Introduction

Heavy equipment inspection is not just a regulatory requirement; it’s a critical component of operational efficiency and safety in industries that rely on massive machinery. Ensuring that your heavy equipment is in top shape can prevent costly downtime, accidents, and repairs. By prioritizing regular inspections, businesses can enhance their fuel management practices and streamline preventive maintenance efforts.

The Importance of Heavy Equipment Inspection

The significance of heavy equipment inspection cannot be overstated; it safeguards both personnel and investments. Regular inspections help identify potential issues before they escalate, allowing for timely issue management and reducing the risk of catastrophic failures. Moreover, thorough inspections contribute to better reporting & data analysis, providing valuable insights into equipment performance trends over time.

Common Pitfalls to Avoid

While conducting heavy equipment inspections is essential, there are common pitfalls that can undermine the process. Failing to keep an accurate mileage log or neglecting parts inventory management can lead to oversights that compromise safety and efficiency. Additionally, skipping functional tests during inspections can result in unnoticed wear and tear, causing future complications that could have been easily avoided.

Steps to Conduct an Inspection

Conducting a thorough heavy equipment inspection involves several key steps that ensure nothing is overlooked. Start by gathering all necessary documentation related to maintenance history and previous inspection reports; this will inform your current assessment. Next, involve key personnel who understand the machinery’s operational context so they can provide insights during the inspection process while also streamlining work orders for any identified repairs or maintenance needs.

Understanding Heavy Equipment Inspection

Heavy equipment inspection is a crucial process that ensures the safety, efficiency, and longevity of machinery used in various industries. It involves a thorough evaluation of equipment to identify potential issues before they escalate into costly repairs or accidents. By implementing effective heavy equipment inspection protocols, businesses can enhance productivity and minimize downtime.

Definition and Purpose

At its core, heavy equipment inspection refers to the systematic examination of machinery to assess its condition and functionality. The primary purpose is to detect wear and tear, ensuring that all components operate safely and efficiently. Regular inspections not only help in identifying immediate repair needs but also play a vital role in long-term preventive maintenance strategies.

Types of Equipment Inspected

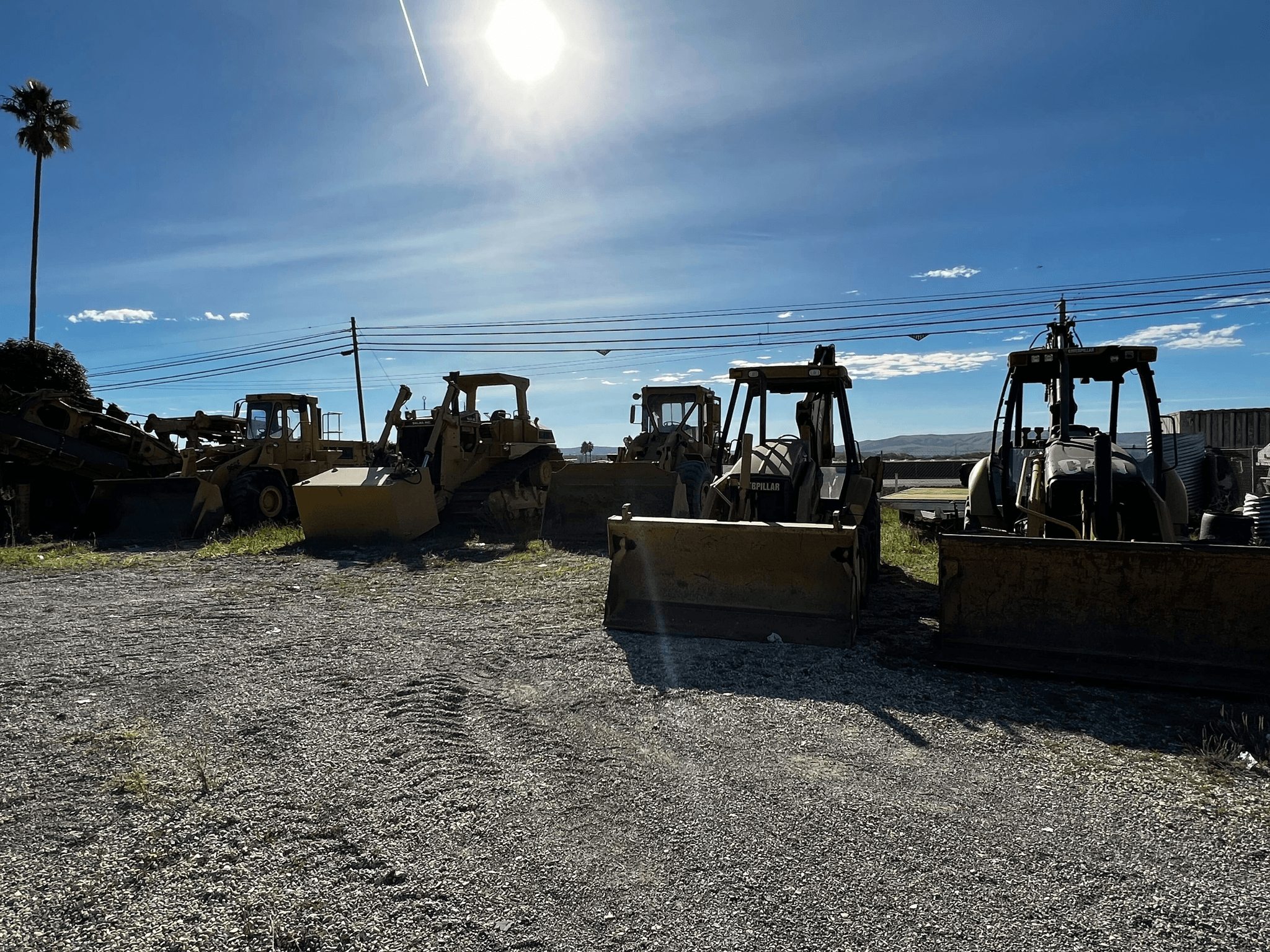

Heavy equipment spans a wide variety of machines used across different sectors, including construction, agriculture, mining, and transportation. Common types include excavators, bulldozers, cranes, forklifts, and backhoes—each requiring specific inspection techniques tailored to their unique functions. Regardless of the type of equipment inspected, maintaining an organized approach through parts inventory management is essential for tracking components effectively.

Regulations and Standards

Regulations governing heavy equipment inspection vary by region but generally aim to ensure safety standards are met across industries. Organizations such as OSHA (Occupational Safety and Health Administration) set forth guidelines that dictate the frequency and type of inspections required for different machinery types. Compliance with these regulations not only enhances safety but also aids in effective reporting & data analysis for future inspections.

Preparing for the Inspection

Getting ready for a heavy equipment inspection is like setting the stage for a grand performance—everything needs to be in place. The preparation phase is crucial as it sets the tone for a successful and thorough inspection. This includes gathering necessary documentation, managing logistics, and ensuring that key personnel are involved to streamline the process.

Gathering Necessary Documentation

Before diving into the heavy equipment inspection, it's essential to gather all relevant documentation. This includes maintenance logs, previous inspection reports, and any compliance paperwork that might be required by regulations or standards. Having these documents on hand not only aids in identifying past issues but also helps in fuel management and preventive maintenance planning.

Moreover, documenting any prior repairs or modifications can provide insights into potential problem areas during the current inspection. Without this information, you may miss critical details that could affect your equipment's performance or safety standards. So, arm yourself with all necessary paperwork—it’s your best friend during inspections!

Scheduling and Logistics

Next up is scheduling and logistics—think of it as orchestrating a well-timed ballet where every dancer has their role to play! Coordinating when and where inspections will take place is vital to ensure minimal disruption in operations while maximizing efficiency. Consider factors like equipment availability, weather conditions, and operational downtime when setting your schedule.

Logistics also involves organizing transportation if some equipment needs to be moved for better access or testing purposes. A well-planned schedule allows you to manage work orders effectively while keeping an eye on parts inventory management—because nobody wants delays due to missing components!

Key Personnel Involvement

Finally, engaging key personnel is crucial for a successful heavy equipment inspection—it’s all hands on deck! Involve operators who are familiar with the machinery; they can provide valuable insights about any quirks or issues that may not be immediately apparent during an initial visual assessment. Additionally, having maintenance staff present ensures that you can address any findings related to preventive maintenance right on the spot.

Don't forget about involving management too; their presence underscores the importance of safety compliance and reporting & data analysis efforts post-inspection! With everyone working together seamlessly, you'll enhance issue management capabilities while ensuring nothing slips through the cracks during this critical process.

Conducting the Inspection

Carrying out a thorough heavy equipment inspection is crucial to ensure safety, efficiency, and longevity of machinery. This process requires a systematic approach that includes visual inspection techniques, functional tests, and identifying wear and tear. By adhering to these steps, operators can effectively manage issues before they escalate into costly repairs or downtime.

Visual Inspection Techniques

Visual inspection techniques are the first line of defense in any heavy equipment inspection. Inspectors should look for obvious signs of damage or wear such as cracks in frames, leaks around hoses, and excessive rust on metal components. A keen eye can help identify potential issues early on—after all, spotting a small problem today can prevent a much larger headache tomorrow.

To enhance the effectiveness of visual inspections, it’s useful to have a checklist tailored for each type of equipment being inspected. This checklist should include critical areas like hydraulic systems, electrical connections, and tire conditions—all vital for effective fuel management and preventive maintenance strategies. Remember that a well-executed visual inspection not only identifies immediate concerns but also aids in developing long-term issue management plans.

Functional Tests and Measurements

Once the visual inspections are complete, it’s time to dive into functional tests and measurements that provide deeper insights into the equipment's performance. These tests often involve running machinery through its paces to check for operational efficiency—think engine performance checks or hydraulic system assessments. Accurate measurements during these tests can reveal discrepancies that might not be visible during standard inspections.

Functional testing is essential for understanding how various components interact under load; this information is invaluable when creating reports for reporting & data analysis purposes later on. Operators should also monitor parameters like fuel consumption during these tests since fuel management plays a significant role in overall operational costs. Remember: if something feels off during functional testing, it probably is—so don’t hesitate to investigate further!

Identifying Wear and Tear

Identifying wear and tear is perhaps one of the most critical aspects of conducting an effective heavy equipment inspection. Over time, even well-maintained machinery will show signs of fatigue; knowing where to look can save you from unexpected breakdowns down the road. Key areas include belts, bearings, tires, and other high-friction components that typically experience significant wear over time.

Regularly tracking wear patterns helps with parts inventory management by ensuring you have necessary replacements on hand when needed—no one wants downtime waiting for parts! Moreover, documenting these findings contributes to your mileage log which tracks usage trends over time; this data is essential for scheduling future maintenance work orders efficiently. Ultimately, identifying wear early allows operators to engage in proactive preventive maintenance rather than reactive repairs.

Fuel Management and Preventive Maintenance

When it comes to heavy equipment, fuel management and preventive maintenance are two sides of the same coin. Efficient fuel usage not only reduces operational costs but also extends the lifespan of your machinery. By prioritizing these aspects, companies can ensure that their heavy equipment inspection processes yield better results and fewer headaches down the line.

Importance of Fuel Efficiency

Fuel efficiency is crucial for any fleet operating heavy machinery, as it directly impacts profitability and environmental sustainability. Effective fuel management strategies can significantly reduce wasted resources and lower emissions, aligning with modern regulatory standards. Moreover, when heavy equipment operates efficiently, it often leads to less wear and tear, which is a key factor in successful preventive maintenance.

Regular Maintenance Practices

Regular maintenance practices are essential for keeping heavy equipment in top shape and ensuring optimal performance during inspections. This includes routine checks on fluid levels, tire pressure, and engine performance—areas that can greatly affect fuel efficiency if neglected. Implementing a structured schedule for preventive maintenance not only helps in identifying potential issues early but also supports accurate reporting & data analysis to track equipment health over time.

Strategies for Issue Management

Implementing effective issue management strategies is vital for minimizing downtime related to heavy equipment failures. This involves maintaining an organized parts inventory management system that ensures quick access to necessary components when repairs are needed. Additionally, utilizing mileage logs helps track usage patterns; this data can be invaluable when creating work orders or conducting future inspections focused on specific areas prone to wear.

Reporting & Data Analysis

These processes not only help in tracking the condition of equipment but also in identifying patterns that can lead to improved operational efficiency. By integrating insights gained from inspections, companies can enhance their fuel management strategies, streamline preventive maintenance efforts, and effectively manage issues before they escalate.

Creating Comprehensive Inspection Reports

Creating comprehensive inspection reports is akin to crafting a fine piece of art; it requires attention to detail and a clear narrative. Each report should include specific observations from the heavy equipment inspection, detailing any wear and tear discovered during the process. Additionally, documenting findings related to fuel management and preventive maintenance can provide invaluable insights for future reference and decision-making.

The structure of these reports should be user-friendly, making it easy for key personnel involved in parts inventory management or work orders to access critical information quickly. Incorporating visual elements such as charts or graphs can further enhance understanding and retention of data presented in these reports. Ultimately, a well-structured report serves as both a historical record and a roadmap for future inspections.

Data Analysis for Future Inspections

Data analysis plays an essential role in shaping future inspections by identifying trends that may not be immediately apparent through casual observation alone. By analyzing past inspection data—such as frequency of repairs or recurring issues—companies can better allocate resources towards preventive maintenance initiatives that address systemic problems rather than just symptoms. This proactive approach not only enhances safety but also optimizes fuel management practices across the board.

Moreover, using advanced analytics tools allows organizations to correlate various factors affecting equipment performance over time, leading to more informed decision-making regarding work orders and parts inventory management. For instance, if certain machines consistently show signs of wear after specific mileage logs are reached, adjustments can be made either in operational practices or scheduled maintenance intervals accordingly. Ultimately, this level of insight fosters continuous improvement within an organization’s heavy equipment management strategy.

The Role of China Inspection Pro in Quality Assurance

China Inspection Pro is pivotal when it comes to ensuring quality assurance throughout the heavy equipment inspection process. Their expertise shines through in delivering thorough inspection services that align with industry standards while also focusing on effective issue management strategies tailored specifically for each client’s needs. By leveraging their resources, companies can ensure that every aspect—from fuel efficiency monitoring to parts inventory management—is handled with utmost precision.

Furthermore, China Inspection Pro's commitment extends beyond mere compliance; they actively assist clients in developing robust reporting frameworks that facilitate ongoing analysis of inspection results over time. This partnership enables businesses not only to meet regulatory requirements but also enhances overall operational effectiveness by keeping a keen eye on areas requiring urgent attention based on previous findings from inspections. In doing so, they contribute significantly towards fostering a culture of safety and reliability within organizations reliant on heavy machinery.

Parts Inventory Management and Work Orders

When it comes to heavy equipment inspection, effective parts inventory management is crucial for ensuring that machinery remains operational and safe. Keeping an accurate record of available parts not only streamlines repairs but also enhances the overall efficiency of equipment management. By knowing what parts are on hand, operators can avoid delays during inspections and repairs, ultimately leading to better fuel management and preventive maintenance practices.

Keeping Track of Equipment Parts

Keeping track of equipment parts requires a systematic approach that integrates technology with traditional methods. Utilizing inventory management software can help you maintain a real-time overview of your parts inventory, making it easier to identify what needs replenishing before an inspection occurs. This proactive strategy minimizes downtime during heavy equipment inspections by ensuring that necessary components are readily available when needed.

Streamlining Work Orders for Repairs

Streamlining work orders for repairs is another vital aspect of effective heavy equipment inspection management. A well-organized work order system allows teams to prioritize tasks based on urgency and importance, thereby enhancing issue management capabilities. When repair processes are efficient, it reduces the time machinery spends offline, allowing for better fuel management through increased operational availability.

Maintaining a Mileage Log for Efficiency

Maintaining a mileage log is essential not just for tracking usage but also as part of your preventive maintenance strategy. By documenting miles driven or hours operated between inspections, you can identify patterns that may indicate when certain pieces of equipment need attention or servicing. This data-driven approach supports reporting & data analysis efforts by providing insights into operational efficiency and wear-and-tear trends on your heavy machinery.

Conclusion

In the world of heavy equipment inspection, staying proactive is key to ensuring both safety and efficiency. Regular inspections not only extend the lifespan of machinery but also prevent costly breakdowns that could halt operations. By integrating best practices into your routine, you can foster a culture of vigilance and responsibility among your team.

Best Practices for Ongoing Inspections

Establishing a consistent schedule for heavy equipment inspections is essential to catch potential issues before they escalate. This includes conducting thorough reviews of all machinery, including Fuel Management practices that optimize performance and reduce costs. Furthermore, documenting findings through Reporting & Data Analysis helps in tracking trends over time, allowing teams to address concerns before they become significant problems.

Encouraging personnel involvement during inspections can lead to valuable insights that might otherwise go unnoticed. Training employees on what to look for during visual checks enhances their ability to identify wear and tear early on. Additionally, maintaining a detailed Mileage Log ensures that you are aware of how often each piece of equipment is used, which aids in determining maintenance needs.

Leveraging Technology in Equipment Management

In today’s digital age, technology plays an indispensable role in streamlining heavy equipment inspection processes. Utilizing software solutions for Parts Inventory Management allows teams to keep track of necessary components and order replacements efficiently when needed. Moreover, mobile applications can facilitate real-time data entry during inspections, ensuring that information is captured accurately and immediately.

Advanced analytics tools provide insights into operational metrics such as fuel consumption and maintenance history, making it easier to implement effective Preventive Maintenance strategies. These tools help identify patterns over time, allowing for better Issue Management by predicting when repairs are likely needed based on usage data rather than waiting for failures to occur. Ultimately, embracing technology not only saves time but also enhances overall productivity.

Enhancing Safety and Compliance through Inspections

Regular heavy equipment inspections are paramount for maintaining compliance with industry regulations and standards aimed at safeguarding workers’ health and safety. By adhering strictly to these guidelines through diligent Inspection practices, organizations can significantly reduce the risk of accidents or injuries on-site. Furthermore, comprehensive Reporting & Data Analysis ensures that all compliance documentation is up-to-date and readily available during audits or evaluations.

Implementing a robust system for Work Orders related to repairs identified during inspections streamlines the process of addressing issues promptly while minimizing downtime. A well-maintained Mileage Log supports this by providing context around usage patterns which directly influence maintenance schedules based on actual wear rather than estimations alone. Ultimately, prioritizing safety through rigorous inspection protocols not only protects employees but also enhances your organization’s reputation in the industry.