Introduction

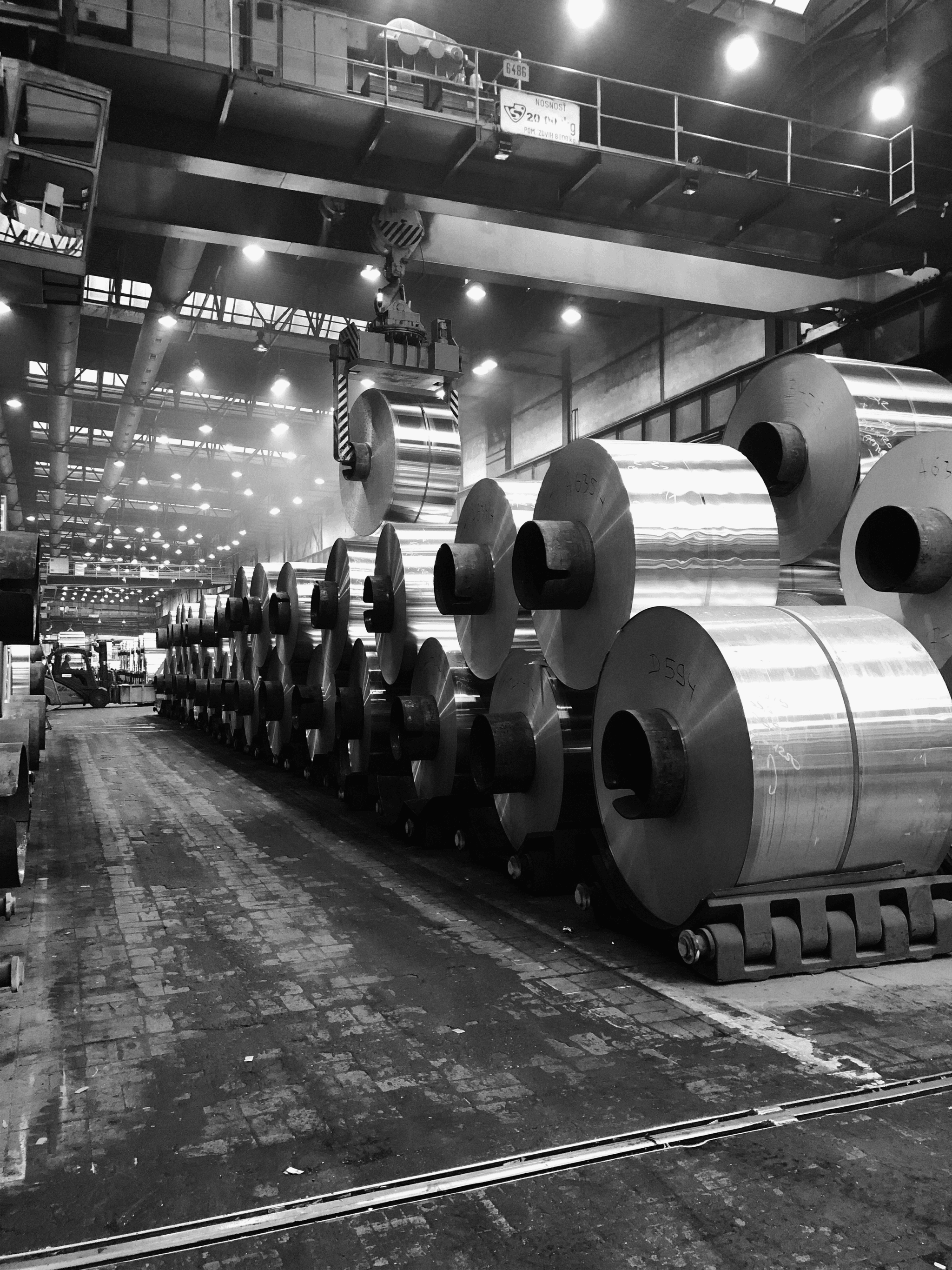

In the world of manufacturing, ensuring the integrity and reliability of products is paramount, especially when it comes to Aluminium Coil Quality Inspection. This process involves meticulous evaluation to guarantee that aluminium coils meet stringent quality control standards. By prioritizing quality testing services, manufacturers can enhance their production processes and deliver superior products to the market.

Understanding Aluminium Coil Quality Inspection

Aluminium Coil Quality Inspection is a systematic approach that assesses various aspects of aluminium coils, from surface finish to structural integrity. This inspection is crucial for identifying potential defects before they escalate into costly issues down the line. By employing effective quality engineering practices during this process, manufacturers can ensure that their products not only meet specifications but also exceed customer expectations.

The Importance of Quality Control Standards

Quality control standards serve as benchmarks in the manufacturing industry, guiding companies toward maintaining high-quality outputs consistently. These standards are essential for establishing trust with customers and stakeholders alike, as they reflect a commitment to excellence in quality management. Adhering to these guidelines not only improves product reliability but also fosters a culture of continuous quality improvement within organizations.

Key Defects to Avoid in Production

When it comes to aluminium coils, certain key defects can undermine product performance and lead to significant financial losses for manufacturers. Common issues include surface imperfections like scratches and dents, which can affect both aesthetics and functionality. Additionally, structural deficiencies such as warping or bending need careful monitoring during production processes to ensure compliance with quality testing protocols.

Overview of Quality Inspection Standards

Quality inspection standards are the backbone of Aluminium Coil Quality Inspection, ensuring that products meet specified requirements and expectations. These standards help manufacturers maintain quality control throughout the production process, minimizing defects and enhancing overall product reliability. By adhering to established quality testing services, companies can foster trust with clients and stakeholders alike.

International Standards for Aluminium Coils

International standards for aluminium coils serve as guidelines that define the acceptable criteria for quality and performance. Organizations such as the International Organization for Standardization (ISO) set these benchmarks to ensure consistent manufacturing practices across the globe. Adopting these standards in quality management not only improves product integrity but also facilitates smoother trade between countries.

Role of ISO and ASTM in Quality Testing

ISO and ASTM (American Society for Testing and Materials) play pivotal roles in establishing protocols for quality testing services related to aluminium coils. ISO provides a framework for quality engineering processes, while ASTM focuses on specific material properties and testing methods that help ascertain compliance with industry standards. Together, they create a comprehensive approach to quality inspection that enhances product reliability and safety.

Importance of Compliance in Quality Management

Compliance with international standards is critical in maintaining an effective quality management system within the aluminium industry. It ensures that all aspects of production align with established guidelines, which can significantly reduce risks associated with defects or failures. Moreover, adherence to these compliance measures often leads to improved customer satisfaction and loyalty—key components in any successful business strategy.

Common Defects in Aluminium Coils

When it comes to Aluminium Coil Quality Inspection, understanding common defects is essential for maintaining high standards in quality control. These defects can not only impact the functionality of the coils but also affect their marketability and overall performance. By identifying these issues early through rigorous quality testing services, manufacturers can implement effective quality management strategies to mitigate risks.

Surface Defects: Scratches and Dents

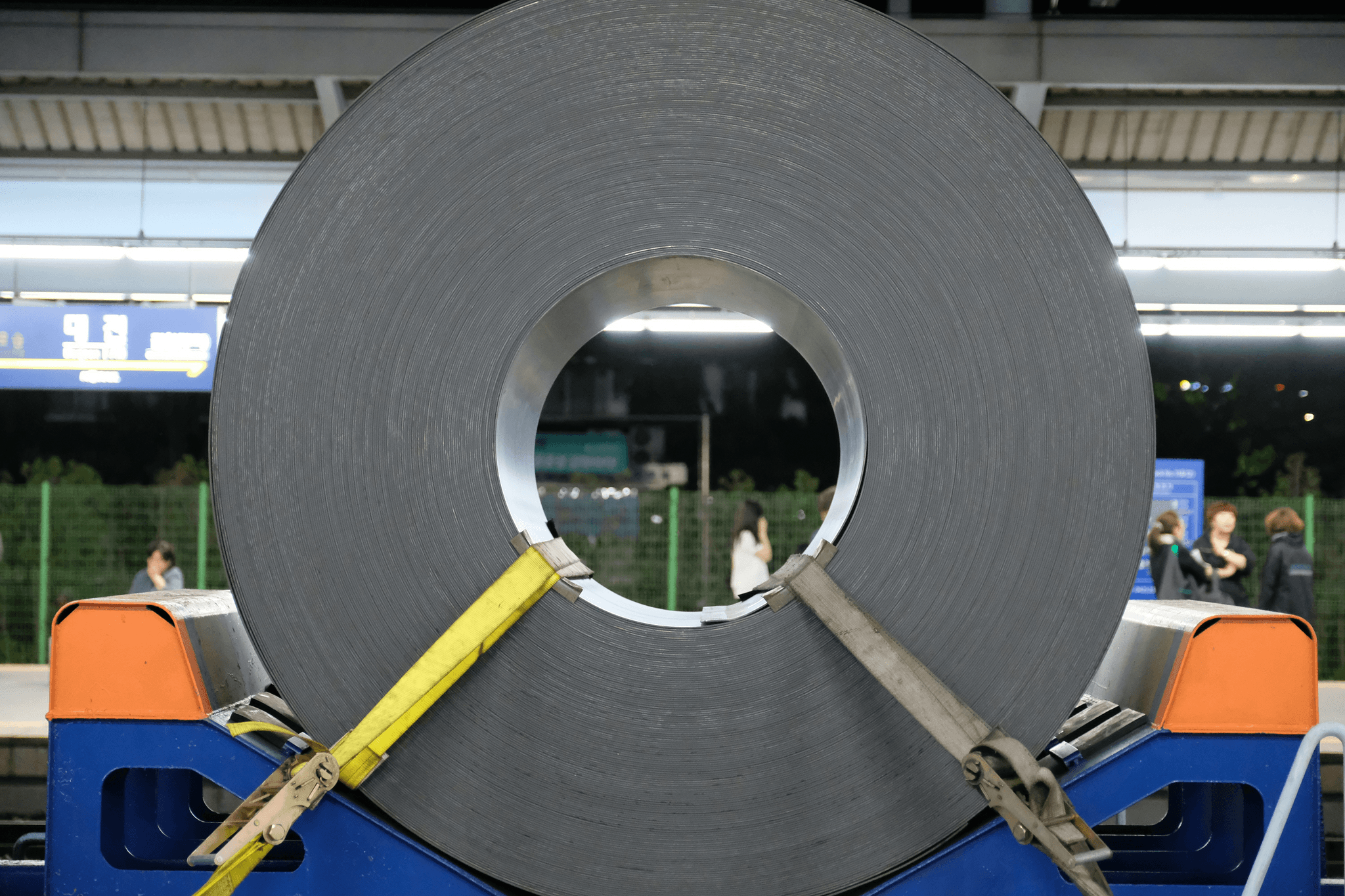

Surface defects such as scratches and dents are among the most visible issues that can arise during production or handling of aluminium coils. These imperfections not only detract from the aesthetic appeal but can also lead to further complications during subsequent processing or usage. Quality engineering techniques aim to minimize these surface issues by implementing better handling practices, protective coatings, and regular inspections throughout the manufacturing process.

To ensure that surface defects are caught early, manufacturers should establish a routine for thorough quality inspection at various stages of production. This includes using specialized tools and technologies designed for detecting such flaws before they escalate into larger problems. Ultimately, addressing surface defects promptly contributes significantly to overall quality improvement and enhances customer satisfaction.

Structural Deficiencies: Warping and Bending

Warping and bending are structural deficiencies that can compromise the integrity of aluminium coils significantly. These issues often arise due to improper handling or inadequate storage conditions, which may lead to deformation over time. Effective quality management practices involve monitoring environmental factors like temperature and humidity levels to prevent such structural anomalies from occurring.

Regular quality testing services should include assessments specifically targeting these structural concerns; this proactive approach enables manufacturers to identify potential weaknesses before they result in product failure. Moreover, employing advanced techniques in quality engineering allows for better design specifications that reduce susceptibility to warping or bending during both manufacturing and transportation phases.

By focusing on preventing structural deficiencies through meticulous planning and execution, companies can maintain high standards of aluminium coil performance while ensuring compliance with industry regulations.

Chemical Composition: Impurities and Oxidation

The chemical composition of aluminium coils plays a critical role in determining their overall performance characteristics; impurities or oxidation can severely weaken the material's strength and durability. Contaminants introduced during production processes may lead to unexpected failures down the line if not properly managed through stringent quality inspection protocols. Ensuring purity requires adherence to strict guidelines laid out by relevant product certification bodies.

To combat oxidation—a common issue especially when coils are exposed to moisture—quality management systems must incorporate protective measures such as proper packaging materials or surface treatments that inhibit corrosion potential over time. Regular sampling methods should be employed as part of a robust routine for chemical composition analysis within established quality testing services frameworks aimed at maintaining optimal material integrity.

In conclusion, understanding these common defects—surface imperfections like scratches, structural deficiencies such as warping, and chemical composition challenges—is crucial for effective Aluminium Coil Quality Inspection strategies geared towards long-term success in manufacturing excellence.

Best Practices for Quality Control

Ensuring high standards in Aluminium Coil Quality Inspection requires a robust approach to quality control. It’s not just about meeting the minimum requirements; it’s about embedding quality into every step of production. By adopting best practices, manufacturers can significantly reduce defects and enhance overall product reliability.

Implementing Quality Engineering Techniques

Quality engineering techniques are essential for optimizing Aluminium Coil Quality Inspection processes. These methods focus on systematically identifying potential issues before they become significant problems, ensuring that quality control measures are proactive rather than reactive. Techniques such as Failure Mode and Effects Analysis (FMEA) can help pinpoint vulnerabilities in production, allowing teams to implement corrective actions early and improve the overall quality management system.

Moreover, embracing statistical process control (SPC) can provide real-time insights into production processes, enabling manufacturers to monitor variations and maintain consistent quality levels. By integrating these engineering techniques, companies not only elevate their product certification chances but also foster a culture of continuous quality improvement among their teams.

Regular Quality Testing Services Protocols

Regular quality testing services are crucial for maintaining the integrity of aluminium coils throughout the manufacturing process. Implementing standardized testing protocols ensures that each batch meets established specifications and adheres to international standards for Aluminium Coil Quality Inspection. This systematic approach helps identify any deviations early on, minimizing waste and enhancing customer satisfaction.

Incorporating a variety of tests—such as tensile strength assessments, surface defect examinations, and chemical composition analysis—provides a comprehensive view of product quality. Establishing a routine schedule for these tests reinforces accountability within the team while promoting an environment where quality control is prioritized at every stage of production.

Training Staff on Quality Improvement Practices

Investing in staff training is vital for fostering a culture of excellence in aluminium coil production. Employees equipped with knowledge about quality improvement practices are more likely to take ownership of their roles in ensuring top-notch Aluminium Coil Quality Inspection outcomes. Regular workshops and training sessions can keep staff updated on industry best practices while empowering them to identify areas needing enhancement within the production line.

Additionally, cross-training employees across various functions enhances their understanding of how different processes impact overall product quality management. This holistic approach not only boosts morale but also cultivates a workforce committed to achieving high standards in every aspect of aluminium coil production.

The Role of Third-Party Inspection

In the realm of Aluminium Coil Quality Inspection, third-party inspections have become a cornerstone for ensuring product excellence. These independent evaluations offer an unbiased perspective on quality control, helping manufacturers identify defects and areas for improvement that internal teams might overlook. By leveraging professional quality testing services, companies can enhance their reputation and ensure compliance with industry standards.

Benefits of Choosing China Inspection Pro

Choosing China Inspection Pro for your Aluminium Coil Quality Inspection needs comes with numerous advantages. This organization specializes in quality engineering and offers comprehensive quality testing services that are tailored to meet specific production requirements. Their expertise not only helps in identifying defects early but also aids in implementing effective quality management strategies that can lead to substantial cost savings in the long run.

Moreover, China Inspection Pro employs highly trained professionals who understand the nuances of quality control within the aluminium industry. They utilize advanced technology and methodologies to perform thorough assessments, ensuring that every coil meets stringent standards before it reaches the market. This commitment to excellence is crucial for manufacturers looking to bolster their quality improvement initiatives.

How Third-Party Inspections Enhance Trust

The presence of a reputable third-party inspection service like China Inspection Pro significantly enhances trust among stakeholders in the supply chain. When customers know that an independent entity has verified the integrity and quality of aluminium coils, they are more likely to engage with suppliers confidently. This trust is pivotal in fostering long-term relationships between manufacturers and clients, leading to repeat business and referrals.

Additionally, third-party inspections provide documented evidence of compliance with international standards, which is essential for product certification processes. This transparency not only reassures customers but also positions companies as leaders in quality management within their respective markets. As a result, businesses can differentiate themselves from competitors by showcasing their commitment to rigorous inspection protocols.

Success Stories of Improved Quality Management

Many companies have experienced remarkable improvements in their Aluminium Coil Quality Inspection processes through collaboration with third-party inspectors like China Inspection Pro. One notable success story involves a manufacturer who faced persistent issues with surface defects such as scratches and dents on their coils. After engaging a third-party inspection service, they implemented targeted interventions based on detailed reports from inspections, resulting in a dramatic reduction in defect rates.

Another case highlights how a company improved its structural integrity by addressing warping issues identified during routine inspections by external experts. By refining their manufacturing processes based on these insights, they not only enhanced product reliability but also gained valuable certifications that boosted marketability across diverse sectors. These success stories illustrate how embracing third-party inspections can lead to significant advancements in overall quality improvement initiatives.

Product Certification in the Aluminium Industry

In the competitive landscape of the aluminium industry, product certification plays a pivotal role in ensuring quality assurance. It serves as a testament to adherence to established quality control standards and practices, which is essential for maintaining customer trust. When manufacturers prioritize certification, they not only enhance their reputation but also contribute to continuous quality improvement throughout their operations.

Why Certification Matters for Quality Assurance

Certification matters significantly because it establishes a benchmark for quality management that stakeholders can rely on. It provides assurance that aluminium coils meet rigorous standards of safety and performance, thereby reducing the risk of defects during production. Furthermore, certified products are often subjected to comprehensive quality testing services that ensure consistency and reliability across batches.

Beyond mere compliance, certification fosters a culture of quality engineering within organizations. By adhering to recognized standards, manufacturers are encouraged to implement best practices in their production processes. This commitment ultimately leads to fewer issues related to aluminium coil quality inspection and enhances overall product integrity.

Navigating the Certification Process

Navigating the certification process can seem daunting at first glance, but it is crucial for achieving high-quality products in the aluminium sector. The journey typically begins with understanding specific requirements set forth by relevant certifying bodies such as ISO or ASTM. Manufacturers must prepare documentation detailing their processes and demonstrate compliance through thorough audits and inspections.

Once initial assessments are completed, companies must invest time in training staff on quality improvement practices that align with certification criteria. This includes implementing effective quality control measures and conducting regular internal audits to ensure ongoing compliance with established standards. By fostering an environment focused on continuous improvement, companies position themselves favorably for successful product certification.

Impact of Certification on Marketability

The impact of product certification on marketability cannot be overstated; it opens doors to new business opportunities and enhances brand credibility among consumers. Certified aluminium coils often command higher prices due to perceived value associated with rigorous quality inspection processes they have undergone. As clients increasingly seek reliable suppliers who prioritize product integrity, having certifications becomes a strategic advantage in competitive bidding situations.

Moreover, certified products can lead to long-term partnerships with clients who value consistent performance over time—an essential aspect of successful business relationships in any industry. By investing in product certification and showcasing these credentials prominently in marketing efforts, manufacturers can effectively differentiate themselves from competitors who may not prioritize such rigorous standards for aluminium coil quality inspection.

Conclusion

In the ever-evolving landscape of the aluminium industry, effective strategies for quality improvement are paramount. Prioritizing Aluminium Coil Quality Inspection not only helps in identifying defects early but also fosters a culture of excellence among teams. By integrating quality control measures into every stage of production, companies can ensure that their products meet or exceed market expectations.

Strategies for Effective Quality Improvement

To drive quality improvement, organizations must adopt a proactive approach to quality testing services and quality engineering practices. Implementing regular audits and feedback loops allows teams to identify areas needing enhancement swiftly. Moreover, fostering an environment where employees feel empowered to suggest improvements plays a crucial role in maintaining high-quality standards.

Building a Robust Quality Management System

A robust quality management system is essential for ensuring consistent results across all processes involved in aluminium coil production. This system should encompass thorough documentation of procedures, employee training on best practices, and adherence to established quality inspection protocols. By investing in comprehensive training programs and utilizing advanced technology for monitoring processes, businesses can significantly enhance their overall operational efficiency.

Future Trends in Aluminium Coil Quality Inspection

Looking ahead, the future of Aluminium Coil Quality Inspection will likely be shaped by advancements in technology and automation. The integration of AI and machine learning will revolutionize how we approach quality control by enabling real-time monitoring and predictive analytics for potential defects. Additionally, increased emphasis on sustainability will push manufacturers to adopt greener practices while ensuring compliance with stringent product certification standards.