Introduction

In today's competitive market, the importance of streamlined QC checks cannot be overstated. Companies are increasingly recognizing that effective quality control (QC) is not just a regulatory requirement but a vital component of their operational success. By implementing robust QC inspections, businesses can ensure that their products meet the highest standards, ultimately leading to enhanced customer satisfaction and loyalty.

The Importance of Streamlined QC Checks

Streamlined QC checks play a critical role in maintaining product integrity throughout the manufacturing process. When businesses focus on efficient QC inspections, they can identify potential issues early on, minimizing costly rework and delays. Moreover, in a global landscape where Made in China products dominate many markets, ensuring rigorous qc checks becomes essential for maintaining brand reputation and consumer trust.

Understanding the Role of QC Inspections

So what is a qc inspector? A qc inspector is the guardian of product quality who meticulously evaluates goods against established standards during various stages of production. Their expertise not only helps in detecting defects but also ensures compliance with industry regulations and client specifications. In essence, these professionals serve as the frontline defenders against quality lapses that could lead to significant financial repercussions for companies.

Key Benefits of a Comprehensive QC Inspection Report

A comprehensive qc inspection report offers invaluable insights that go beyond mere pass/fail assessments; it provides actionable data that can drive continuous improvement within an organization. Such reports highlight trends in defects or non-conformities that may reveal underlying systemic issues needing attention. Ultimately, businesses leveraging thorough qc inspection reports are better positioned to enhance product quality and streamline operations while fostering stronger relationships with suppliers and customers alike.

What is Quality Control?

Quality Control (QC) is the backbone of product reliability and customer satisfaction in today’s competitive market. It encompasses a range of processes aimed at ensuring that products meet specified requirements and standards before reaching consumers. In an age where quality can make or break a brand, understanding what QC entails is essential for businesses looking to thrive.

Defining QC in Today’s Market

In today's market, QC refers not just to the final checks before products hit the shelves but also to a proactive approach throughout the production process. Companies are increasingly recognizing that effective qc checks can save time and money by identifying potential issues early on. With globalization, particularly in manufacturing hubs like China, understanding qc in China has become vital for businesses aiming to maintain quality standards across borders.

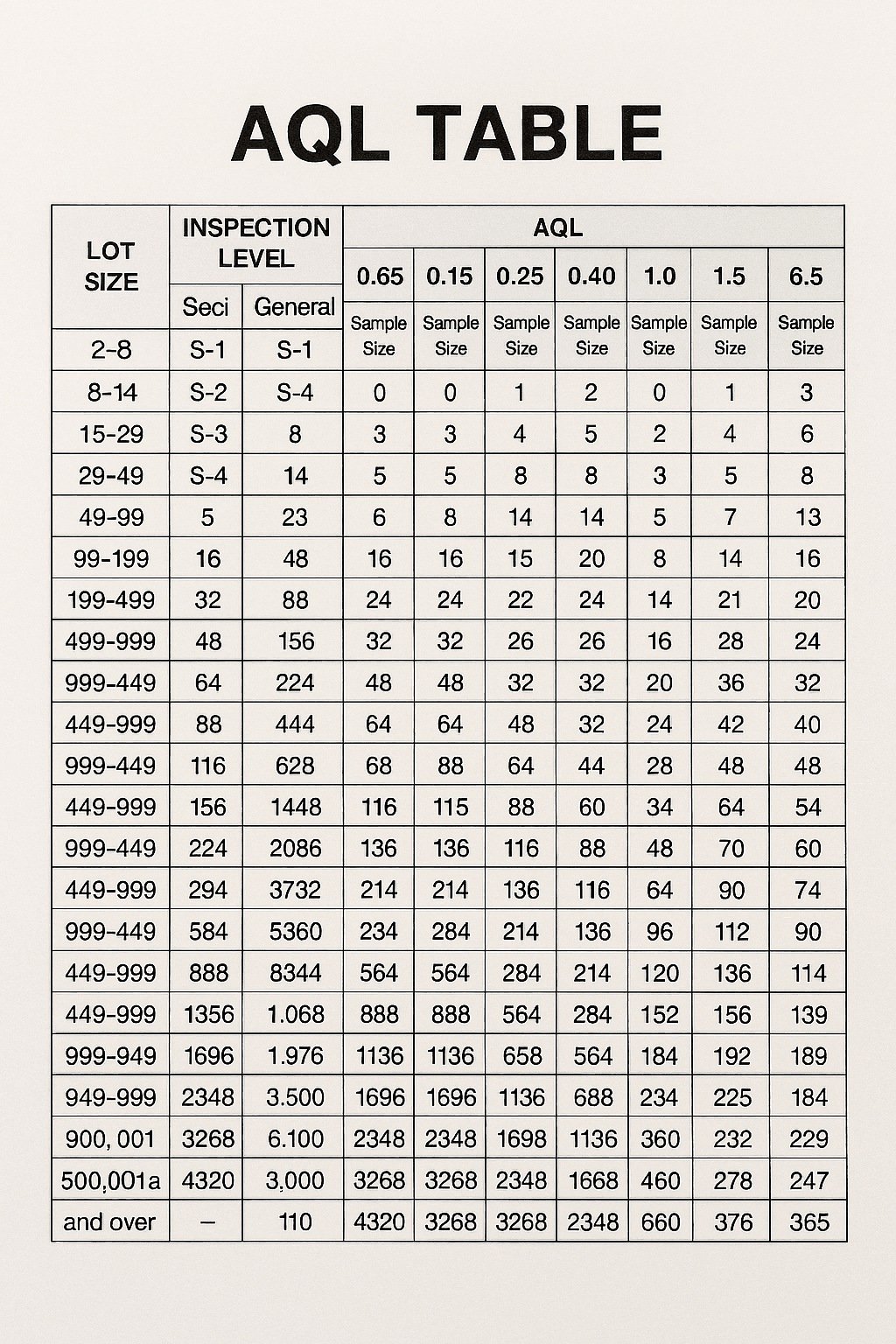

The Process of QC Inspections

The process of qc inspections typically involves several stages, starting from raw material evaluation through to final product testing. This systematic approach ensures that every aspect of production adheres to established quality benchmarks, minimizing defects and enhancing overall product integrity. By integrating rigorous qc inspection reports into their workflow, companies can track compliance and pinpoint areas needing improvement.

The Role of a QC Inspector

A qc inspector plays a crucial role in maintaining product quality throughout the manufacturing journey. Their responsibilities include conducting thorough inspections at various stages, documenting findings in detailed qc inspection reports, and communicating any discrepancies found during inspections. Essentially, what is a qc inspector if not the guardian of quality? They ensure that products not only meet specifications but also align with customer expectations—making them indispensable assets in any quality control strategy.

Best Practices for Effective QC Checks

Quality control (QC) is a critical aspect of ensuring product integrity, especially in industries where standards are paramount. Implementing best practices for effective QC checks can dramatically enhance the reliability of your QC inspection report and streamline operations. By focusing on consistency, training, and technology integration, businesses can elevate their quality assurance processes to new heights.

Utilizing Checklists for Consistency

One of the simplest yet most effective tools in the QC arsenal is the checklist. Utilizing checklists during QC inspections ensures that no critical steps are overlooked, promoting consistency across all evaluations. This method not only standardizes processes but also provides a clear framework for what is expected from each inspection—making it easier to identify discrepancies and maintain high-quality standards.

In the context of qc in China, where diverse manufacturing practices may exist, checklists become even more essential. They help bridge potential gaps between different factories and ensure that every qc company adheres to the same rigorous standards. Furthermore, a well-structured checklist can serve as a reference point when compiling your qc inspection report, making it easier to communicate findings effectively.

Training Your QC Team for Excellence

A well-trained qc inspector is pivotal to achieving excellence in quality control checks. Continuous education and training programs equip your team with the latest knowledge about industry standards and emerging trends in qc inspections. This investment not only boosts their confidence but also enhances their ability to identify potential quality issues before they escalate.

Moreover, fostering an environment that encourages open communication allows your team to share insights and experiences related to common challenges faced during inspections. By doing so, you create a culture of learning that benefits everyone involved in the qc process—ultimately leading to improved product quality and reliability from your chosen qc company. Remember that an informed team is better equipped to produce thorough and actionable qc inspection reports.

Integrating Technology into QC Processes

In today's fast-paced market environment, integrating technology into QC processes has become essential for maintaining competitive advantage—especially when working with manufacturers overseas like those found in China. Utilizing software solutions for data collection enables real-time tracking of quality metrics during inspections while reducing human error associated with manual entries. This technological shift not only streamlines operations but also enhances transparency throughout the entire supply chain.

Furthermore, advanced analytics tools can help identify patterns or recurring issues within products over time—allowing companies to make proactive adjustments rather than reactive fixes after problems arise during qc checks or inspections. Embracing these technologies will empower your organization to produce more accurate and insightful qc inspection reports while positioning you as a leader in quality assurance within your industry.

The Impact of QC Company Choices

Choosing the right QC company can significantly affect your business's success, especially when it comes to ensuring product quality. In an era where global trade is rampant, understanding the nuances of QC in China becomes crucial for maintaining competitive advantage. A well-chosen QC partner not only streamlines your qc checks but also enhances your overall operational efficiency.

Benefits of Partnering with China Inspection Pro

Partnering with a reputable company like China Inspection Pro offers numerous benefits that can transform your qc inspections into a seamless process. This company specializes in delivering thorough qc inspection reports that highlight potential issues before they escalate into larger problems. With their extensive experience and local expertise, they ensure that your products meet international standards while saving you time and money.

Additionally, China Inspection Pro provides tailored solutions that cater to your specific needs, whether you're dealing with textiles, electronics, or machinery. Their team of skilled professionals understands what is a qc inspector’s role and how to leverage it effectively during inspections. By choosing them as your QC partner, you gain access to a wealth of knowledge and resources that are vital for navigating the complexities of quality control in China.

Assessing QC Companies in China

When evaluating potential qc companies in China, it's essential to consider several factors that determine their effectiveness and reliability. Start by examining their track record—how many successful qc inspections have they conducted? Look for testimonials from other businesses; real-world experiences can provide insights into what you can expect from their services.

Moreover, consider the technology they utilize during inspections; modern tools can enhance accuracy and efficiency in generating qc inspection reports. It's also wise to evaluate their communication practices—clear lines of communication ensure that any issues are promptly addressed during the inspection process. Ultimately, a thorough assessment will help you identify which QC company aligns best with your quality assurance goals.

How a Good QC Company Enhances Product Quality

A good QC company plays an integral role in enhancing product quality through meticulous qc checks at every stage of production. By identifying defects early on during the manufacturing process, they help prevent costly recalls or customer dissatisfaction down the line. Their expertise ensures that products not only meet compliance standards but also align with consumer expectations.

Furthermore, effective collaboration between your team and the chosen QC company fosters continuous improvement throughout production cycles. Regular feedback loops allow businesses to refine processes based on insights gained from detailed qc inspection reports. In this way, partnering with a competent QC provider doesn’t just solve immediate problems; it lays the groundwork for sustained excellence in product quality over time.

Navigating Common QC Challenges

Quality control (QC) inspections can sometimes feel like navigating a minefield, especially when dealing with unexpected quality issues. These challenges can arise at any stage of the inspection process, and addressing them promptly is crucial for maintaining product integrity. Understanding how to tackle these common QC challenges not only enhances your qc inspection report but also strengthens your overall quality assurance strategy.

Addressing Quality Issues During Inspections

When it comes to qc checks, identifying quality issues during inspections is half the battle won. A proactive approach requires trained qc inspectors to recognize defects or deviations from standards immediately. By having a clear protocol for reporting these issues, you ensure that they are documented in the qc inspection report and addressed before products reach consumers.

In the context of qc in China, where manufacturing processes can vary widely, it's essential to have a robust system for addressing quality problems on-site. This might involve collaboration between your team and the local qc company to rectify issues quickly and efficiently. Remember, timely intervention can save you from costly recalls or reputational damage down the line.

The Importance of Timely QC Inspections

Timeliness is everything in the world of QC inspections; waiting too long can lead to a cascade of problems that affect production schedules and product quality. Regularly scheduled qc checks help catch potential issues early, ensuring that any necessary adjustments are made before products leave the factory floor. In fast-paced markets like those serviced by many qc companies in China, being proactive is key.

Furthermore, timely inspections allow businesses to maintain better relationships with suppliers by demonstrating commitment to quality standards. When manufacturers see that you value prompt and thorough qc inspections, they are more likely to prioritize your orders and adhere to agreed-upon specifications. Ultimately, this leads to smoother operations and improved product outcomes.

Strategies for Effective Problem-Solving

Effective problem-solving strategies are essential when navigating common QC challenges during inspections. One approach is employing root cause analysis techniques that dig deep into why an issue occurred rather than just treating symptoms; this method ensures that similar problems don't resurface in future qc checks or production runs. Engaging your team in brainstorming sessions can also foster creativity in finding solutions tailored specifically for unique situations encountered during QC inspections.

Additionally, leveraging technology—such as data analytics tools—can enhance decision-making by providing insights into recurring issues across various batches or suppliers within your china qc network. This information allows teams to make informed adjustments quickly based on historical data trends rather than relying solely on instinct or guesswork. Remember: effective problem-solving not only improves immediate outcomes but also contributes significantly toward long-term quality assurance goals.

Building an Optimal QC Inspection Report

Creating a robust QC inspection report is the backbone of effective quality control. A well-structured report not only documents findings from qc inspections but also serves as a strategic tool for continuous improvement. To achieve this, it's essential to understand the components that make up a comprehensive qc inspection report.

Components of a Comprehensive QC Inspection Report

A comprehensive QC inspection report should include several key components: an executive summary, detailed findings, and actionable recommendations. The executive summary provides a quick overview of the qc checks conducted and highlights any major issues encountered during the inspections. Detailed findings should include specific data points, photographs of defects, and notes on compliance with standards, while actionable recommendations guide stakeholders on how to address identified issues effectively.

Another important aspect is the inclusion of timelines for corrective actions and follow-up inspections. This ensures accountability and sets clear expectations for all parties involved in the qc process. By incorporating these elements into your qc inspection report, you create a valuable resource that enhances transparency and fosters better communication among teams.

Real-World Examples of Effective Reporting

Consider a case where a company engaged in manufacturing electronic goods faced significant quality issues due to faulty components sourced from suppliers in China. The QC company they partnered with conducted thorough qc inspections and documented their findings in an extensive report detailing each defect found during their checks. This included photographs showing specific faults alongside clear explanations of how these defects could impact overall product performance.

The effectiveness of this reporting was evident when management used it to negotiate improvements with their suppliers based on documented evidence rather than anecdotal complaints. By presenting concrete data from their qc inspection report, they were able to secure better terms and enhance product quality significantly over time.

Turning Findings into Actionable Insights

The true value of any qc inspection report lies not just in identifying problems but in transforming those findings into actionable insights that drive improvement. After documenting issues found during qc checks, it's vital to analyze trends over time—this helps organizations understand whether certain problems are recurring or if new ones are emerging in production processes.

Once trends are identified, teams can prioritize which issues need immediate attention and develop targeted action plans accordingly. For instance, if multiple inspections reveal similar defects related to a specific supplier's materials, it may be time to reassess that partnership or implement stricter quality controls moving forward.

By taking these steps—documenting findings clearly, analyzing trends diligently, and developing targeted action plans—companies can ensure they are not just reacting to problems but proactively enhancing overall product quality through informed decision-making based on solid data derived from their qc inspections.

Conclusion

Quality control is not just a box to check; it’s the backbone of product excellence. Through diligent qc inspections, businesses can significantly enhance product quality and customer satisfaction. The importance of a thorough qc inspection report cannot be overstated, as it provides vital insights into product performance and areas for improvement.

Enhancing Product Quality Through QC Inspections

Effective qc checks are the first line of defense against defects and inconsistencies in products. By implementing rigorous qc inspections, companies can identify potential issues before they escalate into costly problems or dissatisfied customers. A well-structured qc inspection report serves as a roadmap for continuous improvement, allowing businesses to refine their processes and deliver top-notch products.

The Future of Quality Control in Global Markets

As global markets evolve, the landscape of quality control is also changing dramatically. With advancements in technology and an increasing emphasis on sustainability, the role of qc in China—and beyond—will become even more crucial. Companies must adapt their qc practices to meet these new demands while ensuring that their qc company partners are equipped to handle future challenges effectively.

Choosing the Right QC Partner for Success

Selecting the right qc company can make all the difference in achieving optimal product quality. When evaluating potential partners, consider their expertise in conducting thorough qc inspections and delivering actionable insights through comprehensive reports. Remember, a reliable partner not only enhances your product quality but also strengthens your brand reputation in an increasingly competitive market.