Introduction

In the ever-evolving world of fashion, ensuring the quality of garments is paramount. This begins with a solid understanding of garment checking methods that can help identify potential issues before they reach consumers. By implementing effective textile inspection practices, manufacturers can maintain high standards and enhance their reputation in a competitive market.

Understanding Garment Checking Methods

Garment checking methods encompass a range of techniques designed to evaluate the quality of clothing throughout the production process. From visual inspections to advanced garment testing technologies, these methods ensure that different types of fabric meet specific durability and aesthetic standards. Familiarity with these techniques not only helps in identifying flaws but also plays a crucial role in selecting the right manufacturers for clothing who prioritize quality.

Importance of Textile Inspection

Textile inspection is essential for maintaining garment quality and ensuring customer satisfaction. By conducting thorough inspections at various stages—from fabric selection to final product evaluation—manufacturers can prevent defects that may lead to costly returns or damage to brand reputation. Moreover, consistent textile inspection fosters trust between manufacturers and consumers, ultimately leading to better business outcomes.

Key Considerations for Garment Quality

Understanding different types of fabric is vital since each material has unique characteristics that affect its performance and appearance. Additionally, establishing clear criteria for garment testing helps ensure that all products meet industry standards while aligning with consumer expectations for durability and style.

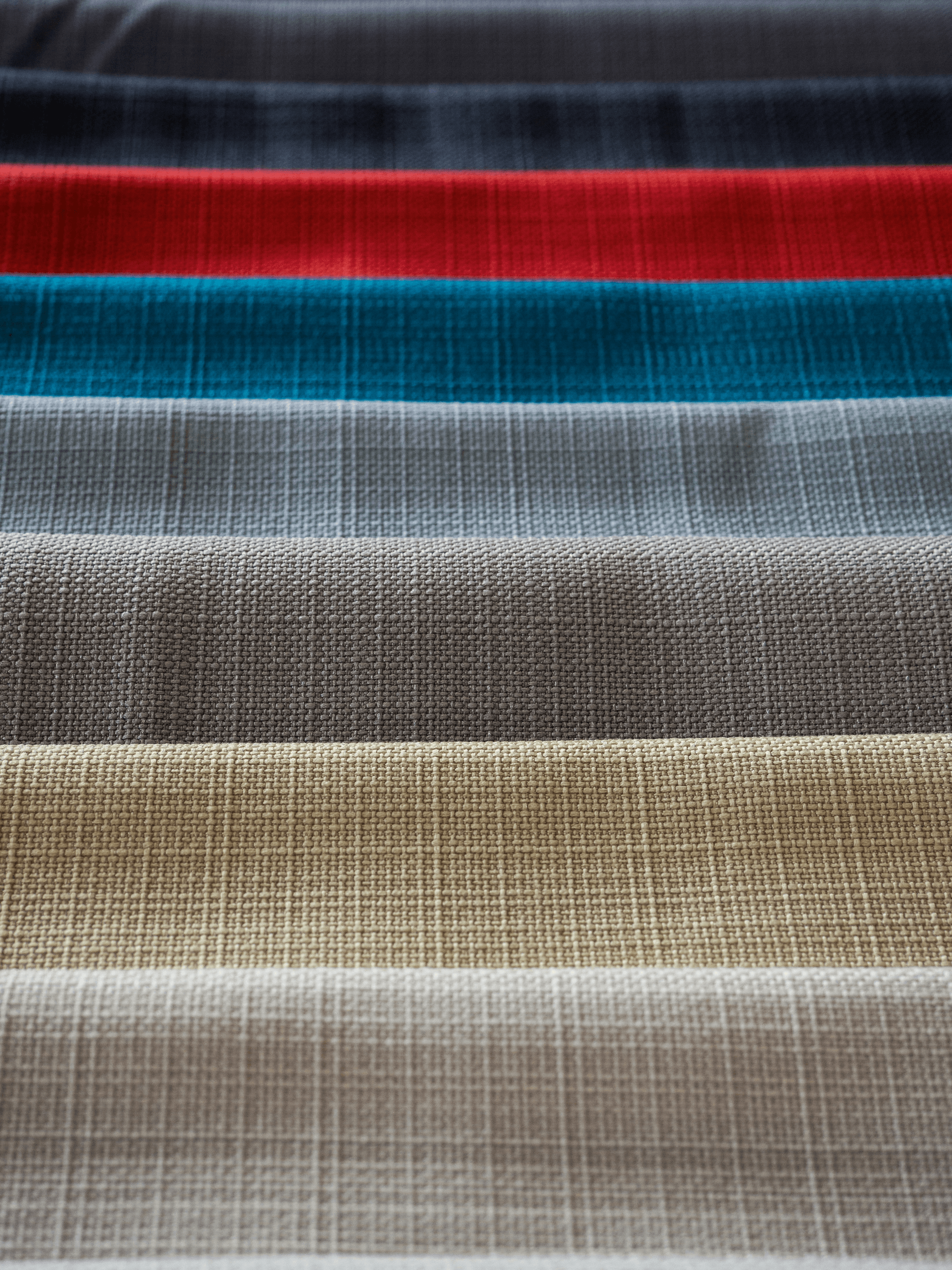

Identify Types of Fabric

Understanding the different types of fabric is crucial for effective garment inspection and ensuring high-quality clothing. Each fabric type comes with its unique properties that can significantly affect the overall quality of a garment. By familiarizing yourself with these fabrics, you can make more informed decisions during textile inspection and garment testing.

Learn About Different Types of Fabric

Fabrics can be broadly categorized into natural and synthetic types, each offering distinct advantages and disadvantages. Natural fabrics like cotton, linen, and wool are breathable and comfortable but may require more care in terms of maintenance.

When inspecting garments, knowing the specific characteristics of different types of fabric allows for better evaluation during quality checks. For instance, certain fabrics may be prone to fading or pilling, while others might stretch or shrink over time. This knowledge empowers manufacturers for clothing to select appropriate materials that align with their quality standards.

Impact of Fabric on Quality

The type of fabric used directly impacts the overall quality of a garment; this is why careful selection is essential during textile inspection processes. Fabrics contribute not only to the aesthetic appeal but also to functionality—think about how a dress made from stiff taffeta behaves differently than one crafted from soft jersey knit. Quality assurance in garment testing often hinges on understanding how various fabrics perform under stress or wear.

In addition to aesthetics and performance, the fabric's ability to withstand washing and daily wear plays a significant role in customer satisfaction. Low-quality materials may lead to dissatisfaction due to issues like color bleeding or loss of shape after washing—issues that are easily caught during thorough garment inspection processes. Thus, prioritizing high-quality fabrics ensures that garments meet consumer expectations while minimizing returns.

Choosing the Right Fabric for Inspection

Selecting the right fabric for inspection involves both an understanding of its properties and an assessment against specific quality criteria relevant to your target market. Manufacturers for clothing should prioritize sourcing materials known for their durability while also considering cost-effectiveness—after all, no one wants a beautiful shirt that falls apart after one wash!

When conducting textile inspections, always consider how well each fabric aligns with your brand’s values; if sustainability is key, look into organic cotton or recycled polyester options as alternatives that still meet quality standards in garment testing scenarios. Furthermore, having clear guidelines on what constitutes acceptable fabric characteristics will streamline your garment checking methods significantly.

Ultimately, choosing the right fabric isn't just about aesthetics; it's about ensuring longevity and satisfaction in every piece you produce—a cornerstone principle in successful garment quality inspections.

Implement Effective Garment Inspection Techniques

These methods not only help identify potential issues early on but also enhance customer satisfaction and brand reputation. By focusing on visual inspection strategies, utilizing technology, and establishing a standard operating procedure, businesses can significantly improve their textile inspection processes.

Visual Inspection Strategies

Visual inspection is one of the most fundamental garment checking methods and should be conducted meticulously. This approach involves examining garments for defects such as fabric flaws, stitching errors, and color inconsistencies. To maximize effectiveness, inspectors should familiarize themselves with different types of fabric since each type may have unique characteristics that require specific attention during the garment inspection process.

Training staff to recognize common issues in various fabrics can lead to more efficient inspections and better overall quality control. For example, lightweight fabrics like chiffon might show different defects compared to heavier materials like denim; understanding these nuances is essential for accurate assessment. A systematic approach—such as using checklists—can further streamline this process and ensure nothing slips through the cracks.

Use of Technology in Garment Testing

In today’s fast-paced fashion industry, relying solely on manual inspections is a recipe for disaster; technology must play a pivotal role in garment testing. Automated systems can quickly identify flaws that might be missed by the human eye while also providing detailed reports on fabric performance metrics. This integration not only speeds up textile inspection but also enhances accuracy in assessing garment quality.

Modern tools such as digital imaging systems or infrared sensors can detect variations in fabric texture or color consistency more efficiently than traditional methods alone. Furthermore, software solutions can analyze data collected from inspections to pinpoint recurring issues with specific manufacturers for clothing or types of fabric used in production. Embracing these technological advancements will ultimately lead to improved outcomes in garment quality inspection.

Establishing a Standard Operating Procedure

Creating a standard operating procedure (SOP) for garment inspection is vital for maintaining consistency across all levels of production and testing processes. An SOP outlines step-by-step guidelines on how inspections should be conducted—ensuring that every team member follows the same protocol regardless of their experience level or familiarity with different types of fabric. This uniformity helps reduce errors and fosters accountability within teams responsible for textile inspection.

Moreover, an SOP should be adaptable; it must evolve based on feedback from inspectors and changes within the industry landscape—including new types of fabric or updated compliance standards from manufacturers for clothing. Regularly reviewing and updating these procedures ensures that your quality assurance practices remain relevant and effective over time. By establishing clear guidelines that incorporate both visual strategies and technological tools, companies can elevate their garment checking methods to new heights.

Collaborate with Reliable Manufacturers for Clothing

When it comes to garment quality inspection, collaborating with reliable manufacturers is crucial. Selecting the right manufacturers for clothing can significantly impact the overall quality of your garments. A focus on quality from your manufacturing partners ensures that you are using the best garment checking methods available, ultimately leading to superior products that meet customer expectations.

Selecting Manufacturers with a Quality Focus

Choosing manufacturers with a strong commitment to quality is essential in the textile industry. Look for partners who specialize in various types of fabric and have established a reputation for excellence in garment inspection and testing. By prioritizing manufacturers that emphasize quality control, you can rest assured knowing your garments will undergo rigorous checks and adhere to high standards throughout production.

Building Relationships for Better Quality Control

Establishing solid relationships with your chosen manufacturers fosters better communication and transparency regarding garment inspection processes. When you collaborate closely, you can share insights about different types of fabric, ensuring that both parties understand the specific requirements needed for effective garment testing. This partnership not only enhances trust but also streamlines textile inspection procedures, resulting in higher-quality outputs.

Assessing Manufacturer Certifications and Standards

To ensure you're working with reputable manufacturers, it's vital to assess their certifications and adherence to industry standards. Look for certifications related to garment checking methods and compliance with international quality benchmarks, which indicate a manufacturer’s commitment to maintaining high-quality production processes. Regularly reviewing these certifications will help keep your supply chain aligned with best practices in garment quality inspection.

Conduct Comprehensive Garment Testing

When it comes to ensuring the quality of clothing, comprehensive garment testing is non-negotiable. This process not only evaluates the durability and wear of garments but also checks their compliance with industry standards. By implementing effective garment testing methods, you can confidently assess the quality of various types of fabric used in your products.

Testing for Durability and Wear

Durability is a key factor in garment quality inspection, as it determines how well a piece of clothing withstands everyday use. Testing for durability involves subjecting garments to rigorous conditions that mimic real-world wear and tear, such as stretching, washing, and exposure to sunlight. Understanding different types of fabric helps in selecting appropriate testing methods; for example, synthetic fabrics may require different stress tests compared to natural fibers.

Incorporating these garment checking methods ensures that you identify any weaknesses in construction or materials early on. Manufacturers for clothing should be aware that rigorous durability tests can significantly reduce returns and increase customer satisfaction. Ultimately, thorough testing for wear not only elevates the brand's reputation but also builds trust with consumers who expect long-lasting quality.

Checking for Compliance with Industry Standards

Compliance with industry standards is crucial in garment inspection processes to ensure safety and quality benchmarks are met. Various organizations set forth guidelines that manufacturers must follow when producing clothing items; adhering to these standards protects both the brand and its customers from potential hazards associated with subpar products. By regularly checking compliance during textile inspection, businesses can avoid costly recalls or negative publicity.

It's essential to familiarize yourself with relevant regulations pertaining to different types of fabric used in your garments—this ensures that your products meet legal requirements while satisfying consumer expectations. Additionally, collaborating closely with manufacturers for clothing who prioritize compliance can streamline this process significantly. Ultimately, maintaining adherence to industry standards not only enhances product credibility but also fosters a culture of accountability within the supply chain.

Analyzing Quality Metrics

Analyzing quality metrics plays a vital role in assessing overall garment quality inspection outcomes effectively. These metrics provide insights into various aspects such as colorfastness, shrinkage rates, and seam strength—all critical factors influencing customer satisfaction and product longevity. By collecting data through systematic testing procedures across different types of fabric, brands can identify trends or recurring issues that may warrant further investigation.

Moreover, utilizing advanced technology during garment testing allows companies to gather precise measurements which lead to informed decision-making regarding production adjustments or material sourcing changes needed for improvement. Engaging with reliable manufacturers for clothing who embrace data-driven approaches will enhance your ability to analyze these metrics accurately over time. In summary, effective analysis not only informs future textile inspection practices but also drives continuous improvement initiatives within your organization.

Regularly Review Textile Inspection Processes

In the fast-paced world of fashion and textiles, regularly reviewing textile inspection processes is crucial for maintaining high standards in garment quality inspection. This entails not only assessing the effectiveness of current garment checking methods but also being proactive about improvements. By continuously refining these processes, manufacturers can ensure that they meet the evolving demands of consumers and industry regulations.

Continuous Improvement Strategies

Adopting continuous improvement strategies is essential for enhancing garment inspection practices. This could involve regular training sessions for staff on the latest garment checking methods or incorporating feedback from previous inspections to refine techniques further. Additionally, establishing a culture of quality within teams encourages everyone to take ownership of their role in ensuring that different types of fabric are inspected meticulously.

Another key aspect is to implement a feedback loop where insights from garment testing inform future inspections, ensuring that past mistakes don't recur. Utilizing data analytics can help identify patterns in defects across various types of fabric, guiding more targeted inspection efforts. Ultimately, this commitment to continuous improvement fosters a more robust quality control system among manufacturers for clothing.

Keeping Up with Industry Trends

Staying abreast of industry trends is vital for any business invested in textile inspection and garment quality assurance. New technologies and methodologies emerge regularly, providing innovative ways to enhance garment testing procedures and improve efficiency. By attending trade shows, participating in webinars, or subscribing to relevant publications, professionals can gain insights into the latest advancements affecting different types of fabric and their handling.

Moreover, understanding consumer preferences allows manufacturers for clothing to adapt their offerings accordingly while ensuring rigorous standards through effective garment inspection techniques. For instance, sustainable fabrics are gaining traction; thus, knowing how these materials behave during testing can lead to better quality outcomes. Keeping up with trends not only improves product offerings but also positions brands as leaders in quality assurance.

Utilizing Reports from China Inspection Pro

Reports from China Inspection Pro provide invaluable insights into textile inspection processes that can significantly enhance overall quality control measures within organizations focused on garment testing. These reports offer detailed assessments and benchmarks against industry standards which can help identify areas needing improvement or adjustment in current practices related to different types of fabric used by manufacturers for clothing.

By analyzing these reports regularly, businesses can make data-driven decisions that bolster their garment checking methods while addressing any inconsistencies found during inspections swiftly and effectively. Furthermore, incorporating findings from such reports into training programs ensures that all team members are aligned with best practices in textile inspection procedures tailored specifically for their unique contexts.

In conclusion, regularly reviewing textile inspection processes through continuous improvement strategies and staying updated on industry trends will substantially elevate your approach to garment quality inspection while utilizing valuable resources like reports from China Inspection Pro will streamline this journey toward excellence.

Conclusion

In the ever-evolving world of fashion, garment quality inspection is not just a checkbox; it's an essential part of the production process. By understanding various garment checking methods and their importance, businesses can ensure that they deliver only the best products to consumers. From identifying different types of fabric to implementing robust inspection techniques, every step plays a crucial role in maintaining high-quality standards.

Summarizing Garment Quality Inspection Essentials

Garment quality inspection revolves around several core principles: knowing your fabric, applying effective testing methods, and collaborating with reliable manufacturers for clothing. Understanding different types of fabric is vital as it directly impacts the durability and aesthetics of the final product. Moreover, employing systematic garment inspection techniques ensures that any issues are identified early on, saving time and resources in the long run.

Elevating Quality Through Effective Methods

To elevate quality through effective methods, brands must embrace both traditional textile inspection and modern technology in their processes. Visual inspections remain invaluable; however, integrating advanced garment testing technologies can significantly enhance accuracy and efficiency. By establishing clear standard operating procedures for garment checking methods, organizations can foster a culture of quality that permeates every level of production.

Next Steps for Your Inspection Journey

As you embark on your journey toward impeccable textile inspection practices, consider reviewing your current processes regularly to identify areas for improvement. Stay updated with industry trends and best practices to adapt quickly in this competitive market while ensuring compliance with industry standards through comprehensive testing protocols. With these strategies in place, you’ll be well-equipped to navigate the complexities of garment quality inspection successfully.