Introduction

In the realm of manufacturing and service industries, the terms inspection and quality control often get tossed around like confetti at a parade. However, understanding the difference between inspection and quality control is crucial for any organization aiming to maintain high standards. While both play vital roles in ensuring product quality, they serve different purposes and employ distinct methodologies.

Understanding Inspection vs. Quality Control

At its core, inspection is about evaluating products or services to ensure they meet specific standards or criteria. It is a snapshot in time—a check-up that highlights whether something passes muster or not. In contrast, quality control encompasses a broader range of processes aimed at preventing defects before they happen, focusing on continuous improvement rather than just assessment.

Importance of Quality in Industries

Quality isn't just a buzzword; it's the lifeblood of successful businesses across various sectors. Companies that prioritize quality assurance see improved customer satisfaction, reduced costs associated with rework, and enhanced brand reputation—essentially making quality control a cornerstone of their operational strategy. The ripple effect of maintaining high-quality standards can lead to increased market share and long-term profitability.

Role of China Inspection Pro

Enter China Inspection Pro: your trusty sidekick in navigating the labyrinth of quality management in manufacturing environments, especially when dealing with overseas production. This organization specializes in providing comprehensive quality inspections tailored to meet international standards while ensuring compliance with local regulations. By leveraging their expertise in quality assurance testing and company quality control practices, businesses can confidently venture into new markets without compromising on product integrity.

The Basics of Inspection

Inspection is a cornerstone of quality management that ensures products meet specified standards before they reach consumers. Its primary purpose is to identify defects or deviations from quality assurance benchmarks, ultimately safeguarding customer satisfaction and brand reputation. Understanding the nuances of inspection can help businesses navigate the complex landscape of quality control effectively.

Definition and Purpose

At its core, inspection involves examining products or processes to verify compliance with established criteria. This process serves as a critical checkpoint in the production cycle, enabling companies to catch issues early and prevent costly recalls or customer dissatisfaction later on. The difference between inspection and quality control lies in their focus; while inspection is about detecting flaws, quality control encompasses broader strategies for maintaining overall product integrity.

Types of Quality Inspections

Quality inspections come in various forms, each tailored to specific stages of production or types of products. Common types include pre-production inspections, during-production inspections, and final random inspections. Each type plays a vital role in ensuring that company quality control measures are effective throughout the entire manufacturing process.

Tools and Techniques Used

A variety of tools and techniques are employed during quality inspections to ensure thoroughness and accuracy. These can range from simple checklists to advanced technologies like automated vision systems that detect defects at lightning speed. By utilizing these tools effectively, companies can enhance their quality assurance practices while minimizing the risk associated with product failures.

What is Quality Control?

Quality control (QC) is a systematic process aimed at ensuring that products and services meet specific quality standards. It involves the identification of defects and the implementation of corrective actions to prevent issues from arising in the future. Understanding quality control is crucial for businesses as it directly impacts customer satisfaction, operational efficiency, and overall product success.

Definition and Importance

Quality control refers to the procedures and activities used to ensure that a company's products or services adhere to defined quality standards. It's essential because it helps businesses maintain consistency, reduce waste, and enhance customer trust by delivering reliable products. The importance of quality control cannot be overstated; without it, companies risk producing subpar goods that may lead to financial losses or damage to their reputation.

Components of Quality Control

The components of quality control typically include inspection, testing, and measurement processes designed to identify defects before they reach the customer. These elements work together seamlessly; for instance, regular quality inspections help catch issues early on while ongoing testing ensures that production methods remain effective over time. Additionally, documentation plays a vital role in QC as it provides data for analysis and continuous improvement efforts.

How It Differs from Quality Assurance

While both quality control and quality assurance (QA) are critical for maintaining high standards in production, they serve distinct purposes within an organization. The primary difference between inspection and quality control lies in their focus: QC is reactive—addressing defects after they occur—while QA is proactive—aiming to prevent defects through process improvements. In other words, while QC deals with identifying problems through inspections or tests, QA focuses on establishing robust systems that ensure consistent product quality over time.

Key Differences Between Inspection and Quality Control

In the realm of product manufacturing and service delivery, understanding the difference between inspection and quality control is paramount. While both processes aim to ensure high standards, they operate differently within a company’s quality assurance framework. By dissecting these two concepts, we can appreciate their unique roles in maintaining product integrity and customer satisfaction.

Critical Comparisons

At first glance, inspection and quality control may seem interchangeable; however, there are critical differences that set them apart. Inspection primarily focuses on evaluating products or services at specific points in the production process to identify defects or deviations from standards. In contrast, quality control encompasses a broader range of activities aimed at preventing defects through systematic processes that include planning, monitoring, and continuous improvement—essentially laying the groundwork for effective quality assurance.

The distinction between inspection and quality control becomes clearer when considering their objectives: inspections are reactive by nature—they identify issues after they occur—while quality control is proactive, aiming to prevent issues before they arise. Furthermore, while inspections often rely on visual assessments or measurements against established criteria, quality control employs statistical methods and process management techniques to ensure consistent output across all stages of production. This difference highlights how companies can benefit from integrating robust company quality control systems alongside regular quality inspections.

The Process of Each

The processes involved in inspection and quality control differ significantly in terms of methodology and implementation. In an inspection scenario, a designated inspector evaluates finished products against pre-defined criteria; this could involve checking dimensions or conducting functional tests to determine if items meet the required specifications. This step typically occurs at various stages throughout production but often culminates in a final assessment before goods leave the factory floor.

On the other hand, implementing effective quality control involves establishing procedures that monitor every aspect of production continuously. This includes setting up metrics for performance evaluation, conducting regular audits of processes, training staff on best practices for maintaining standards, and using tools like Six Sigma or Total Quality Management (TQM) frameworks to foster an environment focused on ongoing improvement rather than merely identifying faults post-production. Thus, while inspections may provide snapshots of product health at specific intervals, comprehensive quality control ensures consistent adherence to standards over time.

Real-World Examples

To illustrate these differences more vividly, consider a manufacturing plant producing electronic devices as an example of how both inspection and quality control function together yet distinctly within an organization’s framework for ensuring product excellence. During routine operations at this plant, inspectors conduct random sampling checks on finished devices—this represents the inspection phase where products are scrutinized for any visible defects or malfunctions based solely on established criteria.

Conversely, the company also employs a robust system of quality control that includes continuous monitoring of assembly line performance metrics such as defect rates per batch produced or time taken per assembly stage—a proactive approach designed to identify potential issues before they escalate into larger problems affecting overall output consistency. In this scenario—the difference between inspection and quality control becomes evident: one assesses completed work while the other actively manages ongoing processes to enhance overall productivity through rigorous oversight aligned with effective quality assurance testing principles.

The Role of Quality Assurance

Quality assurance plays a pivotal role in the broader landscape of quality management, serving as a proactive measure to ensure that products meet specified standards before they hit the market. Unlike the reactive nature of quality control, which often identifies defects after production, quality assurance focuses on enhancing processes to prevent issues from arising in the first place. This distinction highlights the difference between inspection and quality control, emphasizing that while both are crucial for maintaining high standards, they operate with different objectives.

Quality Assurance vs Quality Control

The distinction between quality assurance and quality control is fundamental yet often misunderstood. Quality assurance is about creating processes that lead to consistent product quality, while quality control is more about checking and testing products to identify defects or deviations from standards. Understanding this difference can significantly impact company quality control strategies; organizations can better allocate resources and focus on process improvement rather than just defect detection.

Importance of Quality Assurance Testing

Quality assurance testing serves as a critical checkpoint in product development, ensuring that products not only meet customer expectations but also comply with industry regulations. By implementing rigorous testing protocols within their quality assurance framework, companies can significantly reduce the risk of costly recalls or reputational damage due to subpar products. This proactive approach underscores how essential it is for businesses to prioritize quality assurance testing as part of their overall strategy.

How Quality Assurance Complements Inspection

Quality assurance complements inspection by providing a structured methodology that enhances the effectiveness of inspections themselves. While inspections may identify issues at specific points in time, integrating robust quality assurance practices ensures that these issues are less likely to occur in the future by addressing root causes within processes. Thus, when companies adopt both inspection and effective quality control measures alongside comprehensive quality assurance practices, they create a harmonious system that maximizes product integrity and customer satisfaction.

Implementing Effective Inspection and Quality Control Strategies

In today's competitive landscape, implementing effective inspection and quality control strategies is crucial for any business aiming to maintain high standards. Understanding the difference between inspection and quality control can significantly enhance product reliability and customer satisfaction. By integrating these strategies into your operations, you can create a robust framework that fosters quality assurance.

Steps for Establishing Company Quality Control

Establishing a company quality control system begins with defining clear objectives that align with your business goals. Identify the key processes where quality inspections will take place, ensuring that all staff understand their roles in maintaining quality assurance. Regular training sessions are essential to keep everyone updated on best practices in quality control, reinforcing the importance of consistent monitoring and evaluation.

Next, develop a comprehensive checklist for quality inspections that includes specific criteria based on industry standards. This checklist should be regularly reviewed and updated to reflect any changes in regulations or market demands. Lastly, implement a feedback loop where employees can report issues or suggest improvements; this fosters a culture of continuous improvement within your organization.

Best Practices for Quality Inspections

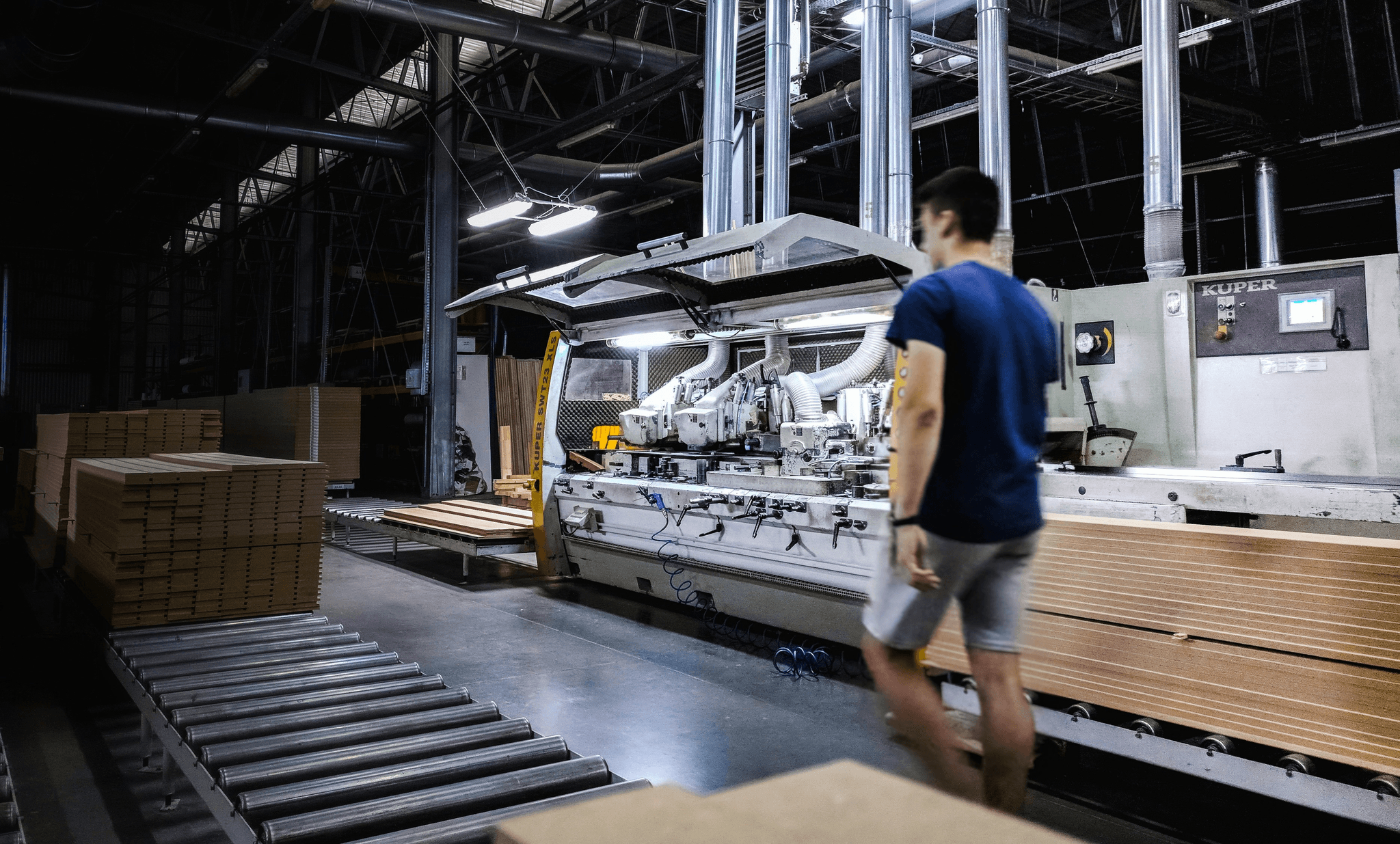

Quality inspections should be thorough yet efficient; employing best practices ensures you catch defects without slowing down production. Start by using standardized methods for conducting inspections, which helps minimize variability in results and enhances the reliability of your findings. Utilize technology such as automated inspection tools to streamline processes while still focusing on critical areas of concern.

Documentation is another key element—keeping detailed records of all inspections allows you to track trends over time and identify recurring issues quickly. This data becomes invaluable when assessing the effectiveness of your current strategies or when making decisions about future improvements in both inspection methods and overall company quality control systems.

Furthermore, engage employees at all levels in the process; their insights can lead to innovative solutions that improve both inspection outcomes and product quality assurance testing efforts.

Integrating Quality Control into Business Processes

Integrating quality control into business processes requires a holistic approach where every department recognizes its role in maintaining product integrity. Begin by mapping out existing workflows to identify touchpoints where quality checks can be seamlessly incorporated without disrupting operations. This integration not only enhances efficiency but also reinforces the commitment to high-quality outputs across the organization.

Communication is vital during this integration phase—ensure that all employees understand how their work impacts overall product quality and customer satisfaction through effective training programs focused on both inspection techniques and broader concepts related to quality assurance. Regular meetings can foster collaboration among teams, encouraging them to share insights about the difference between inspection and quality control as they relate to their specific functions.

Lastly, make use of performance metrics related to both inspection outcomes and overall product success rates; these metrics will help gauge how well integrated your strategies are while providing valuable data for ongoing refinement of processes within your company’s framework for achieving excellence in production standards.

Conclusion

In wrapping up our exploration of the difference between inspection and quality control, it’s essential to highlight how these concepts intertwine yet serve distinct purposes within a company’s quality management framework. While inspection focuses on evaluating products at specific checkpoints, quality control encompasses a broader strategy aimed at maintaining product standards throughout the manufacturing process. Quality assurance, often confused with both, ensures that processes are in place to prevent defects before they happen, showcasing the importance of proactive measures.

Recap of Key Differences

To clarify the key differences between inspection and quality control: inspection is primarily about identifying defects after production, whereas quality control is an ongoing process aimed at preventing defects from occurring in the first place. Quality assurance testing plays a crucial role in this by ensuring that systems are established to maintain high standards. Together, these elements create a robust framework for enhancing product integrity and customer satisfaction.

The Impact on Product Success

The impact of effective inspection and quality control on product success cannot be overstated; it directly influences customer trust and brand reputation. Companies that implement rigorous quality assurance practices often see lower return rates and higher customer loyalty because they deliver consistent and reliable products. Ultimately, prioritizing these strategies leads to increased profitability and market competitiveness—no one wants to be known for subpar quality!

Future Trends in Quality Management

Looking ahead, future trends in quality management are likely to emphasize automation and data analytics within both inspection and quality control processes. As industries evolve, the integration of artificial intelligence into quality assurance will help streamline operations while improving accuracy in identifying defects early on. Embracing these innovations will not only enhance efficiency but also redefine how companies approach their commitment to delivering superior products.