Introduction

In the ever-evolving landscape of business, inspections play a pivotal role in ensuring that products and services meet quality standards. Understanding the importance of inspections is not just about compliance; it’s about safeguarding your brand's reputation and enhancing customer satisfaction. With various types of inspections available, knowing which one suits your needs can be the difference between success and costly setbacks.

Understanding the Importance of Inspections

Inspections serve as a critical checkpoint in the production process, ensuring that quality goods and services are delivered consistently. By implementing different types of inspections, businesses can identify potential issues early on, reducing waste and improving efficiency. Whether it's through social compliance audits or a comprehensive quality inspection table, these evaluations help maintain high standards throughout production.

Why Different Types Matter for Your Business

Not all inspections are created equal; each type serves a unique purpose tailored to specific industry needs. For instance, testing of electronic components is essential for tech companies to ensure functionality and safety, while a piping inspection checklist is vital for industries reliant on fluid systems. Recognizing why different types matter allows businesses to strategically align their inspection processes with their operational goals.

Navigating Quality Standards and Compliance

Navigating the maze of quality standards and compliance requirements can be daunting but is crucial for any business aiming for longevity in today's market. Understanding what a non-conformity report entails will prepare you to address deviations effectively while adhering to regulations like ISO or industry-specific guidelines. By leveraging insights from various inspections—including social compliance audits—companies can foster a culture of continuous improvement that elevates overall production quality management.

Quality Inspections 101

Quality inspections are the backbone of ensuring that products meet the desired standards and specifications. They encompass various processes designed to verify that goods and services produced are not only functional but also safe and compliant with regulations. Understanding the different types of inspections available can help businesses select the right approach to maintain high-quality production.

Overview of Quality Inspection Services

Quality inspection services come in many forms, each tailored to specific needs within industries. From visual checks and measurements to more sophisticated testing of electronic components, these services ensure that every product meets quality benchmarks before reaching consumers. By utilizing a combination of these different types of inspections, businesses can mitigate risks associated with defective products and enhance their operational efficiency.

Importance in Production of Quality Goods and Services

The production of quality goods and services is critical for maintaining customer satisfaction and brand reputation. Inspections play a vital role by identifying defects early in the manufacturing process, thereby reducing waste and minimizing costly rework or recalls later on. Moreover, implementing quality inspections fosters a culture of excellence within organizations, encouraging continuous improvement in production quality management.

How a Quality Inspection Table Can Help

A quality inspection table serves as an invaluable tool for organizing inspection processes systematically. It allows teams to track various parameters related to different types of inspections efficiently, ensuring nothing is overlooked during evaluations. By having all relevant data at their fingertips, inspectors can make informed decisions quickly—ultimately leading to enhanced productivity and higher standards in product quality.

Social Compliance Audits Explained

Navigating the world of inspections can be quite a journey, especially when it comes to social compliance audits. These audits serve as a crucial tool for businesses aiming to ensure ethical practices within their supply chains. They not only help in identifying areas that require improvement but also reinforce the commitment to upholding high standards across different types of inspections.

What are Social Compliance Audits?

Social compliance audits are systematic evaluations designed to assess whether a company adheres to established social and ethical standards. These standards often encompass labor rights, workplace safety, and environmental regulations, ensuring that the production of quality goods and services aligns with societal expectations. By answering the question what is a non-conformity report? during these audits, businesses can identify discrepancies between current practices and required standards.

Benefits for Your Business and Reputation

Engaging in social compliance audits offers numerous benefits for your business, particularly regarding its reputation. Companies that actively participate in these evaluations signal their commitment to ethical practices, which can enhance customer loyalty and trust—an invaluable asset in today’s market. Furthermore, by addressing issues uncovered during these audits, organizations can mitigate risks associated with non-compliance, ultimately leading to improved production quality management.

Ensuring Ethical Standards in Supply Chains

To ensure ethical standards in supply chains through social compliance audits, businesses must adopt a proactive approach towards monitoring their suppliers' practices. Implementing regular checks akin to a piping inspection checklist allows companies to stay ahead of potential issues before they escalate into larger problems. This vigilance not only fosters transparency but also reinforces the importance of various types of inspections that contribute positively towards maintaining an ethical business environment.

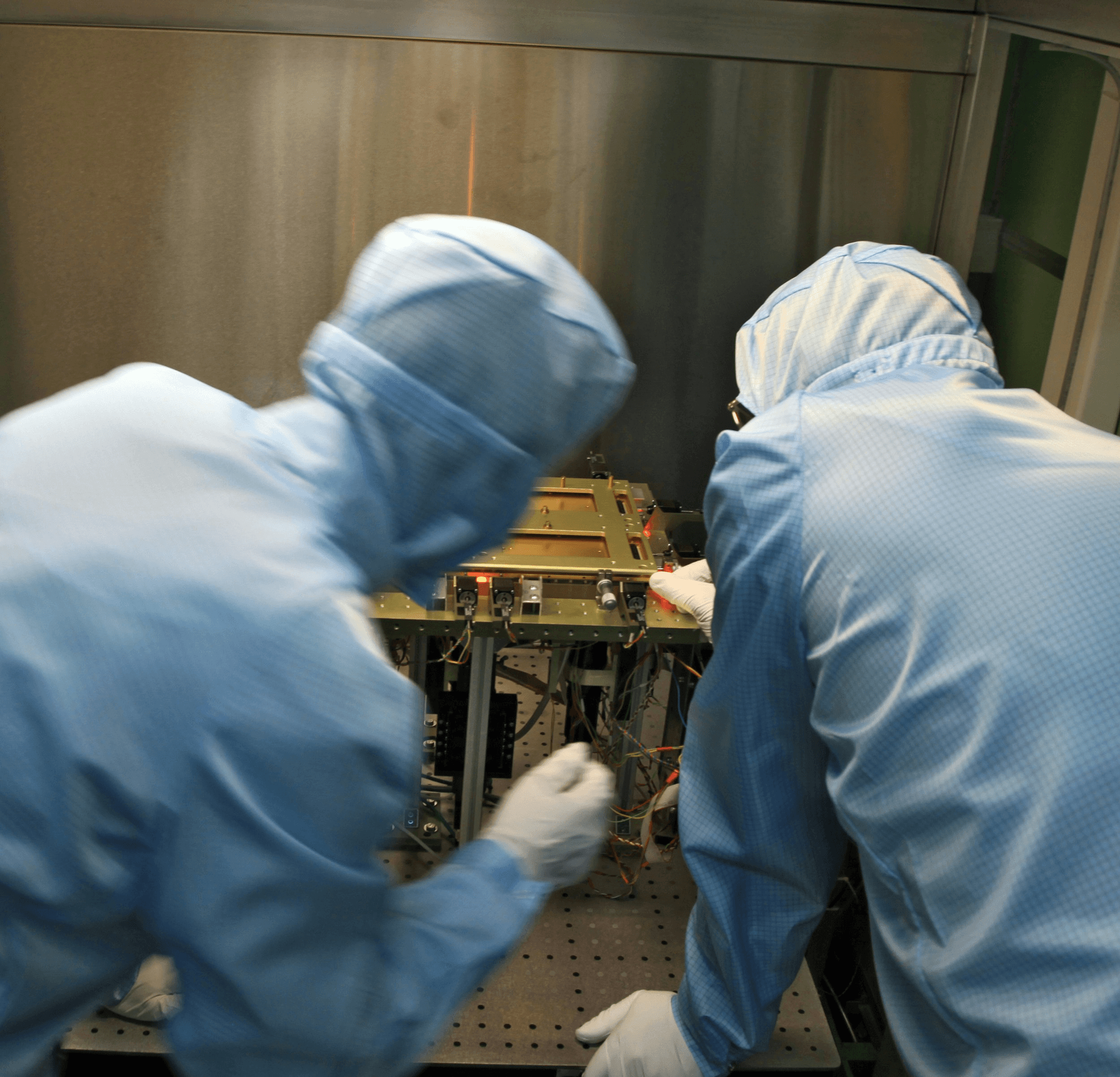

The Role of Testing of Electronic Components

In today's fast-paced technological landscape, the testing of electronic components is not just a formality; it's a necessity. Different types of inspections ensure that every component meets the required standards for performance and safety, ultimately influencing the production of quality goods and services. Without rigorous testing protocols, businesses risk delivering faulty products that could tarnish their reputation and lead to significant financial losses.

Why Testing is Essential

Testing electronic components serves as a safeguard against defects that could compromise functionality. It ensures compliance with industry standards, which is crucial for maintaining trust among consumers and partners alike. Moreover, effective testing can identify potential issues early in the production process, reducing the likelihood of costly recalls and enhancing overall production quality management.

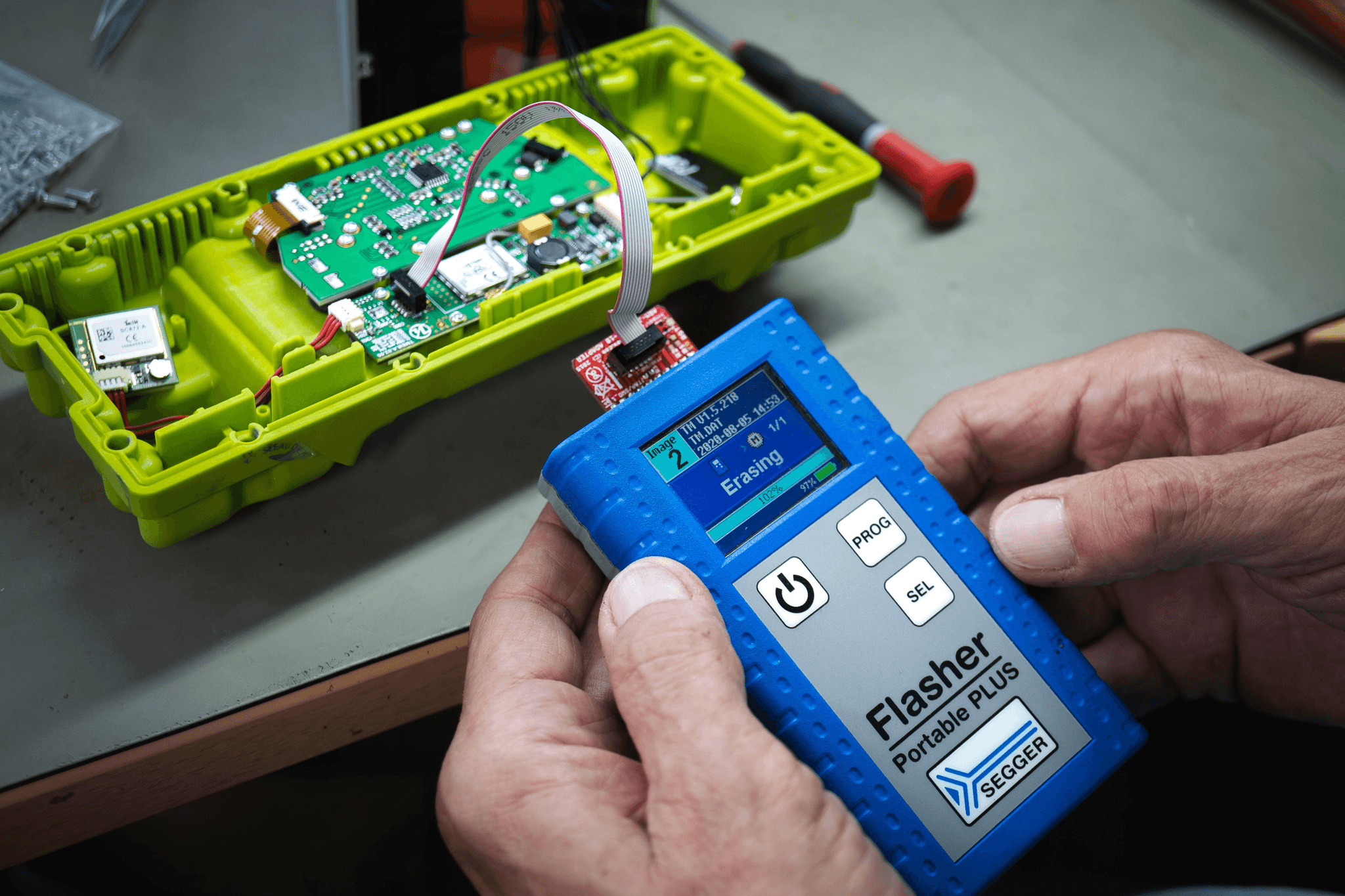

Common Procedures in Electronic Inspections

When it comes to electronic inspections, there are several common procedures that businesses typically employ. These include visual inspections, functional testing, and stress tests to assess durability under various conditions. Utilizing a structured quality inspection table can help streamline these processes by providing clear criteria for each inspection type, ensuring consistency and thoroughness across all evaluations.

How to Implement Effective Testing Protocols

Implementing effective testing protocols requires a strategic approach tailored to your specific products and industry requirements. Start by developing a comprehensive testing plan that incorporates different types of inspections relevant to your components—this might include social compliance audits if labor practices are involved in manufacturing processes. Training staff on how to properly execute these tests is equally important; well-informed personnel will ensure adherence to protocols while also being able to address any non-conformities promptly—after all, what is a non-conformity report if not an opportunity for improvement?

Piping Inspections: A Checklist Approach

Piping inspections are crucial for ensuring the safety and efficiency of any industrial operation. They involve a systematic examination of piping systems to identify potential issues that could lead to failures or accidents. Utilizing a piping inspection checklist can streamline this process, making it easier to address various aspects of piping integrity, which is vital for the production of quality goods and services.

What is a Piping Inspection Checklist?

A piping inspection checklist is a comprehensive tool designed to guide inspectors through the various elements that need evaluation during an inspection. This checklist helps ensure that no critical component is overlooked, ultimately contributing to better compliance with safety standards and regulations. By utilizing this checklist, businesses can maintain high-quality standards while minimizing risks associated with their piping systems.

Key Components to Inspect and Monitor

When conducting a piping inspection, several key components must be closely monitored. These include pipe material integrity, joint connections, insulation conditions, and potential corrosion areas. Regularly checking these elements not only enhances safety but also aligns with broader quality inspection practices, such as social compliance audits and production quality management strategies.

Ensuring Safety Through Regular Inspections

Regular inspections using a well-structured piping inspection checklist are essential in preventing hazardous incidents in industrial environments. By consistently evaluating the condition of pipes and identifying non-conformities early on, businesses can avoid costly repairs and ensure compliance with industry standards. This proactive approach not only safeguards employees but also reinforces the overall commitment to quality across different types of inspections within an organization.

Understanding Non-Conformity Reports

In the realm of quality management, understanding non-conformity reports is crucial for maintaining high standards. These reports serve as formal documentation highlighting instances where products or processes deviate from established standards or specifications. By addressing these discrepancies promptly, businesses can ensure the production of quality goods and services while fostering a culture of continuous improvement.

What is a Non-Conformity Report?

A non-conformity report (NCR) is essentially a detailed account that identifies and documents deviations from expected performance in various inspections, including different types of inspections like social compliance audits and electronic component testing. It outlines what was found to be non-compliant, the implications for quality, and recommendations for corrective actions. Understanding what a non-conformity report entails allows organizations to take proactive steps in their production quality management efforts.

Steps for Addressing Non-Conformities

Addressing non-conformities involves several systematic steps to ensure effective resolution. First, it’s essential to investigate the root cause of the issue documented in the NCR, which might involve revisiting your quality inspection table or piping inspection checklist to identify patterns or recurring problems. Once identified, implementing corrective actions followed by regular monitoring ensures that similar issues do not arise in future inspections—ultimately enhancing your overall production of quality goods and services.

Importance in Production Quality Management

Non-conformity reports play a pivotal role in production quality management by providing insights into areas needing improvement across different types of inspections. They help organizations track compliance with industry standards and regulations while also spotlighting potential risks within supply chains—especially critical during social compliance audits or when testing electronic components. By prioritizing NCRs as part of their operational strategy, businesses can boost their reputation while ensuring they consistently meet customer expectations.

Conclusion

In the fast-paced world of business, understanding the impact of different types of inspections is crucial for maintaining high standards and ensuring customer satisfaction. Quality inspections not only help in the production of quality goods and services but also safeguard a company's reputation in an increasingly competitive market. By implementing robust inspection protocols, businesses can significantly reduce risks associated with non-compliance and product failures.

The Impact of Different Inspections on Business

Different types of inspections play a pivotal role in shaping a company's operational efficiency and overall success. For instance, social compliance audits can enhance a brand's image by demonstrating commitment to ethical practices, while rigorous testing of electronic components ensures that products meet safety standards before reaching consumers. Ultimately, these inspections contribute to effective production quality management, leading to improved customer trust and loyalty.

How to Choose the Right Inspection Type

Choosing the right inspection type requires a thorough understanding of your business needs and industry standards. Start by assessing what is most critical for your operations—whether it’s ensuring compliance through social compliance audits or maintaining safety with a piping inspection checklist. By aligning inspection strategies with specific goals, companies can optimize their processes and ensure they are producing quality goods and services that meet or exceed expectations.

Leveraging Experts Like China Inspection Pro

To navigate the complexities surrounding different types of inspections, partnering with experts like China Inspection Pro can be immensely beneficial. Their specialized knowledge in various areas—including testing of electronic components and conducting social compliance audits—can streamline your inspection processes while mitigating risks associated with non-conformity reports. With their support, businesses can confidently uphold high standards in production quality management without getting bogged down by the intricacies involved.