Introduction

In today's fast-paced and highly regulated industries, third party inspection services have become indispensable. They serve as a crucial line of defense in ensuring that products and processes meet established standards, thereby enhancing overall quality management in construction projects and beyond. By leveraging these services, businesses not only maintain compliance but also foster trust among stakeholders.

Importance of Third Party Inspection Services

Third party inspection services play a vital role in verifying the integrity and safety of various projects, from construction to the testing of electronic components. These independent assessments help identify potential issues before they escalate into costly problems, ensuring that quality standards are upheld throughout the production process. Moreover, such inspections provide an objective evaluation that can significantly enhance the credibility of a company’s quality management practices.

Benefits of Quality Management in Construction Projects

Implementing robust quality management practices in construction projects leads to safer work environments and higher overall project success rates. By utilizing tools like a piping inspection checklist, teams can systematically address potential risks and ensure compliance with industry regulations. Furthermore, effective quality management fosters continuous improvement through regular social compliance audits, which can identify areas for enhancement while minimizing non-conformity reports.

Key Factors in Selecting Inspection Services

Choosing the right third party inspection services requires careful consideration of several key factors to ensure optimal outcomes for your projects. First and foremost is assessing the expertise and reputation of potential providers; their experience can greatly influence the effectiveness of inspections conducted on production of quality goods and services. Additionally, understanding what constitutes a non-conformity report will help you gauge how effectively an inspection service can manage deviations from expected standards.

What Are Third Party Inspection Services?

When it comes to ensuring the quality and safety of products and projects, third party inspection services play a vital role. These independent evaluations help organizations maintain compliance with industry standards and regulations, ultimately safeguarding their reputation and bottom line. By engaging third party inspectors, companies can focus on their core operations while leaving the intricate details of quality management in construction projects to specialists.

Definition and Overview

Third party inspection services refer to independent assessments conducted by qualified professionals who evaluate various aspects of production or construction processes. These services are designed to verify that products, materials, or systems meet specified requirements, thereby ensuring they are safe for use and compliant with relevant standards. In a world where quality assurance is paramount, these inspections provide an unbiased perspective that helps prevent costly mistakes.

Types of Inspection Services

There’s a diverse range of inspection services available to cater to different industries and needs. Some common types include visual inspections, non-destructive testing (NDT), material verification, and audits for social compliance. Additionally, specialized inspections such as piping inspection checklists or the testing of electronic components ensure that every facet of production aligns with established guidelines for quality goods and services.

Key Industries Utilizing Inspection Services

Numerous industries rely heavily on third party inspection services to uphold their quality standards and regulatory compliance. The construction sector is one such field where these inspections are crucial for maintaining safety protocols during project execution. Additionally, manufacturing industries—especially those involved in electronics—benefit from rigorous testing processes that ensure product reliability; this includes the meticulous evaluation of electronic components before they hit the market.

The Role of Quality Management in Construction Projects

In the realm of construction, quality management plays a pivotal role in ensuring that projects not only meet standards but also exceed expectations. By implementing robust quality management practices, companies can effectively utilize third party inspection services to guarantee compliance and safety throughout the project lifecycle. This proactive approach not only minimizes risks but also fosters a culture of excellence that resonates across all phases of construction.

Ensuring Compliance and Safety

Ensuring compliance and safety is paramount in any construction project, as even minor oversights can lead to significant consequences. Third party inspection services are instrumental in this regard, providing an unbiased assessment that verifies adherence to industry regulations and safety protocols. By integrating these services into quality management in construction projects, stakeholders can rest assured that their work environment is safe for all personnel involved.

Additionally, quality management systems facilitate the identification of potential hazards before they escalate into serious issues. Regular inspections conducted by third party providers help ensure that materials and methods used align with established standards. This vigilance not only protects workers but also enhances the overall integrity of the project.

Streamlining Quality Inspection Processes

Streamlining quality inspection processes is essential for maintaining efficiency without sacrificing standards. The integration of third party inspection services allows for a more structured approach to evaluating construction activities, ultimately leading to better resource allocation and time management. With clearly defined procedures in place, teams can focus on their core tasks while ensuring that quality checks are performed consistently.

Moreover, effective communication between contractors and third party inspectors fosters transparency throughout the project timeline. This collaboration ensures that everyone is on the same page regarding expectations and outcomes, which is crucial for successful delivery. By leveraging technology such as digital reporting tools within a well-organized quality inspection table, teams can enhance accuracy and reduce delays stemming from miscommunication.

Importance of a Piping Inspection Checklist

A piping inspection checklist serves as an invaluable tool within the framework of quality management in construction projects—particularly when it comes to ensuring compliance with industry standards related to piping systems. This checklist acts as a roadmap for inspectors, detailing critical criteria such as material specifications, installation practices, and testing protocols for electronic components when applicable. Utilizing such checklists ensures thorough evaluations are conducted without overlooking any vital aspects.

Furthermore, having a standardized piping inspection checklist contributes significantly to consistency across various projects or sites managed by different teams or contractors. It simplifies training processes for new employees who need guidance on what constitutes compliance during inspections while promoting adherence to best practices outlined by social compliance audits or regulatory bodies.

In conclusion, incorporating a piping inspection checklist into your quality management strategy not only enhances operational efficiency but also mitigates risks associated with non-conformance—ultimately leading to higher-quality production of goods and services.

Evaluating Inspection Service Providers

Choosing the right inspection service provider is crucial for ensuring that your projects meet the highest standards of quality management in construction projects, as well as in other industries. With a plethora of options available, it can be challenging to sift through potential providers and identify those that genuinely stand out. By focusing on their expertise, reputation, certifications, and how they handle social compliance audits, you can make an informed decision that aligns with your quality goals.

Assessing Expertise and Reputation

When evaluating third party inspection services, the first step is to assess their expertise and reputation in the industry. Look for providers with a proven track record in areas relevant to your needs—whether it’s testing of electronic components or conducting thorough inspections on construction sites using a piping inspection checklist. Online reviews, testimonials from previous clients, and case studies can offer valuable insights into their reliability and effectiveness.

Additionally, consider how long the provider has been in business; longevity often indicates a solid reputation built on trust and successful project execution. Engage with industry peers or professional networks to gather recommendations about reputable inspection service providers who excel in delivering quality goods and services. Ultimately, selecting a provider with a strong reputation will enhance your project's overall success.

Importance of Certifications and Accreditations

Certifications and accreditations are critical indicators of an inspection service provider's commitment to quality management standards. Look for organizations that hold relevant certifications from recognized bodies; this not only demonstrates their expertise but also assures you that they adhere to established protocols during inspections. For instance, ISO certifications are widely respected across various industries—especially when it comes to ensuring compliance within construction projects.

Moreover, accredited providers often have access to advanced technologies and methodologies that enhance the accuracy of inspections—be it for electronic components or physical structures. These credentials signify their dedication to continuous improvement through rigorous training programs for staff members involved in quality assurance processes.

How to Review Social Compliance Audits

Social compliance audits play an essential role in evaluating third party inspection services by ensuring they adhere not only to technical standards but also ethical practices within production environments. Reviewing these audits involves examining reports detailing how well a company complies with labor laws, environmental regulations, and safety standards throughout its operations. This scrutiny helps ensure that the production of quality goods and services aligns with ethical practices—a vital aspect for many businesses today.

When assessing social compliance audits from potential providers, look for transparency regarding past non-conformity reports (what is non conformity report). Understanding any issues previously identified—and how they were resolved—can provide insight into the provider's commitment to maintaining high standards over time. Additionally, consistent positive audit results indicate reliability and integrity within their operational framework.

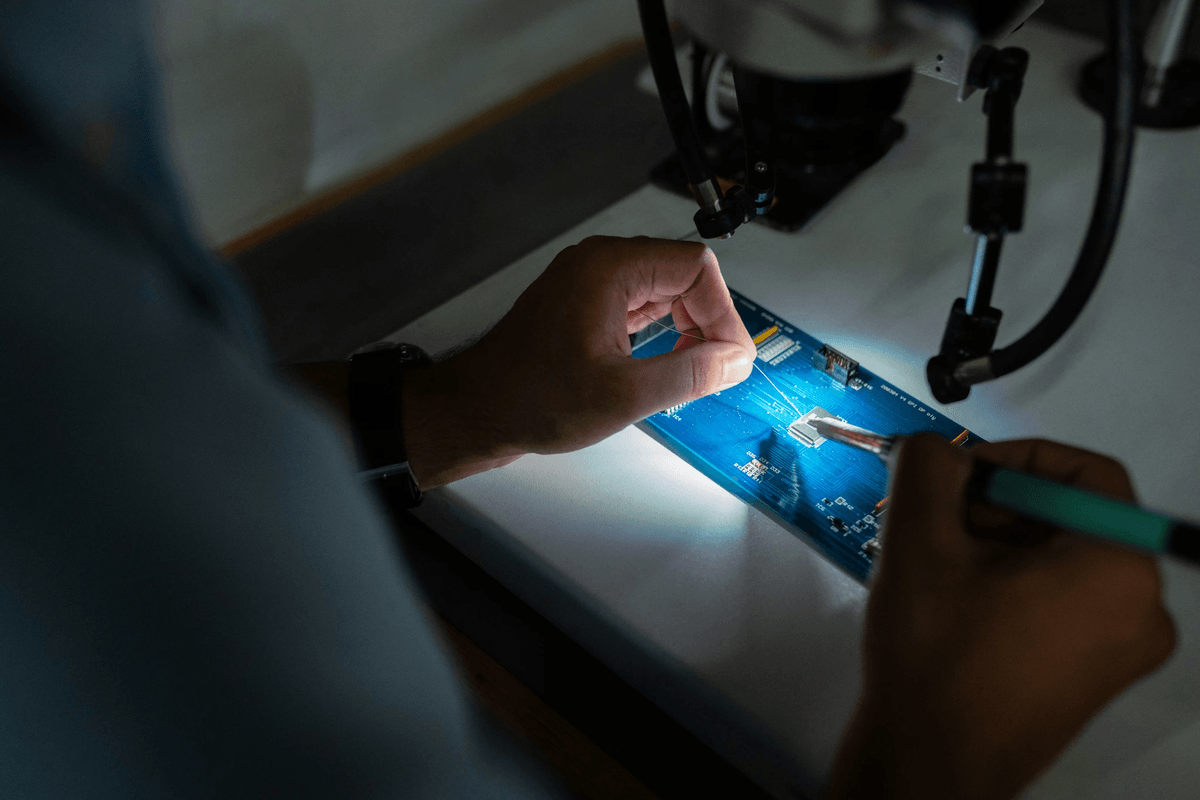

The Testing of Electronic Components

In the realm of electronics, the testing of electronic components is crucial to ensure that products meet industry standards and consumer expectations. Third party inspection services play a vital role in this process, providing an objective assessment that enhances quality management in construction projects and manufacturing. By implementing thorough testing protocols, companies can minimize defects and improve overall production of quality goods and services.

Understanding the Inspection Process

The inspection process for electronic components begins with defining specific criteria based on product requirements and regulatory standards. Third party inspection services utilize a systematic approach to evaluate each component's functionality, durability, and safety features. This rigorous examination not only identifies potential issues early on but also ensures compliance with established quality management practices.

Standards for Quality in Electronics

Quality standards in electronics are paramount; they dictate how components are tested and validated before reaching consumers. Organizations such as the International Electrotechnical Commission (IEC) set these benchmarks to uphold safety, reliability, and performance across various electronic applications. Adhering to these standards during inspections helps mitigate risks associated with non-conformity reports that could arise from subpar products.

Tools and Technologies Used

To effectively carry out inspections of electronic components, advanced tools and technologies are employed by third party inspection services. These may include automated testing equipment, thermal imaging cameras, and software for data analysis that streamline the assessment process significantly. Utilizing such technologies not only enhances accuracy but also contributes to maintaining a comprehensive quality inspection table essential for tracking compliance over time.

Production of Quality Goods and Services

In the realm of production, ensuring quality goods and services is paramount for any business aiming to thrive. This not only involves efficient processes but also the implementation of effective third party inspection services to verify compliance with established standards. By focusing on quality management in construction projects and other industries, organizations can significantly enhance their output while minimizing risks.

Establishing a Quality Inspection Table

A quality inspection table serves as a foundational tool in the production process, providing a structured approach to assessing products before they reach the market. This table outlines specific criteria that must be met, including dimensions, materials, and functionality—essentially acting as a comprehensive piping inspection checklist for various goods. By establishing such tables, companies can effectively streamline their operations and ensure that every item produced meets predetermined quality benchmarks.

The inclusion of third party inspection services can further bolster this process by offering an unbiased evaluation. These experts bring specialized knowledge to the table, helping organizations identify potential flaws before they escalate into costly issues. Ultimately, a well-constructed quality inspection table not only enhances product integrity but also fosters consumer trust.

Continuous Improvement through Quality Audits

Quality audits are vital for fostering continuous improvement within any organization’s production framework. Regular audits help identify gaps in quality management in construction projects or manufacturing processes that may otherwise go unnoticed—essentially serving as a reality check for operational efficiency. Through these evaluations, businesses can implement corrective actions based on findings and continuously refine their practices.

Moreover, incorporating insights from social compliance audits during these assessments ensures that ethical standards are upheld alongside product quality. This holistic approach facilitates not just adherence to regulations but also promotes sustainable practices within supply chains. As organizations embrace continuous improvement through rigorous auditing processes, they position themselves for long-term success in delivering high-quality goods and services.

The Impact of Non-Conformity Reports

Understanding what is a non-conformity report (NCR) is crucial for any business aiming to maintain high standards of production quality. An NCR documents instances where products or processes deviate from established specifications or regulations—essentially flagging areas needing attention before they impact overall output negatively. The timely resolution of issues highlighted in these reports is essential for maintaining compliance with industry norms and enhancing customer satisfaction.

By addressing non-conformities promptly through third party inspection services, companies can mitigate risks associated with poor-quality products entering the market. Furthermore, analyzing trends from NCRs provides invaluable data that informs future improvements across all levels of production—from testing of electronic components to large-scale construction projects. In essence, embracing non-conformity reports as part of an ongoing commitment to excellence paves the way for sustained growth and innovation.

Conclusion

In the ever-evolving landscape of construction and manufacturing, making informed decisions on third party inspection services is crucial. These services not only ensure compliance with industry standards but also significantly enhance the overall quality management in construction projects. By understanding the nuances of inspection processes, organizations can better navigate their choices and select providers that align with their specific needs.

Making Informed Decisions on Inspection Services

Organizations should prioritize understanding what these services entail, including the various types of inspections available and how they can benefit their projects. For instance, utilizing a piping inspection checklist can streamline processes and provide clarity during evaluations, ensuring that no detail is overlooked.

Moreover, assessing potential providers based on their expertise and reputation will lead to more informed decisions. It's essential to consider certifications and accreditations that validate an inspector's qualifications in quality management in construction projects. By doing so, businesses can mitigate risks associated with non-compliance and enhance their project outcomes.

Enhancing Quality Assurance in Industries

Quality assurance isn't just a buzzword; it's a fundamental aspect of successful operations across industries. The testing of electronic components is a prime example where rigorous standards must be met to ensure safety and functionality. Implementing robust quality management practices helps organizations maintain high standards while fostering continuous improvement through regular quality audits.

Establishing a quality inspection table is an effective way for teams to visualize their processes and track compliance metrics over time. This proactive approach not only enhances product reliability but also minimizes the chances of receiving non-conformity reports that could jeopardize project timelines or budgets. Ultimately, investing in thorough inspections leads to greater customer satisfaction and brand loyalty.

Final Thoughts on Choosing Reliable Inspection Providers

Choosing reliable inspection providers requires diligence but pays off significantly in the long run. Organizations should look for partners who are well-versed in social compliance audits, as these assessments help ensure adherence to ethical production practices alongside technical specifications. By fostering strong relationships with reputable third party inspection services, companies can build trust while enhancing their operational integrity.

In conclusion, whether it's through meticulous testing of electronic components or ensuring quality goods production through established protocols like piping inspection checklists, prioritizing third party inspection services will elevate overall project success rates. Remember that each decision made today impacts tomorrow’s outcomes; choose wisely for lasting benefits!