Introduction

In the realm of quality management, understanding non conformance reports is crucial for maintaining high standards and ensuring products meet specified requirements. A non conformance report (NCR) serves as a formal document that highlights instances where processes, products, or services deviate from established standards. By addressing these discrepancies, organizations can enhance their quality assurance practices and foster a culture of continuous improvement.

Understanding Non Conformance Reports

What is a non conformance report? At its core, it is a tool used to document deviations from expected outcomes in quality management systems. These reports are essential for identifying issues that may compromise the integrity of products or services and ultimately affect customer satisfaction.

Importance in Quality Management

The importance of non conformance reports in quality management cannot be overstated; they provide organizations with insights into potential weaknesses in their processes. By systematically analyzing these reports, businesses can implement corrective actions to mitigate risks and improve overall performance. Furthermore, effective handling of NCRs contributes to building trust with customers by demonstrating a commitment to quality assurance.

Role in Quality Assurance and Control

Non conformance reports play a pivotal role in both quality assurance and control by serving as a feedback mechanism within the management system. They help organizations track recurring issues, facilitating proactive measures to prevent future occurrences. Ultimately, leveraging NCRs effectively ensures that quality management software is utilized to its fullest potential, driving continuous improvement throughout the organization.

What is a Non Conformance Report?

In the world of quality management, understanding what a non conformance report (NCR) is can be pivotal for organizations striving for excellence. An NCR serves as a formal document that identifies and details instances where products or processes deviate from established standards or requirements. This reporting mechanism plays a crucial role in quality assurance and quality control, enabling businesses to address issues proactively and maintain high-quality outputs.

Definition and Purpose

A non conformance report is essentially a tool used to capture deviations from expected performance or compliance within a management system. Its primary purpose is to document discrepancies, analyze their root causes, and facilitate corrective actions to prevent recurrence. By systematically addressing these non-conformities, organizations enhance their quality management efforts and build robust quality control processes.

Common Scenarios Leading to a Non Conformance Report

Non conformance reports can arise in various scenarios across different industries—think manufacturing defects, service delivery failures, or even compliance lapses with regulatory standards. For instance, if a product fails to meet specification requirements during testing, an NCR will be generated to investigate the issue further. Additionally, operational inefficiencies such as late project deliveries or substandard materials can trigger the need for an NCR as part of ongoing quality assurance efforts.

Key Components of a Non Conformance Report

A well-structured non conformance report typically includes several key components that ensure clarity and effectiveness in addressing issues identified within the management system. These components often consist of detailed descriptions of the non-conformity itself, including its nature and severity; identification of affected products or processes; root cause analysis; proposed corrective actions; and follow-up measures for verification after implementation. By incorporating these elements into an NCR template within quality management software, organizations can streamline their reporting process while enhancing overall accountability in their quality control initiatives.

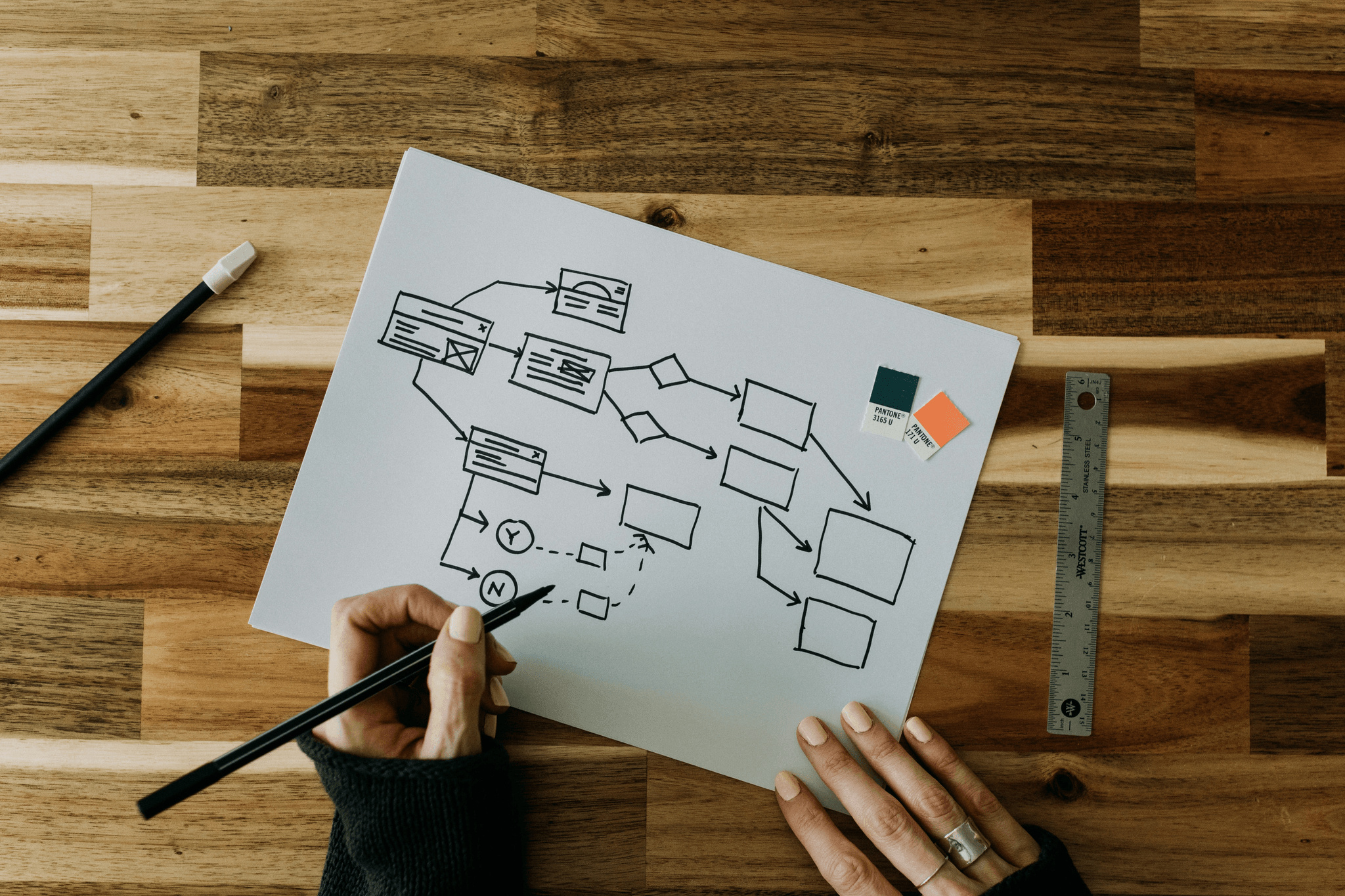

The Process of Creating a Non Conformance Report

Creating a Non Conformance Report (NCR) is essential for maintaining quality assurance in any management system. This process involves several steps to ensure that the report accurately reflects the issue at hand, enabling effective quality control and facilitating improvements. By following a structured approach, organizations can leverage their quality management software to document and address non-conformances effectively.

Steps in Documentation

The first step in documenting a Non Conformance Report is to clearly define what is a non conformance report by describing the specific deviation from established standards or procedures. Next, it's crucial to gather evidence, such as photographs or test results, that illustrate the issue and support your findings. Finally, the NCR should include an analysis of potential impacts on quality management and outline corrective actions needed to resolve the situation.

Once all relevant information is compiled, it’s time to draft the report using standardized templates available in most quality management software systems. This ensures consistency across reports and aids in tracking non-conformances over time. Proper documentation not only helps with immediate resolution but also serves as valuable data for future quality control efforts.

Involving Stakeholders

Involving stakeholders throughout the NCR process enhances accountability and fosters collaboration within teams focused on quality assurance and improvement. Key stakeholders may include department heads, quality control personnel, and even external suppliers who play a role in maintaining product or service standards. Engaging these parties early on allows for diverse perspectives that can lead to more comprehensive solutions.

Communication with stakeholders should be ongoing; regular updates about progress on addressing non-conformances are vital for keeping everyone aligned with quality goals. Moreover, involving team members encourages ownership of both problems and solutions within the management system—an important aspect of building a culture of continuous improvement in quality management practices.

Reporting and Communication Protocols

Establishing clear reporting and communication protocols is critical for ensuring that non-conformance reports are effectively managed within an organization’s framework for quality control. Reports should be submitted through designated channels outlined by your organization's policies so they can be tracked efficiently within your chosen quality management software platform. Consistent communication regarding NCRs not only keeps everyone informed but also promotes transparency across departments.

It’s essential that findings from NCRs are communicated promptly to all relevant parties involved in maintaining compliance with established standards—this includes training sessions or meetings where lessons learned can be shared openly. Additionally, follow-up communications after corrective actions have been implemented help verify effectiveness and reinforce best practices moving forward within the scope of overall quality management initiatives.

Impact on Quality Management Systems

Non Conformance Reports (NCRs) play a crucial role in the overall effectiveness of quality management systems. They serve as a formal mechanism to document deviations from expected standards, ensuring that issues are not just noted but actively addressed. By integrating NCRs into quality management software, organizations can streamline their processes, making it easier to track and resolve non-conformities.

Integration with Quality Management Software

Integrating Non Conformance Reports into quality management software is like adding turbo to an engine; it enhances performance significantly. By leveraging technology, organizations can automate the documentation process, allowing for real-time tracking of issues and trends related to quality assurance and control. This integration not only simplifies reporting but also provides comprehensive data analytics that help management pinpoint problem areas within their quality control systems.

Moreover, effective integration means that stakeholders across departments have access to relevant information regarding what is a non conformance report and its implications on the overall management system. This transparency fosters collaboration among teams striving for higher standards in quality management. Ultimately, when NCRs are seamlessly integrated into existing software solutions, they become powerful tools for driving continuous improvement.

Enhancing Quality Control Processes

Non Conformance Reports are essential for enhancing quality control processes within any organization striving for excellence in its products or services. By systematically identifying where deviations occur, organizations can implement targeted interventions aimed at correcting these lapses in quality assurance. This proactive approach helps minimize the risk of recurring issues and ensures that all aspects of production align with established standards.

Incorporating feedback from NCRs into routine audits further strengthens the quality control framework by promoting accountability among team members involved in the process. As patterns emerge from repeated non-conformances, organizations can adjust their strategies accordingly—whether it's refining training programs or revising operational procedures—to improve overall performance dramatically. Such enhancements not only elevate product integrity but also bolster customer satisfaction and trust.

Addressing Issues through Continuous Improvement

The essence of addressing issues through Non Conformance Reports lies in fostering a culture of continuous improvement within an organization’s management system. Each NCR offers valuable insights into potential weaknesses in processes or products that need attention to ensure compliance with industry standards related to quality assurance and control. By treating each report as an opportunity rather than merely a setback, companies can cultivate an environment focused on growth and innovation.

Incorporating lessons learned from NCRs into strategic planning allows businesses to evolve continually while maintaining high-quality benchmarks across all operations—an essential aspect of effective quality management practices today. With time, this commitment transforms organizational culture by embedding principles of accountability and excellence at every level—from frontline employees to top executives managing complex systems of operations.

How Non Conformance Reports Drive Quality Assurance

Non Conformance Reports (NCRs) play a pivotal role in driving quality assurance by providing a structured approach to identifying and addressing discrepancies in processes or outputs. By systematically documenting what is a non conformance report, organizations can create a clear pathway for improvement that not only rectifies current issues but also prevents future occurrences. This proactive stance on quality management is essential for fostering an environment where quality control becomes ingrained in the organizational culture.

Identifying Trends and Patterns

One of the most significant benefits of utilizing non conformance reports is their ability to reveal trends and patterns over time. By analyzing multiple NCRs, organizations can identify recurring issues that may indicate deeper systemic problems within their management system or processes. This data-driven approach allows businesses to shift from reactive quality control to proactive quality assurance, enabling them to address root causes rather than merely treating symptoms.

For instance, if several NCRs highlight similar defects in a product line, it may signal an underlying issue with manufacturing practices or materials used. Recognizing these patterns helps organizations make informed decisions about necessary changes in their quality management software or procedures, ultimately leading to improved overall performance and customer satisfaction. The insights gained from NCR analysis not only enhance immediate responses but also contribute significantly to long-term strategic planning within the realm of quality management.

Action Plans for Improvement

Once trends have been identified through non conformance reports, it's crucial for organizations to develop actionable plans aimed at driving improvement across their operations. These action plans often involve cross-departmental collaboration, ensuring that all stakeholders are aligned on the objectives and methods for addressing identified issues related to quality assurance and control. Effective communication about what is a non conformance report fosters transparency and encourages buy-in from team members who are essential for implementing changes successfully.

Typically, an action plan will outline specific steps needed to rectify the identified non-conformities while establishing timelines and responsible parties for each task. By leveraging insights from NCRs alongside existing quality management systems, companies can prioritize improvements based on factors such as severity of impact or frequency of occurrence. This structured approach not only enhances operational efficiency but also strengthens the organization's commitment to maintaining high standards of product integrity.

Case Studies: Success Stories in Quality Management

To illustrate how effectively managed non conformance reports can drive significant improvements in quality assurance, consider the case study of a manufacturing firm that faced recurrent defects in its production line components. After implementing a robust system for tracking NCRs using specialized quality management software, they were able to identify specific machines responsible for frequent failures due to outdated calibration processes. With this insight, they developed targeted training programs and updated maintenance schedules which led to a remarkable 30% reduction in defect rates over six months.

Another example comes from the food industry where an organization utilized NCRs as part of its comprehensive food safety protocol during audits and inspections. By meticulously documenting instances of non-compliance with safety standards via detailed reports, they uncovered trends related directly to supplier inconsistencies that had previously gone unnoticed by traditional inspection methods alone. Consequently, they established stricter supplier evaluation criteria which dramatically improved compliance rates across their supply chain—demonstrating how effective use of what is a non conformance report can lead not only to immediate fixes but also long-lasting enhancements across entire sectors.

The Role of China Inspection Pro in Non Conformance Management

In the realm of quality management, understanding what is a non conformance report (NCR) is vital for organizations striving for excellence. China Inspection Pro stands out as a key player in this field, providing expertise that enhances quality assurance and control processes. Their comprehensive approach ensures that businesses not only identify non-conformances but also address them effectively within their quality management systems.

Expertise in Quality Assurance and Control

China Inspection Pro boasts a wealth of experience in quality assurance, making them a trusted partner for companies seeking to improve their management and quality practices. Their team of specialists understands the nuances of non conformance reporting, ensuring that each report is meticulously crafted to meet industry standards. With their guidance, organizations can implement robust quality control measures that prevent recurrence and promote continuous improvement.

Moreover, the integration of quality management software into their processes streamlines documentation and enhances communication regarding non-conformance issues. By leveraging technology, China Inspection Pro facilitates real-time tracking of NCRs, enabling quicker responses to potential problems. This proactive stance not only mitigates risks but also fosters a culture where quality is prioritized across all levels.

Real-World Applications of Non Conformance Reports

The practical applications of non conformance reports are vast and varied within different industries serviced by China Inspection Pro. For instance, in manufacturing sectors, NCRs help pinpoint defects or deviations from specifications during production runs—ultimately safeguarding product integrity and customer satisfaction. By analyzing these reports systematically, businesses can refine their processes and enhance overall product quality.

In the service sector, understanding what is a non conformance report allows organizations to identify lapses in service delivery or compliance with established protocols. This identification leads to actionable insights that inform training programs or process re-engineering efforts aimed at elevating service standards. The versatility of NCRs ensures they are valuable tools across industries striving for excellence in both products and services.

Delivering Actionable Recommendations for Quality

One of the standout features of China Inspection Pro's approach is their commitment to delivering actionable recommendations based on insights gleaned from non conformance reports. After thorough analysis, they provide tailored strategies that address identified issues while aligning with best practices in quality management systems. These recommendations often include process improvements or adjustments to existing protocols to enhance overall efficiency.

Furthermore, by fostering collaboration among stakeholders during the NCR process—ranging from frontline employees to upper management—China Inspection Pro ensures that solutions are practical and widely accepted within the organization’s culture. This collaborative approach reinforces accountability while driving engagement around continuous improvement initiatives tied directly to quality control efforts. Ultimately, these recommendations empower organizations not just to react but proactively shape their future performance.

Conclusion

In the realm of quality management, understanding and effectively utilizing Non Conformance Reports (NCRs) is paramount. These reports not only serve as a tool for identifying deviations but also play a crucial role in enhancing quality assurance and quality control processes. By fostering a proactive approach to non-conformance, organizations can significantly improve their overall management system.

Best Practices for Effective Non Conformance Reporting

To ensure that Non Conformance Reports are effective, it’s essential to follow best practices in documentation and communication. First, clarity is key; each report should succinctly outline what is a non conformance report, the nature of the deviation, and its impact on quality management. Additionally, involving relevant stakeholders early in the process fosters collaboration and ensures that corrective actions are well-informed and timely.

Moreover, leveraging quality management software can streamline the reporting process, making it easier to track issues and resolutions over time. Regular training sessions on how to create effective NCRs will empower employees at all levels to contribute meaningfully to quality assurance efforts. Ultimately, consistency in reporting practices leads to better insights into trends affecting quality control.

Building a Culture of Quality Management

Creating a culture centered around quality management requires commitment from all organizational levels. It’s vital that leadership actively promotes the importance of addressing non-conformances through open communication about what is a non conformance report and its implications for overall success. When employees see that their input on NCRs leads to real changes within the management system, they become more engaged in maintaining high-quality standards.

Encouraging continuous feedback loops where team members can share experiences related to quality control fosters an environment of trust and accountability. This not only enhances individual responsibility but also strengthens teamwork as everyone works towards common goals in quality assurance. Over time, this cultural shift will yield significant dividends in product reliability and customer satisfaction.

Future Trends in Quality Control and Assurance

As we look ahead, several trends are emerging that will shape how organizations approach non-conformance reporting within their quality management systems. One notable trend is the increasing integration of artificial intelligence into quality management software—enabling predictive analytics that identify potential issues before they escalate into formal NCRs. This proactive stance represents a significant evolution from traditional reactive approaches.

Another trend involves greater emphasis on data-driven decision-making; organizations are harnessing big data analytics to gain deeper insights into patterns associated with non-conformances across various sectors of production or service delivery. As companies strive for excellence in both efficiency and effectiveness through enhanced quality control measures, these advancements will be pivotal in maintaining competitive advantage.

Lastly, collaboration across industries will become more pronounced as businesses share best practices regarding what is a non conformance report through forums or partnerships aimed at collective improvement in standards of practice within their respective fields.