Introduction

In the world of industrial operations, ensuring the reliability and efficiency of pumps is paramount. Pump Quality Inspections serve as a critical checkpoint to assess the performance and longevity of these essential machines. By understanding how to conduct a Pump Quality Inspection, businesses can proactively address issues before they escalate into costly failures.

Understanding Pump Quality Inspections

Pump Quality Inspections encompass a series of assessments aimed at evaluating the condition and functionality of pumps. These inspections not only focus on detecting mechanical failures but also ensure compliance with industry standards and protocols for pump quality inspections. A thorough understanding of what these inspections entail is key to maintaining operational excellence.

Importance of Regular Pump Inspections

Regular pump inspections are vital for preventing unexpected breakdowns that can disrupt production schedules and lead to financial losses. By identifying common problems found in pump quality inspections early on, companies can implement timely maintenance strategies that enhance performance and extend equipment lifespan. Ultimately, investing in regular inspections translates into improved reliability and reduced downtime.

Overview of Inspection Services

Inspection services provide comprehensive evaluations that include everything from visual checks to detailed performance analyses. These services often utilize step-by-step pump inspection checklists, ensuring no crucial aspect is overlooked during assessments. Additionally, leveraging best practices for ensuring pump quality through professional inspection services can significantly improve overall operational efficiency while adhering to industry standards and protocols for pump quality inspections.

Fundamentals of Pump Quality Inspections

Understanding the fundamentals of Pump Quality Inspections is crucial for maintaining the efficiency and longevity of pumping systems. These inspections serve as a proactive measure to identify potential issues before they escalate into costly repairs or system failures. By grasping the essentials, businesses can ensure their pumps operate at peak performance and comply with industry regulations.

What is a Pump Quality Inspection?

A Pump Quality Inspection is a systematic evaluation designed to assess the mechanical integrity, operational efficiency, and overall condition of pumping systems. This inspection encompasses various components, including motors, seals, bearings, and impellers, ensuring that each part functions optimally within specified parameters. Regularly conducting these inspections helps in identifying Common Problems Found in Pump Quality Inspections early on, thereby reducing downtime and maintenance costs.

How to Conduct a Pump Quality Inspection

To conduct a thorough Pump Quality Inspection, one should begin with a comprehensive Step-by-Step Pump Inspection Checklist that outlines all necessary components to evaluate. Start by visually inspecting the pump for any signs of wear or damage; this includes checking for leaks around seals or abnormal vibrations during operation. Following this initial assessment, it's essential to measure performance metrics such as flow rate and pressure while comparing them against manufacturer specifications; this will provide insight into how well the pump is performing.

Importance of Compliance with Industry Standards

Compliance with Standards and Protocols for Pump Quality Inspections is not just about ticking boxes; it’s about ensuring safety and reliability in operations. Adhering to established industry standards helps mitigate risks associated with pump failures that could lead to environmental hazards or operational disruptions. Moreover, staying compliant not only enhances your reputation but also ensures you are leveraging Best Practices for Ensuring Pump Quality throughout your organization.

Standards and Protocols for Pump Quality Inspections

When it comes to ensuring optimal performance and longevity of pumps, understanding the standards and protocols for Pump Quality Inspections is crucial. These guidelines help maintain safety, efficiency, and compliance with industry regulations. By adhering to established standards, organizations can significantly reduce the risk of mechanical failures and enhance overall operational reliability.

Overview of Relevant Standards

The world of Pump Quality Inspections is governed by various standards that dictate how inspections should be conducted. Organizations such as the American National Standards Institute (ANSI) and the International Organization for Standardization (ISO) provide frameworks that ensure consistency in inspection processes. These standards not only outline technical requirements but also emphasize safety measures that must be adhered to during inspections.

In addition, industry-specific guidelines may also apply depending on the application of the pumps being inspected. For instance, pumps used in hazardous environments must comply with additional safety protocols to mitigate risks associated with leaks or failures. Understanding these relevant standards is essential for anyone involved in how to conduct a Pump Quality Inspection effectively.

Key Protocols to Follow

Following key protocols during Pump Quality Inspections can make all the difference between a routine check-up and a thorough evaluation that prevents future issues. First on the list is establishing a comprehensive Step-by-Step Pump Inspection Checklist tailored to specific pump types and applications; this ensures no critical component is overlooked during an inspection.

Another crucial protocol involves documenting findings meticulously; this documentation serves as a reference point for future inspections and aids in identifying trends over time—especially when addressing Common Problems Found in Pump Quality Inspections like leaks or unusual vibrations. Additionally, utilizing modern technology such as vibration analysis tools or thermal imaging cameras can greatly enhance accuracy during inspections.

Role of China Inspection Pro in Compliance

China Inspection Pro plays a pivotal role in helping organizations navigate the complexities of compliance related to Pump Quality Inspections. With their expertise in local regulations and international standards, they ensure that every inspection meets stringent quality benchmarks while minimizing potential liabilities for businesses.

Their services extend beyond mere compliance checks; they provide valuable insights into Best Practices for Ensuring Pump Quality through tailored inspection services designed specifically for various industries. By partnering with China Inspection Pro, companies can confidently manage their pump systems while staying ahead of any regulatory changes or industry advancements.

Common Problems Found in Pump Quality Inspections

When it comes to Pump Quality Inspections, identifying issues early can save time, money, and headaches down the line. Regular inspections are crucial for maintaining pump efficiency and longevity, but certain problems tend to crop up more frequently than others. In this section, we’ll delve into the common mechanical failures, signs of wear and tear, and how to troubleshoot these issues effectively.

Identifying Mechanical Failures

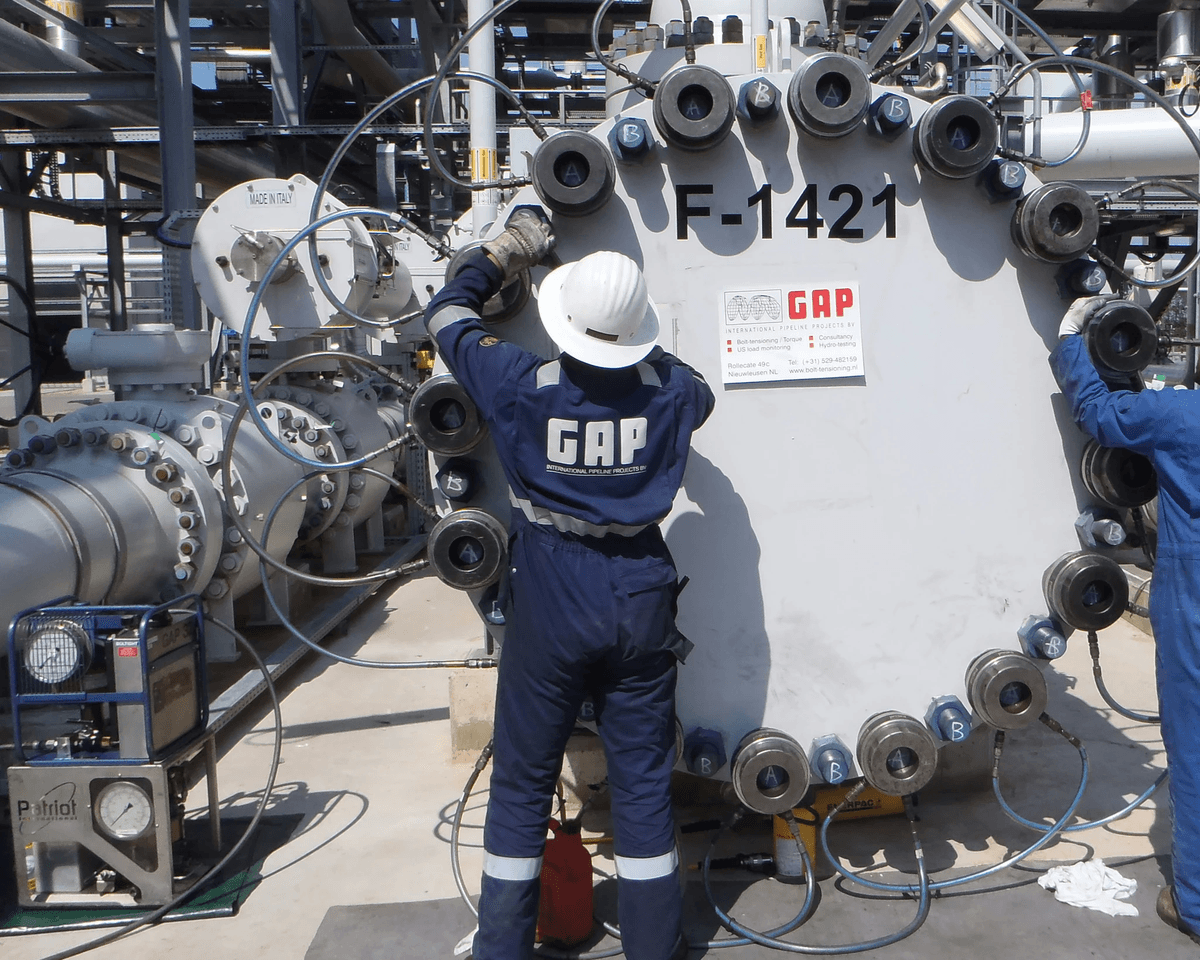

Mechanical failures are among the most critical concerns during Pump Quality Inspections. These failures often manifest as unusual noises, vibrations, or even leaks that can indicate internal problems such as misalignment or bearing wear. Knowing how to conduct a Pump Quality Inspection involves not only recognizing these symptoms but also understanding their implications for overall pump performance.

To pinpoint mechanical failures efficiently, inspectors should utilize diagnostic tools such as vibration analysis equipment and thermal imaging cameras. These technologies help in detecting irregularities that may not be visible to the naked eye. By adhering to established Standards and Protocols for Pump Quality Inspections during this phase, you ensure a thorough evaluation that can prevent catastrophic breakdowns.

Signs of Wear and Tear

Wear and tear are inevitable in any pumping system; however, recognizing the early signs can extend your equipment's lifespan significantly. During inspections, look out for corrosion on metal components or excessive buildup of debris around seals—both indicators that maintenance is overdue. Regularly checking these factors is essential when following your Step-by-Step Pump Inspection Checklist.

Another common sign of wear includes changes in operational efficiency; if a pump isn’t delivering its rated capacity or shows fluctuating pressure readings, it may be time for an inspection service intervention. Inspectors should also evaluate seals and gaskets for leaks since deterioration here often leads to larger issues down the line. By keeping an eye on these signs of wear and tear during routine inspections, you can implement Best Practices for Ensuring Pump Quality effectively.

Troubleshooting Common Issues

Troubleshooting common issues found during Pump Quality Inspections requires both skill and experience. Once mechanical failures or signs of wear are identified, it's crucial to determine whether they stem from improper installation or lack of maintenance practices over time. For instance, if a pump is vibrating excessively but shows no signs of physical damage upon inspection, it could be due to misalignment—a fixable issue if caught early.

When addressing these problems systematically through your inspection services framework—considering both immediate fixes and long-term solutions—you’ll enhance operational reliability significantly. Always refer back to compliance with industry standards while troubleshooting; this ensures that all repairs meet necessary safety guidelines while extending equipment life expectancy further than you'd expect!

In summary, being vigilant about identifying mechanical failures and recognizing signs of wear will empower you to troubleshoot effectively during your next round of Pump Quality Inspections.

Step-by-Step Pump Inspection Checklist

Conducting effective Pump Quality Inspections requires a structured approach to ensure all critical components are thoroughly assessed. This checklist will guide you through the essential items to inspect, documentation practices, and how technology can enhance the inspection process. Following these steps will not only help in identifying potential issues but also align with Standards and Protocols for Pump Quality Inspections.

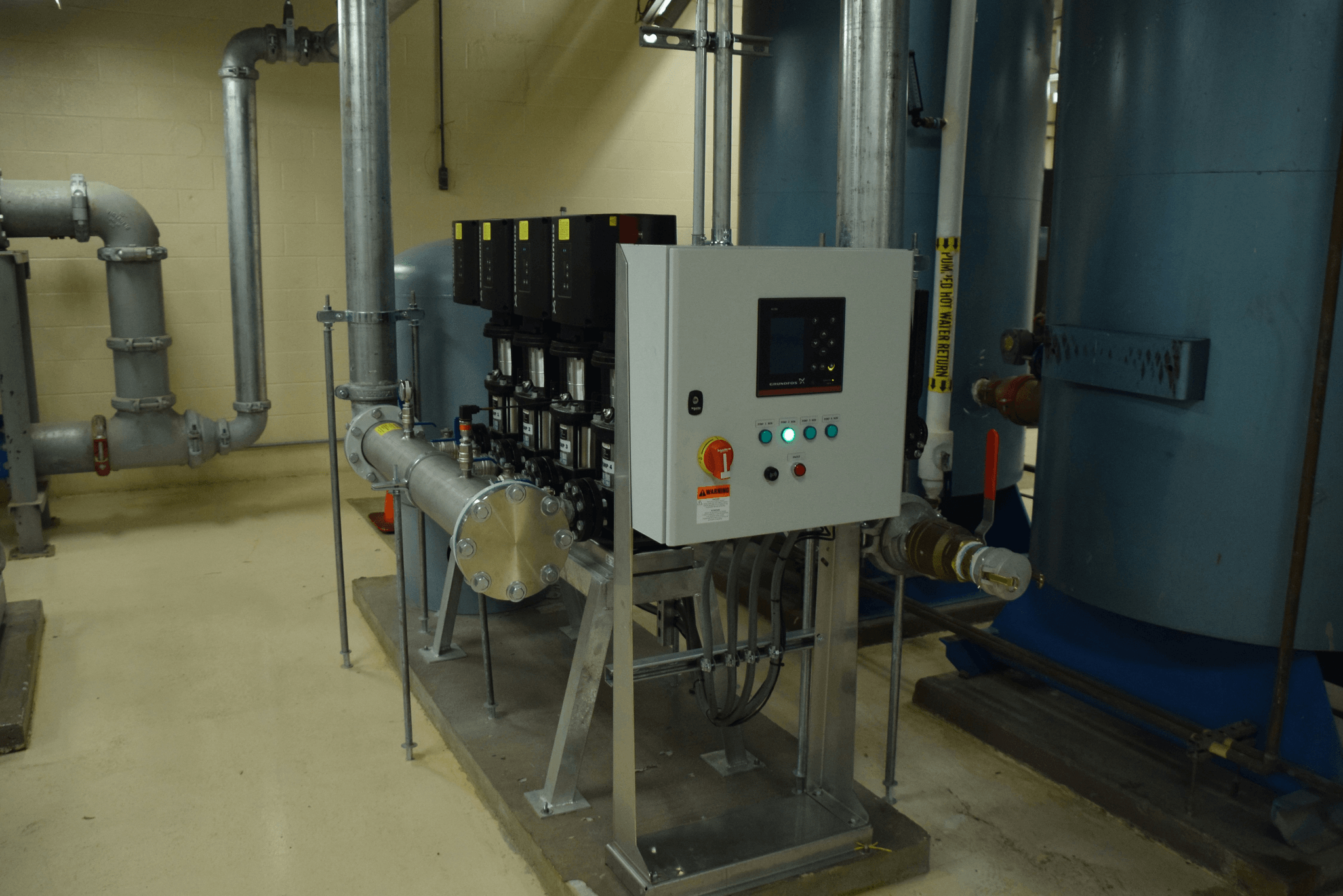

Essential Items to Inspect

When performing a Pump Quality Inspection, start by examining key components such as seals, bearings, and impellers. These parts are often prone to wear and tear, making them crucial for identifying Common Problems Found in Pump Quality Inspections. Additionally, check for leaks in piping connections and ensure that all electrical connections are secure; any irregularities here can lead to significant operational issues.

Don't forget to evaluate the pump's alignment and vibration levels, as misalignment can cause premature failure. It’s also wise to assess the lubrication system—insufficient lubrication is a common culprit behind mechanical failures in pumps. Lastly, reviewing operational parameters like flow rate and pressure will provide insights into the pump's overall performance.

Documentation and Reporting Guidelines

Documentation plays a pivotal role during Pump Quality Inspections as it provides a record of findings that can be referenced later for compliance or maintenance purposes. Ensure that every inspection detail is logged meticulously—from initial observations to final recommendations—this aligns with best practices for ensuring pump quality. Use standardized forms or digital tools designed specifically for inspections; this consistency aids in comparing data over time.

After completing your inspection checklist, compile your findings into a comprehensive report that highlights any issues discovered along with suggested corrective actions. This report should be clear enough for stakeholders who may not be familiar with technical jargon yet need an understanding of the pump's condition. Remember, effective communication through documentation can significantly enhance decision-making processes related to maintenance or upgrades.

Using Technology in Inspections

Incorporating technology into your Pump Quality Inspections can streamline processes and improve accuracy significantly. Tools such as infrared thermography cameras help detect thermal anomalies while ultrasonic leak detectors can identify leaks without direct contact—making these technologies invaluable assets during inspections. Furthermore, utilizing software designed for inspection services allows you to organize data efficiently while providing real-time updates on pump conditions.

Mobile applications can also facilitate on-site documentation by allowing inspectors to take notes directly on their devices while capturing images of any identified issues instantly—a great way to ensure nothing slips through the cracks! As technology continues evolving, leveraging these innovations will not only enhance your inspection capabilities but also align with industry standards more effectively.

Best Practices for Ensuring Pump Quality

When it comes to maintaining the efficiency and longevity of pumps, best practices are essential. Implementing a proactive approach to pump quality inspections can significantly reduce downtime and costly repairs. By focusing on regular maintenance, training, and leveraging professional inspection services, organizations can ensure optimal performance and compliance with industry standards.

Regular Maintenance Tips

Regular maintenance is the backbone of effective pump quality inspections. Establishing a routine schedule that includes visual checks, lubrication of moving parts, and monitoring of operating conditions helps in identifying potential issues before they escalate into serious problems. Additionally, keeping a detailed log of maintenance activities provides valuable insights into the pump's performance over time and aids in compliance with standards and protocols for pump quality inspections.

Don't forget that cleanliness is key; ensuring that the area around the pump is free from debris can prevent wear and tear on components. Always check for leaks or unusual noises during your inspections—these could be signs of common problems found in pump quality inspections that need immediate attention. Following a step-by-step pump inspection checklist can help streamline this process, ensuring no critical aspect is overlooked.

Training and Certification Importance

Investing in training and certification for personnel involved in conducting pump quality inspections cannot be overstated. Knowledgeable staff are better equipped to recognize mechanical failures or signs of wear during their evaluations, leading to more accurate assessments of equipment health. Moreover, understanding how to conduct a pump quality inspection according to established protocols ensures compliance with industry standards.

Certification programs also emphasize safety practices that protect both personnel and equipment during inspections. With proper training, employees can troubleshoot common issues effectively while adhering to best practices for ensuring pump quality throughout their operational life cycle. Ultimately, well-trained teams contribute significantly to maintaining high-quality standards within an organization.

Leveraging Professional Inspection Services

Experts who specialize in pump quality inspections bring valuable experience and advanced technology that can detect problems often missed by less experienced personnel. By leveraging these services regularly, organizations can stay ahead of potential issues before they evolve into major disruptions.

Professional inspectors follow established standards and protocols for pump quality inspections which ensures thoroughness in their evaluations—something that's vital given the complexity of modern pumping systems. They also provide detailed reports based on their findings along with actionable recommendations tailored specifically to each situation—a boon when dealing with common problems found in pump quality inspections like mechanical failures or inefficiencies due to wear over time.

In conclusion, embracing best practices such as regular maintenance tips combined with ongoing training enhances overall operational efficiency while utilizing professional inspection services ensures compliance with industry standards—ultimately leading towards improved reliability in your pumping operations.

Conclusion

In conclusion, understanding the significance of Pump Quality Inspections is essential for maintaining operational efficiency and safety in various industries. Regular inspections not only help identify potential issues before they escalate but also ensure compliance with established Standards and Protocols for Pump Quality Inspections. By adhering to best practices, organizations can effectively manage their pump systems, prolonging their lifespan and enhancing performance.

Key Takeaways on Pump Quality Inspections

First, knowing how to conduct a Pump Quality Inspection is crucial; it involves a systematic approach that encompasses visual checks, operational tests, and adherence to industry standards. Additionally, recognizing common problems found in pump quality inspections—such as mechanical failures or signs of wear—can aid in timely interventions that prevent costly downtimes.

How to Stay Compliant and Efficient

Staying compliant and efficient requires a proactive approach to pump maintenance and inspection services. Organizations should familiarize themselves with the relevant standards and protocols for pump quality inspections while implementing a step-by-step pump inspection checklist tailored to their specific needs. Furthermore, leveraging professional inspection services can provide valuable insights into best practices for ensuring pump quality while keeping operations running smoothly.

Future Trends in Pump Inspection Services

Looking ahead, future trends in pump inspection services are likely to be shaped by advancements in technology and data analytics. The integration of smart sensors and predictive maintenance tools will enhance the ability to conduct thorough inspections while identifying potential issues before they arise. As industries continue to prioritize efficiency and sustainability, embracing these innovations will be key for organizations aiming to uphold high standards in pump quality inspections.