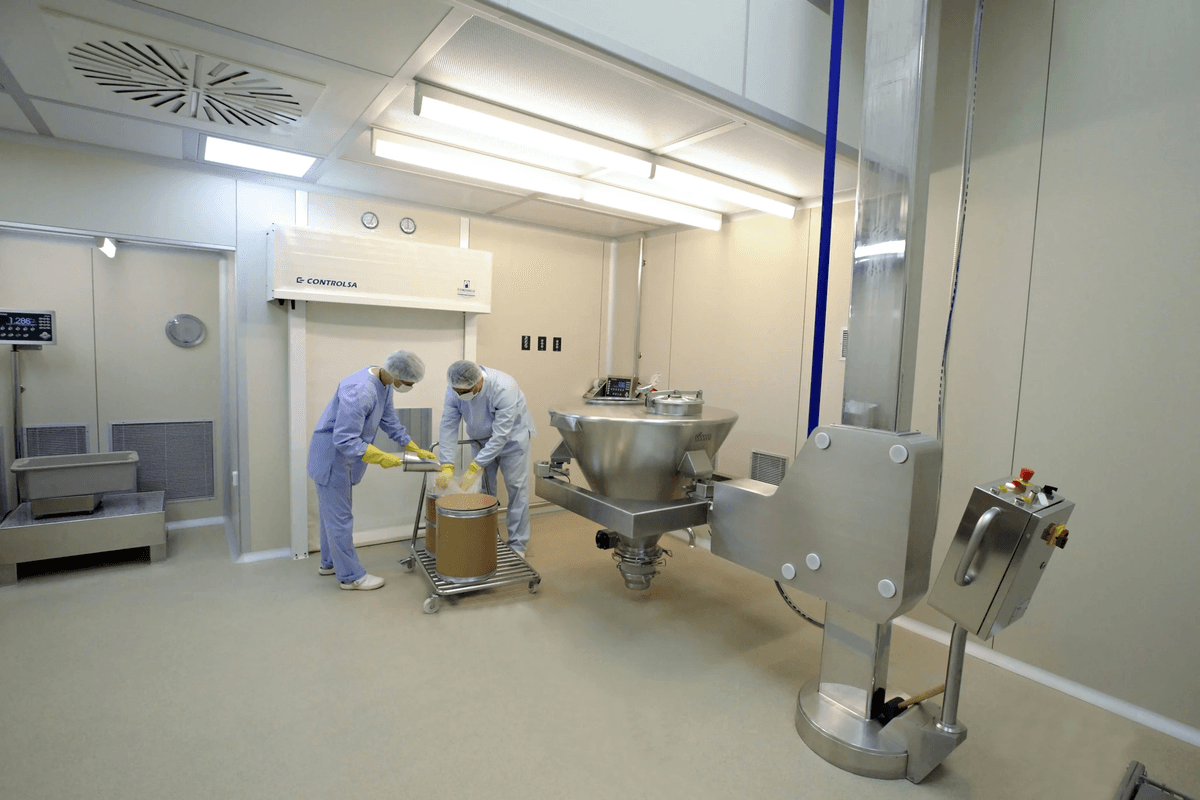

Compliance with industry standards and regulations is another critical aspect where quality assurance shines through manufacturing processes. Adhering to established guidelines ensures that products meet specific safety criteria while maintaining consistency across production lines—essentially creating a framework for businesses to operate within legal parameters safely. Quality control mechanisms facilitate this compliance by regularly monitoring processes against regulatory benchmarks.

Moreover, demonstrating compliance through effective qa quality initiatives can significantly enhance a company's credibility within its sector. Clients are more likely to choose suppliers who prioritize manufacturing quality inspection as part of their operational strategy since it reflects an organization's commitment to excellence and responsibility toward consumer safety. In today’s competitive landscape, ensuring adherence to industry regulations is not just beneficial; it's imperative for sustainable growth.

Quality Control in Global Manufacturing

In today's interconnected world, manufacturing quality inspection has become a pivotal concern for businesses aiming to maintain high standards and satisfy customer expectations. The landscape of global manufacturing is fraught with challenges that can compromise quality assurance and ultimately affect brand reputation. From varying regulations across countries to supply chain complexities, manufacturers must navigate these hurdles to uphold quality control.

Challenges Faced by Manufacturers Worldwide

Manufacturers across the globe encounter several significant challenges that impact their quality assurance efforts. One major hurdle is the inconsistency in regulatory standards; different countries have diverse requirements for quality and safety, making it difficult to establish a uniform approach to manufacturing quality inspection. Additionally, maintaining effective communication with suppliers and partners worldwide can lead to misunderstandings about quality expectations, resulting in defects that could have been avoided with better oversight.

Another challenge lies in the rapid pace of technological change, which often outstrips manufacturers' ability to adapt their quality control processes accordingly. As new materials and methods emerge, ensuring that these innovations meet established quality assurance standards becomes increasingly complex. Furthermore, labor shortages in various regions can lead to rushed production schedules, putting additional strain on the already delicate balance of maintaining high-quality output.

Case Study: China Inspection Pro's Approach

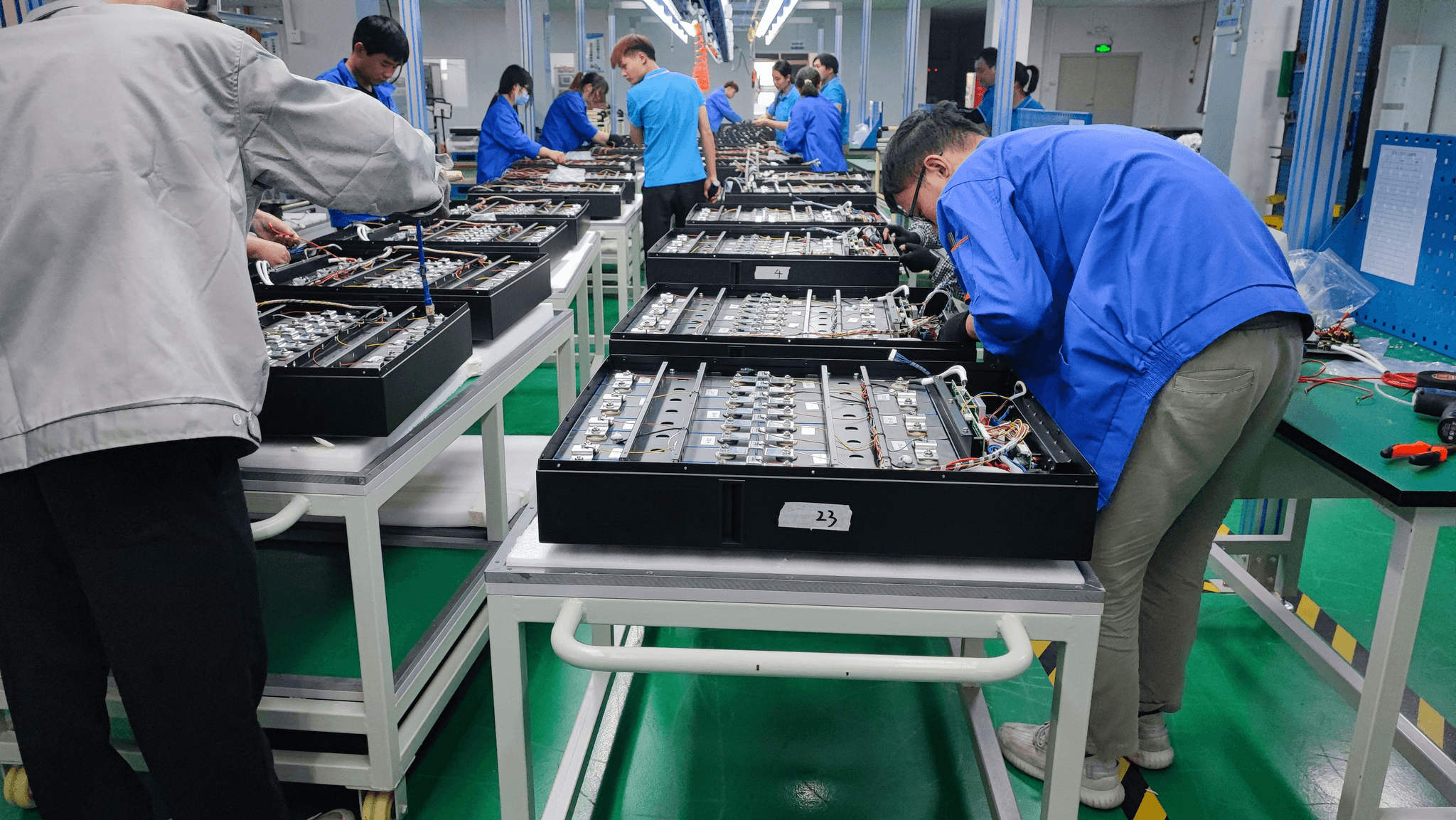

China Inspection Pro serves as an exemplary case study for addressing the challenges faced by manufacturers through effective quality control strategies. This company specializes in providing comprehensive manufacturing quality inspection services tailored specifically for businesses operating within China’s vast industrial landscape. By employing skilled inspectors who are well-versed in both local regulations and international standards, they ensure that products meet stringent requirements before reaching consumers.

Their approach emphasizes proactive communication with clients throughout the production process, allowing them to identify potential issues early on—an essential aspect of effective QA quality management. By focusing on real-time inspections rather than relying solely on post-production checks, China Inspection Pro significantly reduces defect rates while enhancing overall product reliability and safety. This model not only reinforces trust among clients but also showcases how strategic partnerships can elevate global manufacturing standards.

Strategies for Effective Quality Control

To combat the myriad challenges facing global manufacturers today, implementing robust strategies for effective quality control is crucial. First and foremost, investing in training programs focused on both employees and suppliers will foster a culture of continuous improvement regarding manufacturing quality inspection practices. By emphasizing the importance of both individual accountability and team collaboration within QA processes, organizations can significantly enhance their overall product integrity.

Moreover, leveraging technology plays a vital role in modernizing traditional approaches to quality assurance quality management systems. Tools such as AI-driven analytics allow manufacturers to predict potential defects before they occur—transforming reactive inspections into proactive measures that prioritize customer satisfaction while minimizing wasteful expenditures related to rework or recalls.

Lastly, establishing clear communication channels across all levels—from factory floor workers up through management—ensures everyone understands their role within the larger framework of maintaining high-quality standards consistently throughout production cycles. By fostering an environment where feedback is valued and acted upon promptly, companies can create a resilient infrastructure capable of adapting swiftly amid changing market demands while prioritizing ongoing improvements in both product excellence and operational efficiency.

The Relationship Between Quality Assurance and Profitability

Quality assurance is not just a buzzword; it’s a pivotal strategy that directly correlates with profitability in manufacturing. By implementing robust quality control measures, businesses can experience significant cost savings while enhancing their brand image. The relationship between quality assurance and profitability is clear: invest in quality, reap financial rewards.

Cost Savings Through Early Defect Detection

One of the most compelling reasons to prioritize manufacturing quality inspection is the cost savings associated with early defect detection. Identifying issues during the production process rather than after products hit the market can save manufacturers substantial amounts of money in rework, returns, and customer dissatisfaction. This proactive approach to quality control not only mitigates financial loss but also streamlines operations, allowing companies to allocate resources more effectively.

Building Customer Trust with Quality Products

In today’s competitive landscape, building customer trust hinges on delivering high-quality products consistently. Quality assurance plays a crucial role in establishing this trust; when customers know they can rely on a brand for superior quality, they are more likely to become repeat buyers and advocates for that brand. Implementing rigorous QA processes fosters loyalty and enhances reputation—two invaluable assets that translate into increased profitability over time.

Long-term Financial Gains from Quality Investments

Investing in quality assurance isn’t just about immediate returns; it’s about laying the groundwork for long-term financial success. Companies that prioritize manufacturing quality inspection often find themselves with reduced operational costs and improved efficiency over time. Additionally, as these organizations cultivate a reputation for excellence through consistent product quality, they position themselves favorably within their industry, leading to sustained profitability and growth.

Future Trends in Quality Inspection

The landscape of manufacturing quality inspection is evolving rapidly, driven by technological advancements and changing consumer expectations. As businesses strive for excellence, the integration of innovative solutions into quality assurance processes is becoming paramount. This section explores the future trends that promise to reshape the way we approach quality control.

Technological Innovations in Quality Control

Technological innovations are revolutionizing manufacturing quality inspection, allowing for more precise and efficient processes. From advanced imaging systems to real-time data analytics, these tools enhance the effectiveness of quality assurance efforts. By implementing cutting-edge solutions, manufacturers can achieve higher standards of quality and ensure their products meet stringent requirements.

Moreover, innovations such as IoT (Internet of Things) devices enable continuous monitoring throughout the production line, providing instant feedback on quality control metrics. This proactive approach not only helps identify potential issues early but also streamlines workflows and reduces waste. As technology continues to advance, the synergy between manufacturing quality inspection and modern tools will become increasingly vital for maintaining high-quality standards.

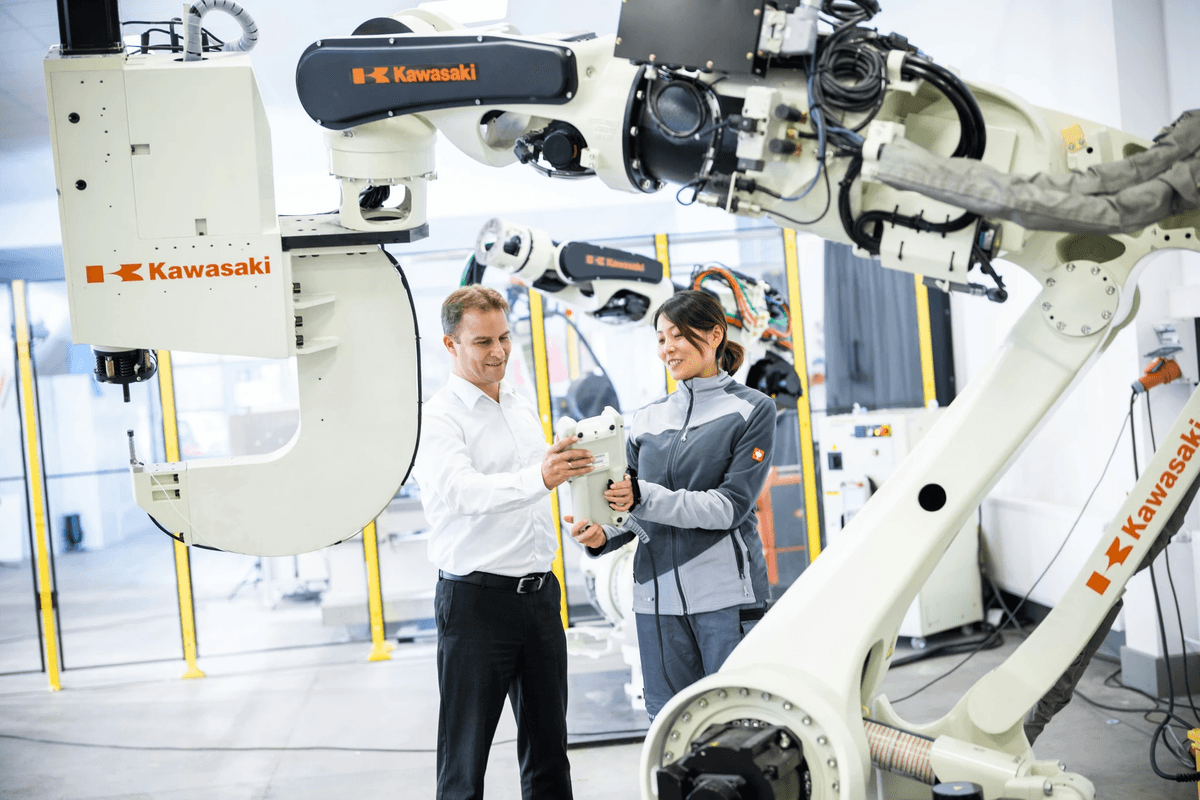

The Rise of AI and Automation in Quality Assurance

Artificial Intelligence (AI) and automation are making significant inroads into quality assurance practices within manufacturing settings. These technologies facilitate more accurate inspections by analyzing vast amounts of data at speeds unattainable by human inspectors alone. With AI-driven algorithms detecting patterns and anomalies, manufacturers can enhance their overall quality control strategies.

As a result, QA professionals can focus on higher-level decision-making rather than getting bogged down with repetitive tasks like manual inspections. Automation not only boosts efficiency but also minimizes human error—an essential factor in achieving consistent product reliability and safety through rigorous inspection processes. The rise of AI ensures that manufacturers remain competitive while adhering to the highest standards in quality assurance.

Sustainability and Quality: A Growing Concern

Sustainability is emerging as a critical component of effective manufacturing quality inspection strategies today. Consumers increasingly demand products that align with environmental stewardship, prompting manufacturers to integrate sustainable practices into their operations without compromising on product integrity or safety standards. This shift necessitates an evolution in how we perceive both quality control and sustainability.

Quality assurance now encompasses not only traditional metrics but also environmental impacts throughout the production lifecycle—ensuring that materials are sourced responsibly and waste is minimized during manufacturing processes. By prioritizing sustainability alongside robust QA practices, companies can enhance their brand reputation while meeting regulatory compliance regarding environmental standards. Ultimately, this holistic approach fosters a culture where both sustainability and high-quality production go hand-in-hand.

Conclusion

In the ever-evolving landscape of manufacturing, the significance of manufacturing quality inspection cannot be overstated. Quality assurance is not just a checkbox on a compliance list; it’s a commitment to excellence that elevates standards across the board. By prioritizing quality control, businesses can ensure their products not only meet but exceed customer expectations.

Elevating Manufacturing Standards Through Quality Inspection

Manufacturing quality inspection serves as the backbone of any successful production process, ensuring that every item produced adheres to stringent standards. This meticulous attention to detail fosters an environment where quality and quality assurance are paramount, leading to consistent product reliability. As manufacturers embrace rigorous quality control measures, they elevate industry benchmarks and set themselves apart from competitors who may overlook these essential practices.

The Competitive Edge from Quality Assurance

Quality assurance is more than an internal process; it’s a powerful marketing tool that builds brand loyalty and customer trust. When companies invest in comprehensive QA quality strategies, they create a perception of reliability that resonates with consumers seeking high-quality products. This competitive edge translates into increased market share and profitability as customers gravitate towards brands known for their unwavering commitment to excellence in quality assurance and control.

Investing in Quality: A Path to Success

Investing in manufacturing quality inspection is akin to planting seeds for future growth; the returns can be substantial when done right. By integrating advanced techniques in quality control and embracing innovative solutions, manufacturers can significantly reduce defects and enhance overall efficiency. Ultimately, prioritizing both quality and quality assurance leads not only to immediate cost savings but also paves the way for long-term success within an increasingly competitive marketplace.