Introduction

In today's competitive business landscape, understanding quality checks is not just a luxury—it's a necessity. Quality assurance (QA) serves as the backbone of any successful operation, ensuring that products and services meet established standards. By defining quality and implementing effective quality control (QC) measures, businesses can enhance their reputation and profitability.

Understanding Quality Checks in Business

So, what is a quality check? It refers to systematic evaluations designed to ensure that products or services meet specific standards before they reach the customer. These checks are crucial for maintaining consistency and reliability in business offerings, fostering trust with consumers who expect nothing less than excellence.

Importance of Quality Assurance for Success

Quality assurance is more than just a checklist; it's an integral part of business strategy that drives success. When companies prioritize QA quality practices, they reduce errors and improve customer satisfaction rates significantly. This focus on quality not only enhances brand loyalty but also positions businesses favorably against competitors who may overlook these essential processes.

How Quality Control Impacts Your Bottom Line

The relationship between quality control and your bottom line is undeniable; effective QC measures can lead to substantial cost savings over time. By minimizing defects and inefficiencies through rigorous quality checks, businesses can avoid costly recalls or rework expenses that eat into profits. Ultimately, investing in QA quality assurance pays dividends by boosting operational efficiency and enhancing overall financial performance.

Defining Quality and Assurance

In the realm of business, quality and assurance are foundational concepts that ensure products and services meet the highest standards. To truly grasp what is a quality check, one must recognize its role in maintaining these standards. Quality assurance (QA) encompasses various processes designed to prevent defects and ensure that the end product aligns with customer expectations.

What Is a Quality Check?

A quality check is a systematic process used to evaluate products or services against predefined criteria. Essentially, it involves assessing whether certain quality standards have been met before a product reaches the customer. By defining quality in this context, businesses can identify areas for improvement and ensure consistent delivery of high-quality outcomes.

Quality checks can take many forms, including inspections, testing, and audits. They serve as critical checkpoints in the production process, helping organizations catch potential issues before they escalate into larger problems. Ultimately, understanding what is a quality check empowers businesses to enhance their overall performance through proactive measures.

Key Principles of QA Quality Assurance

The key principles of QA quality assurance revolve around several core tenets: prevention over inspection, continuous improvement, and customer focus. Prevention emphasizes building quality into processes from the outset rather than merely inspecting finished products for defects. This proactive approach not only saves time but also reduces costs associated with rework or returns.

Continuous improvement is another essential principle within QA quality assurance that encourages organizations to regularly assess their processes and systems for efficiency gains. By fostering a culture of ongoing enhancement, businesses can adapt to changing market demands while consistently delivering superior products or services. Furthermore, maintaining a strong focus on customer needs ensures that all efforts align with delivering value to clients.

Lastly, effective communication plays a vital role in successful QA practices; sharing insights across teams helps cultivate an environment where everyone understands their contribution to overall quality control efforts. By embedding these principles into daily operations, companies can create robust frameworks for achieving excellence in both products and services.

The Role of Quality Control in Businesses

Quality control (QC) serves as an essential component within the broader scope of quality management systems by providing tangible methods for measuring performance against established standards. The primary aim of QC is to identify any deviations from desired specifications early on—before they impact customers or lead to costly repercussions down the line. This proactive stance reinforces why organizations must prioritize effective QC practices as part of their overall strategy.

In practice, QC involves various techniques such as statistical process control (SPC), inspections at different production stages, and regular audits that help maintain compliance with industry regulations and internal benchmarks alike. These methodologies allow businesses not only to detect errors but also to analyze root causes so they can implement corrective actions swiftly—thereby minimizing disruptions caused by faulty outputs.

Moreover, integrating QC practices fosters accountability among team members who are responsible for upholding product integrity throughout each phase of development or service delivery processes—ultimately leading toward enhanced customer satisfaction levels over time! As companies strive for excellence via improved QA initiatives paired with robust QC measures; they position themselves favorably within competitive markets while ensuring long-term success.

Best Practices for Quality Checks

To ensure that quality and assurance are embedded in every aspect of your business, implementing best practices for quality checks is essential. These practices not only define quality but also enhance the effectiveness of your quality assurance (QA) processes. By focusing on structured approaches, businesses can significantly improve their overall performance and customer satisfaction.

Implementing a Quality Management System

A robust Quality Management System (QMS) is the backbone of effective quality assurance. It helps to define quality standards, streamline processes, and ensure compliance with industry regulations. By integrating a QMS into your operations, you create a framework that supports continuous improvement and facilitates effective quality control (QC).

When considering what is a quality check within the context of a QMS, it becomes clear that these checks are systematic evaluations designed to measure adherence to established standards. A well-implemented QMS allows organizations to monitor performance metrics closely and make data-driven decisions that enhance both QA and QC efforts. Ultimately, this leads to increased efficiency and reduced costs, positively impacting your bottom line.

Training Staff for Effective Quality Control

One of the most critical components in achieving successful QA quality assurance is training staff effectively for their roles in quality control. Employees need to understand what is expected from them regarding quality checks and how their actions directly influence overall product or service outcomes. Regular training sessions not only improve skill sets but also foster a culture of accountability around defining quality.

By investing in staff development, companies can empower employees with the knowledge necessary for effective QC practices while instilling an appreciation for the importance of maintaining high-quality standards. Moreover, ongoing training ensures that employees are up-to-date with new technologies or methodologies related to QA processes. This commitment ultimately enhances team performance and drives better results across all departments.

Leveraging Technology in Quality Assurance

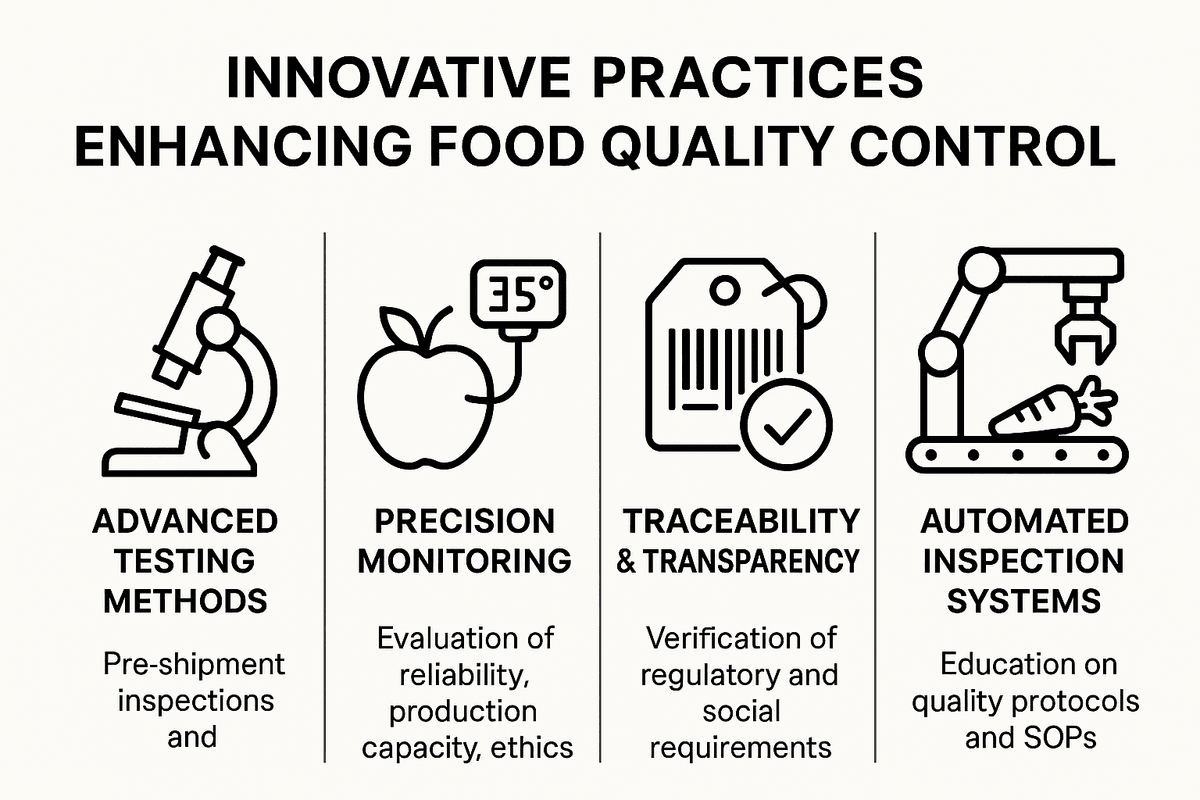

In today's fast-paced business landscape, leveraging technology is paramount for enhancing QA efficiency and effectiveness in conducting quality checks. Advanced software solutions allow businesses to automate many aspects of their QA processes while providing real-time data analysis on product performance metrics. This technological integration helps define quality more clearly by enabling precise tracking of compliance with established standards.

Moreover, utilizing digital tools streamlines communication among teams involved in QC activities, ensuring everyone stays aligned on objectives related to both QA and QC initiatives. The use of data analytics further supports continuous improvement by identifying trends or areas requiring attention within your operations—ultimately leading to enhanced customer satisfaction through superior product offerings.

Quality Check Process Explained

Quality checks are crucial in ensuring that products and services meet predefined standards. A well-structured quality check process not only enhances the reliability of the output but also contributes to overall customer satisfaction. Understanding how to effectively conduct these checks is essential for any business aiming to maintain high-quality standards.

Steps in Conducting a Quality Check

To define quality, one must first understand the structured steps involved in conducting a quality check. The initial step often involves defining what is a quality check specific to your organization’s needs—this sets the stage for all subsequent actions. Following this, businesses should establish clear criteria based on QA quality assurance principles, ensuring that each aspect of the product or service aligns with industry standards.

Next, it’s vital to perform inspections and tests according to these criteria; this is where effective quality control comes into play. Regularly reviewing results allows teams to identify areas needing improvement, making adjustments as necessary. Finally, feedback loops are essential; gathering insights from various stakeholders can help refine future processes and enhance overall quality and assurance efforts.

Tools and Techniques for Effective QC Quality Control

When it comes to effective QC quality control, utilizing the right tools can make all the difference in achieving desired outcomes. Various software solutions are available that streamline data collection and analysis, allowing businesses to monitor their QA quality assurance processes efficiently. Additionally, employing techniques such as Six Sigma or Lean methodologies can significantly improve operational efficiency while minimizing waste.

Visual inspection tools like gauges and calipers also play a critical role in maintaining product integrity during checks. Moreover, automated systems equipped with sensors can provide real-time data on production lines—this proactive approach helps catch defects before they escalate into larger issues. By leveraging these tools strategically, organizations can ensure that their definition of quality translates into tangible results.

The Importance of Documentation in Quality Assurance

Documentation serves as the backbone of any successful QA quality assurance program; without it, consistency becomes a challenge across various operations. Keeping detailed records of every quality check not only aids compliance with regulatory requirements but also provides valuable insights for continuous improvement initiatives within your organization’s framework of quality control practices. Each documented procedure should clearly outline what is a quality check performed at different stages of production.

Furthermore, having an organized documentation system allows teams to trace back issues when they arise—a crucial factor when trying to define why certain problems occurred during production runs or service delivery scenarios. This historical data empowers businesses with knowledge that informs better decision-making for future projects while reinforcing accountability among team members involved in maintaining standards of excellence in both products and services offered by the company.

Quality Inspections and Industry Standards

In the realm of quality checks, aligning with industry standards is paramount to ensuring that products and services meet customer expectations. Quality assurance (QA) plays a crucial role in this alignment, as it establishes the framework for maintaining quality and assurance throughout production processes. By adhering to recognized standards, businesses can enhance their credibility and foster trust among consumers.

Aligning with ISO Standards

ISO standards are internationally recognized benchmarks that define quality parameters across various industries. To define quality effectively, organizations must integrate these standards into their operational processes, thereby establishing a solid foundation for QA quality assurance practices. This alignment not only streamlines operations but also enhances overall product reliability, which is essential in today's competitive market.

Implementing ISO standards involves regular audits and assessments to ensure compliance with established criteria. Such practices reinforce the importance of quality control (QC) by identifying areas needing improvement while promoting a culture of continuous enhancement within the organization. Ultimately, companies that embrace ISO standards position themselves as leaders in quality management, paving the way for long-term success.

Role of China Inspection Pro in Quality Checks

China Inspection Pro serves as a vital ally for businesses seeking to maintain high-quality assurance levels during manufacturing processes. Their expertise in conducting thorough inspections ensures that products meet both domestic and international QA quality requirements before reaching consumers' hands. By leveraging their services, companies can minimize risks associated with poor-quality goods entering the market.

What is a quality check without proper oversight? With China Inspection Pro's rigorous evaluation methods, organizations can gain valuable insights into their production lines while identifying potential defects early on. This proactive approach not only saves time but also safeguards brand reputation by preventing costly recalls or customer dissatisfaction stemming from subpar products.

Moreover, partnering with China Inspection Pro allows businesses to tap into local knowledge about regulatory requirements specific to various markets. Understanding these nuances empowers companies to navigate complexities seamlessly while ensuring compliance with all necessary guidelines related to quality control (QC). As such, they become better equipped to deliver exceptional products consistently.

Understanding Regulatory Requirements in Quality Assurance

Regulatory requirements form an essential aspect of any comprehensive QA strategy aimed at ensuring product safety and reliability across industries. These stipulations dictate what constitutes acceptable levels of performance concerning health regulations, environmental factors, or consumer protection laws—ultimately defining what is a quality check within specific contexts. Organizations must stay informed about these evolving regulations to maintain compliance effectively.

Failure to adhere to regulatory requirements can lead not only to financial penalties but also damage brand reputation significantly—an outcome no business desires! Therefore, integrating these guidelines into existing QC systems becomes crucial for fostering an environment where safety remains paramount alongside product excellence throughout all stages of development and distribution processes alike.

In conclusion, understanding regulatory frameworks enables organizations not just merely comply but also thrive within competitive landscapes by demonstrating commitment towards delivering high-quality products consistently over time through effective QA practices tailored specifically around those very regulations governing them!

Measuring Quality Check Success

Measuring the success of quality checks is crucial for any business aiming to maintain high standards and improve its operations. Understanding what a quality check entails, along with the metrics that define quality, can help organizations gauge their performance effectively. By focusing on key performance indicators (KPIs), businesses can ensure their quality assurance (QA) processes are not just effective but also aligned with their overall goals.

Key Performance Indicators for Quality Assurance

Key Performance Indicators (KPIs) serve as benchmarks that help businesses understand how well they are performing in terms of quality assurance. To define quality, organizations often track metrics such as defect rates, customer satisfaction scores, and process efficiency ratios. These KPIs provide a clear picture of how effective the QA quality assurance processes are and highlight areas that may require improvement or adjustment.

In addition to traditional metrics, companies might also consider implementing real-time monitoring tools to gain insights into ongoing operations. This proactive approach allows businesses to respond swiftly if any QC quality control issues arise during production or service delivery. Ultimately, the right KPIs not only measure success but also drive continuous improvements in both quality and assurance.

Continuous Improvement through Quality Control

Continuous improvement is a fundamental principle of effective quality control practices within organizations. By regularly assessing and refining QA processes, businesses can enhance their overall performance and ensure they meet customer expectations consistently. The cycle of Plan-Do-Check-Act (PDCA) is often utilized as a framework for this ongoing enhancement in defining what is a quality check.

Quality control isn't just about identifying defects; it's about fostering an environment where every team member feels empowered to contribute to improvements in both products and services. Encouraging feedback loops within teams helps identify potential issues early on, allowing for swift corrective actions before problems escalate into larger challenges. This culture of continuous improvement ensures that companies remain competitive while upholding high standards of QA quality.

Gathering Feedback for Future Quality Checks

Gathering feedback is an essential component of refining future quality checks and enhancing overall performance in QA practices. Customer feedback provides invaluable insights into how well products or services meet expectations, helping businesses define what constitutes a successful outcome in terms of both quality and assurance. Regularly soliciting input from stakeholders—including employees—can uncover hidden inefficiencies or areas needing attention within existing QC processes.

Moreover, integrating feedback mechanisms into daily operations encourages a culture of openness where everyone feels responsible for maintaining high-quality standards. This collaborative approach not only enhances employee engagement but also strengthens the commitment to achieving excellence across all levels of the organization. By making informed adjustments based on collected feedback, companies can continuously elevate their standards in QA and establish themselves as leaders in their respective industries.

Conclusion

In the ever-evolving landscape of business, the significance of quality checks cannot be overstated. What is a quality check, you ask? It’s not just a box to tick; it’s a crucial component of your operational success that ensures products and services meet established standards. By prioritizing quality assurance and implementing robust QA quality practices, businesses can foster customer loyalty and enhance their reputation in the marketplace.

The Value of Quality Checks in Business

Quality checks serve as the backbone of effective quality control systems, ensuring that every product meets customer expectations and regulatory standards. When companies define quality through rigorous QC quality control measures, they not only reduce wastage but also increase efficiency across all departments. Ultimately, investing in comprehensive quality assurance translates into higher profit margins and sustained business growth.

Future Trends in Quality and Assurance

As technology advances, so too do the methodologies surrounding QA quality assurance. Automation and artificial intelligence are set to redefine what is considered a quality check by enabling real-time monitoring and predictive analytics for better decision-making. Furthermore, as businesses increasingly focus on sustainability, integrating eco-friendly practices into their quality and assurance processes will become essential for maintaining competitive advantage.

Taking the Next Step for Quality Improvement

To elevate your organization’s approach to defining quality, begin by assessing your current QA practices and identifying gaps that need addressing. Engage your team in training sessions focused on enhancing their understanding of QC quality control principles—after all, well-informed employees are key to successful implementation. Finally, embrace feedback loops from customers to continuously refine your processes; this proactive approach will ensure that your commitment to excellence remains unwavering.