Introduction

In the fast-paced world of manufacturing, ensuring quality is paramount; this is where final random inspections come into play. These inspections serve as a last line of defense, verifying that products meet established standards before they reach consumers. By implementing effective quality control measures, businesses can safeguard their reputation and ensure customer satisfaction.

Importance of Final Random Inspections

Final random inspections are crucial for identifying defects and non-conformities in products just before shipment. This process not only helps in maintaining high-quality standards but also significantly reduces the risk of costly recalls or returns later on. When a quality control inspector conducts these inspections, they provide valuable insights that can enhance production processes and overall product reliability.

The Role of Quality Control in Manufacturing

Quality control acts as the backbone of any successful manufacturing operation, ensuring that every product meets specific criteria before it leaves the facility. It encompasses various methods and practices, including regular quality checks and adherence to industry regulations. By prioritizing quality control, manufacturers can boost efficiency while minimizing waste and improving customer trust.

How AQL Sampling Impacts Quality Checks

AQL sampling (Acceptable Quality Level) plays a vital role in determining how many items should be inspected during final random inspections. This statistical method helps businesses make informed decisions about which batches to sample, balancing thoroughness with practicality. By leveraging AQL sampling effectively, companies can optimize their quality testing services while maintaining high standards for every product produced.

Understanding Final Random Inspection

In the world of manufacturing, final random inspection (FRI) serves as a crucial checkpoint before products hit the market. This process involves a quality control inspector evaluating a random sample of goods to ensure they meet specified standards. By leveraging AQL sampling techniques, businesses can maintain high-quality output while minimizing waste and preventing costly recalls.

What is Final Random Inspection

Final random inspection is a systematic approach to assessing the quality of products just before they are shipped to customers. It typically involves selecting a sample from the entire batch and conducting thorough quality checks against predetermined criteria. This method not only helps in identifying defects but also ensures that the products adhere to industry regulations and customer expectations.

Benefits of Implementing Final Random Inspections

Implementing final random inspections brings numerous benefits that can enhance overall product quality and customer satisfaction. First, it acts as an effective safeguard against defective items reaching consumers, thus protecting your brand's reputation. Additionally, regular quality inspections can lead to improved production processes by identifying recurring issues that need addressing.

Moreover, utilizing quality testing services for final random inspections allows companies to save time and resources in the long run by catching problems early on in the manufacturing process. These inspections foster transparency between manufacturers and clients, building trust through consistent delivery of high-quality products. Ultimately, investing in FRI can result in fewer returns and increased customer loyalty.

Common Misconceptions About Final Random Inspections

Despite its importance, there are several misconceptions surrounding final random inspections that can lead businesses astray. One common myth is that FRI is only necessary for large-scale production runs; however, even small batches benefit significantly from this type of quality control. Another misconception is that passing an inspection guarantees zero defects; while it minimizes risks, it cannot eliminate them entirely.

Some believe that final random inspections are merely a formality or an unnecessary expense when using reputable suppliers; on the contrary, they are critical for maintaining consistent product standards regardless of supplier reliability. Lastly, many assume that once an inspection is complete, no further action is needed—this couldn’t be further from the truth! Continuous improvement based on inspection findings should always be prioritized to enhance future production cycles.

Preparing for a Quality Control Inspection

Getting ready for a quality control inspection can feel like prepping for an important exam—minus the anxiety of forgetting your notes. A well-structured approach ensures that your final random inspection goes smoothly and effectively evaluates your products. By focusing on essential documentation, training your team, and setting clear quality standards, you can pave the way for a successful quality check.

Essential Documentation You Need

Documentation is the backbone of any quality control process, especially during final random inspections. Essential documents include product specifications, previous inspection reports, and quality assurance protocols that outline how to handle discrepancies. Having these documents readily available not only streamlines the inspection process but also provides valuable insights to the quality control inspector about what to expect during the evaluation.

Incorporating AQL sampling guidelines into your documentation can further enhance clarity and ensure that everyone is on the same page regarding acceptable quality levels. Remember that an organized filing system will save time and reduce stress when it comes time for the actual inspection services. Ultimately, proper documentation helps keep everyone accountable and ensures that nothing slips through the cracks during your quality check.

Training Your Team for Inspection Success

Your team plays a pivotal role in ensuring a successful final random inspection; they are often the first line of defense against potential issues. Training should focus not only on understanding what inspectors look for but also on familiarizing them with company policies regarding quality control processes. Empowering staff with knowledge about AQL sampling techniques will enable them to better prepare products before they face scrutiny from external inspectors.

Regular mock inspections can be beneficial in helping employees understand their responsibilities during actual inspections while also identifying areas needing improvement. This proactive approach builds confidence among team members and fosters a culture of accountability—everyone knows their role in maintaining high-quality standards! Remember, an informed team is key in making sure that any potential hiccups are addressed before they escalate into major problems.

Setting Clear Quality Standards

Establishing clear guidelines ensures that everyone understands what constitutes acceptable product performance prior to a final random inspection or any other type of quality check. These standards should be communicated effectively across all departments involved in production to guarantee alignment throughout every stage of manufacturing.

Moreover, it's essential to regularly review these standards against industry benchmarks and customer expectations so they remain relevant over time—after all, staying ahead means adapting! Implementing periodic assessments allows you to identify gaps where improvements can be made while reinforcing existing protocols among staff members as part of their ongoing training efforts related to quality testing services. By fostering an environment where excellence is expected and celebrated, you'll create a culture dedicated entirely to delivering top-notch products!

The Final Random Inspection Process

When it comes to ensuring quality in manufacturing, the final random inspection is a vital step that cannot be overlooked. This process serves as the last line of defense against defects and ensures that products meet established quality standards before they reach consumers. Understanding the nuances of this process can significantly enhance your quality control efforts and minimize risks associated with poor-quality products.

Step-by-Step Breakdown of the Inspection

The first step in the final random inspection involves selecting a representative sample from a larger batch of products using AQL sampling methods. This statistical approach ensures that inspectors evaluate a fair portion of the goods, which allows for accurate assessment without examining every single item. Once samples are chosen, quality control inspectors meticulously check each item against predefined standards, documenting any discrepancies or defects found along the way.

Next, inspectors assess various aspects such as functionality, appearance, and packaging integrity during their quality checks. Each metric is crucial; for instance, a seemingly minor flaw in packaging could lead to significant issues in customer satisfaction or product returns later on. After completing their evaluations, inspectors compile detailed reports outlining their findings and recommendations for improvement.

The final stage involves communicating these results to relevant stakeholders within your organization and possibly discussing next steps with your quality testing services provider if issues arise. This collaborative approach not only helps address immediate concerns but also fosters continuous improvement throughout your manufacturing processes. Ultimately, understanding this step-by-step breakdown can help businesses optimize their final random inspections effectively.

Key Metrics Quality Inspectors Evaluate

During a final random inspection, several key metrics are evaluated by quality control inspectors to ensure compliance with industry standards and client expectations. These metrics typically include product dimensions, weight specifications, functionality tests, visual appearance checks (like color consistency), and packaging accuracy—all critical elements that contribute to overall product quality. By focusing on these aspects during inspections, businesses can identify potential issues before they escalate into larger problems down the line.

Another important metric is adherence to safety regulations; this is especially vital for industries like food production or electronics where consumer safety is paramount. Quality testing services often have specific guidelines based on regulatory requirements that must be met during inspections. Failure to comply with these regulations not only jeopardizes consumer safety but can also lead to costly recalls or damage to brand reputation.

Moreover, tracking defect rates over time allows companies to pinpoint trends in production flaws and implement corrective actions proactively—an essential component of maintaining high-quality standards across all operations. By keeping an eye on these key metrics during final random inspections, organizations can ensure their products consistently meet customer expectations while enhancing brand loyalty through reliable performance.

Challenges During the Inspection

While conducting a final random inspection may seem straightforward at first glance, several challenges can arise that complicate the process for both inspectors and manufacturers alike. For instance, one common issue is variability among batches; differences in materials or production methods may lead to inconsistencies in product quality even within seemingly identical items from different runs—this makes it difficult for quality control inspectors to establish reliable benchmarks during evaluations.

Additionally, time constraints often pose significant challenges during inspections; manufacturers may push for quicker turnaround times due to tight deadlines or shipping schedules which could compromise thoroughness in evaluating each product's condition adequately—leading potentially undetected defects slipping through cracks unnoticed! Balancing efficiency with thoroughness becomes crucial here as any oversight could result in subpar products reaching consumers’ hands.

Lastly—and perhaps most importantly—communication gaps between teams involved (such as production staff versus inspection services) can hinder effective collaboration throughout this entire process too! Ensuring everyone understands their roles clearly will ultimately contribute towards smoother operations overall while enhancing outcomes from every round of final random inspections conducted moving forward!

Choosing Quality Testing Services

Selecting the right quality testing services is crucial for ensuring that your products meet the highest standards of quality. This decision can significantly impact your overall quality control strategy, especially when it comes to conducting final random inspections and achieving desired AQL sampling results. With numerous inspection services available, understanding how to choose a provider that aligns with your needs is essential for maintaining product integrity.

Criteria for Selecting Quality Testing Providers

When evaluating potential quality testing providers, consider their experience in conducting final random inspections and familiarity with various industries. Look for certifications and accreditations that demonstrate their commitment to quality control standards, as these can be indicators of reliability and professionalism. Additionally, assess their ability to provide comprehensive inspection services—including documentation and clear reporting—so you can make informed decisions based on accurate data.

Another important criterion is the provider's flexibility in adapting to your specific requirements, including customized quality checks tailored to your products. Their responsiveness in communication and willingness to collaborate with your team during the inspection process can make a significant difference in achieving desired outcomes. Ultimately, choosing a quality control inspector who understands your unique challenges will ensure you receive valuable insights into product performance.

Role of China Inspection Pro in Quality Assurance

China Inspection Pro stands out as a leading player in the realm of quality assurance due to its extensive experience and commitment to excellence in final random inspections. Their team of qualified inspectors employs rigorous methodologies designed around AQL sampling principles, ensuring thorough evaluations at every stage of production. By leveraging advanced technology and industry best practices, they deliver reliable insights that help businesses maintain high-quality standards.

Moreover, China Inspection Pro offers tailored solutions that align with diverse manufacturing needs while providing ongoing support throughout the entire inspection process. Their focus on transparency ensures clients receive detailed reports outlining findings from each quality check conducted—an essential element for continuous improvement initiatives within organizations. With an established reputation for delivering accurate results, they enhance overall confidence in product offerings.

How Quality Testing Services Enhance Your Brand

Investing in reputable quality testing services not only safeguards product integrity but also enhances brand reputation among consumers who prioritize quality assurance. By consistently passing final random inspections conducted by skilled professionals, businesses can build trust with customers who expect reliable products backed by rigorous quality control measures. This trust translates into increased customer loyalty and positive word-of-mouth referrals—key drivers of long-term success.

Furthermore, showcasing adherence to high-quality standards through effective inspection services can set your brand apart from competitors who may overlook such diligence. Consumers are increasingly discerning about their purchases; thus demonstrating a commitment to excellence through regular quality checks positions your brand favorably within the market landscape. Ultimately, engaging expert inspection services fosters a culture of accountability that resonates positively with stakeholders at every level.

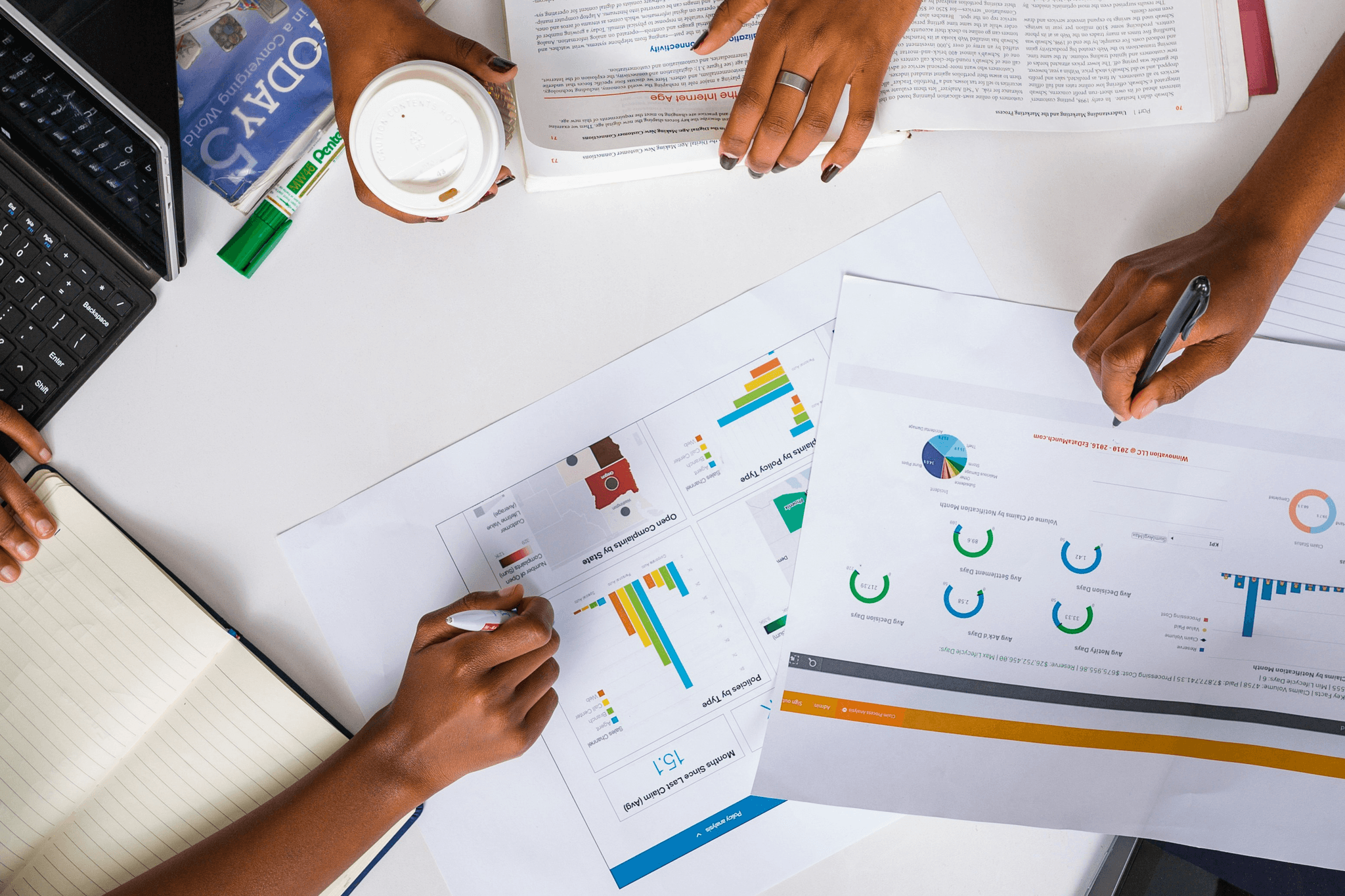

Analyzing Inspection Results

Once the final random inspection is complete, it’s time to dive into the results. Quality control reports are your treasure maps, guiding you through the landscape of your product quality and manufacturing process. Understanding these reports is crucial for making informed decisions that enhance your overall quality check procedures.

Interpreting Quality Control Reports

Quality control reports may seem like a jumble of numbers and jargon at first glance, but they reveal critical insights about your products. Each report outlines key metrics evaluated during the quality inspection, such as defect rates and compliance with AQL sampling standards. By breaking down these figures, you can identify trends over time and pinpoint areas needing improvement, ensuring that your products consistently meet quality expectations.

Next Steps After Receiving Your Inspection Results

Receiving inspection results can feel like opening a box of chocolates—you might get delightful surprises or some bitter truths! Regardless of what’s inside, it’s essential to act promptly on the findings from your final random inspection. Whether it means addressing defects, refining processes with your quality testing services provider, or retraining staff on quality control standards, every step taken post-inspection should focus on enhancing product integrity and customer satisfaction.

Continuous Improvement Based on Findings

The journey doesn’t end with analyzing inspection results; it’s just the beginning! Implementing a continuous improvement strategy based on findings from your quality inspections can significantly elevate product standards over time. Engaging in regular reviews of performance metrics allows you to adapt quickly to changes in production needs while reinforcing a culture of quality within your organization—because who doesn’t want their brand associated with excellence?

Conclusion

In wrapping up our exploration of final random inspections, it’s clear that these quality checks are not just a formality; they are an essential component of effective quality control in manufacturing. By understanding the nuances of final random inspection and the role of AQL sampling, businesses can significantly enhance their product reliability and customer satisfaction. Ultimately, investing in quality testing services leads to a better reputation and a more robust bottom line.

Key Takeaways on Final Random Inspections

Final random inspections serve as a critical checkpoint before products reach consumers, ensuring that only items meeting quality standards are shipped out. One key takeaway is that these inspections help identify defects early in the process, saving time and resources down the line. Additionally, understanding AQL sampling methods allows companies to tailor their quality checks effectively, balancing thoroughness with efficiency.

Best Practices for Quality Control

To optimize your approach to quality control, it's vital to establish clear standards and protocols for your team. Regular training sessions for your quality control inspectors can ensure everyone is on the same page regarding expectations during inspections. Utilizing reliable inspection services not only streamlines the process but also enhances accountability within your organization.

Building a Culture of Quality in Your Business

Creating a culture centered around quality means making it everyone's responsibility—from management to production staff—ensuring that every team member understands their role in maintaining high standards through processes like final random inspection. Encouraging open communication about quality issues fosters an environment where continuous improvement thrives. When businesses prioritize quality testing services as part of their core values, they set themselves apart from competitors who may overlook this crucial aspect.