Introduction

In the world of manufacturing and production, effective management inspections are crucial for maintaining high standards of quality. Understanding the various types of inspection in production management is essential for ensuring that products meet established specifications and customer expectations. This introduction will explore the significance of quality assurance, the role it plays in production, and highlight key types of quality control that help safeguard product integrity.

Understanding Production Management Inspections

Production management inspections serve as a systematic approach to evaluating products at different stages of their lifecycle. These inspections help identify defects or deviations from quality standards before they escalate into larger issues, ultimately ensuring that only top-notch products reach consumers. By employing diverse types of inspection in production management, businesses can streamline their processes and enhance overall efficiency.

The Importance of Quality Assurance

Quality assurance is not just a buzzword; it’s a vital component that underpins successful production operations. Implementing robust quality assurance measures helps organizations minimize risks associated with product failures while fostering customer trust and satisfaction. Furthermore, companies that prioritize quality assurance often see improved operational performance and reduced costs related to rework or recalls.

Key Types of Quality Control

Quality control encompasses various methodologies aimed at maintaining product integrity throughout the manufacturing process. From visual inspections to advanced testing techniques, each type plays a pivotal role in identifying potential issues before they affect end-users. By understanding and implementing these key types of quality control, companies can better position themselves within competitive markets while enhancing their reputation for reliability.

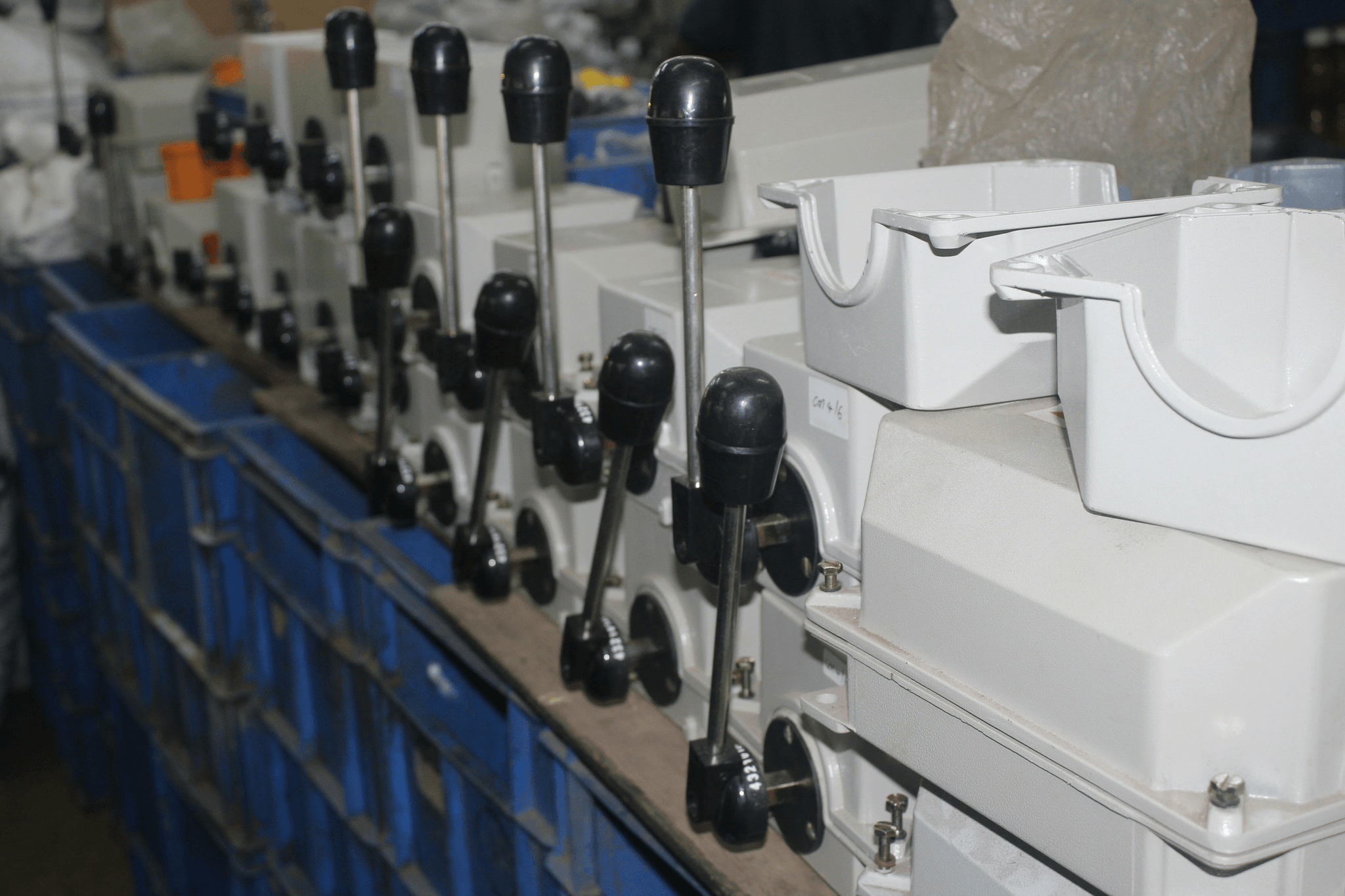

Visual Inspection

Visual inspection is one of the most fundamental types of inspection in production management, serving as the first line of defense in quality assurance. It leverages the human eye's ability to detect flaws that machinery might overlook, ensuring that products meet established quality control standards. This method is not only cost-effective but also allows for immediate feedback, making it a favorite among quality control companies.

Benefits of Eye for Detail

The benefits of having a keen eye for detail cannot be overstated in the realm of quality assurance. Trained inspectors can quickly identify defects such as surface imperfections, color inconsistencies, or assembly errors that could compromise product integrity. This level of scrutiny enhances overall product reliability and customer satisfaction while reducing waste and rework costs associated with faulty items.

Common Applications in Industries

Visual inspection finds its way into various industries, proving its versatility across the board. From manufacturing electronics to food processing and even pharmaceuticals, visual checks are essential for ensuring compliance with strict safety standards and regulations. In these sectors, visual inspection serves as a critical component of quality testing services to maintain high-quality output.

Role in Quality Inspection Services

In the broader scope of quality inspection services, visual inspection plays an indispensable role by providing an initial assessment before more rigorous testing methods are employed. Quality control companies often integrate visual inspections into their processes to create a comprehensive approach to product evaluation. By prioritizing visual assessments alongside other types of inspections in production management, organizations can ensure a robust framework for maintaining high standards in product quality.

Dimensional Inspection

Dimensional inspection is a critical component of quality assurance in production management, focusing on the precise measurement of physical attributes of products. This type of inspection ensures that items meet specified tolerances and standards, which is vital for maintaining quality control throughout the manufacturing process. By utilizing various measurement techniques, companies can identify defects early, reducing waste and enhancing overall efficiency.

Precision Measurement Techniques

Precision measurement techniques are at the heart of dimensional inspection, enabling quality control companies to assess product specifications accurately. These techniques include methods like calipers, micrometers, and coordinate measuring machines (CMMs), all designed to provide exact measurements down to minute details. Implementing these precision tools not only enhances the reliability of quality testing services but also ensures compliance with industry standards.

Tools Used in Dimensional Testing

A variety of tools are employed in dimensional testing to ensure that products adhere to strict specifications during the production process. Common instruments include laser scanners for non-contact measurements, gauge blocks for establishing reference dimensions, and optical comparators for visual inspections against standards. The integration of these tools into quality inspection services allows companies to streamline their processes and improve accuracy in their quality control measures.

Impact on Quality Control Companies

The impact of dimensional inspection on quality control companies cannot be overstated; it serves as a foundation for effective production management practices. By implementing rigorous dimensional testing protocols, these companies can significantly reduce errors and enhance product reliability while fostering customer trust through consistent delivery of high-quality items. Ultimately, this leads to improved operational efficiency and a stronger competitive edge in industries where precision is paramount.

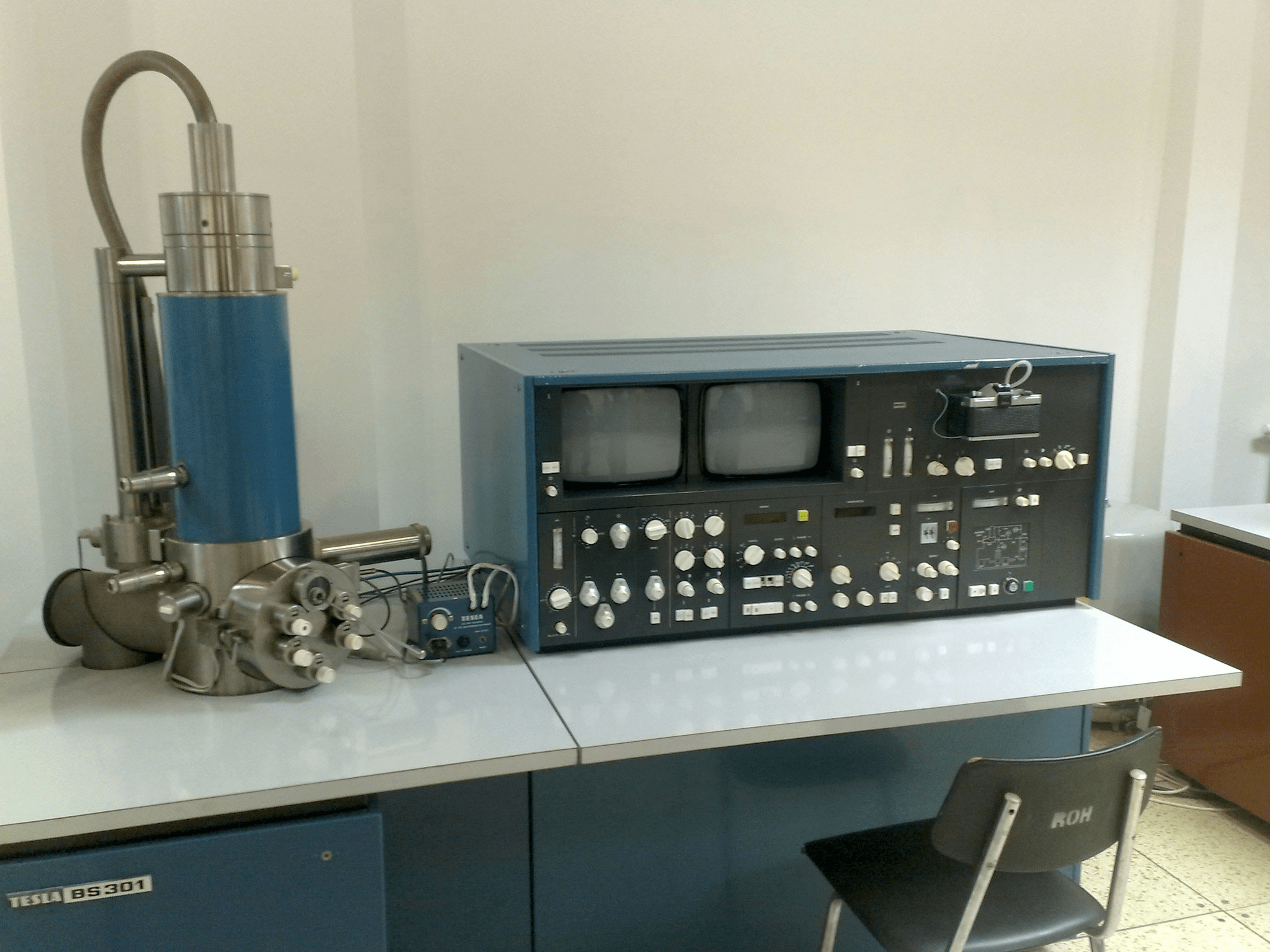

Non-Destructive Testing

Non-Destructive Testing (NDT) is a crucial aspect of quality assurance in production management, allowing companies to assess the integrity and performance of materials and components without causing any damage. This method is particularly valuable as it helps maintain product quality while minimizing waste, a key consideration for quality control companies. NDT encompasses various techniques that ensure compliance with industry standards, making it an indispensable part of the quality inspection process.

Overview of NDT Methods

NDT methods include techniques such as ultrasonic testing, magnetic particle testing, radiographic testing, and dye penetrant testing. Each method has its unique strengths; for instance, ultrasonic testing uses high-frequency sound waves to detect internal flaws, while radiographic testing employs X-rays or gamma rays to visualize internal structures. These types of inspection in production management are essential for identifying defects early on and ensuring that products meet stringent quality control requirements.

Industries Relying on NDT

A wide range of industries relies on non-destructive testing to uphold safety and quality standards. The aerospace sector uses NDT to inspect aircraft components for structural integrity; similarly, the oil and gas industry employs these methods to monitor pipelines and tanks for potential leaks or failures. Manufacturing firms also utilize NDT as part of their quality assurance programs to ensure that their products adhere to regulatory compliance while maintaining high-quality output.

Quality Testing Services and Compliance

Quality testing services incorporating NDT play a vital role in ensuring compliance with international standards such as ISO 9001 and ASME codes. By partnering with expert inspection services that specialize in non-destructive methods, companies can enhance their overall quality control processes while reducing risks associated with product failures. Ultimately, effective use of NDT not only supports regulatory compliance but also boosts customer confidence by guaranteeing the reliability of products through rigorous inspection practices.

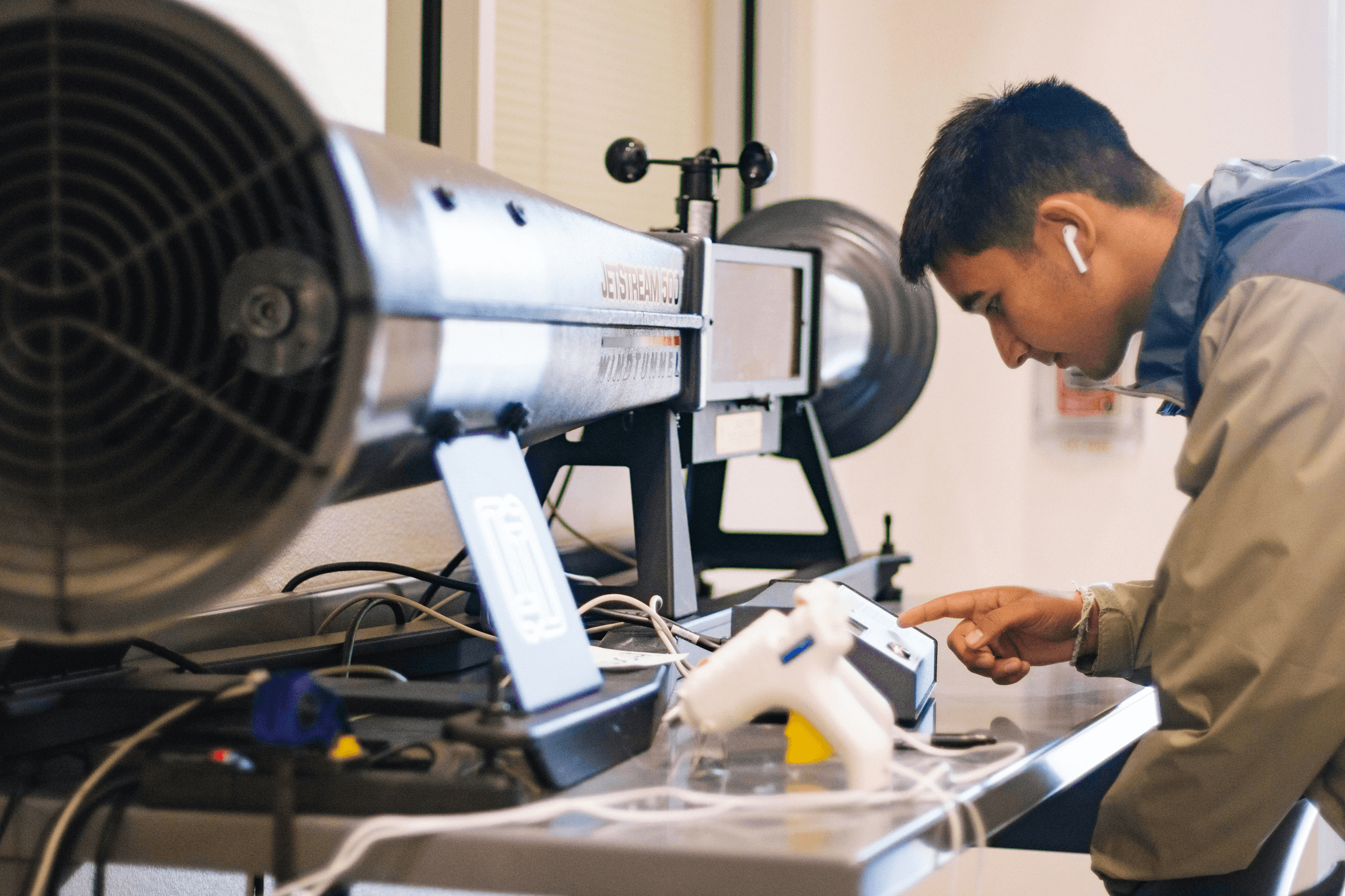

Functional Testing

Functional testing is a crucial aspect of production management, ensuring that products meet their intended performance specifications before they reach the market. This type of inspection in production management evaluates how well a product operates under various conditions, which is essential for maintaining quality assurance and minimizing defects. By implementing robust functional testing protocols, companies can significantly enhance their quality control processes and ensure customer satisfaction.

Ensuring Product Performance

At the heart of functional testing lies the commitment to ensuring product performance meets or exceeds expectations. This involves rigorous testing scenarios that mimic real-world usage, allowing quality control companies to identify potential weaknesses or failures before products are launched. With an effective quality assurance strategy in place, organizations can systematically address any issues discovered during these tests, ultimately leading to more reliable and durable products.

Case Studies of Successful Functional Inspections

Numerous case studies illustrate the importance of functional inspections in various industries. For instance, a leading automotive manufacturer implemented comprehensive functional testing on their new electric vehicle model and identified critical software glitches that could have led to safety issues post-launch. Similarly, a consumer electronics company utilized advanced quality testing services to ensure that their latest smartphone could withstand everyday wear and tear, resulting in fewer returns and higher customer satisfaction ratings.

Integration with Quality Assurance Frameworks

Integrating functional testing into broader quality assurance frameworks is vital for achieving optimal results in production management. By aligning these types of inspection in production management with established quality control methodologies, organizations can create a cohesive approach that promotes continuous improvement across all stages of development. This synergy not only enhances the reliability of products but also strengthens partnerships with inspection services that specialize in comprehensive quality control.

Destructive Testing

Destructive testing is a critical aspect of quality assurance that involves subjecting materials or products to conditions that will cause failure. This type of inspection is essential when assessing the durability and performance limits of a product, providing valuable data that can influence design and manufacturing processes. While it may seem counterintuitive to destroy a product in the name of quality control, the insights gained are invaluable for ensuring long-term reliability.

When and Why It’s Used

Destructive testing is typically employed when other types of inspection in production management are insufficient to guarantee safety and performance. Industries such as aerospace, automotive, and construction often require this rigorous form of evaluation to meet stringent regulatory standards. By understanding material properties under extreme conditions, companies can make informed decisions about material selection and design modifications, thereby enhancing overall quality assurance.

Balancing Risk and Quality Control

One might wonder how destructive testing fits into the broader landscape of quality control companies' strategies, especially considering its inherent risks. The key lies in balancing the need for thorough evaluation with cost-effectiveness; while destructive tests can be expensive due to waste and re-manufacturing costs, they ultimately safeguard against catastrophic failures in the field. By integrating these tests into a comprehensive quality control plan, businesses can ensure they are not only compliant with regulations but also committed to delivering superior products.

Real-World Examples in Production

Real-world applications of destructive testing illustrate its importance across various sectors—take the aerospace industry, for example. Here, components undergo tensile testing until failure to determine their maximum load capacity; this data directly informs design choices that enhance safety features in aircraft manufacturing. Similarly, many automotive manufacturers utilize destructive methods like crash tests to evaluate vehicle safety—an investment that pays dividends through consumer trust and compliance with stringent safety standards.

Conclusion

In the realm of production management, the importance of selecting the right types of inspection cannot be overstated. Each method—be it visual, dimensional, non-destructive, functional, or destructive—serves a unique purpose in ensuring quality assurance and maintaining high standards in quality control. By understanding these distinctions, companies can tailor their approach to meet specific production needs and enhance overall efficiency.

Choosing the Right Types of Inspection

Choosing the appropriate types of inspection in production management is crucial for effective quality control. Each inspection method offers distinct advantages that can cater to different facets of production processes. Companies must consider factors such as product specifications, industry standards, and potential risks when determining which quality inspection techniques to implement.

Benefits of Comprehensive Quality Control

Comprehensive quality control provides numerous benefits that extend beyond mere compliance with regulations; it fosters a culture of excellence within organizations. By integrating various types of inspections into their frameworks, businesses can ensure consistent product performance and reliability while minimizing defects and waste. This holistic approach not only enhances customer satisfaction but also strengthens brand reputation in competitive markets.

Partnering with Expert Inspection Services

Partnering with expert inspection services is a strategic move for any organization aiming to elevate its quality assurance practices. Quality control companies bring specialized knowledge and advanced technologies that can significantly improve the effectiveness of quality testing services. Collaborating with professionals ensures that all types of inspections are conducted efficiently and accurately, ultimately leading to superior products and satisfied customers.