Introduction

In the ever-evolving landscape of the food industry, quality control has emerged as a non-negotiable cornerstone for success. With consumers becoming increasingly discerning about what they eat, maintaining high standards in quality assurance is essential for any food products supplier aiming to thrive. The quest to define quality within this sector not only protects public health but also enhances brand reputation and consumer trust.

The Importance of Quality Control in Food

Quality control in the food industry is vital for ensuring that products meet safety and quality standards before reaching consumers. It encompasses a range of practices designed to prevent defects and ensure consistent delivery of safe, high-quality food. As regulations tighten and consumer expectations rise, effective quality management systems have become indispensable for businesses looking to maintain their competitive edge.

Innovations Driving Quality Assurance

Innovations are revolutionizing how we approach quality assurance in the food sector, with technology playing a pivotal role in enhancing efficiency and accuracy. From AI-driven analytics that predict potential failures to blockchain solutions ensuring transparency throughout the supply chain, these advancements are reshaping traditional notions of quality control. As companies embrace new tools and techniques, they can better align their processes with modern demands for safety and accountability.

Trends in Continuous Improvement Processes

Continuous improvement processes have become a guiding principle for organizations striving to enhance their quality control measures consistently. By adopting methodologies such as Lean or Six Sigma, businesses can refine their operations while fostering a culture of ongoing development among employees and suppliers alike. This commitment not only optimizes production but also strengthens relationships across the supply chain, ultimately benefiting all stakeholders involved.

Defining Quality in the Food Industry

Quality is a multifaceted concept in the food industry, essential for ensuring safety, consistency, and customer satisfaction. To define quality effectively, one must delve into the principles of quality control that govern production processes. These principles serve as the backbone for quality assurance initiatives, enabling food products suppliers to meet both regulatory requirements and consumer expectations.

Understanding Quality Control Principles

Quality control in the food industry revolves around several key principles aimed at maintaining high standards throughout production. These principles include consistency, reliability, and compliance with established regulations that ensure safety and quality. By embracing these principles, companies can not only define quality but also foster a culture of continuous improvement processes that elevate their products above competitors.

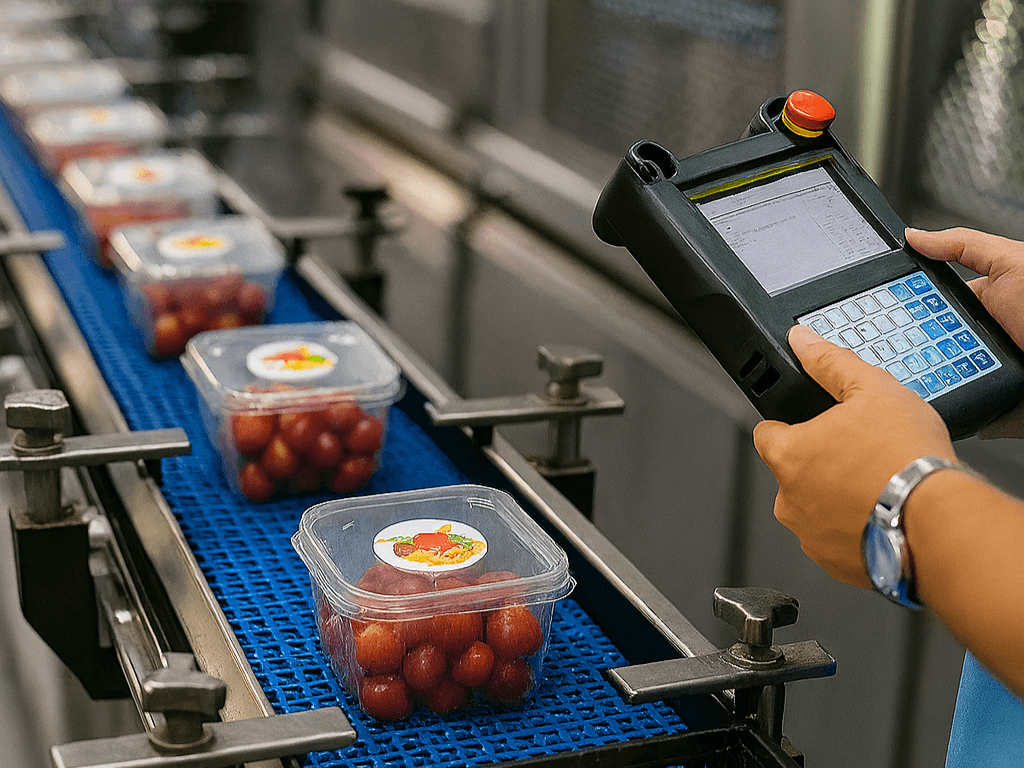

Implementing effective quality control measures requires a systematic approach to monitoring production stages and inspecting finished goods. This involves regular assessments of raw materials and adherence to best practices during processing to minimize defects. Ultimately, understanding these principles is crucial for any organization committed to delivering exceptional food products while maintaining robust quality assurance protocols.

Essential Quality Standards and Regulations

In today's global market, adhering to essential quality standards is non-negotiable for food products suppliers aiming for success. Regulatory bodies such as the FDA (Food and Drug Administration) in the United States set forth guidelines that dictate how food items should be produced, packaged, and labeled. Compliance with these regulations not only safeguards public health but also enhances brand reputation by demonstrating commitment to quality control.

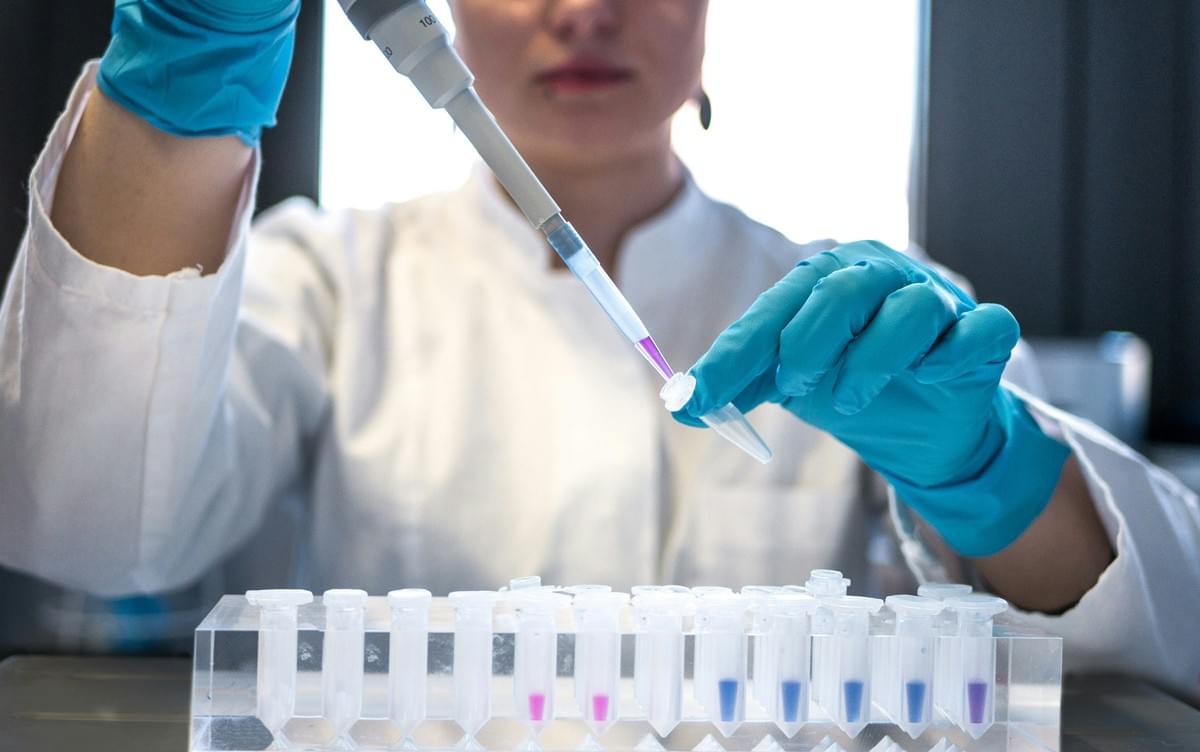

Various certifications such as ISO 22000 or HACCP (Hazard Analysis Critical Control Point) provide frameworks through which organizations can establish their credibility in terms of food safety management systems. These standards require rigorous documentation and regular audits to ensure compliance with safety protocols while enhancing overall product integrity. As such, understanding these essential regulations is pivotal for any entity looking to thrive in an increasingly competitive environment.

Role of Quality Management Systems

Quality management systems (QMS) play an integral role in defining quality within the food industry by providing structured methodologies for continuous improvement processes. A well-implemented QMS allows organizations to systematically monitor performance metrics related to product quality while streamlining operations across various departments within a company. This holistic approach not only enhances efficiency but also fosters collaboration among teams focused on achieving shared goals related to quality assurance.

By integrating technology into their QMS frameworks—such as data analytics tools—companies can gain real-time insights into their production processes and identify areas needing improvement swiftly. Furthermore, effective training programs centered on QMS principles empower employees at all levels to take ownership of their roles in maintaining high-quality standards throughout production cycles. In this way, a robust QMS serves as both a guiding light for operational excellence and a foundation upon which lasting relationships with food products suppliers can be built.

Advanced Technology in Quality Control

In the rapidly evolving landscape of the food industry, advanced technology plays a pivotal role in enhancing quality control. With innovations such as artificial intelligence (AI), blockchain, and the Internet of Things (IoT), businesses are redefining their approaches to quality assurance and management. These technologies not only streamline processes but also ensure that products meet stringent quality standards.

The Impact of AI and Machine Learning

Artificial intelligence and machine learning are revolutionizing quality control in the food industry by enabling real-time data analysis and predictive insights. By utilizing algorithms that learn from historical data, companies can define quality more accurately, identifying potential issues before they escalate into larger problems. This proactive approach fosters continuous improvement processes, allowing businesses to enhance their overall quality management strategies effectively.

Moreover, AI-powered systems can automate routine inspections and monitor production lines for deviations from established standards. This reduces human error while ensuring consistent adherence to quality assurance protocols. As a result, organizations can focus on refining their relationships with food product suppliers through improved communication and collaboration based on data-driven insights.

Blockchain for Transparency in Food Supply

Blockchain technology is emerging as a game changer for transparency in the food supply chain, addressing consumer concerns about food safety and authenticity. By creating an immutable ledger of transactions, blockchain enables stakeholders to trace products back to their origin with unprecedented accuracy—an essential aspect of effective quality control in the food industry. This level of transparency not only builds consumer trust but also reinforces the importance of adhering to established regulations.

With blockchain, every step of a product's journey—from farm to table—can be documented securely and transparently, making it easier for companies to comply with quality inspection requirements. This innovation empowers organizations to audit their suppliers effectively while ensuring that all parties involved maintain high-quality standards throughout the supply chain. Ultimately, embracing blockchain technology contributes significantly to continuous improvement processes within quality management frameworks.

Internet of Things in Quality Assurance

The Internet of Things (IoT) is transforming how businesses approach quality assurance by connecting devices and sensors across production environments. Through IoT-enabled solutions, companies can monitor temperature controls, humidity levels, and other critical parameters essential for maintaining product integrity during storage and transportation—key aspects of defining quality in the food industry. This real-time monitoring allows organizations to respond swiftly to any deviations that could compromise product safety or compliance with regulations.

Additionally, IoT devices facilitate seamless communication between manufacturers and suppliers regarding inventory levels or potential issues affecting product quality inspection outcomes. By fostering collaborative relationships built on timely information sharing with food products suppliers, companies can enhance traceability while minimizing risks associated with poor-quality goods entering the market. As IoT continues its expansion into various sectors within agriculture and processing operations alike, it will undoubtedly play an integral role in driving continuous improvement processes across all facets of food production.

Quality Inspection Techniques

When it comes to quality control in the food industry, inspection techniques are pivotal in ensuring that products meet established standards. The evolution of quality inspection methods has been remarkable, transitioning from traditional approaches to modern technologies that enhance efficiency and accuracy. Understanding these techniques is essential for implementing effective quality assurance measures and driving continuous improvement processes.

Traditional vs. Modern Inspection Methods

Traditional inspection methods often relied on manual checks and sensory evaluations, such as taste tests or visual inspections, which could be subjective and inconsistent. While these methods laid the groundwork for defining quality, they lacked the precision needed in today's fast-paced food production environments. In contrast, modern inspection methods leverage advanced technologies like automated systems and real-time monitoring tools to provide a more objective assessment of product quality.

Modern techniques incorporate data analytics, AI-driven algorithms, and machine learning models that can detect anomalies with high accuracy. These innovations not only streamline the quality control process but also facilitate continuous improvement processes by identifying areas for enhancement quickly. By integrating both traditional wisdom and cutting-edge technology, food companies can ensure robust quality assurance protocols that adapt to changing consumer expectations.

The Role of China Inspection Pro in Quality Control

China Inspection Pro plays a crucial role in enhancing quality control within the food industry by providing comprehensive inspection services tailored for local suppliers and international brands alike. Their expertise ensures that food products suppliers adhere to stringent quality management standards throughout the supply chain, thus minimizing risks associated with subpar products entering the market. With a focus on transparency and accountability, China Inspection Pro helps businesses navigate complex regulatory landscapes while maintaining high-quality benchmarks.

By utilizing both traditional practices alongside modern technological solutions such as AI-powered inspections, China Inspection Pro effectively identifies potential issues before they escalate into larger problems. This proactive approach not only safeguards consumers but also reinforces trust between businesses and their clients through consistent delivery of safe products. As a partner in quality assurance efforts, China Inspection Pro amplifies the importance of rigorous inspections across various stages of production.

Best Practices for Effective Quality Inspection

To achieve optimal results in quality inspection within the food industry, several best practices should be embraced by companies committed to excellence in their operations. First and foremost is establishing clear criteria that define quality—these benchmarks should align with both regulatory requirements and customer expectations to foster consistency across all products inspected. Additionally, investing time in training staff on effective inspection techniques can significantly enhance overall productivity while reducing error rates during assessments.

Another best practice involves leveraging technology as part of regular inspection routines; integrating IoT devices can provide real-time data analytics that support informed decision-making regarding product safety and compliance with established standards. Moreover, fostering strong relationships with food products suppliers encourages open communication about potential challenges related to product integrity—this collaboration is vital for continuous improvement processes aimed at elevating overall performance levels within the supply chain ecosystem.

Lastly, conducting regular audits not only ensures adherence to defined standards but also serves as an opportunity for ongoing education regarding emerging trends affecting quality management practices globally—keeping pace with innovation is essential for success in today’s competitive landscape.

Collaborating with Food Products Suppliers

In the realm of quality control in the food industry, collaboration with food products suppliers is paramount. Building strong relationships can significantly enhance quality assurance practices and foster a culture of continuous improvement processes. By working closely with suppliers, food companies can define quality expectations clearly, ensuring that everyone is on the same page when it comes to delivering safe and high-quality products.

Building Strong Relationships for Quality

Establishing robust relationships with suppliers goes beyond simple transactions; it's about creating partnerships based on trust and shared goals. When both parties commit to quality management, they can work collaboratively to address challenges and innovate solutions together. Open lines of communication allow for timely feedback and adjustments, which are essential for maintaining high standards in quality control.

Moreover, regular meetings and check-ins help reinforce these relationships by providing opportunities for both sides to discuss their expectations regarding quality inspection methods and compliance standards. When suppliers feel valued and engaged, they're more likely to prioritize the necessary measures that contribute to effective quality assurance. Ultimately, strong supplier relationships lead to improved product consistency and reliability in the food industry.

Auditing Suppliers for Compliance

Auditing suppliers is a critical aspect of maintaining quality control in the food industry. Regular audits help ensure that suppliers adhere to established quality standards and regulations while identifying areas where improvements can be made. By conducting thorough assessments of their processes, companies can verify that their partners are committed to upholding high-quality practices.

These audits should encompass various dimensions of compliance—from raw material sourcing to production techniques—ensuring that every step meets defined criteria for safety and quality assurance. Implementing a structured auditing process not only helps identify potential risks but also fosters an environment where continuous improvement processes are embraced by all stakeholders involved. This proactive approach solidifies trust between businesses and their suppliers while enhancing overall product integrity.

Training Suppliers in Quality Assurance

Training is another essential component of successful collaboration with food products suppliers when it comes to achieving top-notch quality control in the food industry. Providing comprehensive training programs empowers suppliers with the knowledge they need about best practices in quality management systems and inspection techniques. This knowledge transfer enhances their ability to meet your specific requirements consistently.

Additionally, training sessions focused on current trends—such as advancements in technology or regulatory changes—can keep your partners informed about what constitutes best practice within the industry today. Encouraging a culture of learning helps foster an environment where continuous improvement processes are not only accepted but actively pursued by everyone involved in the supply chain. In turn, this commitment leads to higher levels of compliance and product excellence across all stages of production.

Case Studies: Success Stories in Quality Control

In the realm of the food industry, case studies showcasing successful quality control initiatives are invaluable for understanding how to elevate standards and practices. These stories reveal not only the importance of quality assurance but also the innovative strategies that industry leaders have employed to define quality and implement effective quality management systems. By examining these successes, other businesses can glean insights into continuous improvement processes that can enhance their own operations.

Lessons from Industry Leaders

Industry leaders often set the bar high when it comes to quality control in the food industry. For instance, a major beverage company revamped its quality inspection protocols by integrating advanced technology, resulting in a significant reduction in product recalls and consumer complaints. This shift not only improved their reputation but also showcased how essential it is to foster strong relationships with food products suppliers for consistent adherence to quality standards.

Moreover, another prominent dairy brand adopted a rigorous auditing process for its suppliers, ensuring compliance with stringent regulations and enhancing overall product integrity. These lessons underline that defining quality goes beyond mere compliance; it's about creating a culture where continuous improvement processes thrive at every level of production and supply chain management.

Implementing Continuous Improvement Processes

Implementing continuous improvement processes is vital for maintaining excellence in quality control within the food sector. A notable example comes from a leading snack manufacturer that embraced Lean Six Sigma methodologies to streamline its operations and reduce waste significantly. By regularly assessing their production lines through data-driven analysis, they were able to identify inefficiencies and enhance their overall quality assurance efforts.

This approach not only improved operational efficiency but also allowed them to redefine what it means to achieve high-quality standards in food products. As they refined their processes, they discovered new ways to engage suppliers more effectively, ensuring everyone involved was aligned with their commitment to outstanding quality management.

Real-World Innovations in the Food Sector

Real-world innovations are transforming how companies approach quality control in the food industry today. One particularly striking example is a farm-to-table restaurant chain that utilizes blockchain technology for complete transparency concerning its ingredient sourcing and supply chain practices. This innovation has empowered consumers with information about where their food comes from while simultaneously reinforcing trust in their commitment to high-quality standards.

Additionally, some companies are leveraging artificial intelligence tools for predictive analytics within their production processes—a move that allows them not only to maintain rigorous quality inspection protocols but also anticipate potential issues before they arise. These real-world innovations illustrate how embracing new technologies can lead businesses toward enhanced accountability and superior product integrity while solidifying long-lasting relationships with food products suppliers.

Conclusion

In wrapping up our exploration of quality control in the food industry, it's clear that a robust framework for quality assurance is crucial for maintaining safety and satisfaction. The future of quality control will be shaped by emerging technologies, evolving regulations, and an unwavering commitment to continuous improvement processes. As we look ahead, the importance of defining quality will remain paramount in ensuring that food products meet consumer expectations.

Future Trends in Quality Control

The landscape of quality control in the food industry is poised for transformation as technology continues to advance. Innovations such as AI-driven analytics and IoT devices are set to revolutionize how we monitor and manage quality assurance processes. These tools will not only enhance efficiency but also provide more accurate data for decision-making, ultimately leading to improved standards across the board.

The Role of Regulations in Quality Assurance

Regulations play a pivotal role in shaping the practices surrounding quality control within the food industry. They establish essential guidelines that help define quality and ensure compliance among food products suppliers. As regulatory frameworks evolve, they will increasingly emphasize transparency and traceability, compelling companies to adopt stringent quality management systems that align with global standards.

Emphasizing the Need for Continuous Improvement

Continuous improvement processes are not just buzzwords; they are vital components of effective quality control strategies in the food industry. By fostering a culture of ongoing enhancement among employees and suppliers alike, organizations can adapt to changing market demands while ensuring product consistency and safety. Ultimately, embracing continuous improvement allows businesses to stay competitive while delivering high-quality products that consumers can trust.