Introduction

In today's competitive marketplace, the production of quality goods and services is not just a goal but a necessity for survival. Businesses that prioritize quality assurance and implement effective quality control measures often find themselves ahead of the curve, gaining customer trust and loyalty. Quality management principles serve as the backbone of this endeavor, guiding organizations toward systematic approaches that enhance their production processes.

The Importance of Quality in Production

Quality in production is paramount; it directly impacts customer satisfaction and brand reputation. When companies focus on the production of quality goods and services, they not only meet but exceed customer expectations, leading to repeat business and positive word-of-mouth referrals. Moreover, consistent quality reduces returns and defects, ultimately saving costs associated with rework or waste.

Understanding Quality Management Principles

Quality management encompasses a set of principles that ensure organizations maintain high standards throughout their production processes. These principles include a strong focus on customer needs, continuous improvement, and employee involvement in quality assurance efforts. By embedding these concepts into their culture, businesses can create an environment where everyone is committed to achieving excellence in the production of quality goods and services.

Overview of Production Planning Strategies

Effective production planning strategies are essential for aligning operational capabilities with market demands while ensuring product quality remains uncompromised. This involves integrating material requirement planning to optimize resource allocation alongside rigorous quality control protocols to monitor outputs consistently. By harmonizing these elements within their operations, companies can achieve streamlined processes that foster both efficiency and high-quality outcomes.

Defining Quality Goods and Services

In the realm of production, defining quality goods and services is crucial for businesses striving to meet consumer demands. Understanding the characteristics that make a product or service truly quality is the first step in effective production planning. This understanding not only enhances customer satisfaction but also reinforces a company's reputation in quality management.

Characteristics of Quality Products

Quality products possess several key characteristics that set them apart in the marketplace. First, they are durable and reliable, ensuring that they perform consistently over time, which is essential for maintaining customer trust. Second, these products often exhibit superior craftsmanship and materials, reflecting a commitment to quality assurance during the production process. Finally, effective quality control measures ensure that each item meets established standards before it reaches consumers, further solidifying its reputation as a quality good.

The Role of Customer Expectations

Customer expectations play a pivotal role in defining what constitutes quality in goods and services. Today's consumers are more informed than ever; they demand transparency and accountability from brands regarding their production processes. Meeting these expectations requires businesses to integrate robust quality management practices into their operations while continuously assessing market trends through material requirement planning to align offerings with consumer desires.

Importance of Consistency in Quality

Consistency is paramount when it comes to delivering quality goods and services; it builds trust between customers and brands over time. Companies must implement strict quality control measures throughout their production lines to ensure that every batch meets predetermined standards without fail. By prioritizing consistency in their offerings, businesses can enhance customer loyalty while also streamlining their production planning processes for greater efficiency.

Quality Assurance and Control Techniques

Quality assurance and control techniques are essential for the production of quality goods and services. These processes help ensure that products meet specified standards, which not only satisfies customer expectations but also enhances brand reputation. By implementing effective quality management practices, organizations can minimize defects and improve overall efficiency in their production planning.

Key Components of Quality Assurance

The foundation of quality assurance lies in its key components, which include systematic processes, defined standards, and continuous improvement practices. Organizations must establish clear quality management protocols that encompass every stage of production, from material requirement planning to final inspection. Additionally, fostering a culture of accountability among employees ensures that everyone is committed to maintaining high standards in the production of quality goods and services.

Another vital aspect is the use of data-driven methodologies to monitor performance and identify areas for improvement. Regular audits and assessments help organizations evaluate their adherence to established quality control measures while providing insights into potential risks. By prioritizing these components within their quality assurance framework, businesses can achieve consistent outcomes that align with customer expectations.

Quality Control Best Practices

Implementing best practices in quality control is crucial for maintaining product integrity throughout the production process. One effective approach involves adopting a proactive stance on defect prevention rather than relying solely on detection after problems arise. This shift allows teams to focus on establishing robust material requirement planning strategies that emphasize early identification and resolution of potential issues.

Moreover, utilizing statistical process control (SPC) tools can help monitor variations in production processes effectively. By analyzing data trends over time, businesses can make informed decisions about adjustments needed to enhance product consistency and reliability. Ultimately, these best practices contribute significantly to the overall success of an organization’s commitment to producing high-quality goods and services.

The Impact of Quality Control on Production

Quality control directly influences the efficiency and effectiveness of production operations by minimizing waste and reducing rework costs associated with defective products. When organizations prioritize rigorous quality management strategies within their production planning frameworks, they not only enhance operational performance but also boost customer satisfaction levels through improved product reliability.

Furthermore, a strong emphasis on quality control fosters a positive organizational culture where employees feel empowered to take ownership of their work processes—leading to increased morale and productivity across teams engaged in the production of quality goods and services. As companies continue adapting to market demands, integrating comprehensive quality assurance measures will be critical for sustaining competitive advantages in an ever-evolving landscape.

Material Requirement Planning in Production

Material Requirement Planning (MRP) is a crucial component in the production of quality goods and services. It serves as a systematic approach to managing inventory levels, scheduling production, and ensuring that materials are available when needed. By utilizing MRP, businesses can enhance their quality management efforts by minimizing waste and optimizing resources.

What is Material Requirement Planning?

At its core, Material Requirement Planning is a method used to plan manufacturing processes efficiently. It involves calculating the materials required for production based on demand forecasts, lead times, and inventory levels. This proactive approach ensures that the right amount of raw materials is available at the right time, thereby supporting quality assurance initiatives throughout the production cycle.

Benefits of Effective Material Management

Effective material management through MRP brings numerous benefits to organizations aiming for high standards of quality control. First and foremost, it reduces excess inventory costs while ensuring that production schedules are met without delays. Additionally, by streamlining material flows and aligning them with market demand, companies can maintain consistency in delivering quality goods and services that meet customer expectations.

Case Study: Toyota's Lean Manufacturing

Toyota's lean manufacturing model exemplifies how effective material requirement planning can lead to superior quality management practices. By implementing just-in-time (JIT) inventory systems within their MRP framework, Toyota minimizes waste while enhancing their ability to produce high-quality vehicles consistently. This case study demonstrates that integrating material requirement planning with quality assurance not only improves operational efficiency but also ensures that the end product meets stringent standards of excellence.

Strategies for Effective Production Planning

In today's competitive market, effective production planning is essential for the successful production of quality goods and services. By aligning production with market demand, leveraging technology, and integrating quality management principles, businesses can ensure they meet customer expectations while maintaining high standards of quality assurance. These strategies collectively enhance operational efficiency and foster a culture of continuous improvement.

Aligning Production with Market Demand

To achieve the production of quality goods and services, companies must first understand market demand dynamics. This involves analyzing customer preferences, trends, and seasonal fluctuations to ensure that production schedules are synchronized with what consumers want. By employing material requirement planning techniques, organizations can adjust their inventory levels accordingly, minimizing waste while maximizing the effectiveness of their quality control measures.

Additionally, aligning production with market demand helps in optimizing resource allocation. When companies know what products are in demand, they can focus on producing those items that meet consumer needs without overextending their capacities. This not only improves profitability but also reinforces the importance of maintaining high-quality standards across all produced goods and services.

Technology’s Role in Production Planning

Technology plays a pivotal role in modern production planning by streamlining processes and enhancing overall efficiency. Advanced software solutions enable organizations to implement effective material requirement planning systems that facilitate real-time tracking of inventory levels and resource needs. This technological integration supports quality assurance initiatives by ensuring that materials used in the production process adhere to established standards.

Moreover, technology enhances communication within teams involved in the production process. With tools for collaboration and data sharing readily available, stakeholders can quickly address any issues related to quality control or supply chain disruptions before they escalate into larger problems. As a result, businesses can maintain high-quality outputs while adapting swiftly to changes in demand.

Integrating Quality Management into Planning

Integrating quality management principles into production planning is crucial for achieving consistent results in the manufacturing process. By embedding quality assurance practices at every stage—from design through to delivery—companies create a robust framework that prioritizes excellence in the production of quality goods and services. This proactive approach not only minimizes defects but also fosters a culture where everyone is committed to upholding high-quality standards.

Furthermore, integrating these principles encourages continuous feedback loops between departments involved in both planning and execution phases. Quality control measures become more effective when insights from various teams inform adjustments to workflows or materials used during manufacturing processes. Ultimately, this leads to better alignment between organizational goals and customer satisfaction through exceptional product offerings.

The Role of Quality Inspection Services

In the quest for the production of quality goods and services, quality inspection services play a pivotal role. These services ensure that products not only meet the established standards but also align with customer expectations. By integrating rigorous quality assurance practices, businesses can enhance their overall production planning, leading to better market outcomes.

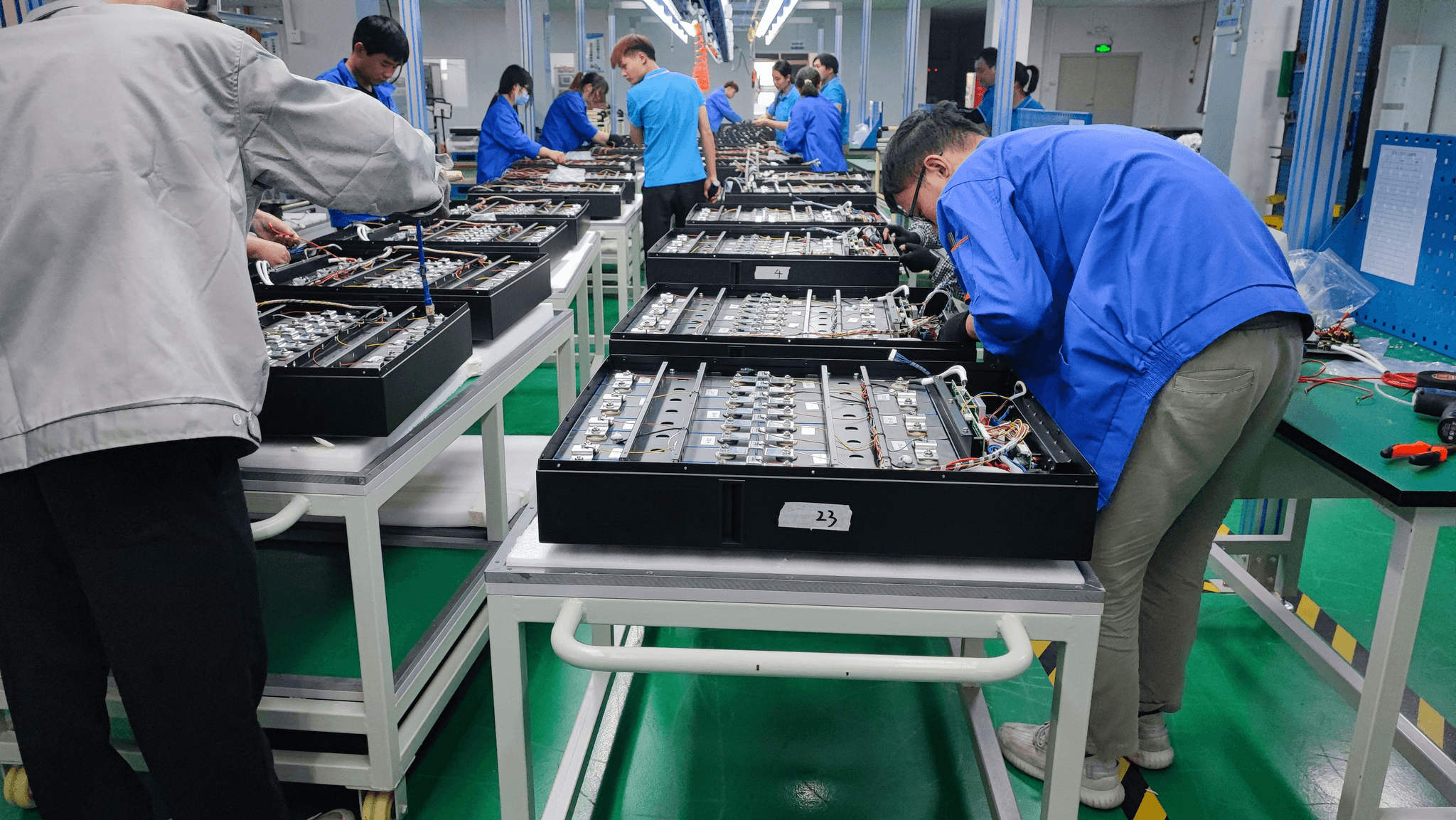

How China Inspection Pro Ensures Quality

China Inspection Pro employs a multifaceted approach to ensure quality throughout the production process. Their team conducts thorough inspections at various stages, from raw material assessment to final product evaluation, ensuring adherence to stringent quality control measures. This proactive engagement in material requirement planning allows manufacturers to identify potential issues early on, ultimately safeguarding the integrity of their products.

Importance of Rigorous Inspections

Rigorous inspections are essential for maintaining high standards in the production of quality goods and services. They serve as a critical checkpoint that verifies compliance with industry regulations and internal benchmarks for quality assurance. By implementing strict quality control protocols, companies can significantly reduce defects and enhance customer satisfaction, fostering long-term loyalty.

Turning Inspection Findings into Actionable Insights

The true value of inspections lies in transforming findings into actionable insights that drive improvement in production planning and execution. When inspection reports highlight areas needing attention, businesses can swiftly address these issues through targeted interventions in their quality management systems. This iterative process not only enhances product consistency but also reinforces the commitment to delivering exceptional quality goods and services.

Conclusion

In the ever-evolving landscape of manufacturing, the production of quality goods and services remains paramount. Elevating standards through robust quality control mechanisms ensures that businesses not only meet but exceed customer expectations. By integrating quality assurance practices into every facet of production planning, organizations can foster a culture of excellence that drives long-term success.

Elevating Standards Through Quality Control

Quality control is not just a checkbox on a to-do list; it's the backbone of successful production management. Implementing comprehensive quality assurance processes allows companies to identify and rectify issues before they escalate, thereby maintaining high standards in the production of quality goods and services. This proactive approach not only enhances product reliability but also builds trust with consumers who expect nothing less than excellence.

The Future of Production Planning

Looking ahead, the future of production planning will be heavily influenced by advancements in technology and data analytics. Material requirement planning systems are evolving to become more intelligent, allowing for real-time adjustments based on market demand fluctuations. As businesses embrace these innovations, they will find new ways to integrate quality management principles seamlessly into their workflows, ensuring that the production of quality goods and services is both efficient and effective.

Achieving Excellence in Quality Goods and Services

Achieving excellence in the production of quality goods and services requires a multifaceted approach that encompasses rigorous quality assurance measures alongside strategic planning initiatives. Companies must prioritize continuous improvement by regularly evaluating their processes and incorporating feedback from both customers and employees alike. Ultimately, a commitment to maintaining high standards through effective quality control will position businesses as leaders in their industries, setting them apart from competitors who may overlook these essential practices.