Introduction

In today's competitive landscape, the significance of quality control cannot be overstated. It serves as the backbone of any successful business, ensuring that products and services meet established standards and customer expectations. By implementing a robust quality assurance framework, organizations can not only enhance their reputation but also drive customer loyalty and satisfaction.

Understanding the Importance of Quality Control

Quality control is essential for maintaining consistency in products and services, ultimately leading to improved efficiency and reduced waste. A well-defined quality control check helps identify defects early in the production process, saving time and resources in the long run. Businesses that prioritize quality management are more likely to thrive as they cultivate trust with their customers.

The Role of Quality Assurance in Business

Quality assurance plays a pivotal role in establishing processes that ensure product integrity throughout the production cycle. By integrating quality inspection protocols into daily operations, companies can proactively address potential issues before they escalate into costly problems. This commitment to excellence not only enhances operational effectiveness but also positions businesses favorably within their industry.

Why You Should Define Quality for Your Team

Defining quality is crucial for aligning team efforts with organizational goals and expectations. When everyone understands what it means to define quality, it fosters a culture of accountability and encourages collaboration among team members. Moreover, clear communication regarding quality standards enables teams to work cohesively towards achieving common objectives while minimizing misunderstandings.

Define Quality in Your Context

Defining quality in your specific context is crucial for effective quality management. It involves understanding what quality means for your products or services and how it aligns with your organizational goals. By establishing a clear definition of quality, you set the stage for successful quality control checks and ensure that everyone on your team is on the same page.

Establishing Clear Criteria for Success

To define quality effectively, start by establishing clear criteria for success. This means identifying measurable attributes that reflect the standards you expect from your products or services. These criteria should be communicated clearly to all teams involved, ensuring that everyone understands what constitutes a successful outcome in terms of quality assurance.

Creating specific benchmarks not only helps in conducting thorough quality inspections but also enables teams to gauge their performance against established standards. When everyone knows what success looks like, it fosters accountability and empowers employees to take ownership of their roles in maintaining high-quality outputs. Moreover, clear criteria facilitate more effective collaboration with external quality control companies when seeking additional insights or support.

Aligning Quality Standards with Business Goals

It's essential to align your defined quality standards with overarching business goals to ensure coherence across the organization. When quality management practices are integrated into strategic objectives, they become part of the company culture rather than an afterthought. This alignment not only enhances operational efficiency but also drives customer satisfaction—an essential ingredient for long-term success.

For instance, if your business goal is to enhance customer loyalty through superior product reliability, then defining that reliability as a key aspect of your quality assurance efforts becomes paramount. By weaving these concepts together, you can create a unified approach where every team understands how their contributions impact overall business performance. This synergy makes it easier to implement consistent and effective quality control measures throughout all processes.

Communicating Quality Expectations Across Teams

Effective communication of quality expectations across teams is vital for fostering a culture of excellence within an organization. Regular meetings and updates can help ensure that everyone remains informed about any changes in standards or new initiatives related to quality control and assurance practices. Additionally, utilizing collaborative tools can streamline this communication process and keep everyone aligned on shared goals.

When teams understand what is expected regarding their roles in maintaining high-quality outputs, they are more likely to engage actively in continuous improvement efforts. Training sessions led by a qualified quality assurance specialist can further enhance understanding and reinforce the importance of adhering to established criteria during production processes or service delivery phases. Ultimately, clear communication about expectations not only mitigates misunderstandings but also cultivates a proactive mindset towards achieving excellence in every aspect of work.

Develop a Quality Control Plan

Creating a robust quality control plan is essential for any organization striving for excellence. This plan not only defines quality but also provides a structured approach to ensure that products or services meet the established standards. By outlining specific procedures and checkpoints, businesses can effectively manage quality assurance throughout their processes.

Key Components of a Quality Control Check

A comprehensive quality control check consists of several key components that work together to ensure product integrity. First, establishing clear criteria for what constitutes acceptable quality is crucial; this includes specifications, tolerances, and performance standards. Next, regular inspections at different stages of production help identify potential issues early on—this proactive approach minimizes costly rework and enhances overall efficiency.

Another important aspect is documentation; keeping thorough records of each quality control check allows teams to track progress and identify trends over time. By regularly reviewing these records, businesses can refine their processes and better define quality in alignment with customer expectations. Ultimately, the goal is to create a cycle of continuous improvement where feedback from each inspection informs future practices.

Tools and Techniques for Effective Quality Management

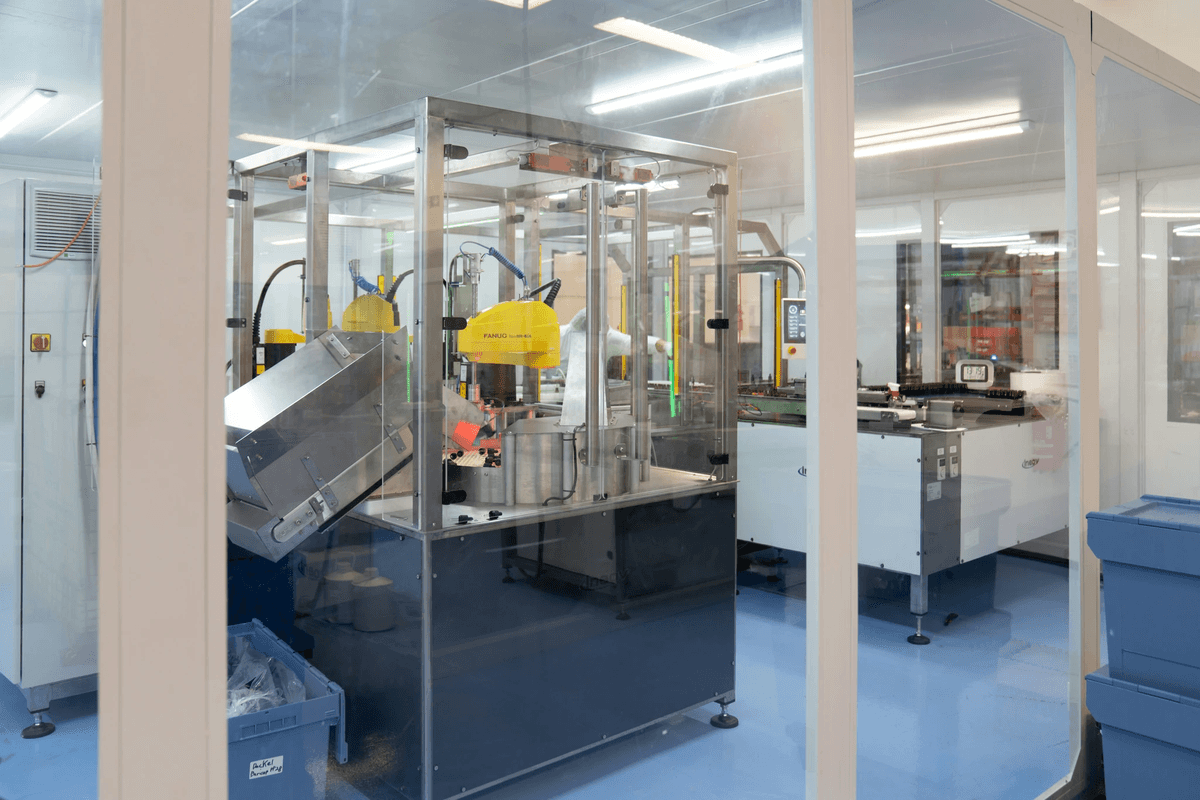

In today’s fast-paced business world, leveraging the right tools and techniques can significantly enhance your quality management efforts. Implementing software solutions designed for quality assurance can streamline data collection during inspections and simplify reporting processes. Additionally, employing statistical process control (SPC) techniques allows teams to analyze variation in production processes, making it easier to pinpoint areas needing attention.

Moreover, visual management tools such as dashboards can provide real-time insights into your quality metrics—this visibility empowers teams to take immediate action when deviations occur. Training employees on these tools ensures everyone understands how to conduct effective quality inspections while fostering a culture of accountability within the organization. By integrating these resources into your plan, you position your business for success in maintaining high-quality standards.

Involving Quality Control Companies for Expertise

Sometimes it pays off to bring in outside expertise when developing your quality control plan—this is where partnering with specialized quality control companies becomes invaluable. These experts have extensive experience in various industries and can offer tailored solutions that align with your specific needs while ensuring compliance with industry regulations. Their insights can help you define quality more accurately based on current best practices.

Additionally, engaging a qualified quality assurance specialist from one of these companies allows you to benefit from their knowledge without overwhelming your internal team with additional responsibilities. They can assist in conducting thorough audits and providing training sessions that elevate your team's understanding of effective inspection methods and standards compliance. Collaborating with experienced professionals ensures that you are not only meeting but exceeding industry benchmarks for excellence.

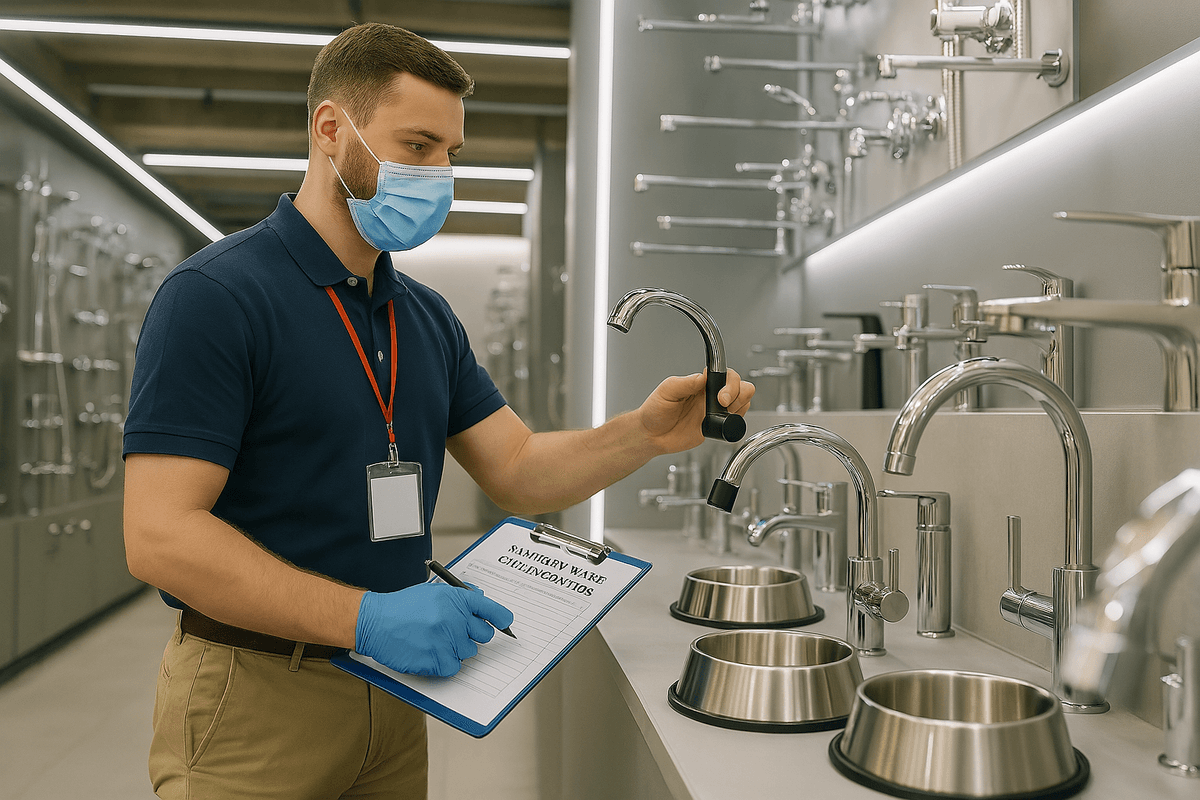

Implement Quality Inspection Procedures

To ensure that your products meet the defined quality standards, implementing robust quality inspection procedures is essential. This involves creating a systematic approach that incorporates checkpoints throughout the production process, ensuring that every stage adheres to established quality control measures. By doing so, you can catch potential issues early and maintain high-quality outputs consistently.

Establishing Checkpoints Throughout Production

Establishing checkpoints throughout production is a critical aspect of effective quality management. These checkpoints serve as designated moments where a thorough quality control check can be performed, allowing teams to assess whether the product meets the defined quality criteria before moving on to the next phase. By integrating these inspection points into your workflow, you not only enhance accountability but also foster a culture of continuous improvement within your organization.

Incorporating regular quality inspections at strategic intervals helps in identifying any deviations from established standards early on. This proactive approach minimizes waste and reduces the costs associated with rework or recalls later in the production cycle. Furthermore, it emphasizes the importance of quality assurance across all teams involved in production, reinforcing their commitment to achieving excellence.

Training Teams on Quality Inspection Methods

Training teams on effective quality inspection methods is vital for ensuring consistent adherence to quality standards. When team members are well-versed in various techniques for conducting thorough inspections, they become invaluable assets in maintaining product integrity throughout the manufacturing process. Regular training sessions can cover everything from visual inspections to more advanced methodologies that utilize technology for enhanced accuracy.

Quality control companies often offer specialized training programs tailored to specific industries or product types, helping your team develop skills that align with best practices in quality assurance. Additionally, fostering an environment where team members feel empowered to speak up about potential issues enhances collaboration and strengthens overall product reliability. Remember, well-trained employees are not just inspectors; they are champions of quality who contribute significantly to your organization’s success.

Utilizing Technology for Enhanced Quality Assurance

In today's fast-paced business environment, leveraging technology for enhanced quality assurance is no longer optional; it’s essential for staying competitive. Advanced tools such as automated inspection systems and data analytics software can streamline your quality control processes while providing real-time insights into production performance metrics. By integrating these technologies into your workflow, you can redefine how you approach and implement your quality inspection protocols.

Moreover, utilizing technology allows for greater precision during inspections—reducing human error and enabling faster identification of defects or inconsistencies in products before they reach customers. Collaborating with a qualified quality assurance specialist can help you select and implement the right technological solutions tailored specifically for your needs. Ultimately, embracing tech-driven solutions will elevate your overall approach to managing product excellence and customer satisfaction.

Conduct Regular Quality Audits

Regular quality audits are the backbone of a robust quality management system. They ensure that your processes not only meet established quality standards but also adapt to any changes in your operational environment. By conducting routine quality inspections, businesses can catch potential issues early and maintain a consistent level of excellence in their products and services.

The Importance of Routine Quality Inspections

Routine quality inspections play a crucial role in maintaining high standards within your organization. These checks help define quality by identifying deviations from set criteria before they escalate into bigger problems. When you prioritize regular inspections, you foster a proactive culture that values continuous improvement and accountability among team members.

Analyzing Data for Continuous Improvement

Analyzing data from your quality control checks is essential for driving continuous improvement in your operations. By examining trends and patterns, you can identify areas where quality assurance efforts may be lacking or where processes can be optimized further. This data-driven approach not only enhances the effectiveness of your quality management strategies but also empowers teams to make informed decisions based on real insights.

Engaging a Quality Assurance Specialist for Insights

Engaging a quality assurance specialist can provide invaluable insights into refining your existing processes and ensuring compliance with industry standards. These professionals bring expertise that can elevate your approach to both routine inspections and overall quality control efforts. Collaborating with experienced quality control companies helps bridge any gaps in knowledge, allowing you to implement best practices that enhance the effectiveness of your entire operation.

Take Action on Quality Insights

Once you've gathered valuable insights from your quality inspections and audits, it’s time to put that information to work. Turning findings into strategic decisions is crucial for refining your quality management processes. By analyzing the data collected during quality control checks, you can identify trends, pinpoint issues, and make informed changes that align with your business objectives.

Turning Findings into Strategic Decisions

The transition from data collection to actionable strategy is where the magic happens in quality assurance. When you define quality based on solid evidence from your inspections, you empower your team to prioritize improvements effectively. This proactive approach not only enhances product quality but also boosts operational efficiency—leading to happier customers and increased profitability.

Collaborating with China Inspection Pro for Best Practices

Partnering with specialized quality control companies like China Inspection Pro can elevate your approach to quality management significantly. Their expertise in conducting thorough quality inspections ensures that you’re not just meeting standards but exceeding them. By leveraging their best practices, you can refine your own processes and implement innovative strategies that drive continuous improvement across your organization.

Creating a Culture of Quality Improvement

Fostering a culture of quality improvement within your organization is essential for long-term success in any industry. Encourage open communication about quality expectations and create an environment where team members feel empowered to share insights and suggest improvements related to their work processes. When everyone understands the importance of maintaining high-quality standards through effective inspection methods, it leads to a collective commitment toward excellence—making every individual a stakeholder in the company's success.

Conclusion

In wrapping up our exploration of quality control, it’s essential to recognize that effective quality management is not just a checkbox on your to-do list; it’s a continuous journey. By implementing robust quality assurance processes, you can foster an environment where excellence thrives and becomes part of your corporate DNA. Remember, defining quality is the first step in ensuring that everyone on your team is aligned toward achieving common goals.

Key Takeaways for Effective Quality Control

First and foremost, establishing clear criteria for success is paramount when you define quality within your organization. This clarity helps teams understand what a successful quality control check looks like and how it aligns with broader business objectives. Furthermore, regular training sessions on quality inspection methods will empower employees to take ownership of their roles in maintaining high standards.

Another key takeaway is the importance of involving specialized quality control companies when necessary. These experts bring invaluable insights and resources that can enhance your existing strategies and ensure compliance with industry standards. Finally, fostering open communication about quality expectations across all levels of your organization can significantly boost morale and productivity.

The Impact of Quality Management on Success

Quality management isn’t just about avoiding defects; it’s about creating value for customers and stakeholders alike. When businesses prioritize effective quality assurance practices, they often see a direct correlation with increased customer satisfaction and loyalty. Moreover, investing in thorough quality control processes can lead to significant cost savings by reducing waste and minimizing rework.

The ripple effect of strong quality management extends beyond immediate financial benefits; it also enhances brand reputation over time. Companies recognized for their commitment to high-quality products or services tend to gain a competitive edge in their respective markets. Ultimately, the impact of prioritizing quality resonates throughout the entire organization—improving employee engagement while driving innovation.

Next Steps for Your Quality Assurance Journey

As you embark on or continue your journey toward superior quality assurance practices, consider conducting an internal audit to assess current processes against best practices in the industry. Engaging a qualified quality assurance specialist could provide fresh perspectives on areas needing improvement or refinement within your existing framework.

Additionally, leverage technology tools designed specifically for tracking performance metrics related to your defined standards—these can streamline data collection while enhancing visibility into compliance efforts across teams. Finally, commit to fostering a culture where continuous improvement is celebrated; this mindset will inspire employees at all levels to contribute actively towards elevating overall product or service excellence.