Introduction

In the world of manufacturing and quality assurance, the visual inspection method stands as a cornerstone of effective quality control. This technique not only helps in identifying defects but also plays a crucial role in maintaining product standards and ensuring customer satisfaction. By implementing a robust visual inspection procedure, organizations can significantly enhance their operational efficiency and product reliability.

Importance of Visual Inspection Technique

The visual inspection technique is vital for detecting issues that might escape other forms of testing, such as automated systems or statistical sampling. It allows trained personnel to assess products visually, ensuring they meet predetermined specifications and standards. With a well-structured visual inspection checklist, companies can systematically evaluate each component, minimizing the risk of errors and enhancing overall product quality.

How Visual Inspection Impacts Quality Control

Visual inspection directly influences quality control by providing immediate feedback on production processes and product integrity. By integrating visual inspections into their workflows, manufacturers can quickly identify trends in defects or inconsistencies that may indicate larger systemic issues. This proactive approach not only improves products but also saves time and resources by addressing problems before they escalate.

Overview of Visual Inspection Standards

Various visual inspection standards guide organizations in implementing effective quality control measures across industries. These standards outline best practices for conducting inspections, including criteria for acceptable defects and required documentation procedures. Adhering to established visual inspection standards ensures compliance with industry regulations while fostering trust among consumers regarding product safety and reliability.

Understanding Visual Inspection Methods

Visual inspection is a cornerstone of quality control processes across various industries. It involves the careful examination of products or materials to identify defects, ensuring that they meet established standards. By leveraging different visual inspection methods, organizations can maintain high-quality output while minimizing waste and improving customer satisfaction.

Key Types of Visual Inspection Methods

There are several key types of visual inspection methods that organizations utilize to ensure product quality. These include direct visual inspection, where inspectors examine items with the naked eye, and enhanced techniques such as magnification or specialized lighting to reveal hidden flaws. Additionally, automated visual inspection systems use cameras and software to detect defects at high speeds, making them an efficient choice in large-scale manufacturing settings.

Each method has its unique advantages depending on the specific requirements of the quality control process. For instance, direct visual inspections are often more cost-effective for smaller operations, while automated systems can significantly reduce human error and increase throughput in larger manufacturing environments. Choosing the right visual inspection method is crucial for aligning with a company's overall quality assurance strategy.

Benefits of Using Visual Inspection Procedures

Implementing robust visual inspection procedures offers numerous benefits that extend beyond mere defect detection. First and foremost, these procedures help maintain compliance with various visual inspection standards that govern industry practices, ensuring products meet regulatory requirements. Moreover, consistent application of a well-structured visual inspection checklist can enhance accountability among staff members while streamlining workflows.

Another significant advantage is cost savings; by catching defects early in the production process through effective quality control measures, companies can avoid costly recalls or rework later on. Additionally, a culture focused on thorough visual inspections fosters continuous improvement within teams as they learn from past mistakes and strive for excellence in their work processes. Ultimately, these benefits contribute to increased customer trust and loyalty.

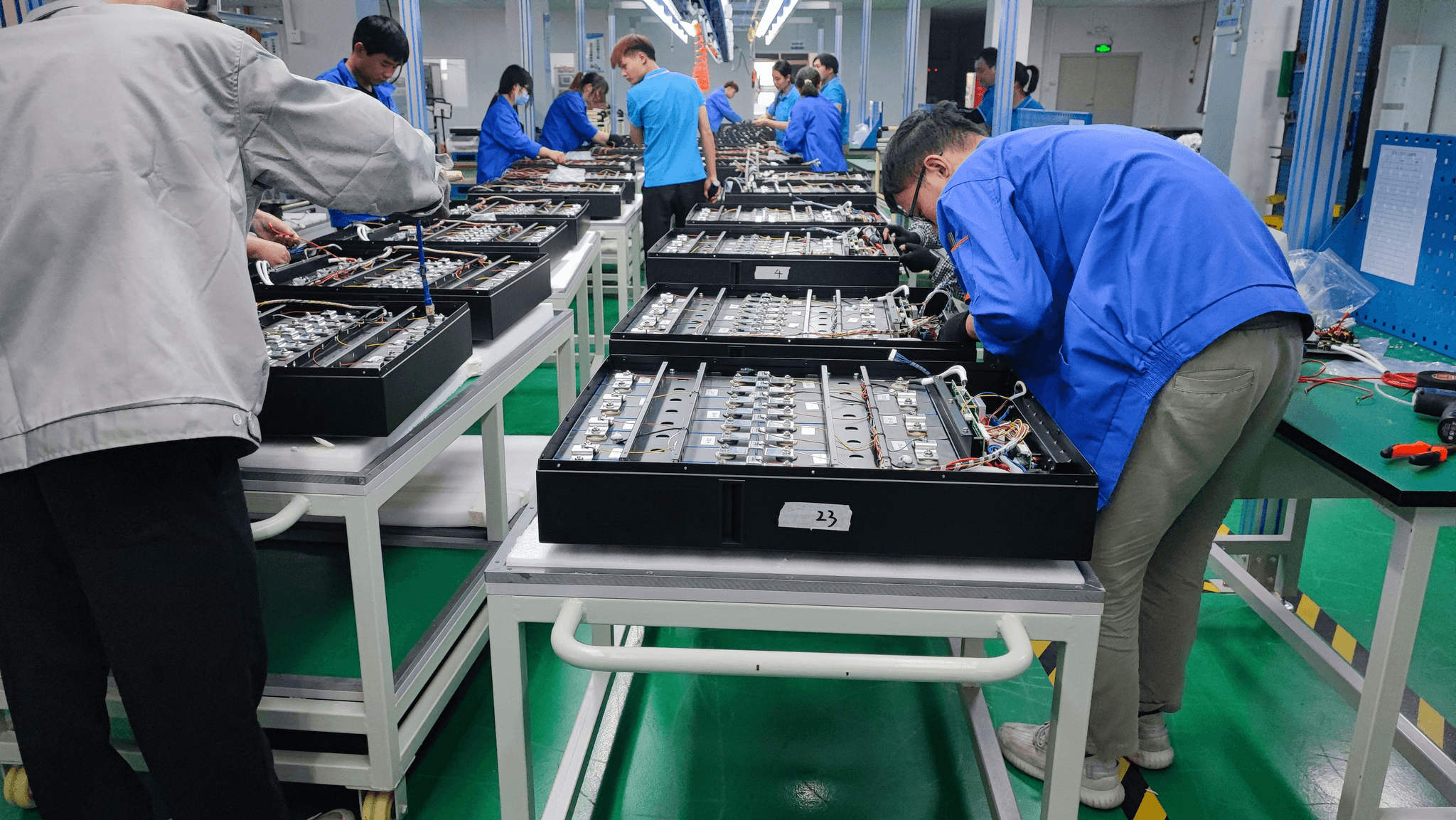

Industry Applications of Visual Inspection

Visual inspection plays an integral role across multiple industries ranging from manufacturing to healthcare and beyond. In manufacturing specifically, it ensures that products adhere to strict safety guidelines while also meeting aesthetic standards—think about how crucial it is for automotive parts or electronics to be flawless! Industries like food production rely heavily on visual inspections to prevent contamination and ensure product integrity throughout processing stages.

Furthermore, sectors such as construction utilize these methods during site inspections to verify compliance with building codes before project completion—no one wants a shoddy structure! The versatility of visual inspection equipment allows it to adapt seamlessly across diverse applications while maintaining rigorous quality control measures tailored for each sector's unique challenges.

Visual Inspection Equipment You Need

When it comes to implementing a robust visual inspection method, having the right equipment is crucial. The tools you select can significantly impact the effectiveness of your visual inspection procedure and overall quality control processes. From basic tools to advanced technologies, understanding what’s available will empower you to enhance your visual inspection in manufacturing.

Essential Tools for Effective Visual Inspection

The foundation of any successful visual inspection procedure lies in its essential tools. At a minimum, inspectors should have magnifying glasses, handheld mirrors, and good lighting sources to spot defects that might otherwise go unnoticed. Additionally, a well-structured visual inspection checklist can help ensure that no detail is overlooked during inspections.

Tools like calipers and gauges are also vital for measuring dimensions accurately and ensuring compliance with established visual inspection standards. These instruments not only assist in identifying flaws but also provide objective data that can be referenced later for quality assurance purposes. Moreover, having a dedicated workspace equipped with these essential tools fosters an environment conducive to thorough inspections.

Advanced Technologies in Visual Inspection

As technology evolves, so do the methods used in visual inspections. Advanced technologies such as automated vision systems and artificial intelligence are revolutionizing how we approach quality control in manufacturing environments. These systems utilize high-resolution cameras and sophisticated algorithms to detect anomalies more efficiently than the human eye could ever achieve.

Incorporating these advanced technologies into your visual inspection process not only increases accuracy but also speeds up production times by reducing manual labor requirements. Furthermore, they allow for real-time data collection which can be analyzed to continuously improve the existing visual inspection procedures and standards being applied across various industries. The integration of technology ensures that your organization remains competitive while maintaining high-quality outcomes.

Choosing the Right Visual Inspection Equipment

Selecting the right equipment for your specific needs is paramount when establishing an effective visual inspection method. Factors such as the type of products being inspected, industry standards required, and budget constraints all play significant roles in this decision-making process. Conducting thorough research on available options will help you identify which pieces of equipment align best with your quality control objectives.

It’s also wise to consider scalability when investing in visual inspection equipment; as production demands change or expand over time, so too should your capabilities for conducting effective inspections without compromising on quality or efficiency. Partnering with reputable suppliers who understand both industry-specific requirements and general best practices can provide invaluable insight into making informed choices about your equipment needs.

Ultimately, equipping yourself with both essential tools and advanced technologies positions you well for success in implementing effective visual inspection procedures tailored specifically for your operational context.

Building a Visual Inspection Checklist

Creating a robust visual inspection checklist is essential for maintaining high standards in quality control. A well-structured checklist serves as a guide to ensure that every crucial aspect of the visual inspection procedure is covered, minimizing the risk of oversight. By implementing effective visual inspection methods, companies can enhance their overall quality assurance processes.

Elements of an Effective Visual Inspection Checklist

An effective visual inspection checklist should include several key elements to ensure thoroughness and accuracy. First, it should outline specific criteria based on the relevant visual inspection standards applicable to your industry, such as ANSI or ISO guidelines. Additionally, including sections for observations, measurements, and notes will help inspectors document findings systematically while adhering to established visual inspection procedures.

Another important element is the inclusion of clear definitions and examples for each item on the checklist. This helps inspectors understand what constitutes a defect or acceptable standard during their inspections. Finally, incorporating space for signatures and dates will facilitate accountability and traceability in your visual inspection quality control efforts.

Tailoring Checklists for Specific Industries

Different industries have unique requirements when it comes to visual inspections; therefore, tailoring checklists accordingly is paramount. For instance, in manufacturing environments where precision is crucial, checklists may need to emphasize specific tolerances and potential defects relevant to production processes. Conversely, in industries like food safety or pharmaceuticals, checklists should focus on hygiene practices and contamination risks during inspections.

Moreover, consider incorporating industry-specific terminology into your checklists to enhance clarity among team members familiar with those terms. Customizing your visual inspection checklist not only streamlines the process but also reinforces compliance with relevant regulations governing that particular sector’s quality control measures.

Common Mistakes to Avoid in Checklists

While creating a comprehensive visual inspection checklist is vital, there are common pitfalls that can undermine its effectiveness. One mistake often made is overloading checklists with excessive items that lead inspectors to feel overwhelmed or confused during their assessments—less can be more! Instead of trying to cover every possible scenario at once, focus on critical elements that directly impact product quality.

Another frequent error involves neglecting regular updates based on feedback from users or changes within industry standards; this can render an otherwise useful tool obsolete over time. Lastly, failing to conduct training sessions around the use of these checklists may result in inconsistent application of the visual inspection methods intended for quality control purposes—don't skip this step!

Visual Inspection Standards for Quality Assurance

In the realm of quality assurance, visual inspection standards play a crucial role in ensuring that products meet specified criteria. These standards establish the framework for effective visual inspection methods, guiding organizations in their pursuit of excellence. Adhering to visual inspection procedures not only enhances product quality but also builds trust with consumers and stakeholders.

ANSI and ISO Standards in Visual Inspection

The American National Standards Institute (ANSI) and the International Organization for Standardization (ISO) provide essential guidelines that govern visual inspection methods across various industries. ANSI standards focus on establishing uniform practices while ISO standards emphasize international consistency, ensuring that visual inspection procedures are reliable and effective worldwide. By implementing these standards, companies can enhance their visual inspection checklists and ensure compliance with best practices.

Compliance Requirements for Visual Inspection Methods

Compliance requirements for visual inspection methods are critical to maintaining high-quality production processes in manufacturing environments. Organizations must adhere to specific regulations that dictate how inspections should be conducted, documented, and reported. A robust understanding of these compliance requirements not only streamlines the visual inspection checklist but also minimizes risks associated with non-compliance, ultimately safeguarding the integrity of products.

Importance of Standards in Manufacturing Quality Control

Standards play a pivotal role in manufacturing quality control by providing benchmarks against which products can be evaluated during the visual inspection process. These guidelines help ensure consistency and reliability in inspections, reducing variability that could lead to defects or failures. Moreover, adherence to established visual inspection standards fosters continuous improvement within organizations, enabling them to adapt effectively to new challenges while maintaining high levels of product quality.

Enhancing Visual Inspection Quality Control

To truly elevate visual inspection quality control, organizations must focus on training their staff, leveraging data effectively, and learning from successful case studies in manufacturing. A well-trained workforce is the backbone of any effective visual inspection procedure; without it, even the best visual inspection equipment can fall short. By investing in comprehensive training programs, companies can ensure that their teams are adept at utilizing various visual inspection methods to maintain high standards of quality.

Training Staff on Visual Inspection Techniques

Training staff on visual inspection techniques is crucial for fostering a culture of quality within an organization. Employees should be well-versed in the relevant visual inspection standards and the specific requirements of their industry to ensure compliance and effectiveness. Regular workshops and hands-on training sessions can empower employees with practical skills in using visual inspection checklists and equipment, enhancing their confidence and competence.

Moreover, incorporating technology into training can make it more engaging and effective. For instance, utilizing virtual reality simulations allows employees to practice real-world scenarios without the risk of damaging products or equipment. As they become familiar with various visual inspection methods through interactive learning experiences, teams will be better prepared to identify defects or inconsistencies during actual inspections.

Leveraging Data for Quality Control Improvements

In today's data-driven world, leveraging data for quality control improvements has become essential for maintaining competitive advantage in manufacturing. By analyzing data collected during visual inspections, organizations can uncover trends that may go unnoticed through manual observation alone. This information not only helps identify recurring issues but also aids in refining visual inspection procedures to enhance overall efficiency.

Utilizing advanced analytics tools allows companies to correlate defects with specific processes or materials used during production. This insight enables manufacturers to make informed decisions about adjustments needed in their workflows or supply chains—ultimately leading to improved product quality and reduced waste rates. When integrated effectively into a comprehensive quality management system, these insights can transform how businesses approach their visual inspection processes.

Case Studies: Visual Inspection in Manufacturing Success Stories

Examining case studies of successful implementations of visual inspection methods reveals valuable lessons that other manufacturers can adopt for their own operations. One notable example involves an automotive manufacturer that implemented a rigorous visual inspection checklist as part of its quality assurance process; this led to a significant reduction in defect rates over six months. By standardizing its approach using established visuals from previous inspections alongside real-time data analysis, they enhanced both efficiency and product reliability.

Another success story comes from a pharmaceutical company that adopted advanced imaging technologies within its visual inspection equipment arsenal—allowing them to detect minute anomalies that were previously undetectable by human inspectors alone. The integration of these technologies not only streamlined their production line but also ensured compliance with stringent regulatory requirements surrounding product safety and efficacy—a true win-win scenario!

These case studies underscore the importance of continuously evolving one's approach toward quality control through ongoing training initiatives and innovative practices tailored specifically for each organization’s unique challenges within the realm of manufacturing.

Conclusion

In wrapping up our exploration of visual inspection techniques, it's clear that these methods are not just about looking but also about ensuring quality and safety in various industries. The visual inspection procedure encompasses a range of techniques designed to identify defects and ensure compliance with established standards. By employing a robust visual inspection checklist, organizations can streamline their processes and enhance the effectiveness of their quality control efforts.

Recap of Effective Visual Inspection Techniques

Effective visual inspection methods are the backbone of quality assurance in manufacturing and beyond. These techniques include everything from basic observational skills to sophisticated equipment that enhances detection capabilities. Remember, the right visual inspection equipment paired with a well-structured visual inspection checklist can significantly reduce errors and improve overall product quality.

The Role of Visual Inspection in Quality Control

Visual inspection plays a pivotal role in maintaining high standards within quality control frameworks across various industries. It serves as the first line of defense against defects, ensuring that only products meeting stringent criteria reach consumers. By adhering to established visual inspection standards, organizations can foster trust and reliability in their products while minimizing costly recalls or rework.

Future Trends in Visual Inspection Methodologies

Looking ahead, we see exciting advancements in visual inspection methodologies driven by technology and innovation. Automated systems utilizing artificial intelligence are set to transform traditional practices, offering more precision than ever before in detecting flaws during production processes. As these trends evolve, integrating advanced visual inspection equipment will be essential for staying competitive while upholding rigorous quality control standards.