Introduction

In the fast-paced world of manufacturing and service delivery, maintaining high standards is not just a luxury—it's a necessity. This is where Quality Assurance (QA) and Quality Control (QC) come into play, serving as pivotal frameworks that ensure products and services meet defined criteria. Understanding QA and QC monitoring is crucial for businesses aiming to enhance their operational efficiency and customer satisfaction while adhering to standards like ISO 9001.

Understanding QA and QC Monitoring

Quality Assurance focuses on preventing defects through planned processes, while Quality Control aims to identify defects in finished products. Together, they form a comprehensive quality control system that not only safeguards product integrity but also boosts consumer trust. Utilizing quality control monitoring equipment allows organizations to track compliance with these processes effectively, ensuring that both QA and QC are seamlessly integrated into daily operations.

Importance of Quality Assurance

The significance of Quality Assurance cannot be overstated; it lays the groundwork for consistent quality by establishing systematic processes and procedures. By implementing QA strategies aligned with ISO 9001 standards, organizations can streamline operations and enhance overall productivity. This proactive approach helps in minimizing errors before they occur, ultimately leading to reduced costs associated with rework or customer complaints.

The Role of Quality Control

Quality Control plays an essential role by providing a safety net that catches any deviations from established quality standards during production or service delivery. Through rigorous testing and evaluation methods, including effective quality auditing practices, businesses can ensure their outputs meet customer expectations consistently. Moreover, investing in advanced quality control monitoring equipment empowers companies to detect issues early on, allowing for timely corrective actions that maintain product excellence.

What is Quality Assurance?

Quality Assurance (QA) is a systematic process that ensures products and services meet specified requirements and standards. It encompasses all activities that establish quality policies, objectives, and responsibilities to enhance customer satisfaction through consistent quality improvement. The purpose of QA is not just to catch defects but to prevent them from occurring in the first place, creating a robust framework for quality control.

Definition and Purpose

At its core, Quality Assurance refers to the processes designed to ensure that the quality of a product or service meets certain standards before it reaches the consumer. This proactive approach focuses on preventing defects rather than merely identifying them post-production. By implementing effective QA strategies, organizations can enhance their reputation, reduce costs associated with rework and returns, and ultimately foster customer loyalty.

Key Components of QA

The key components of Quality Assurance include defining clear quality standards, implementing training programs for staff, conducting regular audits, and utilizing quality control monitoring equipment effectively. These elements work together to create a cohesive system where processes are continuously monitored for compliance with established criteria. Additionally, feedback loops are essential for refining these processes based on real-world performance data.

ISO 9001 and Its Relevance

ISO 9001 is an internationally recognized standard that outlines the criteria for a quality management system (QMS). It emphasizes a process-oriented approach that integrates various aspects of business operations while ensuring continuous improvement through effective quality auditing practices. Adopting ISO 9001 not only demonstrates an organization’s commitment to maintaining high-quality standards but also enhances credibility in competitive markets by showcasing adherence to rigorous quality control systems.

Exploring Quality Control

Quality control (QC) is the backbone of any production process, ensuring that products meet specific standards and requirements. It encompasses various activities aimed at detecting defects and ensuring that the final output aligns with customer expectations and regulatory standards. By implementing a robust quality control system, organizations can enhance their reputation, reduce costs associated with returns, and improve overall efficiency.

Definition and Objectives

At its core, quality control refers to the systematic processes employed to monitor and maintain product quality throughout the manufacturing cycle. The primary objective of QC is to identify any deviations from desired specifications before products reach consumers, thereby minimizing defects and enhancing customer satisfaction. A well-implemented quality control system not only ensures compliance with industry standards like ISO 9001 but also fosters continuous improvement in production processes.

Quality Control vs. Quality Assurance

While often used interchangeably, quality control and quality assurance (QA) serve distinct purposes within an organization’s framework. Quality assurance focuses on establishing processes that prevent defects through proactive measures, while quality control zeroes in on identifying defects in finished products through inspections and testing. Understanding this difference is crucial for businesses aiming to create a comprehensive approach to maintaining high-quality standards; both elements work hand-in-hand to ensure optimal outcomes.

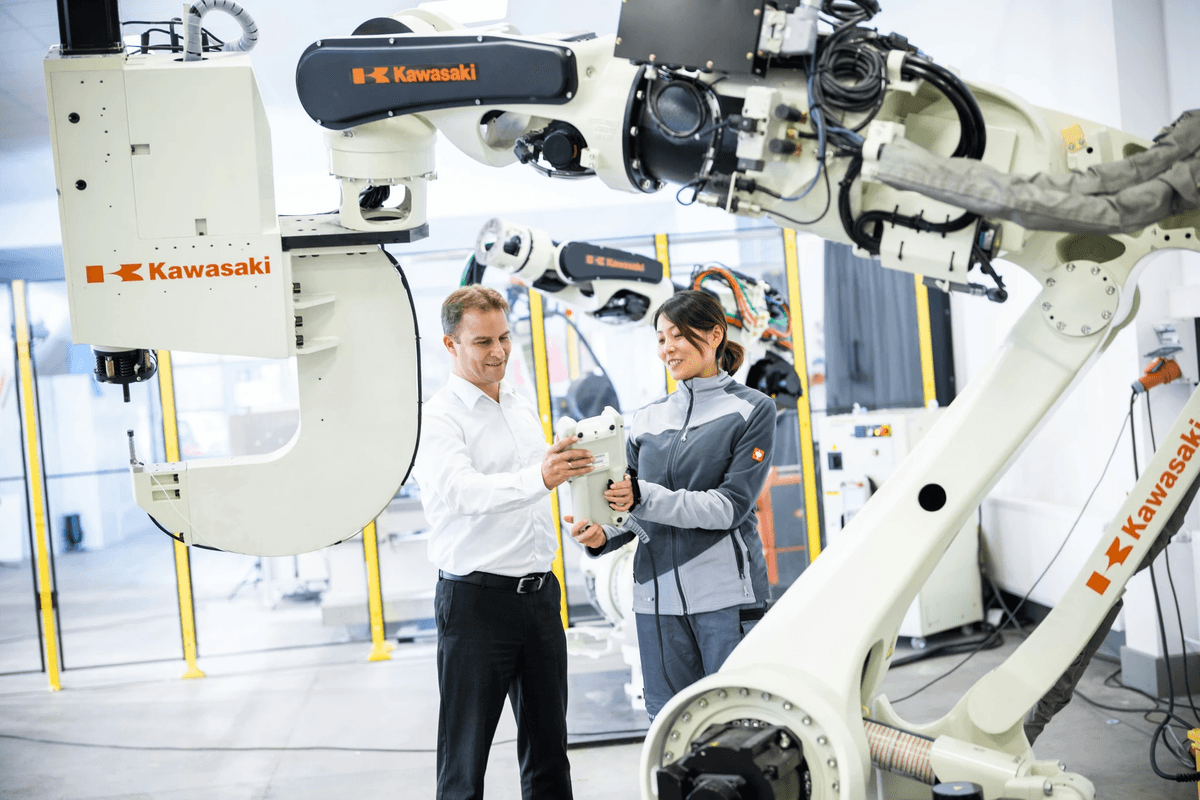

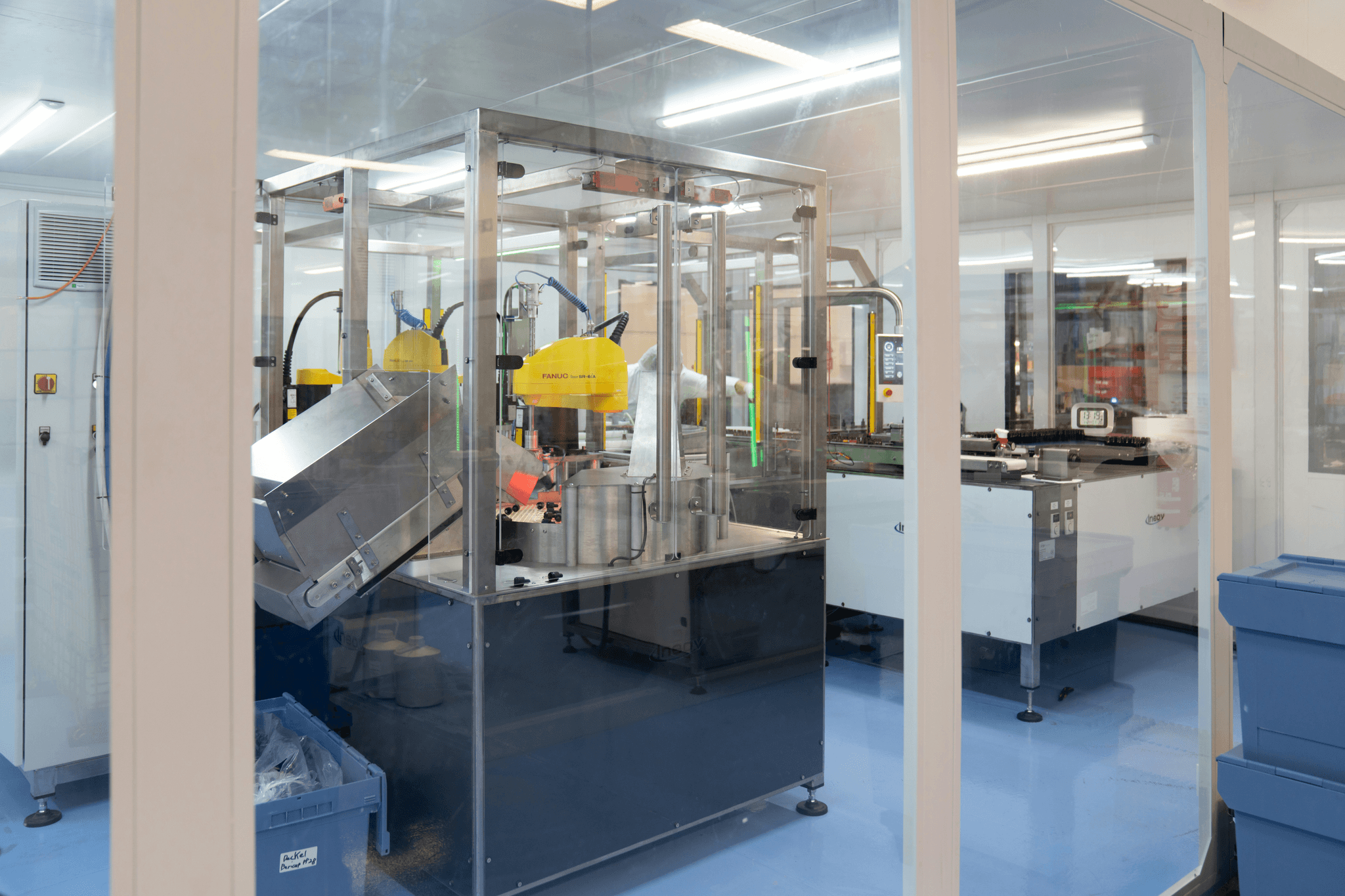

Importance of Quality Control Monitoring Equipment

Quality control monitoring equipment plays a pivotal role in ensuring that products meet established specifications during the production process. This equipment ranges from simple gauges to sophisticated automated systems designed for real-time monitoring of various parameters affecting product quality. Investing in advanced QC tools not only enhances accuracy but also streamlines operations by providing immediate feedback for corrective actions—a necessity for effective audit quality control practices within any organization striving for excellence.

The Interplay Between QA and QC

Quality Assurance (QA) and Quality Control (QC) are two sides of the same coin, working in tandem to ensure that products meet the highest standards. While QA focuses on preventing defects through systematic processes, QC is all about identifying and correcting defects in finished products. This interplay is crucial for a robust quality control system that not only adheres to ISO 9001 standards but also enhances overall operational efficiency.

How QA Supports QC

Quality Assurance lays the groundwork for effective Quality Control by establishing protocols that guide production processes. By implementing ISO 9001 standards, organizations can create a structured framework that ensures consistency in quality across all stages of production. This proactive approach means that when it comes time for quality auditing, the foundation has already been set, making it easier to identify areas needing improvement within the quality control monitoring equipment.

The relationship between QA and QC can be likened to a well-oiled machine; without proper maintenance (QA), even the best monitoring equipment can fail to deliver accurate results. When QA processes are properly executed, they provide valuable data that informs QC practices, allowing for timely interventions when issues arise. Ultimately, this synergy not only boosts product quality but also fosters a culture of continuous improvement.

Benefits of Integration

Integrating QA and QC leads to numerous benefits that extend beyond mere compliance with ISO 9001 regulations. One significant advantage is enhanced product reliability; when both systems work together seamlessly, businesses can reduce variability in their outputs while increasing customer satisfaction levels. Additionally, this integration streamlines operations by minimizing redundancies—saving both time and resources.

Another key benefit lies in cost reduction: by addressing potential issues early through effective quality auditing practices within the integrated system, companies can avoid costly recalls or rework later on down the line. Furthermore, having a cohesive strategy allows organizations to utilize their quality control monitoring equipment more effectively—ensuring they're always operating at peak performance levels without unnecessary expenditure on additional resources or training.

Case Studies in Successful Implementation

Numerous companies have successfully demonstrated how integrating QA and QC can transform operations into models of efficiency and effectiveness. For instance, a leading automotive manufacturer adopted an integrated approach based on ISO 9001 principles; they reported reduced defect rates by over 30% within just one year of implementation thanks to improved communication between their QA teams and QC inspectors. This collaboration allowed them to fine-tune their quality control monitoring equipment based on real-time feedback from production lines.

In another case study involving a pharmaceutical company, integrating these two disciplines resulted in streamlined compliance with regulatory requirements while enhancing overall product safety—a critical factor in an industry where lives depend on high-quality outputs. By investing in robust audit quality control measures alongside their existing protocols, they were able to maintain rigorous oversight without compromising efficiency or incurring excessive costs.

These examples highlight how embracing an integrated approach not only meets stringent industry standards but also positions companies as leaders within their sectors—ultimately translating into increased market share and customer loyalty.

Quality Auditing: A Deep Dive

Quality auditing is a critical component of any effective quality control system. It serves as a systematic examination of a quality system or its components to ensure compliance with established standards, such as ISO 9001. By conducting regular audits, organizations can identify areas for improvement and verify that their quality control processes are functioning as intended.

What is Quality Auditing?

At its core, quality auditing involves the evaluation of an organization’s adherence to its own policies and procedures, as well as external standards like ISO 9001. This process not only assesses compliance but also examines the efficiency and effectiveness of the quality control measures in place. By identifying gaps or weaknesses in the quality control system, organizations can implement corrective actions that enhance overall performance.

Quality auditing can take several forms—internal audits conducted by employees or external audits performed by third-party organizations. Regardless of who conducts them, these audits focus on verifying that quality control monitoring equipment is properly utilized and maintained to ensure accurate results. In essence, effective quality auditing helps businesses maintain high standards while continuously improving their processes.

Steps of a Quality Audit

Conducting a successful quality audit involves several key steps that ensure thoroughness and reliability in findings. The first step is planning the audit, which includes defining the scope, objectives, and criteria based on relevant standards like ISO 9001. This initial phase sets the stage for what will be examined during the audit process.

Next comes executing the audit itself—collecting evidence through interviews, observations, and reviewing documents related to the quality control system in place. During this stage, auditors pay close attention to how well employees use their quality control monitoring equipment and whether these tools align with established practices.

Finally, after gathering all necessary information, auditors analyze their findings and compile them into an audit report detailing strengths and weaknesses within the organization’s practices. This report serves as a roadmap for improvement initiatives aimed at enhancing both compliance with regulations like ISO 9001 and overall product quality.

Audit Quality Control Best Practices

To maximize the effectiveness of any audit process, certain best practices should be followed consistently across all assessments. First among these is ensuring auditor independence; having impartial auditors helps eliminate biases that could skew results or interpretations of data regarding your quality control systems.

Another crucial practice involves maintaining clear communication throughout each phase of the audit—before it begins (to set expectations), during (to clarify findings), and after (to discuss recommendations). Such transparency fosters collaboration between auditors and staff members while promoting buy-in for necessary changes identified through analysis.

Lastly, leveraging technology can significantly enhance audit effectiveness; utilizing advanced software solutions allows for better tracking of findings related to your organization's use of quality control monitoring equipment over time while streamlining reporting processes too! By adhering to these best practices consistently across all audits conducted within your organization’s framework will ultimately lead you towards achieving higher levels of compliance with industry standards like ISO 9001.

Benefits of a Robust QC System

In today’s competitive landscape, having a robust quality control (QC) system is essential for any organization aiming to thrive. A well-implemented QC system not only enhances product quality but also fosters customer satisfaction and reduces costs associated with waste. By integrating quality control monitoring equipment and adhering to ISO 9001 standards, businesses can streamline their processes and achieve remarkable results.

Enhancing Product Quality

A robust QC system significantly enhances product quality by ensuring that every item meets established standards before reaching the consumer. Utilizing advanced quality control monitoring equipment allows organizations to detect defects early in the production process, minimizing the risk of substandard goods hitting the market. Moreover, regular quality auditing helps maintain compliance with ISO 9001, reinforcing a culture of continuous improvement and attention to detail.

With a focus on enhancing product quality, companies can build a strong reputation for reliability and excellence. This commitment not only attracts new customers but also retains existing ones who appreciate consistent high-quality products. Ultimately, investing in an effective QC system translates to fewer returns and complaints, which is music to any business's ears.

Improving Customer Satisfaction

Customer satisfaction is paramount for any business aiming for long-term success, and a robust QC system plays a crucial role in achieving this goal. When organizations prioritize quality control through systematic monitoring and audits, they ensure that customers receive products that meet or exceed expectations. As word spreads about reliable products backed by solid quality assurance practices, customer loyalty naturally grows.

Moreover, implementing ISO 9001 principles within the QC framework provides an added layer of trust for consumers who value transparency and accountability in their purchases. Satisfied customers are more likely to become repeat buyers and recommend your brand to others—a powerful marketing tool that no amount of advertising can replicate! Therefore, investing in effective quality control not only enhances product offerings but also builds lasting relationships with clients.

Reducing Costs and Wastage

A well-structured QC system contributes significantly to reducing costs associated with production inefficiencies and wastage. By employing cutting-edge quality control monitoring equipment during manufacturing processes, businesses can identify flaws early on—saving both time and resources that would otherwise be spent rectifying issues post-production. This proactive approach minimizes waste while optimizing resource allocation throughout the supply chain.

Additionally, regular quality auditing ensures adherence to established protocols which further curtails unnecessary expenses related to non-compliance or rework efforts due to overlooked defects. The result? A leaner operation where every dollar counts! Ultimately, reducing costs not only boosts profitability but also allows companies more flexibility in pricing strategies—benefiting both the organization and its customers alike.

Conclusion

In the realm of quality assurance and quality control, understanding the nuances between these two vital processes is essential for any organization striving for excellence. Quality control monitoring equipment plays a pivotal role in ensuring that products meet established standards, while ISO 9001 provides a framework to guide these efforts systematically. Ultimately, effective quality auditing can illuminate areas for improvement, ensuring that both QA and QC work harmoniously together.

Key Insights on QA and QC Monitoring

Quality assurance (QA) and quality control (QC) are not just buzzwords; they are foundational elements of a successful business strategy. A robust quality control system is necessary to monitor processes and ensure compliance with industry standards like ISO 9001, which emphasizes continuous improvement and customer satisfaction. Through effective quality auditing practices, organizations can identify gaps in their systems, leading to enhanced product integrity and operational efficiency.

The Role of Quality Control Systems

A well-implemented quality control system acts as the backbone of any manufacturing or service-oriented organization. It ensures that products not only meet but exceed customer expectations by utilizing advanced quality control monitoring equipment designed for precision tracking and analysis. By integrating comprehensive audit quality control measures into their operations, businesses can proactively address potential issues before they escalate into costly problems.

How China Inspection Pro Can Help

China Inspection Pro specializes in offering tailored solutions for businesses seeking to enhance their QA and QC processes through state-of-the-art technology and expertise. By leveraging our extensive experience in implementing ISO 9001 standards alongside cutting-edge quality control monitoring equipment, we empower organizations to elevate their product offerings significantly. With our support in conducting thorough quality audits, we help clients achieve lasting improvements that translate into increased customer satisfaction and reduced operational costs.